Agusta A119 Koala - Graupner

Agusta A119 Koala - Graupner

Agusta A119 Koala - Graupner

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Order No. 4461<br />

<strong>Agusta</strong> <strong>A119</strong><br />

<strong>Koala</strong><br />

Scale fuselage kit for<br />

miniature electric helicopter Micro Star 400<br />

Warning!<br />

The contents of this kit can be assembled to produce a working helicopter, but the model<br />

is by no means a harmless plaything. If assembled incorrectly or handled incompetently<br />

or carelessly it can cause serious injury to persons and damage to property.<br />

You alone are responsible for completing the model correctly and operating it safely. The<br />

kit also includes two further information sheets - SHW 3 and SHW 7 - which include<br />

safety notes and warnings. Please be sure to read them and keep to our recommendations.<br />

They are an essential part of these instructions.<br />

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY<br />

Modifications, errors and printing errors reserved. ID# 53114 10/04

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Foreword<br />

The AGUSTA <strong>A119</strong> "<strong>Koala</strong>" is a single-turbine helicopter designed for a wide range of tasks. It<br />

is largely based on the familiar twin-engined A109, but is fitted with only one turbine and a<br />

robust skid landing gear instead of the fixed or retractable wheeled undercarriage. The<br />

capacious cabin provides space for up to seven passengers, 1 tonne of freight or - in the rescue<br />

helicopter version - two stretchers. The Pratt & Whitney PT6B-37A turbine generates a take-off<br />

power of 1002 BHP and a continuous output of 872 BHP, giving the "<strong>Koala</strong>" an exceptional<br />

performance.<br />

This fuselage kit is designed to convert the MICRO STAR 400 mini electric helicopter into a<br />

semi-scale model of the AGUSTA <strong>A119</strong> "<strong>Koala</strong>" helicopter. The original MICRO STAR should<br />

first be test-flown and trimmed out completely. The chassis of the model, complete with tail<br />

boom and boom braces but without canopy and skid landing gear, is then screwed to a lightwood<br />

plywood base plate, to which a semi-scale broad-based skid landing gear is also<br />

attached. The fuselage, consisting of two lightweight vacuum-moulded shells, can then be fitted<br />

round this assembly. The shells are only glued together permanently at the tail end; at the front<br />

they are held together by strips of adhesive tape, so that the chassis can still be removed easily<br />

from the fuselage for maintenance work.<br />

The fuselage is vacuum-moulded from clear smoked-tint plastic, and is designed to be painted<br />

from the outside; the kit includes pre-cut masks for the windows.<br />

The flight battery can be changed through an opening in the bottom of the fuselage, without<br />

having to remove the fuselage shells.<br />

Naturally the flight time which can be achieved per battery charge varies according to the<br />

model’s set-up and the pilot’s flying style; however, since the "<strong>Koala</strong>" is around 100 g heavier<br />

than the basic MICRO STAR 400, you must expect the flight times to be correspondingly<br />

shorter.<br />

Note: in developing this fuselage kit we considered that minimum possible weight and minimum adverse effect<br />

on the model’s flight performance were more important than ease of building. For this reason you will need a<br />

reasonable level of modelling skill, care and patience in order to complete this model satisfactorily, particularly<br />

regarding the trimming and joining of the thin-walled fuselage shells.<br />

Specification<br />

Length excl. rotor approx. 645 mm<br />

Height approx.<br />

205 mm<br />

Width excl. rotor approx. 140 mm<br />

Main rotor Ø<br />

630 mm<br />

Tail rotor Ø<br />

140 mm<br />

All-up weight min. approx. 595 g<br />

Main rotor reduction ratio 13,2:1<br />

Tail rotor reduction ratio 4:1<br />

2

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Warning notes<br />

• The contents of this kit can be assembled to produce a working model, but the model<br />

is by no means a harmless plaything. If assembled incorrectly or handled incompetently<br />

or carelessly it can cause serious injury to persons and damage to property.<br />

