DLR5640-WN - FindTheNeedle.co.uk

DLR5640-WN - FindTheNeedle.co.uk

DLR5640-WN - FindTheNeedle.co.uk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NG/COUNTING<br />

CTION<br />

(-)DO<strong>WN</strong><br />

TIME SETTING(sec)<br />

SET<br />

(+)UP<br />

LOCK<br />

RESET<br />

R<br />

OK<br />

R<br />

1<br />

3<br />

5<br />

7<br />

9<br />

7<br />

3<br />

5<br />

1<br />

9<br />

5<br />

1<br />

7<br />

3<br />

1<br />

5<br />

9<br />

3<br />

7<br />

SPEED<br />

HIGH<br />

SOFT START<br />

LOW<br />

SLOW<br />

QUICK<br />

DC POWER SUPPLY DLC4511-JES<br />

For use with Electric Screwdrivers<br />

Models DLV75 DLV85<br />

P R I : 230V~ 50 / 60Hz<br />

SEC: 37~ 49V ,2A<br />

MADE IN CHINA<br />

9-4,Nakaikegami<br />

2-chome,Ohta-ku,<br />

Tokyo 146-8555,<br />

Japan<br />

7<br />

3<br />

5<br />

1<br />

9<br />

5<br />

1<br />

7<br />

3<br />

1<br />

5<br />

9<br />

3<br />

7<br />

SEC:40V 1.4A<br />

T 5A L<br />

SER.No.<br />

EUse this CONTROLLER in <strong>co</strong>mbination with the<br />

following special ELECTRIC SCREWDRIVERS.<br />

MODELS:DLV30/45/70 -IKE<br />

ETo reduce the risk of injury,user must read<br />

instruction manual.<br />

EAlways use this hearing protection.<br />

EAlways use this tool indoors.<br />

9<br />

5<br />

NITTO KOHKI CO.,LTD.<br />

2-9-4,Nakaikegami,Ohta-ku,<br />

Tokyo,146-8555,Japan<br />

MADE IN JAPAN<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

ON<br />

P<br />

+<br />

1<br />

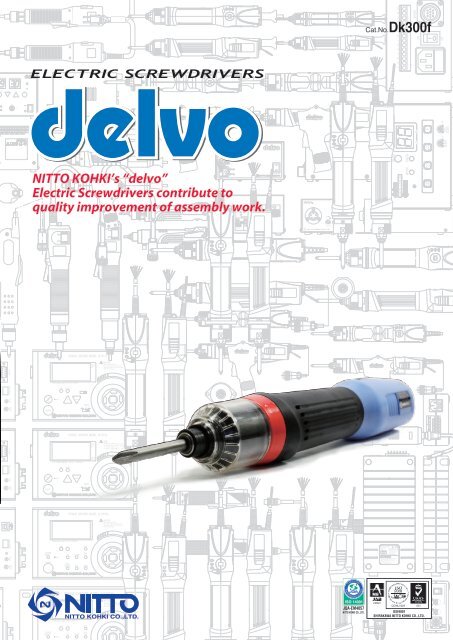

ELECTRIC SCREWDRIVERS<br />

13 14<br />

DRIVER<br />

Cat.No.Dk300f<br />

OK/NG<br />

TIMER<br />

COUNT<br />

A<br />

SPEED<br />

HIGH<br />

B<br />

F<br />

SOFT<br />

START<br />

12<br />

1 2 3 4 6 7 8 10 11<br />

ON<br />

OFF<br />

SLOW<br />

3 +<br />

NITTO KOHKI’s “delvo”<br />

5 -<br />

Electric Screwdrivers <strong>co</strong>ntribute to<br />

quality improvement of assembly work.<br />

1 2 3<br />

SER.No.<br />

SCREW COUNTER<br />

WORK<br />

C/M<br />

7<br />

3<br />

5<br />

1<br />

T 2.5A L<br />

7<br />

3<br />

5<br />

1<br />

TORQUE CHECKER MODEL DLT1173<br />

RS-232C<br />

AUTO<br />

POWER<br />

OFF<br />

CAUTION<br />

• Don't use as impact load.<br />

• Don't apply a torque exceeding the<br />

permissible load(120% of max.torque).<br />

• Read all instructions.<br />

Measuring range: 0.015~1.500N . m<br />

DATA OUTPUT DC IN<br />

ON<br />

OFF<br />

READY LOW BATT<br />

RESET<br />

UP<br />

DO<strong>WN</strong><br />

MODE<br />

ANALOG<br />

OUTPUT<br />

CLEAR<br />

PD TR PP<br />

TORQUE CHECKER MODEL DLT1133<br />

7<br />

3<br />

5<br />

1<br />

Driver Lock Function<br />

Output signal<br />

Torque up Reverse Common GND DC24V<br />

Start<br />

U<br />

R S T<br />

Q<br />

RS-232C<br />

AUTO<br />

POWER<br />

OFF<br />

<br />

<br />

<br />

<br />

<br />

: 0.015~1.500N . m<br />

N . m<br />

DATA OUTPUT<br />

READY<br />

LOW BATT<br />

DC IN<br />

ON<br />

OFF<br />

RESET<br />

UP<br />

DO<strong>WN</strong><br />

MODE<br />

ANALOG<br />

OUTPUT<br />

CLEAR<br />

PD TR PP<br />

TORQUE CHECKER MODEL DLT1673A<br />

CAUTION<br />

• Don't use as impact load.<br />

• Don't apply a torque exceeding the<br />

permissible load(120% of max.torque).<br />

• Read all instructions.<br />

ANALOG<br />

DATA OUTPUT DC IN OUTPUT<br />

POWER<br />

ON/OFF<br />

CLEAR<br />

Measuring range: 0.15~10.00N . m<br />

RESET<br />

GOOD<br />

NG<br />

UP<br />

MEM/<br />

OUTPUT<br />

DO<strong>WN</strong><br />

AVE<br />

UNIT<br />

PRG/<br />

SET<br />

MODE<br />

PRODUCT:CONTROLLER<br />

MODEL:DLC70S-WGB<br />

PRI:100-240V`<br />

50/60Hz<br />

TV06090 >PETP<<br />

TORQUE CHECKER MODEL DLT1973A<br />

POWER<br />

OFF<br />

Measuring range: 4.00~15.00N . m<br />

CAUTION<br />

• Don't use as impact load.<br />

• Don't apply a torque exceeding the<br />

permissible load(120% of max.torque).<br />

• Read all instructions.<br />

NITTO KOHKI CO.,LTD.<br />

ISO 14001<br />

JQA-EM4057<br />

NITTO KOHKI CO.,LTD.<br />

CM021<br />

QC99J1026 051<br />

ISO9001<br />

SHIRAKAWA NITTO KOHKI CO.,LTD.<br />

LOW HIGH QUICK SLOW<br />

SPEED SOFT START<br />

GOOD<br />

NG<br />

UNIT<br />

2 -<br />

POWER<br />

ON/OFF<br />

RESET<br />

UP<br />

DO<strong>WN</strong><br />

PRG/<br />

SET

Selection Chart<br />

Page<br />

5-6<br />

Electric Screwdriver<br />

Controller<br />

Series Model Features Starting Method Model Voltage<br />

7400A<br />

DLV7410A/7410HA/7420A<br />

DLV7419A/7419HA/7429A<br />

Bit Grounding<br />

Low Shock<br />

ESD<br />

Bit Grounding<br />

Low Shock<br />

ESD<br />

Clean Room<br />

DLC1110<br />

100/115/220/<br />

230/240 V AC<br />

7<br />

5700<br />

DLV5720/5720H/5740<br />

DLV5740H/5750<br />

Bit Grounding<br />

Low Shock<br />

ESD<br />

DLC0350<br />

DLC0950<br />

100/115/230 V AC<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13-14<br />

