Electromigration and Its Impact on Physical Design in Future ...

Electromigration and Its Impact on Physical Design in Future ...

Electromigration and Its Impact on Physical Design in Future ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.1 Bamboo Structure<br />

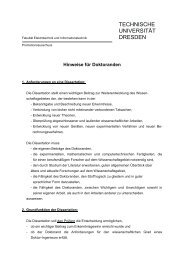

If the wire width is reduced to below the average gra<strong>in</strong> size of the<br />

wire material, the resistance to electromigrati<strong>on</strong> <strong>in</strong>creases, despite<br />

an <strong>in</strong>crease <strong>in</strong> current density. This apparent c<strong>on</strong>tradicti<strong>on</strong> is<br />

caused by the gra<strong>in</strong> boundary locati<strong>on</strong>s. In narrow wires, the gra<strong>in</strong><br />

boundary locati<strong>on</strong>s are perpendicular to the whole wire (as shown<br />

<strong>in</strong> Figure 7) form<strong>in</strong>g a bamboo like structure. As already<br />

menti<strong>on</strong>ed, material transport occurs as much <strong>in</strong> the directi<strong>on</strong> of<br />

the current flow as al<strong>on</strong>g gra<strong>in</strong> boundaries (gra<strong>in</strong> boundary<br />

diffusi<strong>on</strong>, see Secti<strong>on</strong> 2). Because gra<strong>in</strong> boundaries <strong>in</strong> this type of<br />

bamboo structure are often perpendicular to the current flow, the<br />

boundary diffusi<strong>on</strong> factor is demoted, <str<strong>on</strong>g>and</str<strong>on</strong>g> material transport is<br />

reduced accord<strong>in</strong>gly.<br />

Reliability<br />

MTTF [h]<br />

Figure 7. Reduced wire width – less than the average gra<strong>in</strong><br />

size – improves wire reliability with regard to electromigrati<strong>on</strong>.<br />

So-called bamboo wires are characterized by gra<strong>in</strong> boundaries<br />

which are perpendicular to the directi<strong>on</strong> of the electr<strong>on</strong> w<strong>in</strong>d<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> thus permit <strong>on</strong>ly limited gra<strong>in</strong> boundary diffusi<strong>on</strong>.<br />

The bamboo structure improves reliability if the self-heat<strong>in</strong>g limit<br />

of the layer is taken <strong>in</strong>to account. In order to exploit this, wire<br />

widths are deliberately kept narrow enough to ma<strong>in</strong>ta<strong>in</strong> a bamboo<br />

structure. Also the wire material can be annealed selectively<br />

dur<strong>in</strong>g IC process<strong>in</strong>g <strong>in</strong> order to support bamboo formati<strong>on</strong>.<br />

However, the maximum possible wire width for a bamboo<br />

structure, which is about 850 nm for damascene copper [2], is<br />

often too narrow for signal l<strong>in</strong>es carry<strong>in</strong>g large-magnitude<br />

currents <strong>in</strong> analog circuits or for power supply l<strong>in</strong>es. In these<br />

circumstances, slotted wires – <strong>in</strong> which rectangular holes are<br />

carved – can be used. Here, the widths of the <strong>in</strong>dividual metal<br />

structures between the slots support bamboo formati<strong>on</strong>, <str<strong>on</strong>g>and</str<strong>on</strong>g> the<br />

total width of all the metal structures meets power requirements.<br />

Based <strong>on</strong> the same pr<strong>in</strong>ciple, a f<strong>in</strong>e-gra<strong>in</strong> power mesh is often<br />

superimposed <strong>on</strong> the circuit. This mesh c<strong>on</strong>sists of a large number<br />

of wires, <str<strong>on</strong>g>and</str<strong>on</strong>g> the <strong>in</strong>dividual wire widths form a bamboo-like<br />

structure.<br />

It must be po<strong>in</strong>ted out that process anomalies often produce<br />

variati<strong>on</strong>s <strong>in</strong> wire widths – due to etch loss, lithography issues,<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> the like – <str<strong>on</strong>g>and</str<strong>on</strong>g> variati<strong>on</strong>s <strong>in</strong> wire heights – due to metal<br />

depositi<strong>on</strong> fluctuati<strong>on</strong>s, for example – as well as impact<strong>in</strong>g the via<br />

fill rate. It is vital to take these possible process fluctuati<strong>on</strong>s <strong>in</strong>to<br />

account when determ<strong>in</strong><strong>in</strong>g viable <strong>in</strong>terc<strong>on</strong>nect dimensi<strong>on</strong>s.<br />

