Fatigue in thin films Lifetime and damage formation.pdf

Fatigue in thin films Lifetime and damage formation.pdf

Fatigue in thin films Lifetime and damage formation.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Materials Science <strong>and</strong> Eng<strong>in</strong>eer<strong>in</strong>g A319–321 (2001) 919–923<br />

www.elsevier.com/locate/msea<br />

<strong>Fatigue</strong> <strong>in</strong> th<strong>in</strong> <strong>films</strong>: lifetime <strong>and</strong> <strong>damage</strong> <strong>formation</strong><br />

O. Kraft *, R. Schwaiger, P. Wellner<br />

Max-Planck-lnstitut für Metallforschung <strong>and</strong> Institut für Metallkunde of the Uniersity, Seestr. 92, 70714 Stuttgart, Germany<br />

Abstract<br />

Two new techniques, developed for study<strong>in</strong>g the fatigue behavior of th<strong>in</strong> metal <strong>films</strong> on substrates, are presented: The first<br />

technique <strong>in</strong>volves deposition of Cu <strong>films</strong> onto elastic polyimide substrates. Dur<strong>in</strong>g cyclic tensile test<strong>in</strong>g of the film–substrate<br />

composite, the film is subjected to tension–compression cycles, s<strong>in</strong>ce it is plastically deformed, while the substrate undergoes only<br />

elastic de<strong>formation</strong>. Us<strong>in</strong>g this technique, it was found that, for 3 m thick Cu <strong>films</strong>, the number of cycles to failure follows the<br />

phenomenological Coff<strong>in</strong>–Manson relationship. For the other technique, th<strong>in</strong> <strong>films</strong>, here Ag <strong>films</strong> with thicknesses rang<strong>in</strong>g from<br />

0.2 to 1.5 m, are deposited onto micromach<strong>in</strong>ed SiO 2 cantilever beams. The beams are then deflected with a frequency of 45 Hz<br />

us<strong>in</strong>g a nano<strong>in</strong>dentation system. A detailed <strong>in</strong>vestigation of the <strong>damage</strong> <strong>formation</strong> <strong>in</strong> both fatigued Cu <strong>and</strong> Ag <strong>films</strong> revealed<br />

surface roughen<strong>in</strong>g prior to failure. Extrusions <strong>and</strong> cracks are formed <strong>in</strong>side large gra<strong>in</strong>s <strong>and</strong> between small gra<strong>in</strong>s, respectively.<br />

© 2001 Elsevier Science B.V. All rights reserved.<br />

Keywords: Polyimide; <strong>Fatigue</strong>; Th<strong>in</strong> <strong>films</strong>; Cu; Ag<br />

1. Introduction<br />

<strong>Fatigue</strong> of th<strong>in</strong> film materials has not yet been studied<br />

systematically. S<strong>in</strong>ce the mechanical properties of<br />

th<strong>in</strong> <strong>films</strong> may be different from those of bulk materials<br />

[1–3], fatigue behavior cannot be extrapolated from<br />

results of bulk studies. For ductile bulk materials, it is<br />

well-known that fatigue crack <strong>in</strong>itiation processes are<br />

often related to the <strong>formation</strong> of persistent slip b<strong>and</strong>s<br />

[4]. These slip b<strong>and</strong>s, which have a typical width of<br />

several micrometers, lead to extrusions at the sample<br />

surface <strong>and</strong> stress concentrations, or to stra<strong>in</strong> localization<br />

<strong>in</strong>side gra<strong>in</strong>s, <strong>and</strong> eventually to crack <strong>formation</strong>. It<br />

is uncerta<strong>in</strong>, if similar processes can occur <strong>in</strong> th<strong>in</strong> film<br />

materials, s<strong>in</strong>ce the typical size of slip b<strong>and</strong>s <strong>in</strong> bulk<br />

materials exceeds the thickness <strong>and</strong> the gra<strong>in</strong> size of<br />

most th<strong>in</strong> <strong>films</strong>. Indeed, <strong>in</strong> the few TEM studies, conducted<br />

so far on fatigued metal foils <strong>and</strong> th<strong>in</strong> <strong>films</strong>, the<br />

<strong>formation</strong> of dislocation structures was observed to be<br />

suppressed <strong>in</strong> f<strong>in</strong>e gra<strong>in</strong>ed Cu foils [5–7].<br />

