Download this Stacked Stone Wall article as a pdf - Handyman Club ...

Download this Stacked Stone Wall article as a pdf - Handyman Club ...

Download this Stacked Stone Wall article as a pdf - Handyman Club ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

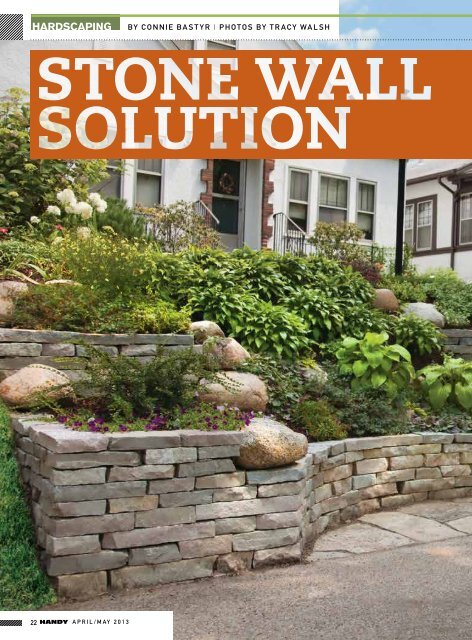

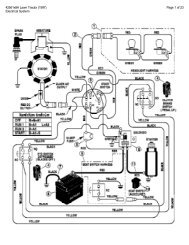

HARDSCAPING<br />

By COnnie b<strong>as</strong>tyr i Photos by tracY walsh<br />

22<br />

APRIL/MAY 2013

This stone retaining wall blends naturally<br />

into the hillside and complements<br />

the bungalow-style home beyond.<br />

No matter how small your yard,<br />

mowing a steep slope can be a<br />

dreadful t<strong>as</strong>k. And if you’re a m<strong>as</strong>ter<br />

gardener (like the owner of <strong>this</strong> city<br />

lot), you might enjoy grooming a series<br />

of beds rather than maneuvering<br />

a mower on a horrible hill. So when<br />

landscaper Scott Reynolds of Creative<br />

Habitats Inc. in Minnetonka, Minnesota,<br />

transformed <strong>this</strong> sloping lot with<br />

a series of beautiful stone walls, we<br />

documented the process to show you<br />

how it’s done.<br />

Although building a dry-stacked<br />

stone wall like <strong>this</strong> one is timeconsuming,<br />

it does not require special<br />

m<strong>as</strong>onry skills, and it can be less<br />

strenuous than working with manufactured<br />

concrete blocks, which are<br />

typically heavier than limestone.<br />

Scott and his crew of two tamed <strong>this</strong><br />

bank (with the help of some power<br />

equipment) in a little more than a<br />

week. Though it might take a bit longer,<br />

a handy DIYer can tackle <strong>this</strong><br />

project and create a timeless and enduring<br />

structure.<br />

HANDYMANCLUB.COM 23

tech art & design<br />

Getting ready<br />

In <strong>this</strong> dry-stacked wall, only the top<br />

course is set in mortar; gravity holds<br />

the other stones in place. The cut Chilton<br />

stones vary in thickness and length<br />

but are a uniform 8-in. width. Chilton<br />

is a type of limestone from Wisconsin<br />

that is available at most stone yards;<br />

you could also use other types of locally<br />

quarried limestone.<br />

For any stone wall that is higher than<br />

24 in., drain tile (surrounded by aggregate)<br />

must be installed.<br />

For inspiration, look at stone walls<br />

in your area and check out stone suppliers’<br />

displays to find types of rock<br />

and designs that you like. This wall is<br />

built in a b<strong>as</strong>ic running bond pattern<br />

in which all of the stones in each row<br />

are the same height, and the joints are<br />

staggered (strengthening the wall).<br />

Using a scale drawing and the dimensions<br />

of the rise and span of the<br />

hill (see “Design,” p. 26), Scott calculated<br />

the wall’s surface area and ordered<br />

20 percent more stone than<br />

the plan required to allow<br />

for w<strong>as</strong>te. (He also included<br />

the buried b<strong>as</strong>e layers<br />

of walls in his calculations.)<br />

Before you begin<br />

designing your wall, Scott<br />

recommends these preparatory<br />

steps:<br />

• Obtain a survey of your property<br />

to be sure your project<br />

fits within the boundaries.<br />

• Dial 8-1-1 to have utilities<br />

marked.<br />

• Tell your neighbors about the project<br />

beforehand; they’ll be more tolerant<br />

of the mess or any inconvenience and<br />

noise if they’re in on the plan.<br />

• Check with your city regarding code<br />

requirements, setbacks, etc., and<br />

about street restrictions for deliveries<br />

of stone and gravel.<br />

•Determine a convenient staging area<br />

for piling extra soil and supplies.<br />

• Know your soil. Is it sand or clay?<br />

• Collect all of the tools and gear you’ll<br />

need before you begin (see “Tool for<br />

the Project,” p. 28).<br />

Laying groundwork<br />

Cut stone is delivered in mixed<br />

lengths and thicknesses (ranging<br />

from about 2 in. to 3 in. thick), but<br />

each course of the wall must be made<br />

of stones of the same thickness. (Aesthetically<br />

and structurally, it’s best to<br />

use the thickest stones for the lower<br />

courses.) To save installation time,<br />

Scott sorts the stones into piles according<br />