5800<br />

7300<br />

7300<br />

BME/<br />

BKE<br />

7000<br />

8000<br />

7104<br />

8104<br />

8204<br />

7500<br />

8500<br />

7100<br />

DLV5820/5820H/5840<br />

DLV7313/7321/7323/7331/7333<br />

DLV7325/7335<br />

DLV7321-B E<br />

DLV7331-B E<br />

DLV7319/7329/7339/7349-BME<br />

DLV7020/7030/7031<br />

DLV8020/8030/8031<br />

DLV7124/7134/7144<br />

DLV8124/8134/8144<br />

DLV8154<br />

DLV8224/8234/8244<br />

DLV7530/7540<br />

DLV7550<br />

DLV8530/8540<br />

DLV8550<br />

DLV7120/7130/7140<br />

Bit Grounding<br />

ESD<br />

Low Voltage<br />

Clean Room<br />

ESD<br />

Clean Room<br />

Low Shock<br />

ESD<br />

Transformerless<br />

Transformerless<br />

Transformerless<br />

High Torque<br />

Transformerless<br />

High Speed<br />

Torque Reach Light<br />

Torque Reach Light<br />

High Torque<br />

Torque Reach Light<br />

Torque Reach Light<br />

High Torque<br />

Transformerless<br />

Lever Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

DLC0350<br />

DLC0250E<br />

DLC1213A<br />

DLC1215<br />

DLC2310<br />

DLC1215<br />

DLE3610<br />

DLC1213A-<br />

B<br />

DLC4511-GGB<br />

DLR1510-JE<br />

100 V AC<br />

100/115/230/240 V AC<br />

100/220 V AC<br />

24 V AC<br />

100/220 V AC<br />

100 V AC<br />

100/115/<br />

230/240 V AC<br />

100/115 V AC<br />

230 V AC<br />

15<br />

7200<br />

8100<br />

DLV7221<br />

DLV7231/7241<br />

DLV7251<br />

DLV8120/8130/8140<br />

DLV8150<br />

Transformerless<br />

High Speed<br />

Transformerless<br />

High Torque<br />

Transformerless<br />

Transformerless<br />

High Torque<br />

Lever Start<br />

115 V AC<br />

1<br />

17<br />

18<br />

19<br />

22<br />

23-24<br />

8200<br />

30<br />

45/70<br />

30/45/70<br />

IKE<br />

3300<br />

3100<br />

30/45/40<br />

Automation<br />

DLV8221<br />

DLV8231/8241<br />

DLV8251<br />

DLV30HL/30SL/30LL<br />

DLV30HP/30SP/30LP<br />

DLV45SL/45LL<br />

DLV45SP/45LP<br />

DLV70LL<br />

DLV70LP<br />

DLV30LL/30SL/30HL-IKE<br />

DLV30LP/30SP/30HP-IKE<br />

DLV45LL/45SL-IKE<br />

DLV45LP/45SP-IKE<br />

DLV70LL-IKE<br />

DLV70LP-IKE<br />

DLV3321/3331<br />

DLV3121/3131/3141/3151<br />

DLV30 A -DJN<br />

DLV45 A -DKN<br />

DLV70LA -DKN<br />

Transformerless<br />

High Speed<br />

Transformerless<br />

High Torque<br />

Transformerless<br />

Brushless Motor<br />

Brushless Motor<br />

For Automation<br />

Brushless Motor<br />

For Automation<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

External<br />

Input Signal<br />

External<br />

Input Signal<br />

DLR70S-WGB<br />

DLC70S-WGB<br />

DLC3310<br />

230 V AC<br />

100 - 240 V AC<br />

24 V AC<br />

100 V AC<br />

100 V AC

Selection Chart<br />

This chart is for reference only.<br />

model<br />

DLV-<br />

7410A/7419A<br />

7410HA/7419HA<br />

5720<br />

5720H<br />

5820<br />

5820H<br />

7313<br />

7321<br />

7323<br />

7325<br />

3321<br />

7020<br />

5750<br />

8020<br />

7420A/7429A<br />

5740<br />

5740H<br />

5840<br />

7319<br />

7329<br />

3121<br />

7120<br />

8120<br />

7124<br />

8124<br />

7031<br />

8031<br />

7030<br />

8030<br />

7333<br />

7335<br />

3331<br />

7220<br />

7221<br />

8220<br />

8221<br />

8224<br />

30<br />

7339<br />

3131<br />

7130<br />

7231<br />

8130<br />

8231<br />

7134<br />

8134<br />

8234<br />

7530<br />

8530<br />

7349<br />

7540<br />

8540<br />

7140<br />

7241<br />

8140<br />

8241<br />

7144<br />

8144<br />

8244<br />

3141<br />

7251<br />

8150<br />

8251<br />

8154<br />

7550<br />

8550<br />

3151<br />

45<br />

70<br />

Torque (Nm)<br />

0 0.02 0.03 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 0.55 0.7 0.75 0.95 1 1.1 1.2 1.5 1.7 2.0 2.7 3.0 3.8 4.5 7.0<br />

1.0 - 2.3<br />

Up to 2.0<br />

1.0 - 3.0<br />

1.0 - 3.0<br />

1.6 - 2.6<br />

1.0 - 3.0<br />

2.0 - 3.0<br />

2.0 - 3.0<br />

2.3 - 2.6<br />

2.6 - 3.0<br />

2.6 - 3.0<br />

2.0 - 3.0<br />

2.0 - 3.5<br />

2.0 - 3.5<br />

3.0 - 3.5<br />

2.6 - 3.5<br />

2.6 - 4.0<br />

3.0 - 3.5<br />

2.6 - 5.0<br />

Torque (Nm)<br />

Screw Size<br />

3.5 - 5.0<br />

3.5 - 5.0<br />

0 0.02 0.03 0.05 0.1 0.13 0.15 0.2<br />

Truque Torque range<br />

1.0 - 2.3<br />

4.5 - 6.0<br />

5.0 - 8.0<br />

Torque (Nm)<br />

0 0.02 0.03 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 0.55 0.7 0.75 0.95 1 1.1 1.2 1.5 1.7 2.0 2.7 3.0 3.8 4.5 7.0<br />

2

NITTO KOHKI's "Delvo" Electric Screwdrivers are high-quality tools for professional use, with<br />

special emphasis on precise torque <strong>co</strong>ntrol and long life. They always apply just the <strong>co</strong>rrect<br />

amount of torque with accurate and positive <strong>co</strong>ntrol at your fingertips. They are smooth and<br />

shockless in operation, too. NITTO KOHKI's customer-oriented service system through our sales<br />

agents ensures that you can use Delvo Electric Screwdrivers with a high degree of reliability.<br />

Shockless<br />

Sophisticated clutches and motor braking mechanism<br />

reduce the shock at the end of the screw tightening<br />

operation and causes less fatigue.<br />

Long Life<br />

Motor brushes stand over a million tightening cycles.<br />

They can be replaced easily.<br />

Brushless motors are adopted.<br />

They are e<strong>co</strong>-friendly, long life, and <strong>co</strong>ver wide torque<br />

range.<br />

High Accuracy<br />

High repeatable torque accuracy provides more<br />

<strong>co</strong>nsistent screw tightening torque.<br />

High Speed<br />

High-speed torque motors cut down screw tightening<br />

time and enhance productivity.<br />

Safety Standards<br />

Models with CE Marking (for the European Union) or<br />

CCC (for People’s Republic of China) are available.<br />

Quieter<br />

Compare Delvo with a <strong>co</strong>nventional pneumatic<br />

screwdriver, and you will hear the difference.<br />

Models for EU<br />

DLV7410A/7419A/7410HA/7419HA/7420A/7429A-BME<br />

DLV7313/7323/7333/7321/7331/7325/7335-CME/CKE<br />

DLV7321/7331-BME/BKE<br />

DLV7319/7329/7339/7349-BME<br />

DLC1213A-GG/GGB/GGU<br />

DLV7530/7540/7550-MKE/BKE<br />

DLV8530/8540/8550-MKE/BKE<br />

DLC4511-GGB/DLR1510-JE<br />

DLC1110-GG/HE<br />

DLV30/45/70 series<br />

Models for the People’s Republic of China<br />

DLV7321/7331-CMC<br />

DLC1213-GC<br />

DLV8124/8134/8144/8224/8234/8244/8154-MJC<br />

DLV8124/8134/8144/8224/8234/8244/8154-MKC<br />

DLV7124/7134/7144-MJC<br />

DLV7124/7134/7144-MKC<br />

DLV5820C/5820HC/5840C<br />

DLV5720C/5720HC/5740C/5740C/5740HC/5750C<br />

DLC0350GC/0950GC<br />

DLV30/45/70 series<br />

3

Green Procurement<br />

NITTO KOHKI has made every effort in environmental improvement schemes on a <strong>co</strong>mpany-wide basis<br />

through the implementation of ISO14001 to execute environmentally <strong>co</strong>nscious business activities. As a part<br />

of our ongoing <strong>co</strong>mmitment to improve the environment, we are also <strong>co</strong>mmitted to exclude or reduce<br />

restricted chemical substances in our products, as designated by the RoHS directives and Laws and<br />

Regulations of Chemical Substances in Japan. For further details, please see the following:<br />

Nitto Kohki group <strong>co</strong>mpanies’ Green Procurement Guidelines have been<br />

established by their environmental <strong>co</strong>mmittee which <strong>co</strong>nsists of members<br />

from all the Nitto Kohki group of <strong>co</strong>mpanies. Nitto Kohki group <strong>co</strong>mpanies<br />

give preferential treatment to suppliers that work to an environmental<br />

policy framework. Nitto Kohki group <strong>co</strong>mpanies periodically survey their<br />

suppliers to ensure their chemical management systems include the<br />

monitoring of environmental issues such as the RoHS directives, and<br />

Japanese laws and regulations of Chemical Substances to minimize<br />

packaging and waste. We are <strong>co</strong>ntinuing our goal to ensure that our<br />

made-to-order items are also <strong>co</strong>vered by our environmental policy.<br />

Green Procurement Policy<br />

Each of the Nitto Kohki group <strong>co</strong>mpanies is clarifying the <strong>co</strong>ntrol<br />

categories of the environmental management substances included in the<br />

parts and auxiliary materials <strong>co</strong>nstituting Nitto Kohki products and those<br />

of the environmental management substances used in the manufacturing<br />

processes. We will promote prohibition and reduction of use of the<br />

environmental management substances ac<strong>co</strong>rding to such <strong>co</strong>ntrol<br />

categories. Through these activities, we will <strong>co</strong>mply with various laws and<br />

regulations related to the environmental management substances and<br />

reduce the impact to the global environmental <strong>co</strong>nservation and to the<br />

e<strong>co</strong>logical system.<br />

S<strong>co</strong>pe of Application<br />

Our Green Procurement Guideline applies to all materials, parts,<br />

products, and auxiliary materials which Nitto Kohki Group <strong>co</strong>mpanies<br />

purchase for production or sales.<br />

Our Green procurement activities<br />

NITTO KOHKI group <strong>co</strong>mpanies <strong>co</strong>ntinually aim to <strong>co</strong>mply with RoHS<br />

directives, and Japanese laws and regulations of Chemical Substances.<br />

•Standard products have been RoHS <strong>co</strong>mpliant. Green procurement<br />

activities on made-to-order products are <strong>co</strong>ntinuing.<br />

•NITTO KOHKI group <strong>co</strong>mpanies are now working to the REACH<br />

Regulation.<br />

•NITTO KOHKI group <strong>co</strong>mpanies are building a database of the chemical<br />

management substances regulated by the RoHS directives, the REACH<br />

Regulation and Japanese laws and regulations of Chemical Substances.<br />

CONTENTS<br />

Selection Chart<br />

DLV7400A series<br />

DLV5700 series<br />

DLV5800 series<br />

DLV7300 series<br />

DLV7300-BME / BKE series<br />

DLV7000 / 8000 series<br />

DLV7104 / 8104 / 8204 series<br />

DLV7500 / 8500 series<br />

DLV7100 / 7200 / 8100 / 8200 (115 V) series<br />

Multiple Controllers<br />

DLV30 series<br />

DLV45 / 70 series<br />

DLV30 / 45 / 70-IKE series<br />

DLR70S-WGB<br />

DLC70S-WGB<br />

DLV3100 / 3300 series<br />

DLV30 / 45 / 70 automation series<br />

DLR5040A / 5340A-WE<br />

<strong>DLR5640</strong>-<strong>WN</strong><br />

Screwdrivers designed for <strong>DLR5640</strong>-<strong>WN</strong><br />

Torque Checkers<br />

Accessories<br />

Sleeves and Vacuum Pickups<br />

NK BIT / Optional Cord<br />

1<br />

5<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

25<br />

27<br />

28<br />

29<br />

31<br />

32<br />

33<br />

4

DLV7400A series<br />

Features<br />

The light and <strong>co</strong>mpact body reduces operator fatigue<br />

• Reduces shock applied to workpieces when fastening screws<br />

• Compliant with EN100015-1<br />

• Lightweight (Standard type 230 g, Clean room type 275 g)<br />

• The Clean Room Type <strong>co</strong>mplies with Class 3 Clean Room Rating<br />

