Halliburton Reservoir Contact Workflow

Halliburton Reservoir Contact Workflow

Halliburton Reservoir Contact Workflow

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HALLIBURTON<br />

<strong>Halliburton</strong> <strong>Reservoir</strong> <strong>Contact</strong> <strong>Workflow</strong><br />

Challenge<br />

Increasing hydrocarbon reserves requires a field development<br />

strategy that involves increasingly complex operations utilizing<br />

experienced personnel. Improving reservoir potential requires<br />

improving recovery rates without compromising the asset’s total<br />

economic life.<br />

Solved<br />

With the <strong>Reservoir</strong> <strong>Contact</strong> workflow, Sperry Drilling services has<br />

made the digital oilfield a reality. Combining our industry leading<br />

geosteering services with other leading <strong>Halliburton</strong> brands and<br />

services, we offer comprehensive field development solutions that<br />

address your asset’s unique challenges.<br />

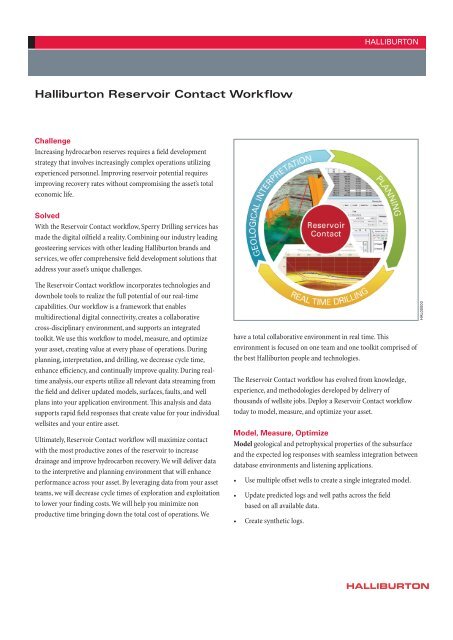

The <strong>Reservoir</strong> <strong>Contact</strong> workflow incorporates technologies and<br />

downhole tools to realize the full potential of our real-time<br />

capabilities. Our workflow is a framework that enables<br />

multidirectional digital connectivity, creates a collaborative<br />

cross-disciplinary environment, and supports an integrated<br />

toolkit. We use this workflow to model, measure, and optimize<br />

your asset, creating value at every phase of operations. During<br />

planning, interpretation, and drilling, we decrease cycle time,<br />

enhance efficiency, and continually improve quality. During realtime<br />

analysis, our experts utilize all relevant data streaming from<br />

the field and deliver updated models, surfaces, faults, and well<br />

plans into your application environment. This analysis and data<br />

supports rapid field responses that create value for your individual<br />

wellsites and your entire asset.<br />

Ultimately, <strong>Reservoir</strong> <strong>Contact</strong> workflow will maximize contact<br />

with the most productive zones of the reservoir to increase<br />

drainage and improve hydrocarbon recovery. We will deliver data<br />

to the interpretive and planning environment that will enhance<br />

performance across your asset. By leveraging data from your asset<br />

teams, we will decrease cycle times of exploration and exploitation<br />

to lower your finding costs. We will help you minimize non<br />

productive time bringing down the total cost of operations. We<br />

have a total collaborative environment in real time. This<br />

environment is focused on one team and one toolkit comprised of<br />

the best <strong>Halliburton</strong> people and technologies.<br />

The <strong>Reservoir</strong> <strong>Contact</strong> workflow has evolved from knowledge,<br />

experience, and methodologies developed by delivery of<br />

thousands of wellsite jobs. Deploy a <strong>Reservoir</strong> <strong>Contact</strong> workflow<br />

today to model, measure, and optimize your asset.<br />

Model, Measure, Optimize<br />

Model geological and petrophysical properties of the subsurface<br />

and the expected log responses with seamless integration between<br />

database environments and listening applications.<br />

• Use multiple offset wells to create a single integrated model.<br />

• Update predicted logs and well paths across the field<br />

based on all available data.<br />

• Create synthetic logs.<br />

HAL00000<br />

HALLIBURTON

HALLIBURTON<br />

Measure actual reservoir properties using any of our best in<br />

class downhole tools including: Azimuthal Lithodensity (ALD)<br />

Sensor, Insite ADR Azimuthal Deep Resistivity Sensor, Insite<br />

AFR Azimuthal Focused Resistivity Sensor, ABG<br />

(At-Bit Gamma) Sensor.<br />

• Correlate measured log responses with predicted logs.<br />

• Use logging-while-drilling data from real-time drilling<br />

operations to update geological models and plans.<br />

• Map distance to bed boundaries.<br />

Optimize wellbore paths across the asset to exploit most<br />

productive reservoir zones by updating geological interpretations<br />

to match actual subsurface measurements. Adjust your well paths<br />

to hit most productive zones. Benefit from complete data<br />

connectivity between Openworks®, InSite®, and EDM applications<br />

based on WITSML standards.<br />

• Geoscientists can optimize earth models in the<br />

OpenWorks database.<br />

• Drilling engineers can optimize well plans in EDM software.<br />

• Geosteering engineers can optimize real-time drilling<br />

plans in the InSite system.<br />

By monitoring real-time measurements from logging while<br />

drilling tools, our geosteering engineers can identify faults and<br />

bed boundaries that were not predicted and make adjustments to<br />

the well path to avoid non productive intervals. Bringing any<br />

consulting experience you need to your wellsite from across<br />

<strong>Halliburton</strong>, including Sperry, Project Management and<br />

Consulting, and Landmark Software and Services, we work with<br />

your asset team to share knowledge and produce results. We will<br />

update your grids, surfaces, and faults based on real-time<br />

measurements and send them to your OpenWorks and EDM<br />

environment so you can leverage the data streaming from our<br />

downhole tools in each wellsite to enhance the accuracy of<br />

operations around your asset.<br />

We will put your well bore in the precise location to maximize<br />

potential recovery, and deliver all data directly into your<br />

Landmark application environment including:<br />

• Structural model<br />

• Surfaces<br />

• Faults<br />

• Well picks<br />

• Control points<br />

• Fault picks<br />

To non-Landmark users, we deliver:<br />

• The structural model, including surfaces, in ZMAP<br />

format (does not include faults, well picks, control points,<br />

and fault picks)<br />

• All logging-while-drilling data<br />

We will deploy a <strong>Reservoir</strong> <strong>Contact</strong> workflow that’s customized<br />

according to your needs, directed or supported from any location:<br />

• Remotely from our real-time operating center<br />

• At your real-time operating center<br />

• Portable solution at your well site<br />

• Application hosting and onsite support<br />

For more information, contact your local <strong>Halliburton</strong> representative or<br />

visit us on the web at www.halliburton.com<br />

© 2011 <strong>Halliburton</strong>. All rights reserved. Sales of <strong>Halliburton</strong> products and services will be in accord solely with the terms and conditions contained in the<br />

contract between <strong>Halliburton</strong> and the customer that is applicable to the sale. H07920-A4 10/11<br />

www.halliburton.com<br />

HALLIBURTON