• When the model helicopter’s motor is running, the two rotors are spinning at high<br />

speed and contain an enormous quantity of rotational energy. Anything and everything<br />

that gets into the rotational plane of the rotors is either damaged or destroyed -<br />

and that includes parts of your body. Please take extreme care at all times with this<br />

machine.<br />

• If any object obstructs the rotational plane of the revolving rotors, severe damage will<br />

probably be caused to the rotor blades as well as the object. Broken parts may fly off<br />

and result in enormous imbalance; the whole helicopter then falls into sympathetic<br />

vibration, you lose control and have no way of predicting what the model will do next.<br />

• You may also lose control if a problem arises in the radio control system, perhaps as<br />

a result of outside interference, component failure or flat or faulty batteries, but in any<br />

case the result is the same: the model helicopter’s response is entirely unpredictable.<br />

Without prior warning it may move off in any direction.<br />

• Helicopters have many parts which are naturally subject to wear, including gearbox<br />

components, motor, ball-links etc., and as a result it is absolutely essential to check<br />

and maintain the model regularly. It is standard practice with full-size aircraft to give<br />

the machine a thorough "pre-flight check" before every flight, and this is equally important<br />

with your model helicopter. Constant checking gives you the opportunity to<br />

detect and correct any faults which may develop before they are serious enough to<br />

cause a crash.<br />

• The kit also includes two further information sheets - SHW 3 and SHW 7 - which include<br />

safety notes and warnings. Please be sure to read them and keep to our recommendations.<br />

They are an essential part of these instructions.<br />

• This helicopter is designed to be constructed and operated by adults, although young<br />

people of 16 years or more may do so under the instruction and supervision of competent<br />

adults.<br />

• The model features sharp points and edges which may cause injury.<br />

• Flying model aircraft is subject to certain legal restrictions, and these must be observed<br />

at all times. For example, it is essential to take out third party insurance, you<br />

must obtain permission to use the flying site, and you may have to obtain a licence to<br />

use your radio control system (regulations vary from country to country).<br />

• It is important to transport your model helicopter (e.g. to the flying site) in such a way<br />

that there is no danger of damaging the machine. Particularly vulnerable areas are the<br />

rotor head linkages and the tail rotor generally.<br />

3

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

• Controlling a model helicopter successfully is not easy; you will need persistence and<br />

determination to learn the skills, and good hand-eye co-ordination is a basic requirement.<br />

• Before you attempt to fly the model you should study the subject of helicopters in<br />

depth, so that you have a basic understanding of how the machines work. Read everything<br />

you can on the theory of helicopters, and spend as much time as you can<br />

watching other model helicopter pilots flying. Talk to chopper pilots, ask their advice,<br />

and enrol at a specialist model flying school if you need to. Many model shops will<br />

also be prepared to help you.<br />

• Please be sure to read right through these instructions before you start work on the<br />

model. It is important that you clearly understand each individual stage of assembly<br />

and the correct sequence of events before you begin building.<br />

• Don’t make modifications to the model’s construction by using parts other than those<br />

specifically recommended, unless you are certain of the quality and suitability of<br />

these other parts for the task.<br />

• We have made every effort to point out to you the dangers inherent in operating this<br />

model helicopter. Since neither we, the manufacturer, nor the model shop that sold<br />

you the kit have any influence over the way you build and operate your model, we are<br />

obliged to disclaim any liability in connection with it.<br />

Liability exclusion / Compensation<br />

As manufacturers, we at GRAUPNER are not in a position to influence the way you build<br />

and set up the model, nor how you install, operate and maintain the radio control system<br />

components. For this reason we are obliged to deny all liability for loss, damage or costs<br />

which are incurred due to the incompetent or incorrect use and operation of our products,<br />

or which are connected with such operation in any way.<br />

Unless otherwise prescribed by binding law, the obligation of the GRAUPNER company<br />

to pay compensation, regardless of the legal argument employed, is limited to the invoice<br />

value of that quantity of GRAUPNER products which was immediately and directly<br />

involved in the event which caused the damage. This does not apply if GRAUPNER is<br />

found to be subject to unlimited liability according to binding legal regulation on account<br />