• The <strong>co</strong>ntroller can adjust speed<br />

(Screw-fastening speed can be set to suit specific fastening <strong>co</strong>nditions)<br />

• The <strong>co</strong>ntroller provides a soft start function<br />

• The initial speed at screwdriver startup can therefore be slowed<br />

down, effectively preventing screw heads from being scratched<br />

For Miniature Screws (1.0 - 2.6 mm)<br />

• The built-in <strong>co</strong>reless motor achieves reduced inertia<br />

• Torque accuracy is within a top-ranked worldwide level<br />

(Based on measurements at our laboratory)<br />

• Compliant with CE<br />

• Use of the Screw Fastening Counter prevents human fastening<br />

errors and enhances accurate fastening <strong>co</strong>ntrol (No CE marking<br />

or CCC applied)<br />

• Screw Fastening Counter Model <strong>DLR5640</strong>-WE works in <strong>co</strong>njunction<br />

with any dedicated SPC-type electric screwdrivers<br />

DLV7400A series<br />

5<br />

Specifications<br />

Electric Screwdriver<br />

Bit Plug Shape Controller<br />

Model<br />

Features<br />

Input Voltage<br />

Control Function<br />

Plug Shape<br />

Mass<br />

Standard Accessories<br />

DLV7419A/7419HA/<br />

7429A-BME<br />

Standard Type<br />

Model<br />

Clean Room Type<br />

Starting Method<br />

Input Voltage<br />

Torque Adjustment<br />

Torque<br />

(Nm)<br />

Free Speed<br />

(min -1 )<br />

Power Consumption<br />

(W)<br />

Screw Size Machine Screw<br />

(mm) Tapping Screw<br />

Bit Type<br />

Mass<br />

Asia<br />

(mm)<br />

(g)<br />

DLV7410A-BME<br />

DLV7410A-BME<br />

DLV7419A-BME<br />

500 - 750<br />

1.0 - 2.3<br />

1.0 - 2.0<br />

DLV7410HA-BME<br />

DLV7419HA-BME<br />

Lever Start<br />

40 V DC<br />

Stepless<br />

0.02 - 0.2<br />

700 - 1,000<br />

Approx. 10<br />

No.<br />

DLV7410A DLV7410HA DLV7420A DLV7419A DLV7419HA DLV7429A<br />

No.0 × 1.8 × 44<br />

1<br />

1<br />

-<br />

1<br />

1<br />

-<br />

No.0 × 2.5 × 44<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

No.1 × 4 × 44<br />

-<br />

-<br />

1<br />

-<br />

-<br />

1<br />

Connection Cord DLW9070<br />

Spring for Low Torque<br />

Suspension Bail<br />

Sleeve for Vacuum DLS2124<br />

1<br />

1<br />

1<br />

-<br />

1<br />

1<br />

1<br />

-<br />

1<br />

-<br />

1<br />

-<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

-<br />

1<br />

1<br />

DLV7410HA-BME<br />

11<br />

Standard type 230 / Clean room type 275<br />

ø4<br />

DLV7420A-BME<br />

DLC1110-GG/HE<br />

DLV7420A-BME<br />

DLV7429A-BME<br />

0.15 - 0.4<br />

450 - 600<br />

1.6 - 2.6<br />

1.4 - 2.3<br />

DLC1110-EN DLC1110-FE DLC1110-GE DLC1110-GG DLC1110-HE DLC1213A-GGB* 1 DLC1213A-HEB* 1<br />

Standard Standard Standard With CE Mark With CE Mark With CE Mark Standard<br />

100 V AC, 50/60 Hz 115 V AC, 50/60 Hz 220 V AC, 50/60 Hz 230 V AC, 50/60 Hz 240 V AC, 50/60 Hz 230 V AC, 50/60 Hz 240 V AC, 50/60 Hz<br />

Soft Start, Speed Control, ESD Protected<br />

Asia<br />

Asia<br />

UK<br />

Europe<br />

UK<br />

Europe<br />

UK<br />

(g)<br />

900<br />

2,300<br />

Europe<br />

UK<br />

*1 : An optional <strong>co</strong>rd is required to <strong>co</strong>nnect with this model.<br />

