Intumescent tape - Marino\WARE

Intumescent tape - Marino\WARE

Intumescent tape - Marino\WARE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Intumescent</strong> Tape<br />

Is on the rise (No Pun Intended)<br />

<strong>Intumescent</strong> <strong>tape</strong>: One product to fill many needs.<br />

By Don Pilz<br />

<strong>Intumescent</strong> <strong>tape</strong> has changed the<br />

fire-stopping industry for the better<br />

over the last few years and is<br />

now doing the same for sound walls.<br />

Once primarily used for fire-rated<br />

doors, safes and gun cabinets, intumescent<br />

<strong>tape</strong> is now used for building<br />

joints with phenomenal results<br />

for fire and sound protection.<br />

As structural engineers continue<br />

to design buildings requiring more<br />

and more dynamic movement, the<br />

benefits of intumescent <strong>tape</strong> could<br />

not have come at a better time. The<br />

reason intumescent <strong>tape</strong> works so<br />

well is because it’s relatively thin and<br />

can be concealed within the framing<br />

assembly without hindering movement.<br />

However, intumescent <strong>tape</strong>s<br />

can’t merely be “field-installed” into<br />

the framing assembly. The position<br />

and location of the intumescent<br />

<strong>tape</strong> is critical to the effectiveness<br />

of the joint assembly. That is why<br />

steel/intumescent composite tracks<br />

are tested and certified with Underwriters<br />

Laboratories. Each building<br />

joint assembly is tested through UL<br />

according to UL-2079 Tests for Fire<br />

Resistance of Building Joint Systems.<br />

Some intumescent <strong>tape</strong>s expand up<br />

to 35 times their original size. With<br />

this type of performance it’s no wonder<br />

steel framing manufactures have<br />

sought out different ways to utilize<br />

the capabilities of intumescent <strong>tape</strong>s.<br />

CEMCO FAS Track 1000 is just one<br />

example of the efficient use of intumescent<br />

<strong>tape</strong> within a steel deflection<br />

track. <strong>Intumescent</strong> <strong>tape</strong> is attached to<br />

the upper web along the outer edges<br />

similar to what contractors have done<br />

for years with foam <strong>tape</strong> to increase<br />

STC or IIC sound ratings. The <strong>tape</strong><br />

works as a gasket, sealing off irregularities<br />

in the structure. It also works<br />

as an isolator lending a sound deadening<br />

element to the deflection track.<br />

This type of fire-rated deflection<br />

track can increase STC ratings of the<br />

wall assembly without the traditional<br />

usage of fill materials such as acoustic<br />

sealant that can prohibit the amount<br />

of dynamic movement.<br />

Currently, field applied sealants at<br />

the head-of-wall, whether they are<br />

acoustic or fire sealant can drastically<br />

reduce the movement capabilities of<br />

the joint. In recent year’s sealant manufacturers<br />

have responded to this issue<br />

by making the head-of-wall joints<br />

wider with more flexible material so<br />

they can provide greater movement.<br />

The typical sealant filled head-of-wall<br />

joints can range in size from 3/4 to<br />

1 inch wide, and although the larger<br />

joint will provide more movement they<br />

generally will not get more than 1/4<br />

inch compression or extension before<br />

they tear away from the drywall, leaving<br />

an unprotected gap within the<br />

building joint. A tear or crack in a<br />

sealant filled joint system means it has<br />

failed as a fire stop before it has even<br />

been called upon to perform.<br />

THE DILEMMA<br />

Most concrete multi-family structures,<br />

such as hotels or condos,<br />

require 3/4 inch overall movement.<br />

At the same time the UBC requires<br />

Sound Transmission Class ratings<br />

and Impact Insulation Class ratings<br />

for dwelling units, which include<br />

hotels, motels, apartments, condominiums,<br />

dormitories, and monasteries<br />

to be at a minimum 50 STC<br />

or IIC rating. Sound ratings can be<br />

greatly reduced through sound flank-<br />

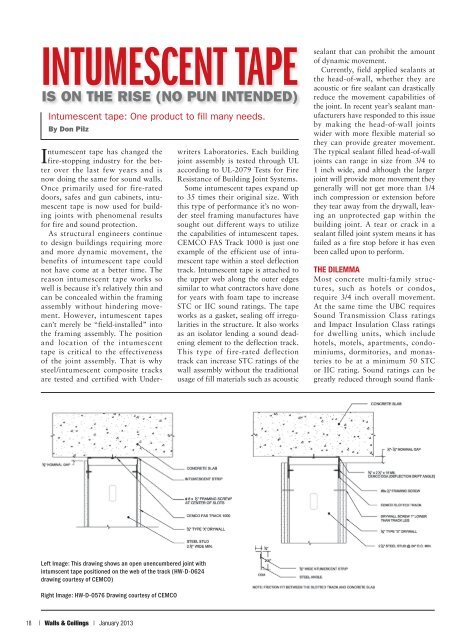

Left Image: This drawing shows an open unencumbered joint with<br />

intumscent <strong>tape</strong> positioned on the web of the track (HW-D-0624<br />

