Process Control System

Process Control System

Process Control System

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

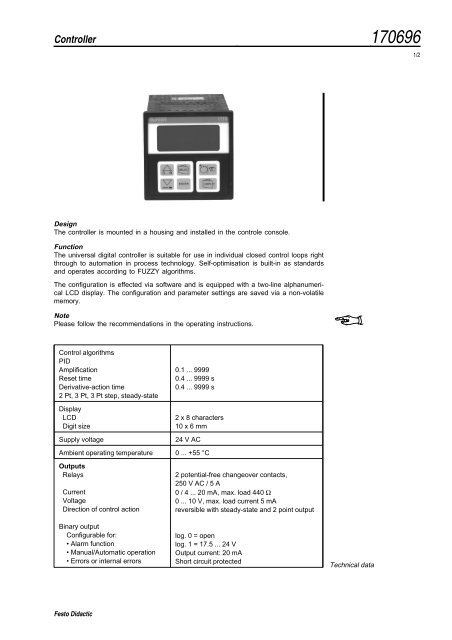

<strong>Control</strong>ler 170696<br />

1/2<br />

Design<br />

The controller is mounted in a housing and installed in the controle console.<br />

Function<br />

The universal digital controller is suitable for use in individual closed control loops right<br />

through to automation in process technology. Self-optimisation is built-in as standards<br />

and operates according to FUZZY algorithms.<br />

The configuration is effected via software and is equipped with a two-line alphanumerical<br />

LCD display. The configuration and parameter settings are saved via a non-volatile<br />

memory.<br />

Note<br />

Please follow the recommendations in the operating instructions.<br />

<strong>Control</strong> algorithms<br />

PID<br />

Amplification<br />

Reset time<br />

Derivative-action time<br />

2 Pt, 3 Pt, 3 Pt step, steady-state<br />

0.1 ... 9999<br />

0.4 ... 9999 s<br />

0.4 ... 9999 s<br />

Display<br />

LCD<br />

Digit size<br />

Supply voltage<br />

2 x 8 characters<br />

10 x 6 mm<br />

24 V AC<br />

Ambient operating temperature 0 ... +55 °C<br />

Outputs<br />

Relays<br />

Current<br />

Voltage<br />

Direction of control action<br />

2 potential-free changeover contacts,<br />

250 V AC / 5 A<br />

0 / 4 ... 20 mA, max. load 440 Ω<br />

0 ... 10 V, max. load current 5 mA<br />

reversible with steady-state and 2 point output<br />

Binary output<br />

Configurable for:<br />

• Alarm function<br />

• Manual/Automatic operation<br />

• Errors or internal errors<br />

log. 0 = open<br />

log. 1 = 17.5 ... 24 V<br />

Output current: 20 mA<br />

Short circuit protected<br />

Technical data<br />

Festo Didactic