pdf, 2.83mb - Steinemann Technology AG

pdf, 2.83mb - Steinemann Technology AG

pdf, 2.83mb - Steinemann Technology AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.steinemann.com<br />

<strong>Steinemann</strong> Graphic Systems:<br />

The Art of Finishing.

The profitable one<br />

<strong>Steinemann</strong> Lotus<br />

Laminating system with solvent-free PUR adhesive

<strong>Steinemann</strong> Lotus<br />

Laminating system with solvent-free PUR adhesive<br />

Possible applications<br />

Folding boxes for all film types. Commercial printing of all kinds. Magazine or<br />

book covers in short to long runs. Packagings for foods, luxury products,<br />

cosmetics and pharmaceuticals.<br />

20<br />

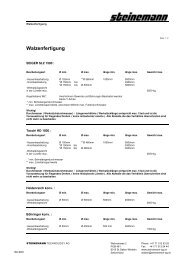

Technical Data<br />

Minimum sheet size (length x width) 34 x 30 cm<br />

Maximum sheet size (length x width 145 x 104 cm<br />

Maximum sheet output* 10000 sheets/hour<br />

or maximum production speed 80 m/min.<br />

(option: 100 m/min.)<br />

Sheet weight 100 – 600 g/m 2<br />

Adhesive quantity applied 1.8 – 4 g/m 2<br />

Film thickness* 10 – 100 µm<br />

Maximum film roll diameter 410 mm<br />

*depending on in-house conditions and the substrates, sheet formats, films and adhesives used

<strong>Steinemann</strong> Lotus<br />

Laminating system with solvent-free PUR adhesive<br />

The advantages<br />

• Migration-free PUR adhesive – environmentally neutral after curing.<br />

• The least-cost laminating process – upwards of a daily production output of<br />

approx. 10000 sheets.<br />

• Low energy costs – the PUR technology used needs no drying system.<br />

• Processing of all film types – such as PE, PET, PLA, OPP, Acetate or Nylon,<br />

thanks to the Hot-Knife cutting system.<br />

• Perfect stack quality – the cold-laminating method prevents sheet distortion,<br />

no decurling is needed.<br />

«Winning on the hotly contested packaging market.»<br />

<strong>Steinemann</strong> is even to be found twice at Spanish packaging manufacturer Cartonajes Torralba. The convincing<br />

features of the two Lotus laminating systems are their high laminating quality and favourable<br />

operating costs. «We were in a position to invest in a second machine just 20 months after installing the first<br />

one. We‘ve acquired customer after customer on the hotly contested market, and have now become one of<br />

the leading suppliers on the domestic market. Be it packaging for shoes, toys or confectionery – there is<br />

growing demand for laminated packagings,» says Juan Torralba, Managing Director of Cartonajes Torralba<br />

in Alicante, Spain.<br />

• Optimum film adhesion – the PUR adhesive is thermally stable.<br />

21

<strong>Steinemann</strong><br />

Swiss Quality. Worldwide<br />

STEINEMANN TECHNOLOGY <strong>AG</strong><br />

Schoretshuebstrasse 24<br />

POP 461<br />

CH-9015 St. Gallen<br />

Switzerland<br />

Phone +41 71 313 51 51<br />

Fax +41 71 313 52 52<br />

www.steinemann.com<br />

STEINEMANN TECHNOLOGY<br />

(SHANGHAI) MACHINERY CO. LTD.<br />

Building 8, Xietong Group<br />

the Fourth Industry Park<br />

25 Caolianzhi Road<br />

201804 Jiading, Shanghai<br />

China<br />

Phone +86 21 395 96 603<br />

Fax +86 21 395 96 623<br />

www.steinemann.com<br />

© Copyright 2012 by <strong>Steinemann</strong> <strong>Technology</strong>. Subject to modifications. All data are without obligation.<br />

STEINEMANN TECHNOLOGY ASIA<br />

808, 8 th Floor, P.J. Tower<br />

18 Persiaran Barat<br />

46200 Petaling Javy<br />

Selangor, Malaysia<br />

Phone +60 3 7954 18 22<br />

Fax +60 3 7954 18 77<br />

www.steinemann.com<br />

27