of deliberate or gross negligence.<br />

4

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Contents<br />

• Foreword ......................................... P.2<br />

• Warnings ......................................... P.3<br />

• Accessories, extra items required ....................... P.6<br />

• Building the base plate and landing gear .................. P.7<br />

• Grundplatte mit Landegestell anfertigen ................. P.7<br />

• Completing the chassis .............................. P.10<br />

• Preparing the fuselage shells .......................... P.11<br />

• Final trimming of the fuselage shell ...................... P.12<br />

• Horizontal stabilisers ................................. P.13<br />

• Completing and painting the model ...................... P.14<br />

• Centre of Gravity ................................... P.14<br />

• General safety measures .............................. P.15<br />

• Basic helicopter terminology............................ P.16<br />

• List of parts ........................................ P.18<br />

The instructions<br />

We have invested considerable effort in producing these instructions, with the aim of ensuring<br />

that your model helicopter will fly reliably and safely. Please take the trouble to follow the<br />

instructions step by step, exactly as described, as this guarantees a successful outcome. This<br />

applies to you whether you are a relative beginner or an experienced expert.<br />

• The comprehensive illustrations show how the model is constructed; be sure to read the<br />

instructions which accompany the drawings.<br />

• All gears, bearings and moving joints must be greased or oiled carefully.<br />

• You will find the parts list at the end of these instructions.<br />

5

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Accessories<br />

Mechanics and recommended accessories for the AGUSTA <strong>A119</strong> <strong>Koala</strong><br />

Mechanics:<br />

MICRO STAR 400<br />

Order No. 4441<br />

Order No. 4441.RCU<br />

Factory-assembled model including motor<br />

As 4441, plus four servos, speed controller and gyro system<br />

Radio control system: see main <strong>Graupner</strong> catalogue<br />

We recommend a radio control system equipped with special helicopter options, or a microcomputer<br />

radio control system such as the mc-12, mc-14, mc-15, mc-19, mc / mx-22 or mc-24.<br />

Servos:<br />

C 121 micro-servo<br />

Order No. 5106<br />

Gyro system:<br />

PIEZO NT-310 pico gyro system<br />

Order No. 5134<br />

Speed controller:<br />

PICO SC 20<br />

Order No. 7160<br />

or<br />

PICO 25<br />

Order No. 7172<br />

Flight battery:<br />

LiPo 1500<br />

Order No. 7635.3BEC<br />

6

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Assembly<br />

Preparing the chassis<br />

We assume that you have already test-flown your MICRO STAR 400 and set it up correctly.<br />

This is important, as access to the components for adjustment and maintenance is greatly<br />

restricted when the mechanics are inside the fuselage.<br />

• Remove the canopy (no longer required).<br />

• Remove the flight battery.<br />

• Unscrew the stabiliser panels from the mounting flanges.<br />

• Locate the self-tapping screws which retain the tail boom braces and unscrew them from the<br />

flange on the tail boom. Rotate the flange through 180° on the tail boom, so that the<br />

stabiliser mounting is on the underside, then re-fit the screws to secure the boom braces<br />

again.<br />

• Remove the speed controller from the underside of the chassis (it is re-installed later).<br />

• Unscrew the tail rotor bellcrank and disconnect it from the pushrod.<br />

• Loosen the clamping screws in the tail rotor housing, and withdraw the tail rotor housing to<br />

the rear.<br />

• Separate the skid landing gear (no longer required) from the chassis by undoing the four<br />

retaining screws. The screws are re-used.<br />

Building the base plate and landing gear<br />

The first step is to insert the two lateral stiffeners in both sides of the base plate, and fix them in<br />

place using cyano-acrylate adhesive ("cyano"). This is the procedure: lay the plate down flat and<br />

glue the stiffeners to the rear of the plate only. Allow the glue to set hard, then pack up the rear<br />

end by about 6 mm and glue the stiffeners to the front of the base plate, so that the plate takes<br />

up the same angle as the stiffeners.<br />

Glue the balsa in-fill piece to the underside of the base plate, flush with the rear edge. When the<br />

glue is dry, continue the circular opening in the base plate through the balsa. Round off the<br />

outside edges of the balsa in-fill piece as shown, using abrasive paper.<br />

7

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Drill two 2 mm Ø holes in each of the carbon fibre skid tubes, taking care to drill at exactly the<br />

same angle: the rear ones should be 22 mm from the end, and the front ones spaced 135 mm<br />

from them. Caution: do not drill right through the tubes: just drill into them!<br />