drawing courtesy of CEMCO)<br />

Right Image: HW-D-0576 Drawing courtesy of CEMCO<br />

18 | Walls & Ceilings | January 2013

BlazeSeal intumescent <strong>tape</strong>. (Courtesy of Rectorseal<br />

Test Lab)<br />

After 3/4 inch movement test, according to<br />

UL-2079, the acoustic sealant separates from<br />

drywall (Photo courtesy of Rectorseal Test Lab)<br />

After burn test, intumescent <strong>tape</strong> expands to<br />

completely fill in head-of-wall gap (Photo courtesy<br />

of Rectorseal Test Lab)<br />

ing paths. To reduce flanking paths,<br />

drywall should be sealed tight to the<br />

framing member around the perimeter.<br />

However, in traditional metal<br />

stud framed walls, framing screws<br />

that attach the stud to the track cause<br />

the drywall to hump up around the<br />

framing screw that provides a flanking<br />

path and increases sound transmission.<br />

Sound ratings can also be<br />

reduced in metal stud framing at the<br />

hard connection between the metal<br />

track and the floor or ceiling. For<br />

this reason, resilient partition isolation<br />

pads, acoustic sealant or foam<br />

<strong>tape</strong>s are sometimes utilized between<br />

the track and the ceiling or floor to<br />

reduce the potential sound loss due<br />

to flanking paths. But none of these<br />

sound aids provide fire protection if<br />

movement is required.<br />

What’s the contractor to do? On one<br />

hand, you have to provide an average<br />

of 3/4 inch overall movement for the<br />

building structure. On the other hand,<br />

you are required to provide applicable<br />

sound protection for dwelling units.<br />

Traditionally sound protection and fire<br />

protection do not work hand in hand<br />

when movement is involved.<br />

Making matters worse, contractors<br />

are bidding projects in a very competitive<br />

environment these days and in the<br />

past the traditional means and methods<br />

of a sealant filled head-of-wall<br />

joints were not watched very closely<br />

by the inspectors. So head-of-wall fire<br />

rated joints could be done relatively<br />

inexpensively by installing smaller<br />

width joints of 1/4 to 1/2 inch which<br />

will save material and labor costs rather<br />

than what is actually called out on<br />

the UL report at 3/4 to 1 inch. When<br />

you take into consideration the overall<br />

movement is based on the width of the<br />

joint and the percentage of the compression<br />

or extension listed on the UL<br />

report (typically listed at 18 to 25 percent)<br />

it is clear that making the joint<br />

smaller will only limit the amount of<br />

movement causing the joint to underperform.<br />

Most buildings are designed<br />

with a certain movement criteria. Certain<br />

walls within all structures are<br />

also designed to be fire-rated to enable<br />

safe egress hence the requirement for<br />

fire-rated walls with dynamic movement.<br />

A fire-rated joint that underperforms<br />

may not sound like a big deal<br />

during construction but if by underperforming<br />

the joint splits open and<br />

allows smoke to pass through the wall<br />

it can put lives at risk.<br />

SOLUTION<br />

Find out the movement requirement<br />

of the building structure and find a<br />

joint system that will provide it. If the<br />

UL report requires a 1-inch joint filled<br />

with a particular type of fire sealant<br />

then install it accordingly. If acoustic<br />

or fire sealant will not provide enough<br />

movement find something that will.<br />

There are deflection tracks with factory<br />

applied intumescent <strong>tape</strong>s, such<br />

as CEMCO FAS Track 1000, that will<br />

provide fire, smoke, and sound protection.<br />

This product is certified through<br />

UL according to UL-2079 and can<br />

meet greater deflection requirements<br />

with no fatigue splitting or cracking.<br />

But what if the project is already<br />

underway and the top track is already<br />

installed when you, the contractor<br />

find out the movement requirement is<br />

greater than what is achievable with<br />

fire sealant? It’s a little too late to<br />

switch out the installed deflection<br />

track for one with a factory applied<br />

intumescent <strong>tape</strong>. There is a solution.<br />

CEMCO DDA (Deflection Drift<br />

Angle) is a light gauge composite steel<br />

angle with intumescent <strong>tape</strong> along the<br />

inside leg which can be tapped into<br />

place over the leg of the installed top<br />

track. There are no mechanical fasteners<br />

required for installation. The<br />

3/4-inch horizontal leg of the product<br />

is friction fit between the web of the<br />

track and the overhead structure. This<br />

allows the wall assembly to move vertically<br />

and laterally without compromising<br />

the fire stop material. This type of<br />

fire-stopping product has other advantages;<br />

provides a universal fit for any<br />

wall width, gauge, height, whether the<br />

wall is standard, shaft wall, radius, or<br />

raked. It can go over either slotted or<br />

deep leg deflection track and finally it<br />

can provide up to 1¾-inch unencumbered<br />

joint protection.<br />

CONCLUSION<br />

Do your research when selecting<br />

head-of-wall fire protection. Make<br />

sure the manufactures joint system<br />

has been tested according to UL-2079<br />

“Tests for Fire Resistance of Building<br />

Joint Systems” and can provide<br />

the movement the building structure<br />

requires. If you decide to go with a<br />

steel/intumescent deflection track,<br />

make sure it has been sound tested<br />

and can meet the required STC rating.<br />

Finally, field installations can be very<br />

difficult make sure the joint system<br />

is being constructed as intended and<br />

described in the UL report. Underperforming<br />

joints are unacceptable, especially<br />

in multi-family dwellings. W&C<br />

After 23 years in the construction<br />

industry as a foreman<br />

and building envelope consultant,<br />

Don Pilz is now the R&D<br />

Manager for CEMCO, assisting consultants<br />

and contractors with detailing needs. He<br />

can be reached at dpilz@cemcosteel.com.<br />

January 2013 | www.wconline.com |<br />

19