to their thickness in 1/4-in.<br />

A<br />

B<br />

Add gravel backfill<br />

<strong>as</strong> each course<br />

of stone is completed.<br />

This allows you<br />

to completely and<br />

e<strong>as</strong>ily fill any gaps<br />

between the rocks<br />

before the row is<br />

covered by the next<br />

course.<br />

A power plate compactor is f<strong>as</strong>ter and<br />

more effective than hand tamping, and<br />

you can rent one from most home centers<br />

and rental companies. They weigh nearly<br />

200 pounds but move along e<strong>as</strong>ily when<br />

running. Wear hearing and eye protection,<br />

gloves and reinforced-toe boots.<br />

A maul’s top end<br />

is ideal for tamping<br />

down the high<br />

end of a stone or<br />

for packing smaller<br />

are<strong>as</strong> of gravel. The<br />

tool’s weight and<br />

long handle make<br />

it e<strong>as</strong>y to lift and<br />

drop, and the flat<br />

top works <strong>as</strong> a mini<br />

plate compactor.<br />

C<br />

24<br />

APRIL/MAY 2013

Digging in<br />

When terracing a hill, always work<br />

from the bottom up. The crew began<br />

by digging a 12-in.-wide x 7-in.-deep<br />

trench along the edge of the sidewalk,<br />

being careful not to disturb the soil<br />

below. They smoothed the b<strong>as</strong>e, making<br />

sure it w<strong>as</strong> level with the horizon<br />

(which is typically not parallel with the<br />

grade of the sidewalk).<br />

The next step is to spread a 2-in. layincrements<br />

before starting the project.<br />

The maximum allowed height for a<br />

dry-stacked stone wall is 4 ft. Because<br />

<strong>this</strong> site’s walls are less than 24 in.<br />

high, they do not require the installation<br />

of drain tile. If they were higher<br />

than 2 ft., they would have needed a<br />

perforated drainpipe under the b<strong>as</strong>e<br />

(see illustration, opposite), and the first<br />

12 in. of stones would need to be 18 in.<br />

wide front-to-back.<br />

er of compactable three-quarter-clear<br />

gravel, which is angular and contains<br />

no crushed material. The angled surfaces<br />

of the stones help to lock them<br />

in place, preventing shifting, and the<br />

absence of crushed material allows water<br />

to drain more e<strong>as</strong>ily. (Scott says you<br />

can use three-quarter-minus gravel for<br />

<strong>this</strong> purpose but only if you have sandy,<br />

good-draining soil.)<br />

Pack the 2-in. layer using a power<br />

Cutting stone<br />

For most of the project, you can pick<br />

through the stones to find a good fit,<br />

but sometimes you need a custom<br />

shape or size. You can use these<br />

methods for cutting stone:<br />

• Chisel and hammer (score and tap<br />

along the score line with the chisel<br />

several times)<br />

• Maul (whack and hope to get lucky)<br />

• Diamond-blade g<strong>as</strong> saw (rental)<br />

• Hydraulic splitter<br />

Get the free stone mobile app at<br />

splitter<br />

Some stones have visible grain lines that http:/ / gettag.mobi<br />

To watch Scott<br />

may indicate where they are likely to demonstrate how<br />

to use a hydraulic<br />

split, but in most c<strong>as</strong>es your results will<br />

stone splitter,<br />

depend on luck. You (and any bystanders<br />

or helpers) should always wear eye<br />

scan <strong>this</strong><br />

tag or visit<br />

<strong>Handyman</strong><strong>Club</strong>.<br />

and hearing protection when cutting or com/magazine.<br />

breaking stone. — CB<br />

D<br />

For times when<br />

a stone’s fit is<br />

almost (but not<br />

quite) perfect,<br />

Scott’s crew keeps<br />

a bucket of limestone<br />

chips handy<br />

to prop the gap.<br />

These shims become<br />

tightly affixed<br />

under the<br />

weight of the wall.<br />

E<br />

<strong>Stone</strong> shim<br />

F<br />

<strong>Stone</strong> shim<br />

Each row of stones is stepped back (battered)<br />

1/4 in. along the front faces. It’s a<br />

subtle graduation, apparent only when<br />

compared with a level. Battering adds significant<br />

strength to a dry-stacked wall.<br />

Put a stone sliver (shim) in any wedge-shape openings along the back sides; then fill<br />

behind it with gravel. The shim prevents gravel from sneaking through the spaces.<br />