In fatigue test<strong>in</strong>g of metals, it is common to dist<strong>in</strong>guish<br />

between regimes of high cycle fatigue (HCF) <strong>and</strong><br />

low cycle fatigue (LCF). In the former, the stress<br />

* Correspond<strong>in</strong>g author. Tel./fax: +49-711-2095123.<br />

E-mail address: oliver.kraft@po.uni-stuttgart.de (O. Kraft).<br />

amplitude does not exceed the yield strength of the<br />

material <strong>and</strong> the number N f of cycles to failure is<br />

typically above 10 3 –10 4 . In the LCF regime, the material<br />

is plastically stra<strong>in</strong>ed <strong>in</strong> each cycle. Therefore, it is<br />

common to report lifetimes of a material as a function<br />

of the plastic stra<strong>in</strong> range pl us<strong>in</strong>g the empirically<br />

established Coff<strong>in</strong>–Manson relationship [8]:<br />

pl<br />

2 = f(2N f ) c (1)<br />

where f <strong>and</strong> c are the fatigue ductility coefficient <strong>and</strong><br />

exponent, respectively. In the HCF regime, fatigue tests<br />

are usually conducted under stress control <strong>and</strong> lifetimes<br />

generally obey a similar equation:<br />

a<br />

2 = f(2N f ) b (2)<br />

where a is the applied stress amplitude, f <strong>and</strong> b are<br />

the fatigue strength coefficient <strong>and</strong> exponent, respectively.<br />

It was found that Cu foils or <strong>films</strong> with a<br />

thickness of more than 10 m follow, depend<strong>in</strong>g on the<br />

fatigue test conducted, one of these empirical relationships<br />

[5,6,9,10]. However, it is not obvious if the relationships<br />

still hold for <strong>films</strong> with smaller thickness <strong>and</strong><br />

gra<strong>in</strong> size.<br />

0921-5093/01/$ - see front matter © 2001 Elsevier Science B.V. All rights reserved.<br />

PII: S0921-5093(01)00990-X

920<br />

O. Kraft et al. / Materials Science <strong>and</strong> Eng<strong>in</strong>eer<strong>in</strong>g A319–321 (2001) 919–923<br />

It is the aim of this paper to elucidate the fatigue<br />

mechanisms <strong>in</strong> constra<strong>in</strong>ed volumes <strong>and</strong> to determ<strong>in</strong>e<br />

fatigue lifetimes under these conditions. We present<br />

two methods, which we developed to study the fatigue<br />

behavior of th<strong>in</strong> metal <strong>films</strong> on substrates: The<br />

first technique <strong>in</strong>volves tensile test<strong>in</strong>g of Cu <strong>films</strong> deposited<br />

onto elastic polyimide substrates. Tensile test<strong>in</strong>g<br />

of these specimen results <strong>in</strong> tension–compression<br />

cycles <strong>in</strong> the plastically deformed th<strong>in</strong> film while the<br />

substrate is elastically deformed only. The second<br />

technique utilizes the cyclic deflection of th<strong>in</strong> Ag <strong>films</strong><br />

deposited onto micromach<strong>in</strong>ed SiO 2 cantilever beam<br />

us<strong>in</strong>g a nano<strong>in</strong>dentation system.<br />

2. Experimental<br />

2.1. Tensile test<strong>in</strong>g<br />

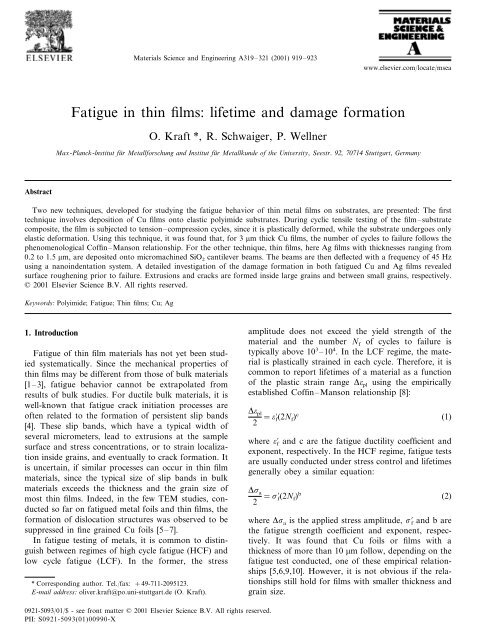

For process<strong>in</strong>g of the tensile specimen, shown <strong>in</strong><br />

