You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

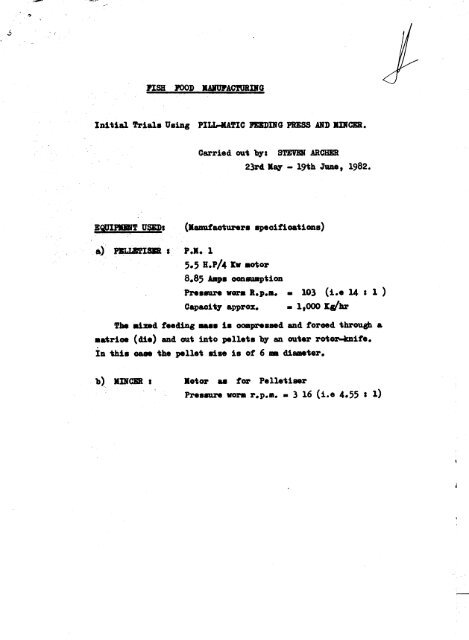

Carried ou" by I<br />

STEVEtl ARCHER<br />

23rcl M. - 19"h June, 1982.<br />

<strong>EQUI~</strong> <strong>Up</strong>;<strong>pa</strong> (aarmtacnurer•• pecit1oa"iOllB)<br />

~) PJlLt&'naR. P.K. 1<br />

5.5 B.P/. X•• cnor<br />

8.85 Jap. OOIl8WIption<br />

Pressure •••• R.p... • 103 (i.e 14 I 1 )<br />

Ca<strong>pa</strong>ci"7 approx.<br />

• 1,000 XJhr<br />

Theai_cl teecling au. ls OOlIpNs88cland toroed through a<br />

.a"rloe (die) and out into pelle"s 'b7 an ou"er rcnor-bite.<br />

In this oase the pellet si •• i8 ot 6 •• di_ter.<br />

b) KUCBR I a.tor as tor Pell.ti88r<br />

Pressare vora r.p.a •• 3 16 (i.e 4.55 I 1)

(:1) !J!!! PISII P!LL!l1<br />

lOkg 20 kg )0 kg 40 kg<br />

JaSB 1PISII 33<br />

COT'f(lI lID CAD 33<br />

VIDIA!' POWID 10<br />

MAID'_ DAL 14<br />

VA.!D'. ADJD<br />

3.3 6.6 9.9 l3~<br />

3.3 6.6 9.9 13.2<br />

2.0 4.' 6.0 8.0<br />

1.4 2.8 4.2 ,.6<br />

1 1.'<br />

2 3<br />

(MOIS!UIBCOlt.' • 37.~)<br />

10 kg 20q )0 kg<br />

rJldI BBAD9 20<br />

1PIDS P!l

(ii) Seooacll3teed the 11&1.. p1'Il .a1 throup - this being talr13<br />

abllOrbentaac1. <strong>Up</strong>t t tuu to lIOakthe moisture up reaaining fr_<br />

--<br />

the fish, with.t bloakiag the cUe. Do aen teed cotton ••ed oake<br />

atter ft. or 8D3other hip lIoisture content OOIlpoD.ent.As cotton<br />

••• d cake -"e.I .0Ud when7CMclo. 8•• ti.a the llaobiDekee<strong>pa</strong><br />