Fit the two skid bars into the holes "dry" (no<br />

glue), and tape the skid tubes down on a flat<br />

surface as shown: the tubes should be 108<br />

mm apart, perfectly "square" and parallel to<br />

each other.<br />

Remove the skid bars from the skid tubes<br />

without disturbing the tubes, and slide lengths<br />

of 3 / 2 mm Ø plastic tube onto them; the ends<br />

of the steel bars should project by about 4<br />

mm; roughen the exposed ends using<br />

abrasive paper.<br />

Now fit the skid bars into the (still fixed) skid<br />

tubes, set them parallel to each other and tilted<br />

to the rear slightly, then glue them securely to<br />

the skid tubes using cyano.<br />

Glue a 20 mm long beech dowel in the front<br />

end of each carbon fibre tube, leaving half their<br />

length projecting.<br />

8

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Measure a point 95 mm from the rear of the original aluminium skid tubes and cut them off at<br />

that point; the remaining curved front ends can now be pushed onto the wooden dowels in the<br />

carbon fibre skid tubes and glued in place. Align the curved ends so that they are parallel to<br />

each other, and check that they form a neat joint with the carbon fibre tubes. Allow the glue to<br />

cure fully.<br />

This completes the landing gear. Glue the assembly to the underside of the base plate as<br />

shown in the picture, taking care to position the plate centrally on the skid bars: tack the parts<br />

together using thin cyano initially, then apply thick cyano to strengthen the joints.<br />

9

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Completing the chassis<br />

Attach the helicopter chassis (complete with tail boom and boom braces) to the base plate using<br />

the four screws with which the original skid landing gear was secured. Attach the speed<br />

controller to the underside of the base plate so that the ON / OFF switch is easily accessible<br />

when the model is complete.<br />

The upper bodywork stand-off pillars<br />

consist of a 70 mm length of 2 mm Ø<br />

carbon fibre rod. Drill a 2 mm Ø hole<br />

in both chassis side frames as shown<br />

in the photo, and push the rod<br />

through them. Adjust the position of<br />

the rod so that it projects by exactly<br />

the same amount on both sides. Cut<br />

two pieces 21 mm long from the 3 / 2<br />

mm Ø plastic tube, push them onto<br />

the carbon fibre rod as far as they will<br />

go, and secure them with cyano.<br />

10

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Preparing the fuselage shells<br />

Cut out the vacuum-moulded fuselage shells, working exactly along the marked lines, and sand<br />

the cut edges smooth using fine abrasive paper.<br />

Using a sharp balsa knife, carefully cut out the rectangular turbine air intakes in the upper part<br />

of the fuselage, aft of the main rotor shaft. Seal the openings by gluing small pieces of fly screen<br />

over them on the inside; they serve as additional air openings to cool the motor.<br />

Cut the openings in the underside of the fuselage for the skid bars, working along the marked<br />

lines. In the top of the shells cut out as large an oval opening as possible for the main rotor<br />

shaft. At the tail end cut the hole for the tail rotor pushrod.<br />

Bend the tailskid to shape from the steel wire supplied; the correct shape is shown in the photo.<br />

Glue it in the bottom vertical stabiliser.<br />

Fit the fuselage shells together as accurately as possible and apply pieces of tape over the<br />

joints. Note that the edges of the shells should butt together; they should not overlap.<br />

11

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

When you are confident that everything lines up correctly and is held securely in place, the rear<br />

part of the shells can be glued together in the following areas only:<br />

• The top of tail boom along the shaft tunnel, then forward and up to just aft of the main rotor<br />

shaft;<br />

• The whole of the upper vertical stabiliser;<br />

• The whole tail cone;<br />

• The whole of the bottom vertical stabiliser.<br />

Do not allow the glue to run onto other areas, otherwise it may be impossible to install<br />

the mechanics when you have finished!<br />

Remove the strips of tape when the glue has set hard. Cut narrow strips of scrap plastic and cut<br />

them into short pieces as shown. Glue these small rectangles along the joint line in the front<br />

section of the fuselage, fitting them in groups of three to form locating tongues: in each case<br />

glue two pieces on the inside of one shell, with a third strip between them on the other side (see<br />

photo). Roughen all joints with abrasive paper before applying the glue.<br />

Final trimming of the fuselage shell<br />

Gently spread the fuselage shells on the underside so that the chassis can be installed from underneath.<br />