Fig. 1a, the 125 m thick polyimide substrates (Kapton,<br />

Du Pont) were <strong>in</strong>itially cleaned by r<strong>in</strong>s<strong>in</strong>g with<br />

ethanol <strong>and</strong> pressurized CO 2 . Then, the sample was<br />

mounted <strong>in</strong> the deposition system (base pressure of<br />

5×10 −7 mbar) <strong>and</strong> activated by an oxygen plasma<br />

(O 2 pressure 1×10 −2 mbar, power 100 W, bias<br />

−300 V). Without break<strong>in</strong>g vacuum, 3 m thick Cu<br />

<strong>films</strong> were then sputter deposited at a substrate temperature<br />

of 300°C, a rate of 60 nm per m<strong>in</strong> with an<br />

Ar pressure of 2×10 −3 mbar, a power of 150 W<br />

<strong>and</strong> a bias of −80 V. After deposition, the samples<br />

were annealed <strong>in</strong> a vacuum furnace (6×10 −6 mbar)<br />

at a temperature of 400°C.<br />

The tensile tests were performed <strong>in</strong> an electromechanical<br />

tensile tester (Zwicki 1120, Zwick) under<br />

load control. Samples were cyclically loaded between<br />

a m<strong>in</strong>imum load of 2 N to maximum loads <strong>in</strong> the<br />

range of 15–60 N. Under these conditions, the film is<br />

stra<strong>in</strong>ed with constant total stra<strong>in</strong> ranges between 0.7<br />

<strong>and</strong> 2.1% as determ<strong>in</strong>ed from the crosshead displacement<br />

<strong>and</strong> monitored as a function of the number of<br />

cycles. It is not possible to determ<strong>in</strong>e the film stress<br />

us<strong>in</strong>g this configuration because the externally applied<br />

force is predom<strong>in</strong>antly governed by the mechanical<br />

properties of the substrate. However, microtensile<br />

tests on comparable samples us<strong>in</strong>g an X-ray diffraction<br />

technique enabled the measurements of stress–<br />

stra<strong>in</strong> behavior dur<strong>in</strong>g such experiments as<br />

exemplified <strong>in</strong> Fig. 1b [11]. On load<strong>in</strong>g <strong>and</strong> unload<strong>in</strong>g,<br />

the film is plastically deformed <strong>in</strong> tension <strong>and</strong> <strong>in</strong><br />

compression for a total <strong>and</strong> plastic stra<strong>in</strong> range of 0.5<br />

<strong>and</strong> 0.15%, respectively.<br />

2.2. Microbeam bend<strong>in</strong>g<br />

Fig. 1. Microtensile test<strong>in</strong>g; (a) Sample geometry of the 125 m thick<br />

polyimide foil substrate <strong>and</strong> the Cu film sputtered <strong>in</strong> the middle<br />

section of the dog-bone shaped sample. (b) Typical stress-stra<strong>in</strong><br />

behavior for a Cu film on a polyimide substrate dur<strong>in</strong>g cyclic load<strong>in</strong>g<br />

as measured by X-ray diffraction (second cycle of 0.7 m thick Cu<br />

film, from [11]). The total applied stra<strong>in</strong> range of the cycle is 0.5%,<br />

whereas the plastic stra<strong>in</strong> range amounts only to about 0.15% as<br />

<strong>in</strong>dicated by the arrow with<strong>in</strong> the hysteresis loop.<br />

The microbeam samples are shown schematically <strong>in</strong><br />

Fig. 2a. They consist of a 2.83 m thick SiO 2 layer<br />

<strong>and</strong> a th<strong>in</strong>ner Ag film. The Ag <strong>films</strong>, rang<strong>in</strong>g from<br />