Neither DLC1213A-GG nor DLC1213A-HE can be used with the DLV7400A series.<br />

3.5<br />

2<br />

Model DLC1213A-GGB or DLC1213A-HEB + Cord DLW9072

For Miniature Screws (1.0 - 2.6 mm)<br />

Torque Diagrams (for reference)<br />

External Dimensions<br />

DLV7410A/7410HA/7420A-BME<br />

Holder clamp<br />

Torque Adjustment<br />

Ring Cover<br />

Bit Torque (Nm)<br />

Value of shock applied to the workpiece as<br />

measured using acceleration pickup.<br />

Ø32<br />

Lock Nut<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

0.04<br />

0.02<br />

DLV7410A/7410HA-BME<br />

DLV7419A/7419HA-BME<br />

DLV7419A/7419HA/7429A-BME<br />

Coupling<br />

Lever Switch<br />

Forward/Reverse<br />

Changeover Switch<br />

196<br />

179.5<br />

165.5<br />

7<br />

7<br />

36<br />

0.50<br />

0.45<br />

0.40<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9<br />

Torque Scale<br />

Shock Waveform Comparison<br />

between the 7400A series and<br />

our <strong>co</strong>nventional models<br />

High Torque<br />

Spring<br />

(black)<br />

Low Torque<br />

Spring<br />

(silver)<br />

Shock value<br />

Bit Torque (Nm)<br />

DLV7420A-BME<br />

DLV7429A-BME<br />

Torque Scale<br />

Our <strong>co</strong>nventional models<br />

Peak shock value : 33 G<br />

DLV7400A series<br />

Peak shock value : 8 G<br />

Optional Accessories<br />

Sleeve<br />

* Please see page 32 for details.<br />

Vacuum Pickup<br />

DLP5300 (TD04342)<br />

Time<br />

Torque Adjustment Ring Cover<br />

DLW5700 (TD02875)<br />

This minimizes tampering or accidental turning<br />

of the torque adjustment ring once the torque is set.<br />

DLV7400A series<br />

13 Ø32<br />

Ø33.5<br />

Ø8<br />

Ø8<br />

36<br />

13.5<br />

DLC1110<br />

Connector for Screwdriver<br />

Speed Adjustment Knob<br />

91<br />

Soft Start Knob<br />

150<br />

Power Swich<br />

52<br />

48<br />

Power Lamp<br />

Unit: mm<br />

6

DLV5700 series<br />

DLV5700 series<br />

Features<br />

For quality improvement and productivity enhancement<br />

• Grounded bit installation mechanism<br />

• Electro-static discharge (ESD) <strong>co</strong>ntrol<br />

• Low-shock for tightening<br />

(30 % less of standard models)<br />

• Low swing bit mechanism<br />

• Ergonomic design<br />

• High-performance DC motor<br />

• New clutch mechanism<br />

Specifications<br />

Model<br />

Starting Method<br />

Input Voltage<br />

Torque Adjustment<br />

Torque<br />

(Nm)<br />

Free Speed (min -1 )<br />

Power Consumption (W)<br />

Screw Size Machine Screw<br />

(mm) Tapping Screw<br />

Electric Screwdriver<br />

Controller<br />

Bit Type<br />

Mass<br />

Model<br />

Input Voltage<br />

(mm)<br />

Standard Accessories<br />

No.<br />

No.0 × 1.8 × 44<br />

No.0 × 2.5 × 44<br />

No.1 × 4 × 44<br />

Connection Cable<br />

(1.5 m)DLW9081<br />

Suspension Bail<br />

Spring for Low Torque<br />

Bit<br />

Plug Shape<br />

Mass<br />

Torque Diagrams<br />

(for reference)<br />

(g)<br />

Bit Torque (Nm)<br />

External Dimensions<br />

DLC0350E<br />

100 V AC, 50/60 Hz<br />

Asia + Grounding wire<br />

DLV5740/5740H/5750<br />

0.60<br />

0.55<br />

0.50<br />

0.45<br />

0.40<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

DLV5740<br />

DLV5740H<br />

DLV5750<br />

1 2 3 4 5 6 7 8 9<br />

Torque Scale<br />

DLV5720/5720H/5740<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

0.04<br />

0.02<br />

1 2<br />

ø4<br />

230<br />

DLC0350F<br />

115 V AC, 50/60 Hz<br />

U.S.A.<br />

(g) 900<br />

11<br />

DLV5720/5720H<br />

Spring for<br />

High Torque (black)<br />

Spring for<br />

Low Torque (silver)<br />

3 4 5 6 7 8 9<br />

Torque Scale<br />

2<br />

DLC0350G<br />

230 V AC, 50/60 Hz<br />

UK<br />

For Miniature Screws (1.0 - 3.0 mm)<br />

300<br />

DLC0950E<br />

DLC0950G<br />

100 V AC, 50/60 Hz 230 V AC, 50/60 Hz<br />

Asia + Grounding wire<br />

DLV5720 DLV5720H DLV5740 DLV5740H<br />

DLV5750<br />

1<br />

1<br />

-<br />

1<br />

-<br />

1<br />

1<br />

1<br />

1<br />

1<br />

Bit Torque (Nm)<br />

DLC0350<br />

DLV5740H/5750<br />

1<br />

-<br />

Optional Accessories<br />

DLC0950<br />

DLV5720 DLV5720H DLV5740 DLV5740H DLV5750<br />

Lever Start<br />

40 V DC<br />

36 V DC<br />

Stepless<br />

0.02 - 0.2<br />

0.15 - 0.4<br />

0.1 - 0.55<br />

500 - 750<br />

700 - 1,000<br />

450 - 600<br />

1,200 - 1,800<br />

670 - 1,000<br />

Approx. 10<br />

Approx. 35<br />

1.0 - 2.3<br />

1.6 - 2.6<br />

1.0 - 3.0<br />

1.0 - 2.0<br />

1.4 - 2.3<br />

1.0 - 2.6<br />

3.5<br />

1,800<br />

Sleeve Vacuum Pickup<br />

DLP5300 (TD04342)<br />

* Please see page 32 for details.<br />

Torque Adjustment Ring Cover<br />

DLW5700 (TD02875)<br />

This minimizes tampering or accidental turning<br />

of the torque adjustment ring once the torque is set.<br />

DLV5720/5720H/5740<br />

Torque Adjustment Ring<br />

Holder clamp<br />

165.5<br />

Lever switch<br />

DLV5740H/5750<br />

Torque Adjustment Ring<br />

Holder clamp<br />

188.5<br />

Lever switch<br />

6.5<br />

91<br />

150<br />

99 172<br />

Power lamp<br />

External output terminal<br />

52<br />

48<br />

69<br />

65<br />

ø32<br />

36<br />

ø32<br />

38<br />

DLC0350<br />

Power lamp<br />

Lock Nut<br />

Coupling<br />

Forward/Reverse<br />

Changeover Switch<br />

External output terminal<br />

DLC0950<br />

Lock Nut<br />

Coupling<br />

Forward/Reverse<br />

Changeover Switch<br />

Soft-Start Adjustment Knob<br />

Speed Adjustment Knob<br />

Connector for screwdriver<br />

Power Switch<br />

Soft-Start Adjustment Knob<br />

Speed Adjustment Knob<br />

Connector for screwdriver<br />

Power Switch<br />

Unit: mm<br />

7

DLV5800 series<br />

Features<br />

In response to the needs of cell production system<br />

space-saving DELVO screwdrivers are released.<br />

Controller is designed for emphasis on space-saving size and lightness.<br />

• Clear disengagement of clutch (low-shock mechanism unavailable)<br />

• Grounded bit installation mechanism<br />

• Complied with EN100015-1<br />

• New lever is adopted<br />

• Low swing bit mechanism<br />

• Low voltage transless <strong>co</strong>ntroller<br />

For Miniature Screws (1.0 - 2.6 mm)<br />

DLC0250E<br />

DLV5820/5820H/5840<br />

Specifications<br />

Electric Screwdriver<br />

Model<br />

Starting Method<br />

Input Voltage<br />

Torque Adjustment<br />

Torque<br />

Free Speed<br />

Power Consumption<br />

Screw Size<br />

(mm)<br />

Bit Type<br />

(W)<br />

Machine Screw<br />

Tapping Screw<br />

Mass<br />

Cord Length<br />

Grounding Bit Feature<br />

(mm)<br />

(g)<br />

(m)<br />

Standard Accessories<br />

No.<br />

DLV5820<br />

No.0 × 1.8 × 44<br />

No.0 × 2.5 × 44<br />

No.1 × 4 × 44<br />

Suspension Bail<br />

Connection Cable (1.5 m)<br />

Spring for Low Torque (Silver)<br />

Bit<br />

(Nm)<br />

(min -1 )<br />

Optional Accessories<br />

DLV5820 DLV5820H DLV5840<br />

Lever Start<br />

40 V DC<br />

Stepless<br />

750<br />

DLV5820H<br />

0.02 - 0.20<br />

1.0 - 2.3<br />

1.0 - 2.0<br />

ø4<br />

Sleeve Vacuum Pickup<br />

DLP5300 (TD04342)<br />

* Please see page 32 for details.<br />

1<br />

1<br />

-<br />

1<br />

1<br />

1<br />

1,000<br />

Approx. 10<br />

3.5<br />

2<br />

11<br />

230<br />

1.5 (with <strong>co</strong>nnector)<br />

Equipped as standard<br />

DLV5840<br />

-<br />

1<br />

1<br />

1<br />

1<br />

-<br />

Torque Adjustment Ring Cover<br />

DLW5700 (TD02875)<br />

0.15 - 0.40<br />

600<br />

1.6 - 2.6<br />

1.4 - 2.3<br />

Controller<br />

Torque Diagrams (for reference)<br />

Bit Torque (Nm)<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

0.04<br />

0.02<br />

1 2<br />

DLV5820/5820H<br />

Spring for High Torque<br />

(black)<br />

Spring for<br />

Low Torque (silver)<br />

3 4 5 6 7<br />

Torque Scale<br />

Model<br />

Input Voltage<br />

Function<br />

Mass<br />

8<br />

Plug Shape<br />

9<br />

(g)<br />

0.50<br />

0.40<br />

0.30<br />

0.20<br />

0.15<br />

0.10<br />

1 2<br />

DLV5840<br />

3 4 5 6 7<br />

Torque Scale<br />

DLC0350<br />

DLC0250E<br />

100 V AC, 50/60 Hz<br />

Grounded Bit Installation Mechanism<br />

300<br />

U.S.A.<br />

Case Material<br />

Antistatic material<br />

* Electric screwdrivers DLV5800 series can be also used with<br />

DLC0350.<br />

Bit Torque (Nm)<br />

8<br />

9<br />

DLV5800 series<br />

This minimizes tampering or accidental turning of the torque adjustment ring once the torque is set.<br />

External Dimensions<br />

DLV5820/5820H/5840<br />

DLC0250E<br />

108<br />

165.5<br />

Connection cable<br />

1.5 m<br />

ø32<br />

DLV5840<br />

No.123456<br />

36<br />

40 68<br />

DLC0250E<br />

Unit: mm<br />

8

DLV7300 series<br />

DLV7300 series<br />

For Miniature Screws (1.0 - 3.5 mm)<br />

Features<br />

• The dedicated <strong>co</strong>ntroller realizes high-accuracy screw<br />

tightening<br />

• High repeatable torque accuracy<br />

• The <strong>co</strong>ntroller provides a soft start function. The initial<br />

speed at screwdriver startup can therefore be slowed<br />

down, effectively preventing screw heads from being<br />

scratched.<br />

• Variable speed adjustment enables to select optimum<br />

screw tightening speed.<br />

• DLV7325, DLV7335 meet Class 5* 1 Clean Room<br />

standards<br />

* 1: Based on Nitto's standard of measurement DLV7313/7323/7333 DLV7321/7331 DLV7325/7335 DLC1213A<br />