taming bat the ootton h•• llou.l48dit •• lt around the wora.<br />

(iii)<br />

,ha. teed the cotton ••• d, slewer than the others clueto 1arse<br />

hard aInmk.. :BcUlthe oottOJl••ed and the aai.. geraaMal need griading<br />

at 1e•• t trioe.<br />

ti••••<br />

'lhe7 Callbe ted tosether the MCOIld(and third)<br />

(iT) Peeclingthe compOllents in at the back ot the mouth, (the ead<br />

•• arest the motor) _au<br />

that 7ou.Calloover the reat ot the llouth with<br />

the bucket, preTenting too _oh tood aettiag epm baelt oa.t.<br />

Abox coa1ddo with beillg producedthat fits<br />

('hi •. ooald ad.clto the Atet., ot a claD&eroua _cbiDe).<br />

aroaDdthe mouth.<br />

(T) BoB't feed fre. fish after grain without first oleaning out the<br />

bOlll.<br />

PIlLLB'nSDlG<br />

BD'OBE S'lAR'l'DG<br />

(i) Greate/vase1iae the iJmer and outer rillS on both sides of the die -<br />

stop. knives squeaking.<br />

(ii) are.,./Vueline the outer and inner edges of the die - hopefu113<br />

a110llsfor eaaier retDOTal.<br />

(iii)<br />

'lighten the Alaa 07 nat bet•• eni aDd! of a turn 1I0000e than<br />

haDdtight.<br />

(ii.T) II8M t1gb.tlln the la't8a _tU' r.U.,<br />

!l9J!GBA'1'.I<br />

(i) ,he better IIlixedthe food, the taster<br />

e.,.<br />

d1strilnltian of lIoisture in it<br />

(ii) Ideal if a pellet is producednear13 1 _ lODge<br />

if can be fed, clueto a lION<br />

If fed too fast the machineblocka, it fed too alowbuds of halfai<br />

••d pellets are produoed.<br />

(iil)<br />

Allowa break after ""17 10 - 15 kg tor the aach1neto olear<br />

~ iapenclingbloakages (dOll't stop the lIotor).<br />

(iT) ,he {eea rate needs to be practioecl.<br />

•../3

(1)<br />

(11)<br />

(11i)<br />

(1v )<br />

heting<br />

Ra"e "00 tan<br />

K01s-ture oon"en" ot mirnre "00 low<br />

Jl1Dure no" mixed pYper17 - SOM <strong>pa</strong>rts "00 ch7<br />

I.A<br />

!<strong>Up</strong>s of 00""0.11seed cake tha" ge" in"o "he grOWlc1II1xture t<br />

when thrown eN" ot the grinder.<br />

Blockages ar •. ot"en preoeeded 'b1'a change in motor tOlle.<br />

It illa 1s J:aeard in "1ae, wa"er should be poured in". "he lIachiDe.<br />

S_·U.a the extra m01sture allows 1t to olear 1".lt.<br />

(1) UIUIOl'eW~ ou"er riAB<br />

(11) 1UldoA18ll-kel ." aad reaOft wuhers &ad oa.ter ladte.<br />

(111) '1'ara "he W01'Il uiAB a 19 _ open eaded. spumer - t1ts 0.11"0"he<br />

end of ~e shaft. C1oabr1. to begin with ('bao1ara:N.a) as this puIles<br />

"he die oa.1I. !.ben remove the inDer kn1fe and turn "he worman"i-ol""<br />

wiee "0 push the food ou". 0.1108"he food 1s 100" the AlaD ke1' nu" aIld<br />

block 08Il 'be put baok •. and. ued "0 pull the •••• eN". eaU. "he ~1<br />

before return1ng werta~ otherwi. food gets puhed 111"0~e bearinge aad<br />

behind the bac* of "he W01"ll.<br />

(1v) The mo'tor has Ba •• "_"10 •.••••• " when onr1oaded. Doa.,,, U7<br />

sad restart the machiDe •• it ORts oat, as it 1s blocked &ad1'- will<br />

"'17 blow the :ftl.s.

lB'l'lmIlDtDG TBJ: MOS! PRACTICALPac.TAaB 0' 1IBISH PISH THAt<br />

CB BB ADlBD TO CltOUO SPJICIjI, ULAPIA Pm.JBlS '1'0 IUD .l PJrLLBT<br />

or :rooD~ALIft'.<br />

P.lle".<br />

•••• proclu.oecl aiA, tJarM ditt.rea" he. ti. peroen"aaesl<br />

(P.roan•••• et aoinve cl he. ti •• ~ iA srowulpell.t •• ~)<br />

* (1) CCM'iU'!<br />

Ua1.JLB ~ Jlrellh Pi. and.5Of, Or_cl Speoial P.ll." •<br />

•• ill'trareOGIltut 4~<br />

If_ maoMneru<br />

bloald.na- "he pellet.<br />

well, e••113 haDclliA,the 10 kc wi"hout<br />

prod.uoecl •••• ta1rq larP.<br />

'btataot ve-q<br />

o.<strong>pa</strong>ct - teadiq to 'breat.4p a U"tle wheaapreaclout tor dJ7iAg.<br />