When you do this it is important to ensure that the tail rotor pushrod exits the fuselage<br />

through the appropriate opening. Check that the fuselage shell is a snug fit all round the chassis<br />

when the shells are held together with a few strips of adhesive tape: the openings at the bottom<br />

should be a close fit round the skid bars, but without placing the fuselage under strain. Check<br />

that the main rotor is free to rotate without any danger that the swashplate, pushrods or other<br />

linkage components could foul the fuselage.<br />

12

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Slide the tail rotor assembly onto the tail boom again, working from the rear underside, and replace<br />

it in its original position. Trim the opening in the fuselage shell as required to ensure that<br />

none of the moving parts fouls the bodywork.<br />

Connect the tail rotor bellcrank to the pushrod, then replace the crank in its original position.<br />

Check that the tail rotor works correctly, with no tendency to foul or jam at any point.<br />

Mark the outline of the rectangular opening in the base plate on the fuselage shell, and cut it out<br />

so that the flight battery can be fitted from the underside and slid into the nose of the fuselage. If<br />

you wish, you can just leave this access hatch open; alternatively you can cut a rectangular<br />

hatch cover from scrap flat plastic sheet left over from the fuselage shells. The cover can be attached<br />

using a tape hinge, and held closed with another strip of tape.<br />

Horizontal stabilisers<br />

Cut out the cambered bottom shells for the horizontal stabilisers along the marked lines. Cut<br />

pieces of plastic tube to length and glue them in the two shells, 8 mm from the leading edge and<br />

parallel to it. Sand the edges of the open top surface of the stabiliser panels flat by rubbing them<br />

on a sheet of abrasive paper; it does not matter if you sand a little off the top of the plastic tubes<br />

at the same time.<br />

The prepared stabiliser shells can now be glued to the flat stabiliser top sections (scrap plastic).<br />

Allow the glue to set hard, then cut out the stabiliser panels and sand the glued edges smooth<br />

all round. Working from the angled root face of the panels, drill a 2 mm Ø hole into the plastic<br />

tube, and check that the remainder of the 2 mm carbon fibre rod can be slid into the two tubes.<br />

13

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Drill 2 mm Ø holes at the marked points in the tail boom so that the carbon fibre rod can be<br />

fitted through them; the rod acts as the horizontal stabiliser joiner and spar. Fit the stabiliser<br />

panels on the joiner rod, and check that they are horizontal when viewed from the tail. At the<br />

same time ensure that they rest snugly against the fuselage sides.<br />

When you are confident that everything fits correctly, remove the stabiliser panels, remove the<br />

strips of tape holding the fuselage shells together, and remove the chassis from the fuselage<br />

once more.<br />

Completing and painting the model<br />

The fuselage should be painted on the outside using fast-drying spray paint.<br />

Caution:<br />

In order to save weight the fuselage shells are moulded in very thin plastic. This makes<br />

them vulnerable to distortion caused by the softening action of the paint solvent. You<br />

can avoid this happening by applying the paint sparingly, in thin coats.<br />

Before applying the paint, you must mask out the windows using the pre-cut self-adhesive<br />

masks provided in the kit. Rub down the surfaces to be painted using very fine abrasive paper<br />