Specifications<br />

Electric Screwdriver<br />

(mm)<br />

Bit Type<br />

Controller<br />

Bit Shank:<br />

ø4 mm<br />

Model<br />

Bit Shank:<br />

Hex.6.35 mm<br />

Starting Method<br />

Input Voltage<br />

Torque Adjustment<br />

Torque<br />

(Nm)<br />

Free Speed (min -1 )<br />

Power Consumption (W)<br />

Screw Size Machine Screw<br />

(mm) Tapping Screw<br />

Mass<br />

(g)<br />

For CME<br />

DLC1213A-EN<br />

DLC1213A-FE* 3<br />

DLC1213A-GE<br />

DLC1213A-GG<br />

DLC1213A-GG U<br />

DLC1213A-HE<br />

DLC1215-EN* 4<br />

DLC1215-GE* 4<br />

DLC2310-CE* 4<br />

DLE3610-EN* 4<br />

DLV7313-CME<br />

Standard<br />

DLV7323-CME<br />

DLV7321-CME<br />

DLV7323-CKE<br />

DLV7321-CKE<br />

DLV7333-CME<br />

DLV7331-CME<br />

DLV7333-CKE<br />

DLV7331-CKE<br />

Lever Start<br />

36 V DC<br />

Stepless<br />

0.3 - 1.2<br />

500 - 700<br />

Approx. 35<br />

2.0 - 3.5<br />

2.0 - 3.0<br />

Model Features Input Voltage Control Function Plug Shape Mass(kg)<br />

Standard<br />

100 V AC, 50/60 Hz<br />

Standard<br />

115 V AC, 50/60 Hz<br />

Asia<br />

Standard<br />

220 V AC, 50/60 Hz Soft start,<br />

UK<br />

With CE Mark 230 V AC, 50/60 Hz Speed <strong>co</strong>ntrol<br />

Europe<br />

With CE Mark 230 V AC, 50/60 Hz<br />

UK<br />

2.3<br />

Standard<br />

240 V AC, 50/60 Hz<br />

Without Plug<br />

2 Screwdrivers for 1 Controller 100 V AC, 50/60 Hz<br />

2 Screwdrivers for 1 Controller 220 V AC, 50/60 Hz<br />

Asia<br />

Multiple Controller<br />

Power Supply for DLC2310-CE<br />

24 V AC, 50/60 Hz<br />

100 V AC, 50/60 Hz<br />

Asia<br />

0.36<br />

9<br />

* 3 : This model is made to order. *<br />

4 : See page 16 for details of the models other than DLC1213A series.<br />

Plug Shape<br />

Standard Accessories<br />

No.0 × 1.8 × 44<br />

No.0 × 2.5 × 44<br />

No.1 × 3 × 44<br />

No.1 × 4 × 44<br />

No.1 × 7 × 50<br />

No.2 × 4 × 44<br />

No.2 × 4.5 × 50<br />

No.2 × 7 × 50<br />

DLS2124<br />

DLS2127<br />

DLS2130<br />

DLS2134<br />

DLS2135<br />

Suspension Bail<br />

Bit<br />

Sleeve<br />

ø4<br />

Asia<br />

No.<br />

11<br />

3.5<br />

2<br />

DLV7313<br />

-CME<br />

1<br />

1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

0.03 - 0.15<br />

ø7<br />

Up to 2.0<br />

Up to 1.7<br />

DLV7321 / 23<br />

-CME<br />

-<br />

1<br />

-<br />

1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

For CKE<br />

23<br />

Europe<br />

700 - 1,000<br />

9<br />

DLV7331 / 33<br />

-CME<br />

-<br />

-<br />

1<br />

-<br />

-<br />

1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

6.35<br />

0.05 - 0.5<br />

1.0 - 3.0<br />

1.2 - 2.6<br />

350<br />

DLV7321 / 23 /<br />

31 / 33-CKE<br />

-<br />

-<br />

-<br />

-<br />

1<br />

-<br />

-<br />

1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1<br />

*<br />

2 : Vacuum pump for suction of screw is<br />

available as option. See page 27 for details<br />

of the vacuum pump.<br />

UK<br />

DLV7325<br />

-CME<br />

-<br />

1<br />

-<br />

1<br />

-<br />

-<br />

-<br />

-<br />

1<br />

1<br />

1<br />

-<br />

-<br />

DLV7335<br />

-CME<br />

-<br />

-<br />

1<br />

-<br />

-<br />

1<br />

-<br />

-<br />

-<br />

1<br />

1<br />

1<br />

-<br />

DLV7325 / 35<br />

-CKE<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

1<br />

102<br />

DLV7325-CME* 2<br />

DLV7325-CKE<br />

0.05 - 0.5<br />

700 - 1,000<br />

1.0 - 3.0<br />

1.2 - 2.6<br />

DLC1213A<br />

143<br />

Receptacle<br />

Clean Room Use<br />

400<br />

1.2<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

Pilot<br />

Lamp<br />

Power Switch<br />

DLV7335-CME* 2<br />

DLV7335-CKE<br />

Torque Diagram (for reference)<br />

Bit Torque (Nm)<br />

0.3 - 1.2<br />

500 - 700<br />

2.0 - 3.5<br />

2.0 - 3.0<br />

Optional Accessories<br />

Torque Adjustment<br />

Ring Cover for DLV7303<br />

DLW5500 (TD00333)<br />

This minimizes tampering or accidental turning<br />

of the torque adjustment ring once the torque is set.<br />

DLV7331<br />

/7333/7335<br />

0.2<br />

0.15<br />

DLV7313<br />

0.05<br />

0<br />

1 2 3 4 5 6 7<br />

Torque Scale<br />

145<br />

DLV<br />

7321/7323/7325<br />

Fuse Holder<br />

Cord 2 m<br />

External Dimensions<br />

Speed Adjustment Knob<br />

Soft-Start Adjustment Knob<br />

Plug<br />

DLV7313/7323/7333<br />

DLV7313 : 215 DLV7323 / 7333 : 225<br />

ø34<br />

ø30<br />

Forward / Reverse<br />

Changeover Switch<br />

36<br />

ø32<br />

DLV7321/7331<br />

215<br />

Lever Switch<br />

Nozzle for Connection<br />

Vacuum Pump<br />

DLV7325/7335/7319/7329/7339<br />

247<br />

ø32<br />

Lever Switch<br />

Nozzle for Connection<br />

Vacuum Pump<br />

40<br />

Cord<br />

1.5 m<br />

Cord<br />

1.5 m<br />

Torque<br />

Adjustment Ring<br />

Plug<br />

5<br />

Torque<br />

Adjustment Ring<br />

Forward / Reverse<br />

Changeover Switch<br />

ø40<br />

Sleeve<br />

Forward / Reverse<br />

Changeover Switch<br />

ø40<br />

Lever Switch<br />

Cord 1.5 m<br />

Unit: mm<br />

9

DLV7300-BME/BKE series<br />

Features<br />

DLV73 1-B E : 215<br />

Workpiece-<strong>co</strong>nscious electric screwdrivers<br />

• Statistic electricity buildup is prevented to protect workpieces<br />

from electrostatic discharge<br />

• Minimal impact in screw tightening protects workpieces from<br />

damaging and enables stable screw tightening<br />

• Meet Class 5* 1 or more Clean Room standards<br />

Specifications<br />

ESD<br />

ESD / Low Shock<br />

Model<br />

Bit Shank:ø4 mm DLV7321-BME* 2 DLV7331-BME* 2<br />

DLV7319-BME* 2 DLV7329-BME* 2 DLV7339-BME DLV7349-BME* 2<br />

Bit Shank:Hex. 6.35 mm DLV7321-BKE DLV7331-BKE<br />

* 3 : This model is made to order. Starting Method<br />

Lever Start<br />

Input Voltage<br />

36 V DC<br />

Torque Adjustment<br />

Stepless<br />

Torque<br />

(Nm) 0.05 - 0.5 0.3 - 1.2 0.2 - 0.4 0.25 - 0.55 0.45 - 0.95 0.55 - 1.2<br />

Free Speed (min -1 ) 700 - 1,000 500 - 700<br />

700 - 1,000<br />

500 - 700<br />

Power Consumption (W)<br />

Approx. 35<br />

Screw Size Machine Screw 1.0 - 3.0 2.0 - 3.5<br />

2.0 - 3.0<br />

3.0 - 3.5<br />

(mm) Tapping Screw 1.2 - 2.6 2.0 - 3.0<br />

2.0 - 2.6<br />

2.6 - 3.0<br />

3.5<br />

For BME<br />

11<br />

Bit Type<br />

(mm)<br />

For BKE<br />

9<br />

23<br />

6.35<br />

Mass<br />

(g)<br />

350 400<br />

*<br />

2 : These models are made to order.<br />

Model<br />

Input Voltage Plug Shape Control Mass(kg) Europe<br />

UK<br />

DLC1213A-ENB 100 V AC, 50/60 Hz USA<br />

Grounding,<br />

DLC1213A-FEB* 3 115 V AC, 50/60 Hz USA<br />

Soft Start,<br />

DLC1213A-GGB 230 V AC, 50/60 Hz Europe<br />

Speed Control<br />

DLC1213A-HEB 240 V AC, 50/60 Hz UK<br />

2.3<br />

Measurement Point Conventional Product DLV7300-B E<br />

Part<br />

Handle<br />

Static Electricity (V)<br />

350<br />

5<br />

Handle Lever Switch<br />

Surface Resistance ( ) more than 10 13<br />

10 4<br />

Power Cable<br />

Forward / Reverse Switch Static Electricity (V)<br />

25<br />

2<br />

•<br />

Static Electricity<br />

110<br />

5<br />

•<br />

(V)<br />

Power Cable<br />

Surface Resistance ( ) more than 10 13 10 10<br />

Lever Switch<br />

Static Electricity (V)<br />

350<br />

2<br />

Surface Resistance ( ) more than 10 13<br />

10 4<br />

Standard Accessories<br />

External Dimensions<br />

DLV7319/29 DLV7339/49 DLV7321 DLV7331 DLV7321/31<br />

* 1: Based on Nitto’s standard of measurement<br />

Electric Screwdriver<br />

Controller<br />

DLV73 1/DLV73 9<br />

No.<br />

-BME -BME -BME -BME -BKE<br />

No.0 × 2.5 × 44 1 - 1 - -<br />

No.1 × 3 × 44 - 1 - 1 -<br />

No.1 × 4 × 44 1 - 1 - -<br />

No.1 × 7 × 50 - - - - 1<br />

No.2 × 4 × 44 - 1 - 1 -<br />

No.2 × 7 × 50 - - - - 1<br />

DLS2124<br />

1 - - - -<br />

DLC1213A- B<br />

DLS2127<br />

1<br />

1 - - -<br />

143<br />

DLS2130<br />

1<br />

1 - - -<br />

DLS2134 - 1 - - -<br />

Pilot<br />

Lamp<br />

Suspension Bail<br />

1<br />

Bit<br />

Sleeve<br />

ø7<br />

ø4<br />

Plug Shape<br />

2<br />

102<br />

Receptacle<br />

Speed Control Volume<br />

ø32<br />

Screw Suction Sleeve<br />

For Miniature Screws (1.0 - 3.5 mm)<br />

Power Switch<br />

145<br />

Soft Start Adjustment Volume<br />

DLC1213A-<br />

Material<br />

Synthetic resin with carbon fiber<br />

Anti-static material<br />

* Measurement <strong>co</strong>nditions (Temperature:22 ℃ Humidity:66 %)<br />

(1) Static electricity •<br />

Earth the measurement equipment and measuring person.<br />

Grip the screwdriver five times using Ansel Edmont electronic <strong>co</strong>ntrol glove.<br />

Measure each part of the screwdriver<br />

using electronic measurement equipment manufactured by Shishido electrostatic Ltd.<br />

(2) Surface resistance •<br />

Measure using Sim<strong>co</strong> Japan surface resistivity measurement<br />

equipment.<br />

DLV73 9-BME : 247<br />

Bit Torque (Nm)<br />

Lever Switch<br />

1.2<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

B<br />

U.S.A.<br />

Forward/Reverse Changeover Switch<br />

Fuse Holder(fuse:2 A)<br />

Torque Diagram<br />

(for reference)<br />

0.3<br />

Power Cable 2 m<br />

DLV7331<br />

0<br />

1 2 3 4 5 6 7<br />

Torque Scale<br />

Screw Suction Pump<br />

Connection Nozzle<br />

Connect with Suction Pump<br />

DLP2530(Option)<br />

ø40<br />

DLV7349<br />

Power Cable<br />

1.5 m<br />

DLV<br />

7339<br />

DLV<br />

7329<br />

DLV<br />

7321<br />

DLV7319<br />

Unit: mm<br />

DLV7300-BME/BKE series<br />

10

DLV7000/8000 series<br />

Features<br />

100 / 115 V AC Direct Transformerless Precision Miniature Screw Type<br />

• A built-in <strong>co</strong>ntroller model saves space and facilitates layout change<br />

