Dual Poly Liner Mobility Optimizes Wear and Stability in THA - Healio

Dual Poly Liner Mobility Optimizes Wear and Stability in THA - Healio

Dual Poly Liner Mobility Optimizes Wear and Stability in THA - Healio

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

■ Emergent Hip Technologies?<br />

A<br />

dual-mobility acetabular component<br />

consists of a large, fixed,<br />

porous-coated acetabular component<br />

<strong>and</strong> a bipolar femoral component<br />

(Figure 1). These components are often<br />

called tripolar components. This configuration<br />

provides a stable, well-fixed<br />

implant platform aga<strong>in</strong>st bone <strong>and</strong> 2 articular<br />

<strong>in</strong>terfaces, a large polyethylene surface<br />

directly apposed to a highly polished<br />

metal implant, <strong>and</strong> a st<strong>and</strong>ard-sized (28-<br />

or 32-mm) femoral head captured with<strong>in</strong><br />

polyethylene (Figure 2). This concept<br />

was conceived, developed, <strong>and</strong> described<br />

by the French orthopedic surgeon, Gilles<br />

Bousquet, <strong>in</strong> 1976. 1<br />

The dual-mobility implant was developed<br />

to reduce the <strong>in</strong>cidence of dislocation<br />

<strong>in</strong> patients at risk of <strong>in</strong>stability who required<br />

total hip arthroplasty (<strong>THA</strong>). Patients at <strong>in</strong>creased<br />

at risk may <strong>in</strong>clude those: (1) older<br />

than 75 years; (2) who have had prior hip<br />

surgery; (3) with neuromuscular diseases;<br />

(4) with cognitive dysfunction; <strong>and</strong> (5) with<br />

American Society of Anesthesiologists<br />

scores 3. Hip <strong>in</strong>stability rema<strong>in</strong>s one of<br />

the most common causes of <strong>THA</strong> failure,<br />

especially follow<strong>in</strong>g revision <strong>THA</strong>.<br />

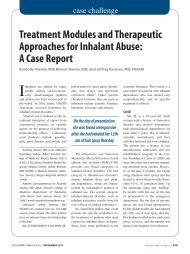

The dual-mobility acetabular component<br />

potentially provides substantially<br />

greater range of motion than conventional<br />

articulations with large femoral heads<br />

(Figure 3). This theoretical protection <strong>in</strong><br />

stability has been confirmed <strong>in</strong> a number<br />

of studies (Table 1). 1 The dual-mobility<br />

cup has also been used successfully <strong>in</strong> revision<br />

<strong>THA</strong>, where the dislocation rate us<strong>in</strong>g<br />

conventional, nonconstra<strong>in</strong>ed implants<br />

may be 10% to 20% (Table 2). This high<br />

rate of stability achieved with the dualmobility<br />

cup <strong>in</strong> patients at <strong>in</strong>creased risk<br />

of dislocation has been accompanied by a<br />

survival rate that compares favorably with<br />

<strong>THA</strong> us<strong>in</strong>g conventional, unconstra<strong>in</strong>ed<br />

articular surfaces (Table 3). 2<br />

Recent modifications of the orig<strong>in</strong>al<br />

dual-mobility implant have sought to <strong>in</strong>crease<br />

the durability of the device, reduce<br />

the potential for soft tissue imp<strong>in</strong>gement<br />

that might be associated with the orig<strong>in</strong>al<br />

prosthesis, <strong>and</strong> <strong>in</strong>crease the flexibility of<br />

the acetabular shell.<br />

The dual-mobility design us<strong>in</strong>g firstgeneration<br />

cross-l<strong>in</strong>ked polyethylene has<br />

been shown to reduce polyethylene wear<br />

to rates below those reported for conventional<br />

articulations us<strong>in</strong>g conventional<br />

polyethylene. Moreover, when the dualmobility<br />

concept is paired with the current<br />

generation of highly cross-l<strong>in</strong>ked polyethylene,<br />

the wear rates are 97% lower than<br />

those obta<strong>in</strong>ed with the first-generation<br />

cross-l<strong>in</strong>ked polyethylene <strong>in</strong> dual-mobility<br />

cups (Figure 4).<br />

The orig<strong>in</strong>al dual-mobility acetabular<br />

shell was hemispherical. This design, especially<br />

<strong>in</strong> larger sizes, had the potential to<br />

be associated with iliopsoas imp<strong>in</strong>gement.<br />

An anatomic shell has been developed that<br />

seeks to avoid this complication. A surgical<br />

technique with dedicated <strong>in</strong>strumentation<br />

has been developed to optimize the<br />

<strong>in</strong>sertion of this shell.<br />

A major drawback of the orig<strong>in</strong>al<br />

monoblock dual-mobility <strong>and</strong> monoblock<br />

anatomic variation of the acetabular<br />

shell has been the <strong>in</strong>ability to augment the<br />

press-fit fixation with cancellous screws.<br />

Moreover, the monoblock versions require<br />

surgeons to use a unique implant<br />

that is not rout<strong>in</strong>ely a part of an operat<strong>in</strong>g<br />

room acetabular cell <strong>in</strong>ventory. In the past<br />

6 months, a modular dual-mobility shell<br />

has become available (Figure 5). St<strong>and</strong>ard<br />

hemispherical shells can be converted to<br />

a dual-mobility implant with the <strong>in</strong>sertion<br />

of a highly polished, th<strong>in</strong> metal <strong>in</strong>sert that<br />

articulates with the bipolar polyethylene<br />

femoral head. Thus, a st<strong>and</strong>ard acetabular<br />

design that is rout<strong>in</strong>ely stocked by<br />

hospitals, is familiar to orthopedic surgeons,<br />

<strong>and</strong> is <strong>in</strong>serted us<strong>in</strong>g conventional<br />

<strong>in</strong>strumentation can be converted <strong>in</strong>traoperatively<br />

to a dual-mobility cup if additional<br />

stability is needed. This modular<br />

1<br />

2<br />

3<br />

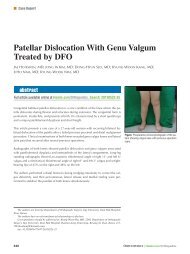

Figure 1: Fixed porous shell <strong>and</strong> bipolar femoral component. Figure 2: The 3 components of a dual mobility cup: fi xed porous shell, polyethylene bipolar component,<br />

<strong>and</strong> femoral head. Figure 3: Potential range of motion of a dual-mobility cup (ADM) vs conventional articulations with large femoral heads.<br />

e446<br />

ORTHOPEDICS | ORTHOSuperSite.com