0.2 to 1.5 m <strong>in</strong> thickness, were sputter deposited at<br />

a temperature of about −190°C <strong>and</strong> annealed at +<br />

100°C. A detailed description of film deposition <strong>and</strong><br />

the test<strong>in</strong>g procedure is given <strong>in</strong> [12]. The test<strong>in</strong>g procedure<br />

is briefly described as follows, the beams are<br />

deflected by a commercial nano<strong>in</strong>dentation system<br />

(Nano II, MTS Corp.), which applies a cyclic load<br />

P=P mean +P o cos(2t), where P mean is the mean<br />

load, P o the load amplitude <strong>and</strong> the frequency,<br />

which was chosen to be 45 Hz. In this configuration,<br />

the largest stra<strong>in</strong> occurs at the fixed end of the beam<br />

(as <strong>in</strong>dicated <strong>in</strong> Fig. 2a). Based on elastic beam bend<strong>in</strong>g<br />

theory, this stra<strong>in</strong> can be calculated from the<br />

lever length L <strong>and</strong> the applied load as:<br />

= P(L−x) (z−q) (3)<br />

IE<br />

where I is the moment of <strong>in</strong>ertia, E the Young’s<br />

modulus of the substrate material, q the position of<br />

the neutral axis, <strong>and</strong> x <strong>and</strong> z the coord<strong>in</strong>ates along<br />

the length <strong>and</strong> the thickness of the beam. The mo-

O. Kraft et al. / Materials Science <strong>and</strong> Eng<strong>in</strong>eer<strong>in</strong>g A319–321 (2001) 919–923 921<br />

3. Results<br />

3.1. Tensile test<strong>in</strong>g<br />

The 3 m thick Cu <strong>films</strong> on the polyimide substrates<br />

had gra<strong>in</strong>s which were found to be equiaxed rather than<br />

columnar with a median gra<strong>in</strong> size of 0.8 m. Also, no<br />

dist<strong>in</strong>ct texture was observed. As a typical example,<br />

Fig. 3a shows the total stra<strong>in</strong> range as a function of the<br />

number of cycles for a bare substrate <strong>and</strong> a sample with<br />

aCufilm. The maximum load was 25 N. It can be seen<br />

that the stra<strong>in</strong> range for the sample with the film is<br />

<strong>in</strong>itially smaller because the sample stiffness is higher<br />

due the film. After about 4000 cycles, the stra<strong>in</strong> range<br />

Fig. 2. Microbeam bend<strong>in</strong>g; (a) Schematic of the sample <strong>and</strong> load<strong>in</strong>g<br />

geometry, the beam consists of a 2.83 m thick SiO 2 layer onto which<br />

0.2–1.5 m thick Ag <strong>films</strong> were sputter deposited. The load P is<br />

<strong>in</strong>duced by a nano<strong>in</strong>dentation system with a wedge-shaped tip hav<strong>in</strong>g<br />

a wedge length of 10 m <strong>and</strong> an open<strong>in</strong>g angle of 90°. The tip<br />

contacts the beam <strong>in</strong> the dark shaded area, where the Ag film has<br />

been removed by focused ion beam mill<strong>in</strong>g. (b) Schematic of the<br />

stra<strong>in</strong><strong>in</strong>g conditions: The load P is cycled with an amplitude of P<br />

around a mean value of P mean . The result<strong>in</strong>g cyclic stra<strong>in</strong> for the Ag<br />

film at the fixed end of the beam (hatched area <strong>in</strong> (a)) is also<br />

represented.<br />

ment of <strong>in</strong>ertia <strong>and</strong> the position of the neutral axis<br />

depend on the thicknesses <strong>and</strong> the elastic properties of<br />

the beam <strong>and</strong> film [13]. As a result of the applied cyclic<br />

load, the metal film at the fixed end of the microbeam<br />

is subjected to a cyclic stra<strong>in</strong> as schematically shown <strong>in</strong><br />

Fig. 2b. For lifetime studies, the lever length, the mean<br />

load <strong>and</strong> the load amplitude were varied, result<strong>in</strong>g <strong>in</strong><br />

values for mean <strong>and</strong> <strong>in</strong> the range of 0.2–2.3% <strong>and</strong><br />