• High repetitive torque accuracy<br />

• Available with lever type (DLV7000 series) for each screw alignment<br />

and push to start type (DLV8000 series) for rapid screw tightening<br />

• The high-speed type (DLV7031/8031) available at 1200 min -1 for<br />

improving work efficiency (100 V AC only)<br />

For Miniature Screws (1.0 - 3.5 mm)<br />

DLV7000/8000 series<br />

Specifications<br />

Electric Screwdriver<br />

Standard Accessories<br />

No. DLV7020 / 8020 DLV7030 / 8030 / 7031 / 8031<br />

No.0 × 2.5 × 44<br />

1 -<br />

No.1 × 3 × 44 -<br />

1<br />

No.1 × 4 × 44<br />

1 -<br />

No.2 × 4 × 44 -<br />

1<br />

Suspension Bail<br />

1<br />

Bit<br />

Model<br />

100 V AC Input<br />

115 V AC Input<br />

Starting Method<br />

Torque Adjustment<br />

Torque<br />

Free Speed<br />

Power Consumption<br />

Screw Size<br />

(mm)<br />

(Nm)<br />

(min -1 )<br />

(W)<br />

Machine Screw<br />

Tapping Screw<br />

External Dimensions<br />

DLV7020/7030/7031<br />

Standard<br />

High Speed<br />

DLV7020-EMN<br />

DLV7020-FME* 1<br />

DLV7030-EMN<br />

DLV7030-FME* 1<br />

DLV8020-EMN<br />

DLV8020-FME* 1 DLV8030-EMN<br />

DLV8030-FME* 1<br />

DLV7031-EMN DLV8031-EMN<br />

Lever Start<br />

Push to Start<br />

Lever Start<br />

Push to Start<br />

Stepless<br />

0.05 - 0.55<br />

0.3 - 1.1<br />

0.1 - 0.55<br />

0.3 - 1.1<br />

900<br />

650<br />

900<br />

650<br />

1.0 - 3.0<br />

1.2 - 2.6<br />

2.0 - 3.5<br />

2.0 - 3.0<br />

1.0 - 3.0<br />

1.2 - 2.6<br />

2.0 - 3.5<br />

2.0 - 3.0<br />

DLV8020/8030/8031<br />

0.3 - 1.0<br />

1,200<br />

Approx. 30<br />

2.0 - 3.0<br />

2.0 - 3.0<br />

3.5<br />

Bit Type<br />

(mm)<br />

11<br />

Mass<br />

(g)<br />

400 410<br />

400 410<br />

Asia<br />

Plug Shape<br />

(EMN/FME type)<br />

* 1 : These models are made to order.<br />

Optional Accessories<br />

Torque Adjustment Ring Cover<br />

DLW5300 (TD00332)<br />

This minimizes tampering or accidental turning<br />

of the torque adjustment ring once the torque is set.<br />

Approx. 25<br />

DLV7000 series<br />

ø4<br />

Bit Torque (Nm)<br />

1.5<br />

1.0<br />

0.5<br />

DLV8000 series<br />

2<br />

Torque Diagram (for reference)<br />

DLV8020<br />

DLV7020<br />

0<br />

1 2 3 4 5 6 7<br />

Torque Scale<br />

DLV7030<br />

/8030<br />

DLV7031<br />

/8031<br />

Forward/Reverse Changeover Switch<br />

Cord 3 m<br />

Forward/Reverse Changeover Switch<br />

Cord 3 m<br />

32<br />

44<br />

32<br />

44<br />

Lever Switch<br />

240<br />

236<br />

Torque Adjustment Ring<br />

Torque Adjustment Ring<br />

Unit: mm<br />

11

9<br />

7<br />

5<br />

3<br />

1<br />

DLV7104/8104/8204 series<br />

Features<br />

The most popular models have been redesigned<br />

• Equipped with bit grounding mechanism<br />

• Long-life cam is utilized<br />

• The clear plastic torque adjustment ring <strong>co</strong>ver minimizes<br />

unintentional tampering of the preset torque<br />

• The changeover switch enables operators to change forward/reverse<br />

rotation with a single hand<br />

• The ergonomically designed grip can be held tightly to resist<br />

against tightening reaction force, resulting in reduced operator<br />

fatigue<br />

Specifications<br />

Electric Screwdriver<br />

Bit Type<br />

Plug Shape<br />

Model<br />

Starting Method<br />

Input Voltage<br />

Torque Adjustment<br />

Torque<br />

Free Speed<br />

External Dimensions<br />

DLV7124 / 7134 / 7144<br />

Bit<br />

48<br />

(Nm)<br />

(min -1 )<br />

(W)<br />

Power Consumption<br />

Screw Size Machine Screw<br />

(mm) Tapping Screw<br />

Mass<br />

(g)<br />

U.S.A.<br />

ø6<br />

For MJE/MJH<br />

For MKE/MKH<br />

For 8154-MKE/MKH<br />

For MJE/MJH<br />

14<br />

24 5<br />

For MJE/MKE<br />

Standard Accessories<br />

263<br />

Brush Holder<br />

134<br />

DLV7124-<br />

MJE<br />

DLV7124-<br />

MJH<br />

DLV7124-<br />

MKE<br />

DLV7124-<br />

MKH<br />

DLV7134-<br />

MJE<br />

DLV7134-<br />

MJH<br />

DLV7134-<br />

MKE<br />

DLV7134-<br />

MKH<br />

Lever Start<br />

Changeover<br />

Switch<br />

Cord 3 m Bit 51<br />

DLV7104 series<br />

DLV8124 / 8134 / 8144 / 8224 / 8234 / 8244<br />

264<br />

Brush Holder<br />

134<br />

For Machine Screws (2.6 - 6.0 mm)<br />

DLV8104/8204<br />

series<br />

Changeover<br />

Switch<br />

Cord 3 m<br />

DLV8154<br />

51<br />

ø39.5<br />

264<br />

134<br />

DLV8154<br />

Standard High Torque High Speed<br />

DLV7144-<br />

MJE<br />

DLV7144-<br />

MJH<br />

DLV7144-<br />

MKE<br />

DLV7144-<br />

MKH<br />

DLV8124-<br />

MJE<br />

DLV8124-<br />

MJH<br />

DLV8124-<br />

MKE<br />

DLV8124-<br />

MKH<br />

DLV8134-<br />

MJE<br />

DLV8134-<br />

MJH<br />

DLV8134-<br />

MKE<br />

DLV8134-<br />

MKH<br />

DLV8144-<br />

MJE<br />

DLV8144-<br />

MJH<br />

DLV8144-<br />

MKE<br />

DLV8144-<br />

MKH<br />

DLV8154-<br />

MJE<br />

DLV8154-<br />

MJH<br />

DLV8154-<br />

MKE<br />

DLV8154-<br />

MKH<br />

DLV8224-<br />

MJE<br />

DLV8224-<br />

MJH<br />

DLV8224-<br />

MKE<br />

DLV8224-<br />

MKH<br />

DLV8234-<br />

MJE<br />

DLV8234-<br />

MJH<br />

DLV8234-<br />

MKE<br />

DLV8234-<br />

MKH<br />

Push to Start<br />

230 V AC, 50/60 Hz<br />

Stepless<br />

0.25 - 0.75<br />

900<br />

0.5 - 1.7 1.2 - 3.0<br />

600<br />

0.25 - 0.75<br />

900<br />

0.5 - 1.7 1.2 - 3.0<br />

600<br />

2.0 - 4.5<br />

400<br />

0.35 - 0.7<br />

2,000<br />

35 45<br />

2.6 - 3.0<br />

2.3 - 3.0<br />

2.6 - 4.0<br />

2.3 - 3.5<br />

720<br />

3.5 - 5.0<br />

3.0 - 4.0<br />

2.6 - 3.0<br />

2.3 - 3.0<br />

2.6 - 4.0<br />

2.3 - 3.5<br />

710<br />

3.5 - 5.0<br />

3.0 - 4.0<br />

4.5 - 6.0<br />

4.5 - 5.0<br />

910<br />

2.6 - 3.0<br />

2.3 - 3.0<br />

UK<br />

• Bit No.1 × 6 × 70: 1 pc.<br />

• Bit No.2 × 6 × 70: 1 pc.<br />

• Bit No.1 × 7 × 75: 1 pc.<br />

• Bit No.2 × 7 × 75: 1 pc.<br />

• Bit No.2 × 7 × 75: 1 pc.<br />

• Bit No.3 × 7 × 50: 1 pc.<br />

ø7<br />

For MKE/MKH<br />

23<br />

For MJH/MKH<br />

9 6.35<br />

unit : mm<br />

• Spare Carbon Brush: 2 pcs.<br />

• Suspension Bail: 1 pc.<br />

• Spare Carbon Brush: 2 pcs.<br />

• Suspension Bail: 1 pc.<br />

• Spare Carbon Brush: 2 pcs.<br />

• Suspension Bail: 1 pc.<br />

Bit Torque (Nm)<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

1 2 3 4 5<br />

6 7 8 9<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.5 - 1.7<br />

1,800<br />

2.6 - 4.0<br />

2.3 - 3.5<br />

710<br />

Torque Diagram (for reference)<br />

DLV8154<br />

DLV7144/8144<br />

DLV7134/8134<br />

DLV7124/8124<br />

0<br />

1 2 3 4 5<br />

Torque Scale<br />

DLV8244<br />

DLV8234<br />

DLV8224<br />

ø50<br />

DLV8244-<br />

MJE<br />

DLV8244-<br />

MJH<br />

DLV8244-<br />

MKE<br />

DLV8244-<br />

MKH<br />

1.2 - 3.0<br />

1,100<br />

3.5 - 5.0<br />

3.0 - 4.0<br />

6 7 8 9<br />

DLV7104/8104/8204 series<br />

Torque Adjustment<br />

Ring<br />

Torque Adjustment<br />

Ring Cover<br />

ø39.5<br />

Torque Scale<br />

Lever<br />

ø50<br />

Torque Adjustment<br />

Ring<br />

Torque Adjustment<br />

Ring Cover<br />

ø39.5<br />

Torque Scale<br />

ø50<br />

140<br />

24<br />

40<br />

unit: mm<br />

12

DLV7500/8500 series<br />

Features<br />

Low vibration, low noise, and easy gripping in a <strong>co</strong>mpact design<br />

• The easily visible torque reach light goes on when the set torque is reached<br />

• The <strong>co</strong>mbination of an advanced clutch design and the auto-stop circuit assures torque accuracy<br />

• The long life motor with a yoke made of advanced materials further assures a long service life<br />