(600 - 1200 grit) to ensure that the paint adheres well. This is particularly important along the<br />

joint line; if you neglect this, the paint may tend to flake off later when you peel off the adhesive<br />

tape which is used to hold the fuselage shell halves together.<br />

We recommend that you paint the horizontal stabiliser panels separately from the fuselage, and<br />

only attach them to the model when painting is complete. The same applies to the vacuummoulded<br />

dummy exhaust pipes.<br />

Cut out the decals from the sheet supplied, and apply them to the model in the arrangement<br />

shown in the kit box illustration. The best way of fitting the black window frames is to cut them<br />

out initially along the outside edges only, and apply them to the model in this state. Then you<br />

can cut carefully along the inside lines and peel off the excess material.<br />

Centre of Gravity<br />

The model’s CG should be as close as possible to the main rotor shaft, but up to 2 cm aft of it<br />

should not present problems. The CG can be corrected by adding lead ballast to the extreme<br />

fuselage nose, but since this adds unwanted weight it should only be done if there is really no<br />

alternative.<br />

14

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

General safety measures<br />

• Take out adequate third-party insurance cover.<br />

• Wherever possible join the local model flying club.<br />

At the flying site:<br />

• Never fly your model above spectators.<br />

• Do not fly models close to buildings or vehicles.<br />

• Avoid flying over agricultural workers in neighbouring fields.<br />

• Do not fly your model in the vicinity of railway lines, major roads or overhead cables.<br />

Pre-flight checks, flying safety:<br />

• Before you switch on the transmitter check carefully that no other model flyer is using the<br />

same frequency.<br />

• Carry out a range check with your RC system.<br />

• Check that the transmitter and flight batteries are fully charged.<br />

• Do not let the model fly out of safe visual range.<br />

Post-flight checks<br />

• Clean the model and check that all screws etc. are still tight.<br />

• Look for wear and damage to the helicopter, and replace worn parts in good time.<br />

• Ensure that the electronic components such as battery, receiver, gyro etc. are still securely<br />

fixed. Remember that rubber bands deteriorate with age and may fail.<br />

• Check the receiver aerial. Conductor fractures inside the insulation are often not visible from<br />

the outside.<br />

• If the main rotor should touch the ground when spinning, replace the blades. Internal blade<br />

damage may not be visible from the outside.<br />

• Never carry the model by the tail boom: too firm a grip will easily deform the tail rotor<br />

pushrod.<br />

15

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

Some basic terms used in model helicopter flying<br />

The term "rotary wing machine" indicates that the helicopter’s lift is derived from rotating "wings"<br />

which take the form of rotor blades. As a result, a helicopter does not require a minimum forward<br />

speed in order to fly, i.e. it can hover.<br />

Cyclic pitch<br />

Cyclic pitch variation is used to steer the machine around the roll and pitch axes. Changing cyclic<br />

pitch has the effect of altering blade pitch depending on its position in the circle. The effect<br />

is caused by tilting the swashplate, which then effectively tilts the helicopter in the required direction.<br />

Collective pitch<br />

Collective pitch provides control over vertical movement, i.e. for climb and descent. The pitch of<br />

both rotor blades is altered simultaneously.<br />

Torque compensation<br />

The spinning rotor produces a moment which tends to turn the whole helicopter in the opposite<br />

direction. This effect must be accurately neutralised, and this is the task of the tail rotor. Tail rotor<br />

blade pitch is altered to vary torque compensation. The tail rotor is also used to control the<br />

model around the vertical (yaw) axis.<br />

Hovering<br />

This is the state in which the helicopter flies in a fixed position in the air, without moving in any<br />

direction.<br />

Ground effect<br />

This occurs only when the machine is close to the ground, and it falls off as altitude rises. At an<br />

altitude of about 1 - 1½ times the rotor diameter ground effect is completely absent. Normally<br />

the revolving airflow from the main rotor is able to flow away freely, but in ground effect the air<br />

strikes an obstacle (the ground) and forms an "air cushion". In ground effect a helicopter can lift<br />

a greater weight, but its positional stability is reduced, with the result that it tends to "break<br />

away" in an unpredictable direction.<br />

Climb<br />

Any excess power above that required for hovering can be exploited to make the helicopter<br />

climb. Note that a vertical climb requires more energy than an angled climb which includes forward<br />

motion. For this reason a model with a given amount of motor power will climb more rapidly<br />

at an angle than vertically.<br />

Level flight<br />

A helicopter absorbs least power when flying straight and level at about half-power. If you have<br />

trimmed the machine carefully for a steady hover, it will tend to turn to one side when flown forward.<br />