0.2–0.6%, respectively. We report our results as a function<br />

of max = mean +1/2. The film is yield<strong>in</strong>g at such<br />

stra<strong>in</strong>s <strong>and</strong> the correspond<strong>in</strong>g stress range <strong>in</strong> the experiment<br />

can, therefore, not be calculated. Fig. 2b also<br />

<strong>in</strong>dicates that under the dynamic load<strong>in</strong>g conditions,<br />

the cyclic stra<strong>in</strong> is phase shifted relative to the cyclic<br />

load. This phase shift was measured throughout the<br />

experiment <strong>and</strong> used to monitor the stiffness of the<br />

beam as a function of the number of cycles as described<br />

elsewhere [12].<br />

All <strong>films</strong> were <strong>in</strong>vestigated by focused ion beam<br />

microscopy (FEI 200) <strong>and</strong> X-ray diffraction to determ<strong>in</strong>e<br />

gra<strong>in</strong> size <strong>and</strong> texture, respectively. After test<strong>in</strong>g,<br />

fatigue <strong>damage</strong> was characterized by scann<strong>in</strong>g electron<br />

<strong>and</strong> focused ion beam microscopy.<br />

Fig. 3. (a) Total stra<strong>in</strong> range for a 3 m thick Cu film on a polyimide<br />

substrate <strong>and</strong> a bare substrate. Both experiments were conducted<br />

under load control with a maximum load of 25 N <strong>and</strong> a m<strong>in</strong>imum<br />

load of 2 N. The lifetime was def<strong>in</strong>ed as the number of cycles at<br />

which the stra<strong>in</strong> range <strong>in</strong>creased. (b) Number of cycles to failure as a<br />

function of total stra<strong>in</strong> range.

922<br />

O. Kraft et al. / Materials Science <strong>and</strong> Eng<strong>in</strong>eer<strong>in</strong>g A319–321 (2001) 919–923<br />

3.2. Microbeam bend<strong>in</strong>g<br />

The gra<strong>in</strong>s <strong>in</strong> the Ag <strong>films</strong> on the SiO 2 microbeams<br />

were found to be columnar <strong>and</strong> had a median gra<strong>in</strong> size<br />

of about 0.9 m <strong>in</strong>dependent of the film thickness. The<br />

majority of gra<strong>in</strong>s was (111)-oriented with a smaller<br />

fraction of (100)-oriented gra<strong>in</strong>s. The latter <strong>in</strong>creased<br />

with <strong>in</strong>creas<strong>in</strong>g film thickness. As an example of a<br />

typical microbeam bend<strong>in</strong>g experiment, Fig. 4a shows<br />

the beam stiffness as function of the number of cycles<br />

for a beam with a 0.8 m thick film <strong>and</strong> a maximum<br />

stra<strong>in</strong> max of 2.2%. Initially, the beam stiffness is nearly<br />

constant. The dramatic decrease <strong>in</strong> stiffness after approximately<br />

6×10 −5 cycles <strong>in</strong>dicates the onset of<br />

severe <strong>damage</strong> <strong>formation</strong>. Similar experiments conducted<br />

on samples with different film thicknesses are<br />

summarized <strong>in</strong> Fig. 4b. The filled symbols denote the<br />

experiments <strong>in</strong> which a dist<strong>in</strong>ct decrease <strong>in</strong> beam stiffness<br />

was observed with<strong>in</strong> 3.9×10 6 cycles accompanied<br />

by crack <strong>formation</strong>. Only <strong>films</strong> with a thickness of 0.6<br />

m or more suffered from fatigue <strong>damage</strong>.<br />

3.3. Damage morphology<br />

Typical micrographs of fatigue <strong>damage</strong> are shown <strong>in</strong><br />

Fig. 5. For both Cu <strong>and</strong> Ag <strong>films</strong>, the <strong>damage</strong> morphology<br />

can be described as follows, extrusions (marked as<br />

E) are formed with<strong>in</strong> large gra<strong>in</strong>s, whereas <strong>in</strong>tergranular<br />

cracks (C) were found <strong>in</strong> f<strong>in</strong>e gra<strong>in</strong>ed regions of the<br />

film. The extrusion height is comparable to the film<br />

thickness. Underneath the extrusions, large voids are<br />

found at the <strong>in</strong>terface between the film <strong>and</strong> the substrate.<br />

Some more detailed observations of the fatigue<br />

<strong>damage</strong> <strong>in</strong> the Ag <strong>films</strong> are described <strong>in</strong> [12].<br />

Fig. 4. (a) Stiffness of a microbeam with 0.8 m thick film cycled to<br />

max of 2.2% at a frequency of 45 Hz. The sudden decrease of stiffness<br />

<strong>in</strong>dicates the onset of <strong>damage</strong> <strong>formation</strong>. (b) Map for <strong>damage</strong> <strong>formation</strong><br />

as a function of Ag film thickness <strong>and</strong> maximum stra<strong>in</strong>. Thick<br />