• Compliant with CE standard<br />

• Antistatic option is available<br />

For Machine Screws (2.6 - 6.0 mm)<br />

DLV7500/8500 series<br />

DLV7500-MKE DLV8500-BKE DLV7550-MKE DLV8550-MKE<br />

Specifications<br />

External Dimensions<br />

DLV7500 series<br />

Lever Switch<br />

Cord 3 m<br />

Standard Accessories<br />

No.1 × 7 × 75<br />

No.2 × 7 × 75<br />

No.3 × 7 × 50<br />

Spare Carbon Brush<br />

Power Cord<br />

Suspension Bail<br />

DLC4511-GGB<br />

DLR1510-JE<br />

High Torque<br />

Standard<br />

High Torque<br />

Standard<br />

Static Electricity (V) 350<br />

2<br />

Lever Switch<br />

Surface Resistance<br />

more than 10 13<br />

10 4<br />

* Measurement <strong>co</strong>nditions (Temperature:22 ℃ Humidity:66 %)<br />

( )<br />

(1) Static electricity<br />

Forward / Reverse Switch Static Electricity<br />

25<br />

2<br />

•<br />

Earth the measurement equipment and measuring person.<br />

(V)<br />

Grip the screwdriver five times using Ansel Edmont electronic <strong>co</strong>ntrol glove.<br />

Static Electricity<br />

110<br />

5<br />

• Turn on the switch of the screwdriver. •<br />

Measure each part of the screwdriver<br />

(V)<br />

using electronic measurement equipment manufactured by Shishido electrostatic Ltd.<br />

Power Cable<br />

Surface Resistance<br />

more than 10 13 10 10 (2) Surface resistance •<br />

Measure using Sim<strong>co</strong> Japan surface resistivity measurement<br />

( )<br />

equipment.<br />

Model<br />

Standard DLV7530-MKE DLV7540-MKE DLV7550-MKE DLV8530-MKE DLV8540-MKE DLV8550-MKE<br />

ESD<br />

DLV7530-BKE DLV7540-BKE DLV7550-BKE DLV8530-BKE DLV8540-BKE DLV8550-BKE<br />

Starting Method<br />

Lever Start<br />

Push to Start<br />

Input Voltage<br />

59 V DC<br />

Torque Adjustment<br />

Stepless<br />

Torque<br />

(Nm) 0.5 - 1.7<br />

1.2 - 2.7<br />

2.0 - 4.5<br />

0.5 - 1.7<br />

1.2 - 2.7<br />

2.0 - 4.5<br />

Free Speed (min -1 ) 1,100<br />

700<br />

500<br />

1,100<br />

700<br />

500<br />

Screw Size Machine Screw 2.6 - 4.0<br />

3.5 - 5.0<br />

4.5 - 6.0<br />

2.6 - 4.0<br />

3.5 - 5.0<br />

4.5 - 6.0<br />

(mm) Tapping Screw 2.3 - 3.5<br />

3.0 - 4.0<br />

4.0 - 5.0<br />

2.3 - 3.5<br />

3.0 - 4.0<br />

4.0 - 5.0<br />

Bit Type<br />

(mm)<br />

9<br />

23<br />

6.35<br />

Mass<br />

(g) 650<br />

650<br />

750<br />

650<br />

650<br />

750<br />

Measurement point Conventional product DLV7500-BKE<br />

Part<br />

Material<br />

Static Electricity (V) 350<br />

5<br />

Handle Lever Switch Synthetic resin with carbon fiber<br />

Handle<br />

Surface Resistance ( ) more than 10 13<br />

10 4<br />

Power Cable<br />

Anti-static material<br />

Electric Screwdriver<br />

ø7<br />

Bit<br />

No. DLV7530 / 7540 /<br />

8530 / 8540<br />

DLV7550 / 8550<br />

1 -<br />

1<br />

1<br />

-<br />

1<br />

2<br />

1<br />

1<br />

DLV8500 series<br />

Torque Reach Light<br />

257<br />

ø39.5<br />

55<br />

ø50<br />

Forward/Reverse Changeover Switch<br />

Receptacle M20<br />

Unit: mm<br />

13

SPEED<br />

HIGH<br />

SOFT START<br />

LOW<br />

SLOW<br />

QUICK<br />

DC POWER SUPPLY DLC4511-JES<br />

For use with Electric Screwdrivers<br />

Models DLV75 DLV85<br />

P R I : 230V~ 50 / 60Hz<br />

SEC: 37~ 49V ,2A<br />

MADE IN CHINA<br />

9-4,Nakaikegami<br />

2-chome,Ohta-ku,<br />

Tokyo 146-8555,<br />

Japan<br />

NUMBER SETTING/COUNTING<br />

MODE SELECTION<br />

ÇR<br />

ÇT<br />

(-)DO<strong>WN</strong><br />

TIME SETTING(sec)<br />

SET<br />

(+)UP<br />

LOCK<br />

RESET<br />

R<br />

OK<br />

R<br />

For Machine Screws (2.6 - 6.0 mm)<br />

Torque Diagram (for reference)<br />

5.0<br />

Bit Torque (Nm)<br />

4.0<br />

3.0<br />

2.0<br />

DLV7550/8550<br />

DLV7540/8540<br />

Specifications<br />

Model<br />

Controller<br />

Function<br />

Input Voltage<br />

Mass (kg)<br />

Plug Shape<br />

External Dimensions<br />

DLC4511-GGB<br />

Speed<br />

Adjustment<br />

Volume<br />

Soft Start<br />

Adjustment<br />

Volume<br />

Receptacle<br />

3<br />

5<br />

DLC4511-GGB<br />

Stepless speed adjustment 80 - 100 %<br />

Soft start: adjustable time setting of slow speed (max. 3 sec.)<br />

External output signals: start and torque up<br />

Electro-static discharge(ESD) <strong>co</strong>ntrol<br />

+<br />

-<br />

SER.No.<br />

T 2.5A L<br />

1<br />

2<br />

3<br />

77.5<br />

81.5<br />

1.0<br />

139 140<br />

Power Switch<br />

Output Terminal<br />

DLV7530/8530<br />

1 2 3 4 5<br />

Torque Scale<br />

DLR1510-JE<br />

Screw <strong>co</strong>unting: OK lamp and buzzer for notification<br />

Variable non-operation time<br />

Setting protection by key lock switch<br />

Setting by touch switch for easy operation<br />

External output signals: Start, Torque up, Count up & Cycle OK<br />

230 V AC, 50/60 Hz<br />

3.5 5.1<br />

Europe<br />

DLR1510-JE<br />

Number<br />

Setting/Counting,<br />

Time Setting Display<br />

Touch Swich<br />

Receptacle<br />

Terminal Block<br />

Fuse Holder<br />

126<br />

Key Lock Swich<br />

143<br />

1 2 3 4 5<br />

Power Swich<br />

177<br />

DLV7500/8500 series<br />

Unit: mm<br />

14

115V<br />

series For Machine Screws (2.6 - 6.0 mm)<br />

seriesDLV7100/7200/8100/8200<br />

15DLV7100/7200/8100/8200(115V)<br />

Bit<br />

Bit Type (mm) Electric Screwdriver<br />

ø6<br />

ø50<br />

ø50<br />

ø7<br />

ø39.5<br />

ø39.5<br />

Plug Shape<br />

ø50<br />

ø50<br />

Bit Torque (Nm)<br />

ø39.5<br />

ø39.5<br />

Features<br />

Long Time Selling, Reliable, and High Performance<br />

• Transformerless space saving model built in automatic stop circuit<br />

• Combination of unique clutch mechanism and automatic stop<br />

circuit maintains high repetitive torque accuracy<br />

• The lever start type DLV7100 / 7200 series is suited for<br />

temporarily tightening screws and tightening screws set at angles<br />

• The DLV8100 / 8200 series is push to start type for <strong>co</strong>ntinuous<br />

screw tightening<br />

Specifications<br />

Standard<br />

High Speed<br />

High Torque Standard<br />

High Torque High Speed<br />

High Torque<br />

Bit Shank: DLV7120- DLV7130- DLV7140- DLV7221- DLV7231- DLV7241-<br />

DLV8120- DLV8130- DLV8140- DLV8150- DLV8221- DLV8231- DLV8241-<br />

Model<br />

Hex. 5 mm FJE FJE FJE FJE FJE FJE<br />

FJE FJE FJE FJE FJE FJE FJE<br />

Bit Shank: DLV7120- DLV7130- DLV7140- DLV7221- DLV7231- DLV7241- DLV7251- DLV8120- DLV8130- DLV8140- DLV8150- DLV8221- DLV8231- DLV8241- DLV8251-<br />

Hex. 6.35 mm FKE FKE FKE FKE FKE FKE FKE FKE FKE FKE FKE FKE FKE FKE FKE<br />

Starting Method<br />

Lever Start<br />

Push to Start<br />

Input Voltage<br />

Torque Adjustment<br />

115 V AC, 50/60 Hz<br />

Stepless<br />

Torque<br />

(Nm) 0.25-0.75 0.5-1.7 1.2-3.0 0.35-0.7 0.5-1.7 1.2-3.0 2.0-4.5 0.25-0.75 0.5-1.7 1.2-3.0 2.0-4.5 0.35-0.7 0.5-1.7 1.2-3.0 2.0-4.5<br />

Free Speed (min -1 ) 900 900 600 1,800 1,800 1,100 700 900 900 600 400 1,800 1,800 1,100 700<br />