HANDYMANCLUB.COM 25

G<br />

To adhere capstones, mortar is applied along the rear half of the previous row, filling<br />

voids and helping to lock the entire system and to protect the most vulnerable layer<br />

from being disturbed.<br />

Even though the<br />

ends of the return<br />

walls will be buried<br />

in soil (and in<br />

<strong>this</strong> c<strong>as</strong>e, abutted<br />

to concrete steps),<br />

they must have the<br />

same gravel b<strong>as</strong>e<br />

and backfill <strong>as</strong> the<br />

face walls.<br />

I<br />

H<br />

Lucky rock<br />

Fieldstone boulders complement the natural-stone walls and add height and interest to the<br />

planting are<strong>as</strong>. In some spots, the wall stone is shaped to wrap around the boulder (inset).<br />

J<br />

Wide gaps between<br />

the patio<br />

flagstones allow<br />

for future planting<br />

of moss or<br />

ground cover:<br />

The homeowner<br />

can simply remove<br />

pockets<br />

of the crushedgranite<br />

sand and<br />

add planting soil.<br />

plate compacter (photo A, p. 24), the top<br />

of a maul or a tamper. Add another 2 in.<br />

of gravel and pack again, continuing until<br />

you have a smooth, level 4-in.-thick<br />

b<strong>as</strong>e. (The remaining 3 in. of trench<br />

depth allows the first course of stone to<br />

be below grade.)<br />

Regardless of their finished height,<br />

stone walls require an 8- to 10-in.-wide<br />

layer of gravel behind them (photo B).<br />

This site h<strong>as</strong> clay soil, which is prone<br />

to hydrostatic pressure and can cause<br />

any retaining wall to bulge and heave,<br />

so Scott used three-quarter-clear gravel<br />

(not three-quarter-minus) behind the<br />

wall <strong>as</strong> well to allow rain and melting<br />

snow to drain.<br />

DESIGN<br />

“I always look at the house for patterns<br />

to mimic in the landscape.<br />

It’s important to consider the entire<br />

composition.”<br />

– Scott Reynolds, Creative Habitats<br />

Scott incorporated arcs in the shape<br />

of the wall partially to give the<br />

natural-stone structure an organic,<br />

flowing design, but also to reflect<br />

curves featured in the entrance area<br />

of the house. He used a 5-ft.-radius<br />

cutout for the patio area. (The center<br />

is about 18 in. from the sidewalk’s<br />

edge.) The same radius w<strong>as</strong> repeated<br />

in the two curved walls on the upper<br />

level. Although the patio side of<br />

the design is different from the wall<br />

on the opposite side of the steps, an<br />

overall balance is achieved through<br />

the careful placement of shrubs and<br />

plantings. — CB<br />

26<br />

APRIL/MAY 2013

Tools<br />

for the<br />

project<br />

In addition to shovels and levels, these are some essential<br />

hand tools for <strong>this</strong> type of project. Although<br />

none are motorized, most of them call for hearing<br />

protection, and all require protective eyewear.<br />

Hand<br />

guard<br />

Pick (pick mattock)<br />

This tool combines an ax<br />

head and a pick for chopping<br />

away at hard soil,<br />

roots and rocks before you<br />

shovel the soil out.<br />

Sledgehammer<br />

Its long handle and 10- to<br />

20-pound weight deliver<br />

great force for packing soil<br />

or gravel or pounding down<br />

a high spot in a stone.<br />

M<strong>as</strong>on’s hammer<br />

Also called a bricklayer’s<br />

hammer, <strong>this</strong> tool’s flat<br />

face and chisel-shape<br />

blade help to chip off<br />

edges of a stone.<br />

Wrecking bar<br />

It works <strong>as</strong> a lever to loosen<br />

and lift large boulders<br />

or adjust heavy stones, or<br />

you can use it <strong>as</strong> a pick to<br />

loosen hard soil.<br />

M<strong>as</strong>on’s chisel<br />

To score a cut line in<br />

stone, tap the top of a<br />

m<strong>as</strong>on’s chisel with a hammer;<br />

then deliver a heavy<br />

blow to split the stone.<br />

Setting stone<br />

As with any wall construction, the b<strong>as</strong>e<br />

course sets the stage for the rest of the<br />

project. For <strong>this</strong> first layer, you can use<br />

stones that have odd shapes or different<br />

thicknesses, <strong>as</strong> long <strong>as</strong> the top surfaces<br />

are all even and level. Just pound<br />

down any high spots using the top end<br />

of a maul (photo C, p. 24). Check for<br />

