Operational Manual - DCU

Operational Manual - DCU

Operational Manual - DCU

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

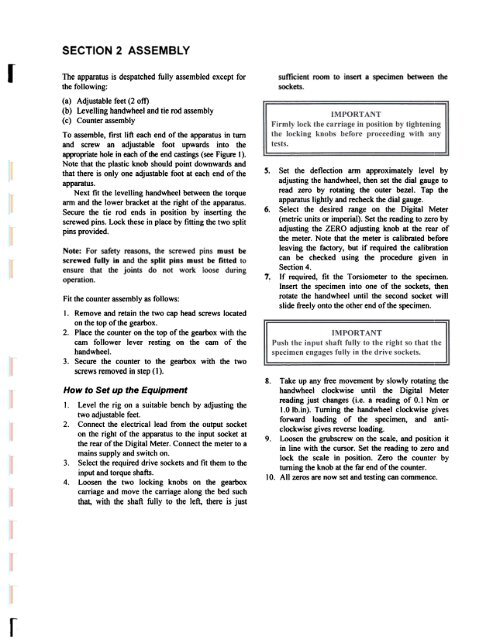

SECTION 2 ASSEMBLY<br />

The apparatus is despatched fully assembled except for<br />

the following:<br />

(a) Adjustable feet (2 oft)<br />

(b) Levelling handwheel and tie rod assembly<br />

(c) Counter assembly<br />

sufficient room to insert a specimen between the<br />

sockets.<br />

To assemble, first lift each end of the apparatus in turn<br />

and screw an adjustable foot upwards into the<br />

appropriate hole in each of the end castings (see Figure I).<br />

Note that the plastic knob should point downwards and<br />

that there is only one adjustable foot at each end of the<br />

apparatus.<br />

Next fit the levelling handwheel between the torque<br />

arm and the lower bracket at the right of the apparatus.<br />

Secure the tie rod ends in position by inserting the<br />

screwed pins. Lock these in place by fitting the two split<br />

pins provided.<br />

Note: For safety reasons, the screwed pins must be<br />

screwed fully in and the split pins must be fitted to<br />

ensure that the joints do not work loose during<br />

operation.<br />

7:<br />

Fit the counter assembly as follows:<br />

1. Remove and retain the two cap head screws located<br />

on the top of the gearbox.<br />

2. Place the counter on the top of the gearbox with the<br />

cam follower lever resting on the carn of the<br />

handwheel.<br />

3. Secure the counter to the gearbox with the two<br />

screws removed in step (1).<br />

How to Set up the Equipment<br />

I. Level the rig on a suitable bench by adjusting the<br />

two adjustable feet.<br />

2. Connect the electrical lead from the output socket<br />

on the right of the apparatus to the input socket at<br />

the rear of the Digital Meter. Connect the meter to a<br />

mains supply and switch on.<br />

3. Select the required drive sockets and fit them to the<br />

input and torque shafts.<br />

4. Loosen the two locking knobs on the gearbox<br />

carriage and move the carriage along the bed such<br />

that, with the shaft fully to the left, there is just<br />

s.<br />

6.<br />

Set the deflection ann approximately level by<br />

adjusting the handwheel, then set the dial gau~;e to<br />

read zero by rotating the outer bezel. Tap the<br />

apparatus lightly and recheck the dial gauge.<br />

Select the desired range on the Digital Nleter<br />

(metric units or imperial). Set the reading to zero by<br />

adjusting the ZERO adjusting knob at the rear of<br />

the meter. Note that the meter is calibrated ~:fore<br />

leaving the factory, but if required the calibration<br />

can be checked using the procedure given in<br />

Section 4.<br />

If required, fit the Torsiometer to the specunen.<br />

Insert the specimen into one of the sockets, then<br />

rotate the handwheel until the second socket will<br />

slide freely onto the other end of the specimen.<br />

8. Take up any free movement by slowly rotatin!~ the<br />

handwheel clockwise until the Digital Meter<br />

reading just changes (i.e. a reading of 0.1 Nm or<br />

1.0 lb. in). Turning the handwheel clockwise ~~ives<br />

forward loading of the specimen, and anticlockwise<br />

gives reverse loading.<br />

9. Loosen the grubscrew on the scale, and positi,:>n it<br />

in line with the cursor. Set the reading to zero and<br />

lock the scale in position. Zero the counter by<br />

turning the knob at the far end of the counter.<br />

10. All zeros are now set and testing can commenc