Dryin, vu ditti_lt<br />

ruoid. bavia, 'beenspread ftt<br />

* (11) SW!<br />

d:u to oODtiAU0U8 raiA, aad."" pellet. weat<br />

iA the .ecl tor 24 hours.<br />

UIIiac 3» he_ ftab aad.6fI/o Ground.Speoial<br />

3_<br />

Pellet •<br />

• oi••.• OGIltut<br />

lfhe ••• hine ••••••••• 10 kc, at a .1__ rate thall (1) bat<br />

with_t 'bloold... Iftae ,.ilet. were -.aller 8ILc1. t1aer. !h. peU.t<br />

dried. ca1eJter o1m.nal7 Md.at.,ecl <strong>pa</strong>la"ible tor at lean 48 hour••<br />

*CU1) SDI!.<br />

Uaia, ~ hellh 'i. _cl 7'" Oroucl Speoial P.llet •<br />

• oill'trareOODtut27.~<br />

pellet.<br />

BISUJJ!S<br />

If_ .ubt M b1.oob4 betore 10kg _lcl be tecl to it, the<br />

produeed.were oa.<strong>pa</strong>ot, eaa111'dri.d., 'bein, alaost too harcl.

CClfCLtJSICIlS<br />

Witha aore afteotift dr.r1Dcay.t. tbaDI ued. the 4~ lI1%ture00\1ld.<br />

be aore practioal. Aa. icleator a better ayatemooald iavolft t.be .ld.<br />

•oof't.. - drier". It a -.11 _ab. wire aettlllg vu laid along t.be<br />

.helfts the pellet. oou.l4be apre•••.• t OIl the shel..... 'hi. would.<br />

ha.•• _other benetit a<strong>pa</strong>rt trOll allowing a larae oiroulatiOD.ot air<br />

_oaget tlle pellet.,<br />

be ••.••d at.<br />

as it raiD approached.the wh.le struoture Oftld.<br />

the ab.e4,pellets &Ad. all. Thethou.t .t uaiag the<br />

.Gbr tor dr71agthe pellets d.uringthe raiDs hall three di.ad.vaataaes<br />

that I ••ea P1J'atq the saoker d••• aot ha.•• a "I8r7 ~ •• oa<strong>pa</strong>ciV;<br />

I eatiaat. 30 kg .t pellets being dried in it at a ts.-; at the lIOat;<br />

20 kg being a... ,"bule oa<strong>pa</strong>oit7• SeOOA41¥ the ooll•• ti_<br />

.t,l'ael<br />

tor tU .oker is easier II&1dthan d.••e. file rea __ *ing tilapia<br />

••••••••••.••• due to a laalt ot the reqaired ooooauthullk••<br />

Third.17'a. tilapia lik. to .at _ok.d pellets, how••n81ti.•.•are thq<br />

to ditt.ren.s<br />

in tut.?<br />

The si.. of the pellet. producedwas larger beOlllUl8 the teed is able<br />

to <strong>pa</strong>ss through the die futer thaDa drier m1xhre; the stre_ is_<br />

1ng oat of the die ,.ts longer bet.en kaite cuts than it wouldit the<br />

8ixture wasbeing aOYedat a slower rate.<br />

be overo••<br />

This large pellet size oould<br />

b7 te.diag the •• chine slower. This wouldalso result 1n<br />

the aixture spendinga loaav ti_<br />

inere••• the t1rmnessof the pellet.<br />

in the die;;:a factor that could<br />

Howeverbecause of the higher<br />

lI!0istur8oOl1tent,whichacts as a lubricant in the die, a wetter pellet<br />

is al1faJ'sgoag to be le.s ooa<strong>pa</strong>ctthan its drier equivalent, whenboth<br />

are dried outI accepting that the drier eq1iivalent, 1las.eilO1lgh .•• i_t ••.<br />