Power Consumption (W) Approx. 35<br />

Approx. 45<br />

Approx. 35<br />

Approx. 45<br />

Screw Size<br />

(mm)<br />

Machine Screw<br />

Tapping Screw<br />

2.6-3.0<br />

2.6-3.0<br />

2.6-4.0<br />

2.3-3.5<br />

3.5-5.0<br />

3.5-4.0<br />

2.6-3.0<br />

2.6-3.0<br />

2.6-4.0<br />

2.3-3.5<br />

3.5-5.0<br />

3.0-4.0<br />

4.5-6.0<br />

4.5-5.0<br />

2.6-3.0<br />

2.6-3.0<br />

2.6-4.0<br />

2.3-3.5<br />

3.5-5.0<br />

3.5-4.0<br />

4.5-6.0<br />

4.5-5.0<br />

2.6-3.0<br />

2.6-3.0<br />

2.6-4.0<br />

2.3-3.5<br />

3.5-5.0<br />

3.0-4.0<br />

4.5-6.0<br />

4.0-5.0<br />

Mass<br />

(g)<br />

700<br />

700<br />

890<br />

690<br />

890<br />

690<br />

890<br />

For FJE<br />

For FKE<br />

Asia<br />

* All models of FJE / FKE series are made to order.<br />

Standard Accessories<br />

No.<br />

No.1 × 6 × 70<br />

No.1 × 7 × 75<br />

No.2 × 6 × 70<br />

No.2 × 7 × 75<br />

No.3 × 7 × 50<br />

Spare Carbon Brush<br />

Suspension Bail<br />

LJT<br />

1<br />

-<br />

1<br />

-<br />

-<br />

External Dimensions<br />

DLV7120/7130/7140/7221/7231/7241<br />

DLV8150/8251<br />

DLV7100/<br />

7200 series<br />

14<br />

24 5<br />

Suspension Bail<br />

Cord 3 m<br />

Cord 3 m<br />

79<br />

Pistol Grip<br />

LKT except DLV7251 / 8150 / 8251-LKT<br />

-<br />

1<br />

-<br />

1<br />

-<br />

2<br />

1<br />

24<br />

Cross Section<br />

Lever Switch<br />

265<br />

134<br />

40<br />

Brush Holder<br />

Torque Adjustment Ring<br />

Forward/Reverse Changeover Switch<br />

Brush Holder<br />

40<br />

265<br />

134<br />

140<br />

DLV8100/<br />

8200 series DLV7251 DLV8150/8251<br />

52<br />

48<br />

9<br />

Torque Adjustment Ring<br />

6.35<br />

• The high speed type DLV7200 / 8200 series enhances working<br />

efficiency<br />

• The high torque type DLV7251 / 8150 / 8251 series is equipped<br />

with a grip, which is useful for tightening big screws like 6 mm<br />

machine screws<br />

DLV7251 / 8150 / 8251-LKT<br />

-<br />

-<br />

-<br />

1<br />

1<br />

DLV8120/8130/8140/8221/8231/8241<br />

DLV7251<br />

Cord 3 m<br />

Cord 3 m<br />

79<br />

Torque Diagram (for reference)<br />

4.5<br />

3.0<br />

1.5<br />

Brush Holder<br />

Forward/Reverse<br />

Changeover Switch<br />

Forward/Reverse<br />

Changeover Switch<br />

Brush Holder<br />

Pistol Grip<br />

24<br />

Cross Section<br />

40<br />

DLV7251/<br />

8150/8251<br />

DLV7140/7241/<br />

8140/8241<br />

DLV7221/8221<br />

0<br />

1 2 3 4 5 6 7 8 9<br />

266<br />

134<br />

266<br />

140<br />

Torque Scale<br />

52<br />

Torque Adjustment Ring<br />

Torque Adjustment Ring<br />

DLV<br />

7130/7231/<br />

8130/8231<br />

DLV7120/<br />

8120<br />

Unit: mm

Multiple Controllers<br />

AC Power Supply DLE3610/Controller DLC2310<br />

Designed specially for use with up to a maximum of 24 “delvo”<br />

7300 Series Electric Screwdrivers <strong>co</strong>nnected with attached 15 m<br />

extension <strong>co</strong>rds drawn out on both sides (each side handles up to<br />

12 screwdrivers).<br />

DLE3610 AC Power Supply and DLC2310 Controller can boost<br />

productivity and reduce <strong>co</strong>sts of setting up production lines. The<br />

dedicated <strong>co</strong>ntroller DLC2310 is employed for each screwdriver.<br />

If more than four units of DLV7300 series are used, installation <strong>co</strong>st<br />

of Model DLE3610 and DLC2310 will be e<strong>co</strong>nomically beneficial.<br />

DLE3610<br />

For DLV7300 series<br />

DLC2310<br />

Model<br />

Input Voltage<br />

Se<strong>co</strong>ndary Output<br />

Capacity<br />

External Dimensions<br />

Plug Shape<br />

Mass<br />

Accessories<br />

Model<br />

Input Voltage<br />

Se<strong>co</strong>ndary Output<br />

External Dimensions<br />

Mass<br />

Accessories<br />

DLE3610A-EN<br />

(Primary Side) 100 V AC, 50/60 Hz<br />

24 V AC, 50/60 Hz, 15 A<br />

360 VA<br />

(mm) W190 × H134 × D188<br />

U.S.A.<br />

9<br />

Two 15 m extension <strong>co</strong>rds<br />

DLC2310-CE / DLC2310-CN<br />

24 V AC, 50/60 Hz<br />

36 V DC, 2 A<br />

W74 × H42 × D118<br />

0.36<br />

Two 0.5 m <strong>co</strong>nnection <strong>co</strong>rds<br />

and two s<strong>co</strong>tch locks<br />

(Connecting terminal)<br />

DLC1215 can <strong>co</strong>ntrol two screwdrivers by one <strong>co</strong>ntroller.<br />

Model<br />

Input Voltage<br />

Output Voltage<br />

Plug Shape<br />

External Dimensions<br />

Mass<br />

(kg)<br />

(Primary Side)<br />

(mm)<br />

(kg)<br />

Multiple Controller DLC1215<br />

(mm)<br />

(kg)<br />

DLC1215-EN<br />

DLC1215-GE<br />

100 V AC, 50/60 Hz 220 V AC, 50/60 Hz<br />

36 V DC × 2<br />

Asia<br />

W143 × D145 × H102<br />

2.4<br />

NOTE: Each "delvo" screwdriver should be operated<br />

independently when tightening screws even though<br />

this <strong>co</strong>ntroller will support up to two "delvo" screwdrivers.<br />

Operating two units simultaneously may cause<br />

malfunction of the <strong>co</strong>ntroller.<br />

DLC2310<br />

Controller<br />

DLE3610 AC Power Supply<br />

AC Input<br />

15 m<br />

15 m<br />

24 V AC<br />

Connection<br />

Cord<br />

Connection<br />

Terminal<br />

Max. 12<br />

Max. 12<br />

Max. 24 Screwdrivers<br />

DLC1215<br />

S<strong>co</strong>tch Lock<br />

(Connecting terminal)<br />

Extension Cord<br />

DLV7313<br />

DLV7321 / 7331<br />

DLV7323 / 7333<br />

DLV7325 / 7335<br />

Screwdrivers<br />

Multiple Controllers<br />

16

9<br />

5<br />

1<br />

7<br />

3<br />

9<br />

5<br />

1<br />

7<br />

3<br />

DLV30 series<br />

Features<br />

E<strong>co</strong>-friendly electric screwdrivers with built-in brushless motors in a transformerless profile<br />

• The series lineup is <strong>co</strong>nsisted of high speed(2,000 min -1 ), standard speed<br />

(1,200 min -1 ), and low speed(650 min -1 ) types with respective torque<br />

range of 0.4 - 3.0 Nm<br />

• Designed to minimize loss of screw fastening torque that may occur after<br />

long-term use, and therefore ensures stable performance<br />

• Both the Lever Start and Push to Start types of models are available. The<br />

Push to Start type is suitable for <strong>co</strong>ntinuous screw tightening. The Lever<br />

Start type is suited for temporary tightening screws and tightening screws<br />

set at angles<br />

• Equipped with a clear plastic torque adjustment ring <strong>co</strong>ver<br />

• Design <strong>co</strong>nforms to the RoHS Directive and thus appeals to<br />

the environmentally <strong>co</strong>nscious user<br />

• Models with CE marking (for the European Union) or CCC<br />

(for People’s Republic of China) are available<br />

• Aluminum <strong>co</strong>uplings with <strong>co</strong>lored rubber rings, namely, red,<br />

blue, and yellow ones, help operators choose the <strong>co</strong>rrect<br />

speed type easily<br />

Yellow for<br />

low speed types:<br />

DLV30LL/30LP<br />

Red for<br />

high speed types:<br />

DLV30HL/30HP<br />

For Machine Screws (2.6 - 5.0 mm)<br />

DLV30SL<br />

DLV30SP<br />

Blue for<br />

standard types<br />

DLV30 series<br />

Specifications<br />

Electric Screwdriver<br />

(mm)<br />

Bit Type<br />

Bit<br />

Model<br />

Starting Method<br />

Free Speed<br />

Input Voltage<br />

Torque Adjustment<br />

(Nm)<br />

Power Consumption<br />

Screw Size<br />

Mass<br />

ø7<br />

High Speed Standard Low Speed High Speed Standard<br />

European Plug<br />

DLV30HL-MKG DLV30SL-MKG DLV30LL-MKG DLV30HP-MKG DLV30SP-MKG<br />

DLV30HL-MJG DLV30SL-MJG DLV30LL-MJG DLV30HP-MJG DLV30SP-MJG<br />

USA Plug<br />

DLV30HL-MKE DLV30SL-MKE DLV30LL-MKE DLV30HP-MKE DLV30SP-MKE<br />

DLV30HL-MJE DLV30SL-MJE DLV30LL-MJE DLV30HP-MJE DLV30SP-MJE<br />

Lever Start<br />

Push to start<br />

(min -1 ) 2,000<br />

1,200<br />

650<br />

2,000<br />

1,200<br />

230 V AC, 50/60 Hz<br />

Low Torque Spring (Standard Accessory)<br />

0.4 - 1.6<br />

High Torque Spring (Built-in)<br />

1.2 - 3.0<br />

(W)<br />

Approx. 45<br />

Machine Screw<br />

2.6 - 5.0<br />

(mm)<br />

Tapping Screw<br />

2.5 - 4.0<br />

(g)<br />

700<br />

For MKG/MKE For MJG/MJE For MKG/MJG For MKE/MJE<br />

Europe<br />

U.S.A.<br />

14<br />

23<br />

9 6.35<br />

Standard Accessories<br />

No. MJG / MJE MKG / MKE<br />

No.2 × 6 × 70<br />