5.2 Short-Length Effects<br />

There are also upper limits set <strong>on</strong> the length of an <strong>in</strong>terc<strong>on</strong>nect to<br />

block electromigrati<strong>on</strong>. One of them is known as the “Blech<br />

length,” <str<strong>on</strong>g>and</str<strong>on</strong>g> any wire that has a length below this threshold length<br />

(typically <strong>on</strong> the order of 5-50 m) will not fail by<br />

electromigrati<strong>on</strong>. In this scenario, mechanical stress buildup<br />

causes a reverse migrati<strong>on</strong> process which reduces, or even<br />

compensates for, the effective material flow towards the anode<br />

(Figure 8).<br />

Gra<strong>in</strong> Boundaries<br />

– Al+ Al+ Al+ Al+ Al+ +<br />

Al+<br />

e - F N1<br />

F N2 F N3<br />

F N4 F N5<br />

w<br />

e -<br />

– Al+ Al+ Al+ Al+ Al+ Al+ Al+ +<br />

e - F N1<br />

F N2 F N3<br />

F N4 F N5<br />

Equilibrium between EM <str<strong>on</strong>g>and</str<strong>on</strong>g> SM<br />

I = c<strong>on</strong>stant<br />

if L wire < “Blech length”<br />

T = c<strong>on</strong>stant<br />

– Al+ Al+ Al+ Al+<br />

Al+ Al+ +<br />

w m<strong>in</strong> … Thermal self-heat<strong>in</strong>g<br />

e -<br />

width limit<br />

w m<strong>in</strong> w MTTF_m<strong>in</strong><br />

Wire Width w [nm]<br />

w < Gra<strong>in</strong>s<br />

(Bamboo Wires)<br />

F N1<br />

F N2<br />

F N3<br />

F N4<br />

F N5<br />

<str<strong>on</strong>g>Electromigrati<strong>on</strong></str<strong>on</strong>g> (EM)<br />

Stress Migrati<strong>on</strong> (SM)<br />

Figure 8. An illustrati<strong>on</strong> of stress migrati<strong>on</strong> caused by the<br />

mechanical stress buildup <strong>in</strong> a short wire. This reversed<br />

migrati<strong>on</strong> process essentially neutralizes the material flow due<br />

to electromigrati<strong>on</strong>.<br />

Specifically, a wir<strong>in</strong>g segment is not susceptible to<br />

electromigrati<strong>on</strong> if the product of the segment’s current density J<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> the segment’s length L is less than a process-technologydependent<br />

threshold value (JL) Blech [4]. The critical product<br />

(JL) Blech , often called the “Blech immortality c<strong>on</strong>diti<strong>on</strong>,” is<br />

obta<strong>in</strong>ed from<br />

( JL)<br />

( JL)<br />

Blech<br />

<br />

<br />

z * q<br />

where Ω is the atomic volume of the wire material (cm 3 /number),<br />

∆σ is the difference <strong>in</strong> the hydrostatic stress at both ends of the<br />

segment, z* is the effective charge of the wire’s material (a<br />

measure of the momentum transfer from electr<strong>on</strong>s to the i<strong>on</strong>s of<br />

the wire’s material), q is the fundamental electr<strong>on</strong>ic charge<br />

(z*q < 0) <str<strong>on</strong>g>and</str<strong>on</strong>g> ρ is the density of the wir<strong>in</strong>g material [39].<br />

The Blech length can be <strong>in</strong>creased by deposit<strong>in</strong>g (stiff) cap layers<br />

<strong>on</strong> top of the copper metal <str<strong>on</strong>g>and</str<strong>on</strong>g> by us<strong>in</strong>g dielectrics with a higher<br />

Young’s module (i.e., higher stiffness) because both support<br />

reverse stress migrati<strong>on</strong>. However, the cap layer also needs to<br />

suppress surface diffusi<strong>on</strong> (see Secti<strong>on</strong> 5.6).<br />

Besides the Blech effect or Blech immortality c<strong>on</strong>diti<strong>on</strong> discussed<br />

above, there is another, related short-length effect. It is based <strong>on</strong><br />

void growth saturati<strong>on</strong> due to mechanical stress buildup. Voidrelated<br />

failures <strong>in</strong> wir<strong>in</strong>g segments require the void to be grown to<br />

a critical size V fail . Reverse stress migrati<strong>on</strong> <strong>in</strong> short segments,<br />

described above, can block void growth so that it cannot reach<br />

V fail (Figure 9). Specifically, the void growth with its <strong>in</strong>crease <strong>in</strong><br />

resistance ∆R does not reach the failure state marked by ∆R fail .<br />

(2)<br />

37