<strong>films</strong> showed fatigue <strong>damage</strong> with<strong>in</strong> 3.9×10 6 cycles (filled symbols)<br />

whereas th<strong>in</strong> <strong>films</strong> did not show structural features of fatigue (open<br />

symbols). The transition occurs for 0.6 <strong>and</strong> 0.8 m thick <strong>films</strong> as<br />

function of maximum stra<strong>in</strong>.<br />

<strong>in</strong>creases, i.e. the sample stiffness decreases. After<br />

10000 cycles, the stra<strong>in</strong> range has reached the level of<br />

the bare substrate <strong>in</strong>dicat<strong>in</strong>g that the film is no longer<br />

contribut<strong>in</strong>g to the sample stiffness. The number N f of<br />

cycles to failure <strong>in</strong> these experiments was def<strong>in</strong>ed as the<br />

<strong>in</strong>terception of two l<strong>in</strong>ear curve fits as demonstrated <strong>in</strong><br />

Fig. 3a. In Fig. 3b, this number is plotted versus the<br />

total stra<strong>in</strong> range. As expected, the lifetime decreases<br />

with <strong>in</strong>creas<strong>in</strong>g stra<strong>in</strong> range follow<strong>in</strong>g a relationship as<br />

given by Eq. (1).<br />

4. Discussion<br />

Two techniques have been developed to study the<br />

fatigue behavior of th<strong>in</strong> <strong>films</strong> on substrates. Central to<br />

both methods is the use of an elastic substrate, which<br />

acts as an antagonist to an external mechanical load<strong>in</strong>g.<br />

As a result, <strong>films</strong> are deformed <strong>in</strong> tension on load<strong>in</strong>g<br />

<strong>and</strong> <strong>in</strong> compression on unload<strong>in</strong>g. Another important<br />

aspect of these experiments is that film fatigue <strong>damage</strong><br />

is not catastrophic because the un<strong>damage</strong>d substrate<br />

ma<strong>in</strong>ta<strong>in</strong>s some mechanical <strong>in</strong>tegrity of the sample.<br />

However, the degradation of the film, i.e. crack <strong>formation</strong><br />

<strong>and</strong> propagation, is manifested as a decrease <strong>in</strong><br />

stiffness of the film–substrate composite. Based on this<br />

dist<strong>in</strong>ct decrease <strong>in</strong> stiffness, the lifetime of Cu <strong>films</strong> on<br />

polyimide substrates was determ<strong>in</strong>ed as a function of<br />

applied total stra<strong>in</strong> range. It was not possible to determ<strong>in</strong>e<br />

the plastic stra<strong>in</strong> range, s<strong>in</strong>ce the film stress was<br />

not measurable dur<strong>in</strong>g the experiments. As a result,<br />

Fig. 3b is plotted as the <strong>in</strong>itial total stra<strong>in</strong> range as a

O. Kraft et al. / Materials Science <strong>and</strong> Eng<strong>in</strong>eer<strong>in</strong>g A319–321 (2001) 919–923 923<br />

significantly slower or suppressed <strong>in</strong> th<strong>in</strong>ner <strong>films</strong>,<br />

which would be qualitatively <strong>in</strong> agreement with the fact<br />

that the strength of metal <strong>films</strong> <strong>in</strong>creases with decreas<strong>in</strong>g<br />

film thickness [1,2,14]. However, it is currently not<br />

clear, if the <strong>formation</strong> of the extrusions is related to the<br />

occurrence of dislocation structures, such as persistent<br />

slip b<strong>and</strong>s, as <strong>in</strong> bulk materials. More systematic studies,<br />

<strong>in</strong>clud<strong>in</strong>g TEM <strong>in</strong>vestigations, are currently pursued<br />

to obta<strong>in</strong> a deeper underst<strong>and</strong><strong>in</strong>g of fatigue<br />

mechanisms <strong>in</strong> th<strong>in</strong> <strong>films</strong>.<br />

5. Summary<br />

Fig. 5. Damage morphology after fatigue test<strong>in</strong>g; (a) Focused ion<br />

beam micrograph of a 3 m thick Cu film on a polyimide substrate,<br />

large extrusions <strong>and</strong> cracks are marked by E <strong>and</strong> C, respectively. (b)<br />