level front-to-back and side-to-side. (If<br />

you can’t get it perfect, err on the side<br />

of a slightly higher front edge than<br />

back.) Make each course level before<br />

you start the next layer — don’t plan to<br />

compensate for height differences later.<br />

As you install each stone, flip and turn<br />

it until you have a solid fit. You might<br />

need to try a different one for compatibility<br />

with neighboring stones and with<br />

the b<strong>as</strong>e. Set the front face of each new<br />

row 1/4 in. back from the previous row<br />

(photo D, p. 25).<br />

Natural stones’ irregular shapes<br />

sometimes make a slight “rocking”<br />

movement unavoidable. You can compensate<br />

by shimming with a stone chip<br />

(called chinking) under the offending<br />

rock (photo E). Where needed, you can<br />

knock off protruding edges of stones<br />

with a maul. Try to avoid leaving gaps<br />

between neighboring stones, but where<br />

they occur, fill vertical spaces with a<br />

stone chip and gravel (photo F).<br />

Use various sizes of levels to check<br />

each stone <strong>as</strong> you install it, adjusting for<br />

level front-to-back and side-to-side. Continue<br />

to backfill with gravel <strong>as</strong> you add<br />

each new course. Scott did not install<br />

landscape fabric because it tends to prevent<br />

drainage and to build hydrostatic Adding outcroppings<br />

pressure — especially in clay soil. If your To help support mounds of soil and<br />

soil is very sandy, you can add landscape plants within each tier, Scott placed<br />

fabric between the gravel backfill and the small boulders <strong>as</strong> outcroppings within<br />

soil behind it. Do not lay fabric directly the tiers (photo I). Strategically set to<br />

against the back of the wall.<br />

support the greatest elevation changes,<br />

For the top course (called capstones), these rocks are partially submerged in<br />

Scott used the thinner (2-in.) stones, the soil to help them stay in position.<br />

being careful to fit the shapes together (One of these boulders w<strong>as</strong> a lucky find:<br />

well (see “Cutting <strong>Stone</strong>,” p. 25). Once When excavating the patio area, Scott<br />

the entire top course w<strong>as</strong> in place, he discovered a large rock buried right in<br />

folded back the row of capstones and the spot where he had planned for one!)<br />

applied mortar (photo G, p. 26) before A small patio created along the sidewalk<br />

(photo J) provides room for potted<br />

pressing them in place. To prevent<br />

soil from seeping p<strong>as</strong>t the top layer of plants or a small sitting area. The flagstone<br />

floor w<strong>as</strong> laid over a 1-in.-thick<br />

stone, you can pack mortar along the<br />

back of the capstone row <strong>as</strong> well. ) b<strong>as</strong>e of compacted granite sand which,<br />

To allow room for a layer of soil and like the gravel used for b<strong>as</strong>e in the walls,<br />

plants, stop adding gravel backfill when is angular rather than rounded so it<br />

you’re 5 in. shy of the top of the wall. You locks together and stays in place. Once<br />

may choose to place landscape fabric on the 1-1/2- to 2-in.-thick flagstones were<br />

top of the gravel before adding the soil. in place, gaps between them were filled<br />

with more granite sand.<br />

Building up<br />

The upper walls are constructed like<br />

the first: Dig a trench, pack in a 4-in.-<br />

thick gravel b<strong>as</strong>e and install level<br />

courses of stone with 8 to 10 in. of<br />

gravel backfill behind. Dig the trench<br />

deep enough that the top of the b<strong>as</strong>e<br />

course is level with (or slightly lower<br />

than) the capstone of the lower wall.<br />

The return walls (the sections that Get the free Proper mobile app at<br />

Planting<br />

run alongside the steps and into the hill) http:/ / gettag.mobi<br />

To see a planting<br />

need to extend into the soil at le<strong>as</strong>t 6 in.<br />

secret from<br />

m<strong>as</strong>ter gardener<br />

beyond their exposed portions (photo H).<br />

Amy Sitze, scan<br />

The hidden portions must also be supported<br />

with packed gravel and a course<br />

com/magazine.<br />

<strong>this</strong> tag to or visit<br />

<strong>Handyman</strong><strong>Club</strong>.<br />

of b<strong>as</strong>e stone.<br />

28<br />

APRIL/MAY 2013