ia it to allow gellatllli.ing<br />

The27.~ .oisture<br />

to take place.<br />

content mixture provedtoo dr7 tor the machine,in<br />

this experiment. Thi. doe. not tally with the results ot the 1st<br />

experiment. A mistake of using too ~l batch•• - (only 5 kg) - in<br />

the 1st experimentmeantthat the machinewasable to puf!lhOld 5 kg<br />

ot drier pellet. before it beganto block up~ In this experi.llellt10 kg<br />

batches wereused meaningthat the drier IDirare had tt.<br />

maohirle.<br />

to blodt the

Having to handle a batch of 10 kg as opposed to 5 kg means that the<br />

heat in the die builds - up to a higher temperature, which has<br />

the effect of reducing the moisture content of the mixture further.<br />

The 35'/> moisture content mixture worked best in this experiment.<br />

Although the machine was not able to run as fast as it did vi th the<br />

45% minure, IDa3'be with a larger batch than 10 kg it would alsc lead<br />

to a blockage in the machine. The pellets were 1-010 easier to dry,<br />

and did not go rancid within the 48 hours that<br />

they were kept.<br />

Rancidity will alW83'Sbe a big problem whentrying to store these<br />

pellets containing tresh fish. This is because rancidity is due to<br />

oxidation of highly unsaturated fats (lipids) of which tresh fish has<br />

more than its fidr share; this oxidation occurs in two stages; the<br />

second causing an "otf-flavour"<br />

and sometimes the production of toxic<br />

compounds. It tile•• pellets needed to be stored for any length ot tillle -<br />

over the weekendtor instance the addition ot an anti-oxidant<br />

(etho2'3"gu.inaM botylated ~dro~toluen. are suggested by Fish Feed<br />

Technology")<br />

could help prevent rancidity.<br />

SUMtURY<br />

A happy _dium between the 45% mixWre and the 35% IIlixture IRq be<br />

'he answer, i.e. around 4C1fo aoi8ture content. This would prove<br />

easier to dry than the 45% III1xtureand easier tor the machine to<br />

work on than the 1~.

IDBAS ON PELLETING<br />

(i)<br />

Heating of the food<br />

If the food oouldbe heated. in a large drumfor instance, I' a<br />

sure this wouldresult in a higher<br />

This wouldhave twobeneficial affeots at least:<br />

quality pellet being produced.<br />

Thehigher teaperature<br />

wouldresult in increased gellatinising between<strong>pa</strong>rtioals - one of the<br />

major faotors affecting pellet firmness.<br />

Seoondl.yheating of the mixture<br />

- <strong>pa</strong>rticular13 if the drumwasrevolved - wouldresult in a moreeven<br />

distribution<br />

of moisture. This wouldcause an increase in the lubricating<br />

affect of moisture as food <strong>pa</strong>sses through the die.<br />

(ii) Moisture oontent of tood<br />

Thedrie'" the mixture - the tirater and easier to dry the pellet is -<br />

aocepting that the mixture has enoughmoisture in it to gelatise.<br />

Also the quicker the machineblocks and the slowet' the pr~ss<br />

of producing<br />

pellets becomes.<br />

Thewetter the mixture the less firm the pellet and the moredifficult<br />

it is to dry.<br />

Howeverthe maohineruns easier - less blocking.<br />

I workedVi th a moisture content of about 31fo. taking tresh fish<br />

to have a moisture content of ~<br />

and prawnheads «J1, (estimated)•<br />

•. ./2

Somefeeds, suchcas gl"OW1d maizemeal, are especial~<br />

useful in<br />

pellet produoingdie to their "Binding"quality. Therefore before<br />

a componentis introduced to the mixture take into account its binding<br />

qualities, this also appliea to rearwing a OOIlpollent froma mixture.<br />

(i)<br />

I access the "binding" qualities<br />

of our raw materials as follows:<br />

Fresh Fish - goodbinder, soales and bones don't alwq's grind-up<br />

very _11 re_!ting in larae <strong>pa</strong>riioals in the pellets - O&Usingwakness.<br />

J(a.Ybeif the fish was <strong>pa</strong>t through the grinder twioe the•• laraer<br />

<strong>pa</strong>riioals wouldbe reduced in size.<br />

(ii) Cotton Seed Cake- goodbinder (sometimestoo good).<br />

Howeverit aeeds grinding several times and even then SOll8<br />

<strong>pa</strong>riioals get through<br />

larae<br />

(iv) liaise Meal- difficult to gl"indto a _all OOllghsize to make<br />

use of its high "binding" quality.<br />

I amsare that heating of these three graia., as _gpsted before,<br />

wouldreSlllt in all inoreaae ill their bintiag qu.li tie. and therefore a<br />

firaer pellet.<br />

- Somethingworth looking into I think.