SEM micrograph show<strong>in</strong>g the 0.8 Ag film, from the test described <strong>in</strong><br />

Fig. 4a, at the fixed end of a microbeam. Large extrusions (marked<br />

by E) are connected by a crack (C).<br />

function of N f . The data follow Eq. (1) with an exponent<br />

of −0.4, which is somewhat higher than typically<br />

observed values of −0.5 to −0.7 for many bulk metal<br />

materials [8]. This is partially accounted for by the use<br />

of the total stra<strong>in</strong> range <strong>in</strong>stead of the plastic stra<strong>in</strong><br />

range, because the difference between the two is more<br />

important at small stra<strong>in</strong> ranges. As a result of this<br />

consideration, the exponent of −0.4 can be regarded<br />

as an upper bound.<br />

The microbeam bend<strong>in</strong>g experiments reveal that the<br />

fatigue behavior changes significantly, when the film<br />

thickness is reduced below 1 m. Fig. 4b shows that<br />

<strong>films</strong> th<strong>in</strong>ner than 0.6 m did not fatigue with<strong>in</strong> 3.9×<br />

10 6 cycles. The <strong>formation</strong> of extrusions appears to be<br />

In an attempt to systematically study the fatigue<br />

behavior of th<strong>in</strong> metal <strong>films</strong> as a function of film<br />

thickness, gra<strong>in</strong> size, <strong>and</strong> stra<strong>in</strong><strong>in</strong>g conditions, we have<br />

developed two new methods. Central to both methods<br />

is the use of an elastic substrate, which acts as an<br />

antagonist to an external mechanical load<strong>in</strong>g. First<br />

results can be summarized as follows; fatigue <strong>damage</strong><br />

<strong>in</strong>cludes the <strong>formation</strong> of large transgranular extrusions<br />

<strong>and</strong> <strong>in</strong>tergranular cracks. The crack <strong>formation</strong> is associated<br />

with a dist<strong>in</strong>ct decrease <strong>in</strong> stiffness of the film–<br />

substrate composite. The lifetime of 3 m thick Cu<br />

<strong>films</strong> on polyimide substrates follows a Coff<strong>in</strong>–<br />

Manson-type relationship. No fatigue <strong>damage</strong> was<br />

found <strong>in</strong> Ag <strong>films</strong> with thicknesses below 0.6 m as<br />

tested by dynamic microbeam deflection.<br />

References<br />

[1] W.D. Nix, Met. Trans. A 20A (1989) 2217–2245.<br />

[2] R.-M. Keller, S.P. Baker, E. Arzt, J. Mater. Res. 13 (1998)<br />

1307–1317.<br />

[3] E. Arzt, Acta Mater. 46 (1998) 5611–5626.<br />

[4] U. Essmann, H. Mughrabi, Phil. Mag. A 40 (1979) 731–756.<br />

[5] S. Hong, R. Weil, Th<strong>in</strong> Solid Films 283 (1996) 175–181.<br />

[6] M. Judelewicz, H.U. Künzi, N. Merk, B. Ilschner, Mat. Sci. Eng.<br />

A186 (1994) 135–142.<br />

[7] D.T. Read, Int. J. <strong>Fatigue</strong> 20 (1998) 203–209.<br />

[8] S. Suresh, <strong>Fatigue</strong> of Materials, Second ed, Cambridge University<br />

Press, Cambridge, 1999, pp. 137–139.<br />

[9] Y. Oshida, P.C. Chen, J. Electr. Packag<strong>in</strong>g 113 (1991) 58–62.<br />

[10] H.D. Merchant, M.G. M<strong>in</strong>or, Y.L. Liu, J. Electron Mater. 28<br />

(1999) 998–1007.<br />

[11] M. Hommel, O. Kraft, <strong>and</strong> E. Arzt. J. Mater. Res., 14 (1999).<br />

[12] R. Schwaiger, O. Kraft, Scr. Mat. 41 (1999) 823–829.<br />

[13] S.P. Baker, W.D. Nix, J. Mater. Res. 9 (1994) 3131–3144.<br />

[14] R. Venkatraman, J.C. Bravman, J. Mater. Res. 7 (1992) 2040.