946 mL – 1 U.S. Quart - BP

946 mL – 1 U.S. Quart - BP

946 mL – 1 U.S. Quart - BP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

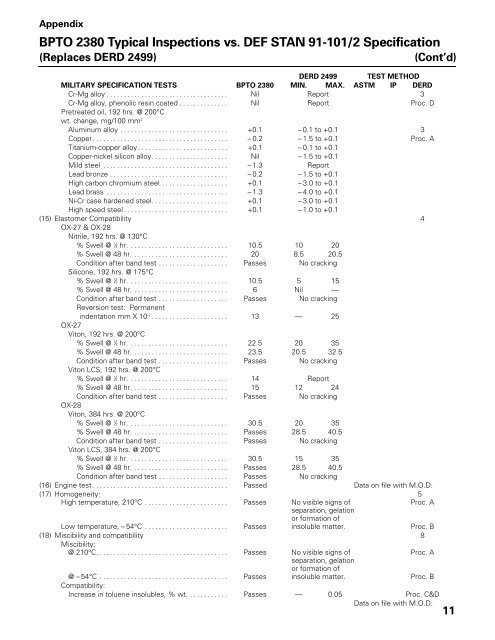

Appendix<br />

<strong>BP</strong>TO 2380 Typical Inspections vs. DEF STAN 91-101/2 Specification<br />

(Replaces DERD 2499) ( C o n t ’ d )<br />

..................................................................................... DERD 2499 TEST METHOD<br />

MILITARY SPECIFICATION TESTS ........................ <strong>BP</strong>TO 2380 MIN. MAX. ASTM IP DERD<br />

Cr-Mg alloy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nil Report 3<br />

Cr-Mg alloy, phenolic resin coated . . . . . . . . . . . . . . Nil Report Proc. D<br />

Pretreated oil, 192 hrs. @ 200°C<br />

wt. change, mg/100 mm 2<br />

Aluminum alloy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.1 <strong>–</strong> 0.1 to +0.1 3<br />

Copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>–</strong> 0.2 <strong>–</strong> 1.5 to +0.1 Proc. A<br />

Titanium-copper alloy . . . . . . . . . . . . . . . . . . . . . . . . . . +0.1 <strong>–</strong> 0.1 to +0.1<br />

Copper-nickel silicon alloy. . . . . . . . . . . . . . . . . . . . . . Nil <strong>–</strong> 1.5 to +0.1<br />

Mild steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>–</strong> 1.3 Report<br />

Lead bronze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>–</strong> 0.2 <strong>–</strong> 1.5 to +0.1<br />

High carbon chromium steel . . . . . . . . . . . . . . . . . . . +0.1 <strong>–</strong> 3.0 to +0.1<br />

Lead brass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>–</strong> 1.3 <strong>–</strong> 4.0 to +0.1<br />

Ni-Cr case hardened steel. . . . . . . . . . . . . . . . . . . . . . +0.1 <strong>–</strong> 3.0 to +0.1<br />

High speed steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.1 <strong>–</strong> 1.0 to +0.1<br />

(15) Elastomer Compatibility ............................................... 4<br />

OX-27 & OX-28<br />

Nitrile, 192 hrs. @ 130°C<br />

% Swell @ 1 ⁄2 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 10 20<br />

% Swell @ 48 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 8.5 20.5<br />

Condition after band test . . . . . . . . . . . . . . . . . . . . Passes No cracking<br />

Silicone, 192 hrs. @ 175°C<br />

% Swell @ 1 ⁄2 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 5 15<br />

% Swell @ 48 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Nil —<br />

Condition after band test . . . . . . . . . . . . . . . . . . . . Passes No cracking<br />

Reversion test: Permanent<br />

indentation mm X 10 -2 . . . . . . . . . . . . . . . . . . . . . . 13 — 25<br />

OX-27<br />

Viton, 192 hrs. @ 200°C<br />

% Swell @ 1 ⁄2 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.5 20 35<br />

% Swell @ 48 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.5 20.5 32.5<br />

Condition after band test . . . . . . . . . . . . . . . . . . . . Passes No cracking<br />

Viton LCS, 192 hrs. @ 200°C<br />

% Swell @ 1 ⁄2 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Report<br />

% Swell @ 48 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 12 24<br />

Condition after band test . . . . . . . . . . . . . . . . . . . . Passes No cracking<br />

OX-28<br />

Viton, 384 hrs. @ 200°C<br />

% Swell @ 1 ⁄2 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.5 20 35<br />

% Swell @ 48 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . Passes 28.5 40.5<br />

Condition after band test . . . . . . . . . . . . . . . . . . . . Passes No cracking<br />

Viton LCS, 384 hrs. @ 200°C<br />

% Swell @ 1 ⁄2 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.5 15 35<br />

% Swell @ 48 hr. . . . . . . . . . . . . . . . . . . . . . . . . . . . Passes 28.5 40.5<br />

Condition after band test . . . . . . . . . . . . . . . . . . . . Passes No cracking<br />

(16) Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Passed Data on file with M.O.D.<br />

(17) Homogeneity:............................................................... 5<br />

High temperature, 210°C . . . . . . . . . . . . . . . . . . . . . . . . Passes No visible signs of Proc. A<br />

..................................................................................... separation, gelation<br />

..................................................................................... or formation of<br />

Low temperature, <strong>–</strong> 54°C . . . . . . . . . . . . . . . . . . . . . . . . Passes insoluble matter. Proc. B<br />

(18) Miscibility and compatibility.......................................... 8<br />

Miscibility:<br />

@ 210°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Passes No visible signs of Proc. A<br />

..................................................................................... separation, gelation<br />

..................................................................................... or formation of<br />

@ <strong>–</strong> 54°C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Passes insoluble matter. Proc. B<br />

Compatibility:<br />

Increase in toluene insolubles, % wt. . . . . . . . . . . . Passes — 0.05 Proc. C&D<br />

..................................................................................... Data on file with M.O.D.<br />

11