AD1 To try and determine the affeots of feeding "Home-produced"<br />

tood in oom<strong>pa</strong>risOD.With that manufactured by teed fins.<br />

I was allocated three tanks of fish. Tanks No. 8, 11 8Ild 12.<br />

Tank 8 was to be fed soleq 011 the "home- produced" pellets. TaDk:11<br />

was to be fed en both the "hoaae- produced" pellet<br />

and manufactured<br />

pellets, receiving each OD.alternate cta.Ys. TaDk 12 was a control,<br />

being fed the llaIlUfacturedpellets as normal. The "home-made"pellets<br />

•• tained the ingredients - fresh fish (tilapia)(3~) , cotton •• ed<br />

oake (3~).<br />

Wheatpollard (~) and liaise Gena •• al (34).<br />

The manufactured pellet8<br />

oontained a. siJDilar mix except that<br />

fish lIl8alwas used instead of fresh fish al'ldthe mi.mtre al80 oontained<br />

a vi taain <strong>pa</strong>ckage.<br />

No. • TABLI OP AVERAGE WEIGHT OF FISH IN' BACH 'lARK OYER<br />

'J.'BIEB 1fEIKS<br />

The average weight8 were deduced from sampleweighinge in which<br />

250 fish were taken from each tank and weighed.<br />

The average weight being worked out.<br />

Start Week1 Week2 Week111<br />

28/5/82 4/6/82 11/6/82 18/6/82<br />

234g 250g 237«<br />

192 192 llC\g<br />

170 182 194.8

Table 2: RESULTS OF CONDITION - FACTORS TAICDf ON 11/6/82<br />

(2 WEDCS Ali'l'ER START OF EXPERIMENT)<br />

10 males and 10 females were taken from each tank<br />

weighed accurately and their standard leng\b.s measured.<br />

From these figures can be deduced the condition factor.<br />

it being expressed as: ~ x 100<br />

(S.L )<br />

Tank No. Condition Factors ( X.F.)<br />

(Male) (Female) Average for both<br />

1 4.58 4.97 4.78<br />

2 4.74 4.82 4.78<br />

3 4.55 5.8 5.18<br />

4 4.76 5.33 5.05<br />

5 4.8 4.76 4.78<br />

6 4.72 4.99 4.86<br />

7 4.91 4.95 4.93<br />

8 4.11 4.23 4.17<br />

9 4.43 4.57 4.50 *small<br />

sample<br />

11 4.40 4.62 4.51<br />

12 4.47 4.78 4.63<br />

1) 4.67 5.42 5.05

This experiment oonclusivel,y proved little really.<br />

Although it does have scraevalue iD that it points out somefactors<br />

to be taken into aocount whena more thorough investigation take'<br />

place.<br />

(i) Workout a vitamin <strong>pa</strong>ckage for the future, so that the experiment<br />

can be carried out on younger fish. lhis experiment did not<br />

last long enough, to provide any.significant results. If the experiment<br />

oould be oarried out on fish that are going to remain in the<br />

production tanks for several months then a definite result oould be<br />

acquired.<br />

(ii) In the future use both oondition factors and sample weighinge to<br />

access the affects of the different feeds. Preferably start these<br />

before feeding the new feed, expeoiall,y the K.F. as this will give<br />

an iDdioation to changes in oondition.<br />

(iii) Also aonitor the amountof feed fed to the fish in terms ma.,ybe<br />

of: weight of feed as tJ, of boq weight and apply this to growth rate.<br />

(iv) Use similar tanks, I feel that the different flows and oxygen<br />

levels between tanks 8 and T8Ilks11 and 12 oou.ldhave had an effect on<br />

the results if they had been carried out for any length of time. The<br />

w..,.the fish in T&Ilk8 'beoame 80 stressed towards the end of the dq<br />

s~ly has an effect on their growth rates.<br />

Oyer a three week period.<br />

The hOlll8-G8de teed is not dangerous to fish, .,-be beiDg le8S<br />

harmtul than the lIW1ufaoturedpellet.