The reason for this phenomenon is that the rotor blade which is moving forward encounters<br />

an increased airflow caused by the wind, and this increases its upthrust compared with the<br />

blade which is moving downwind, where the same airflow has to be subtracted. The net result is<br />

a lateral inclination of the helicopter.<br />

Descent<br />

If the helicopter’s rotor speed is relatively low and you place the helicopter in a fast vertical descent,<br />

the result can be that insufficient air flows through the rotor. This can cause what is<br />

known as a "turbulent ring stage", when the airflow over the blade airfoil breaks away. The helicopter<br />

is then uncontrollable and will usually crash. A high-speed descent is therefore only possible<br />

if the helicopter is moving forward, or if the rotor is spinning at high speed. For the same<br />

reason care should be exercised when turning the model helicopter downwind after flying into<br />

wind.<br />

Flapping motion of the rotor blades<br />

As we have already seen, the forward-moving blade produces greater upthrust than the trailing<br />

blade. This effect can be minimised by allowing the leading blade to rise and the trailing blade to<br />

fall. The rotor head is fitted with what is known as a flapping hinge to allow this movement, and<br />

16

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

this prevents the rotor plane tilting excessively in forward flight. In model helicopters a single<br />

hinge shared by both blades has proved an effective solution to the problem.<br />

Auto-rotation<br />

This term refers to a helicopter flying without motor power. The rotational speed of the main rotor<br />

can be kept high by setting both blades to negative pitch, and the airflow through the rotor as<br />

it descends then keeps the blades turning. The rotational energy stored in the rotor by this<br />

means can be converted into upthrust when the helicopter is close to the ground, by the pilot<br />

applying positive collective pitch. Of course, this can only be done once, and it has to be done at<br />

the correct moment. Auto-rotation allows a model helicopter to land safely when the motor fails,<br />

just like a full-size machine.<br />

However, auto-rotation places considerable demands on the pilot’s judgement and reflexes; you<br />

can only halt the machine’s descent once, and you must not "flare" too early or too late. Much<br />

practice is required to get it right.<br />

17

<strong>Agusta</strong> <strong>A119</strong> <strong>Koala</strong><br />

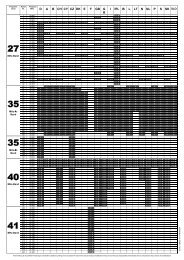

List of parts<br />

Part<br />

Description Material / dimensions in mm No. off<br />

No.<br />

1 Fuselage shell, right / left Clear plastic, smoked tint 1 each<br />

2 Horizontal stabiliser, bottom shell, Clear plastic, smoked tint<br />

1 each<br />

right / left<br />

3 Horizontal stabiliser, top panel,(scrap Clear plastic, smoked tint<br />

1 each<br />

material from parts 1)<br />

approx. 55 x 25<br />

4 Battery hatch cover<br />

Clear plastic, smoked tint<br />

1<br />

(scrap material from parts 1) approx. 55 x 40<br />

5 Dummy exhaust pipes Clear plastic, smoked tint 2<br />

6 Chassis base plate Beech ply, approx. 240 x 60 x 1,5 1<br />

7 Lateral chassis stiffener Beech ply, approx. 205 x 12 x 1,5 2<br />

8 In-fill piece Balsa, 60 x 40 x 6 1<br />

9 Skid bar, front / rear Pre-formed piano wire 1 each<br />

10 Skid bar sheath ABS tube, 2/3 Ø x 135 2<br />

11 Skid tube CFRP tube, 5/3 Ø x 170 2<br />

11 Skid tube tips Nose of aluminium skid tube, 5/4 Ø 2<br />

12 Skid joiner Beech dowel, 3 Ø x 20 2<br />

13 Stand-off pillar CFRP rod, 2 Ø x 70 1<br />

14 Horizontal stabiliser joiner CFRP rod, 2 Ø x 130 1<br />

15 Fly screen Plastic, 50 x 50 1<br />

16 Tailskid piano wire, 1 Ø x 100 1<br />

17 Window masks Masking film, pre-cut 1<br />

18 Full-colour decal sheet 1<br />

18