CONVEYING TECHNOLOGY LOADING ... - BEUMER Group

CONVEYING TECHNOLOGY LOADING ... - BEUMER Group

CONVEYING TECHNOLOGY LOADING ... - BEUMER Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

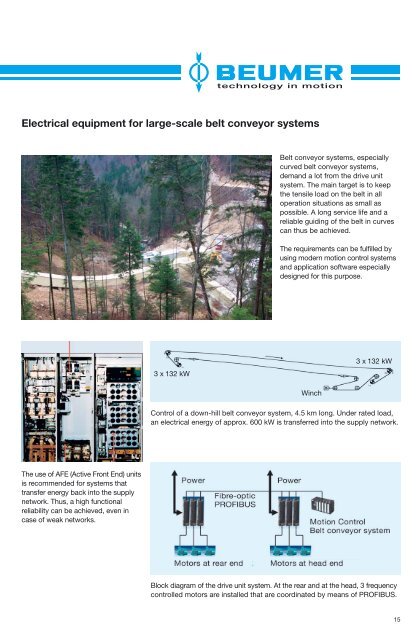

Electrical equipment for large-scale belt conveyor systems<br />

Belt conveyor systems, especially<br />

curved belt conveyor systems,<br />

demand a lot from the drive unit<br />

system. The main target is to keep<br />

the tensile load on the belt in all<br />

operation situations as small as<br />

possible. A long service life and a<br />

reliable guiding of the belt in curves<br />

can thus be achieved.<br />

The requirements can be fulfilled by<br />

using modern motion control systems<br />

and application software especially<br />

designed for this purpose.<br />

3 x 132 kW<br />

3 x 132 kW<br />

Winch<br />

Control of a down-hill belt conveyor system, 4.5 km long. Under rated load,<br />

an electrical energy of approx. 600 kW is transferred into the supply network.<br />

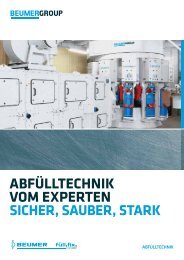

The use of AFE (Active Front End) units<br />

is recommended for systems that<br />

transfer energy back into the supply<br />

network. Thus, a high functional<br />

reliability can be achieved, even in<br />

case of weak networks.<br />

Block diagram of the drive unit system. At the rear and at the head, 3 frequency<br />

controlled motors are installed that are coordinated by means of PROFIBUS.<br />

15