Microtherm® Quilted Panel - Hydrophobic Clean ... - Bagges AS

Microtherm® Quilted Panel - Hydrophobic Clean ... - Bagges AS

Microtherm® Quilted Panel - Hydrophobic Clean ... - Bagges AS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Microtherm ® <strong>Quilted</strong> <strong>Panel</strong> - <strong>Hydrophobic</strong><br />

<strong>Clean</strong>, flexible high temperature insulation<br />

Microtherm ® <strong>Hydrophobic</strong> <strong>Quilted</strong><br />

<strong>Panel</strong> is a truly fl exible high temperature<br />

microporous insulation panel. It has<br />

the additional advantage of being water<br />

repellent at low to moderate temperatures.<br />

With an outer covering of woven<br />

glass cloth the panels offer clean high<br />

performance insulation protection for<br />

complex shapes.<br />

Properties<br />

• Opacifi ed blend of fi lament reinforced silica<br />

• Fully fl exible high temperature microporous<br />

insulation specially treated to repel water<br />

during installation.<br />

• Stable thermal performance for<br />

continuous exposure to temperatures<br />

up to 1000°C (1832°F)<br />

• Resistant to vibration and<br />

system shock loading in use<br />

• Non combustible<br />

• <strong>Clean</strong> to use<br />

• Simple to cut and shape<br />

• Environmentally safe. Contains<br />

no respirable fi bres.<br />

.<br />

Typical applications<br />

• Used for any application where<br />

water or condensation may be<br />

present.<br />

Microtherm is a world leader for thermal insulation solutions • info@microthermgroup.com • www.microthermgroup.com

Microtherm ® <strong>Hydrophobic</strong> <strong>Quilted</strong> <strong>Panel</strong><br />

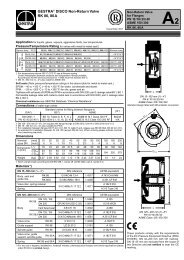

TYPICAL PRODUCT CHARACTERISTICS<br />

Thermal Conductivity<br />

THERMAL CONDUCTIVITY (W/m.K)<br />

0.10<br />

0.09<br />

0.08<br />

0.07<br />

0.06<br />

0.05<br />

0.04<br />

0.03<br />

0.02<br />

0.01<br />

MEAN TEMPERATURE (°F)<br />

200 400 600 800<br />

0<br />

0<br />

0 100 200 300 400 500<br />

MEAN TEMPERATURE (°C)<br />

Specific Heat Capacity<br />

SPECIFIC HEAT CAPACITY (J/kg.K)<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

TEMPERATURE (°F)<br />

MICROTHERM SUPER G HYDROPHOBIC QUILT<br />

240 kg/m 3 density<br />

200 400 600 800<br />

MICROTHERM SUPER G HYDROPHOBIC QUILT<br />

0<br />

0<br />

0 100 200 300 400 500<br />

TEMPERATURE (°C)<br />

0.6<br />

0.4<br />

0.2<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

THERMAL CONDUCTIVITY (Btu.in/ft 2.hr.°F)<br />

SPECIFIC HEAT CAPACITY (Btu/lb.°F)<br />

Size Availability<br />

<strong>Panel</strong> thickness 3 mm ( 1 / 8”) – panel size 500 mm x 500 mm (19 5 / 8” x 19 5 / 8”).<br />

<strong>Panel</strong> thickness 4 mm to 15 mm ( 1 / 8” to 5 / 8”) – panel size 1000 mm x 500 mm (39 3 / 8” x 19 5 / 8”).<br />

Greater thickness can be made but it is often better to use the alternative of two thinner layers.<br />

Performance<br />

Maximum temperature limits Microtherm ® Super G <strong>Hydrophobic</strong> - 1000 °C (1832 °F) for long term exposure.<br />

Thermal conductivity (TC) - Microtherm ® Super G <strong>Hydrophobic</strong> @ 240 kg/m 3 .<br />

0.0258 W/m.K at 100 °C mean<br />

0.0283 W/m.K at 200 °C mean<br />

0.0313 W/m.K at 300 °C mean<br />

0.0347 W/m.K at 400 °C mean<br />

Note: TC will vary as a function of density and sewn cell pitch size. Data shown are for a cell pitch of 25 mm (1”).<br />

Specifi c heat capacity<br />

680 J/kg.K at 0 °C<br />

920 J/kg.K at 200 °C<br />

1000 J/kg.K at 400 °C<br />

Manufacturing Tolerances<br />

Tolerance on panel thickness for densities ≥ 200 kg/m 3 .<br />

± 0.5 mm (0.02”) for panel thickness ≤ 10 mm (≤ 3 / 8”)<br />

± 0.8 mm (0.03”) for panel thickness > 10mm (> 3 / 8”)<br />

Tolerance on panel thickness for densities < 200 kg/m 3 .<br />

± 0.75 mm (0.03”) for panel thickness < 6.25 mm (≤ ¼”)<br />

± 1.0 mm (0.04”) for panel thickness 6.25 mm – 10 mm (¼”- 3 / 8”)<br />

± 1.25 mm (0.05”) for panel thickness > 10 mm (>- 3 / 8”)<br />

Density<br />

<strong>Panel</strong> core density - 170 - 300 kg/m 3 dependent on panel area and thickness.<br />

Standard finish styles available<br />

Woven E glass covering. Stitched on 25 mm (1”) square lattice.<br />

Typical Values<br />

Performance values quoted here are for general guidance.<br />

For more precise information and assistance with design please contact our materials specialists.<br />

The information contained in this datasheet/brochure is intended to assist in designing with Microtherm products. It is not intended to and does not create any warranties,<br />

express or implied, including any warranty of merchantability or fi tness for a particular purpose or that the results shown on this datasheet will be achieved by a user for a<br />

particular purpose. The user is responsible for determining the suitability of Microtherm products for each application. No known health hazards in normal use.<br />

www.microthermgroup.com<br />

Issue ref.121108/03<br />

Microtherm NV • België, Industriepark Noord 1, BE-9100 Sint-Niklaas, T +32 (0)3 760 19 80, F +32 (0)3 760 19 99, info@microthermgroup.com, BTW-BE-0407.566.878 − RPR Sint-Niklaas<br />

Microtherm Inc • U.S.A., 3269 Regal Drive, Alcoa, Tennessee 37701, T +1 865 681 0155, F +1 865 681 0016, sales@microtherm.us<br />

Nippon Microtherm Co. Ltd. • Japan, Korakuen Shinjuku Bldg, 4-15-7, Nishi-Shinjuku, Shinjuku-ku, Tokyo 160-0023, T +81 3 3377 2821, F +81 3 3378 2821, sales@microtherm.co.jp<br />

Microtherm is a registered trademark of Microtherm (GB) Ltd. • BTW BE 0407.566.878 − RPR Sint-Niklaas<br />

46901