ANDRITZ annual report 2012 - ANDRITZ Vertical volute pumps

ANDRITZ annual report 2012 - ANDRITZ Vertical volute pumps

ANDRITZ annual report 2012 - ANDRITZ Vertical volute pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

38<br />

the SuStainaBle Spirit oF eldorado<br />

Eldorado Brasil started up the world’s largest single pulp production line with a design capacity of 1.5 million tons per<br />

year in November <strong>2012</strong>. With a single investment, this new company is on its way to becoming the fifth largest producer<br />

of hardwood pulp in the world. More importantly, the mill is designed to be sustainable at all stages of the process,<br />

having been equipped with the best available technologies and best practices in sustainability.<br />

Located near Três Lagoas, Mato Grosso do Sul state, Brazil, the Eldorado mill construction and start-up was overseen<br />

by a very small internal group, relying very much on the expertise of EPC (Engineering, Procurement, and Construction)<br />

partners like <strong>ANDRITZ</strong>.<br />

The scope of <strong>ANDRITZ</strong>’s delivery was the woodyard (three chipping lines and the chip storage systems), the fiberline<br />

(the world’s largest digester, washing, screening, and bleach plant), the drying/baling plant (two pulp drying systems<br />

with automated baling lines), and the white liquor plant (preparation of cooking chemicals and the largest lime kiln in<br />

South America). In addition, <strong>ANDRITZ</strong> supplied its IDEAS simulator and web-based training tools to prepare the local<br />

operators for taking over the plant.<br />

The technical challenge on this project was one of scale. The main production technologies have been proven in<br />

other installations, as Eldorado did not want to take risks with prototypes of unproven systems in this large single-line<br />

installation. But, the scale-up of the technologies to this world-record volume of production was critical. Many of these<br />

systems are the largest ever manufactured by <strong>ANDRITZ</strong> or any other supplier.<br />

Environmental sustainability is ensured through sustainable forestry and pulp production practices. Systems for spill<br />

control and the minimal release of air and water emissions are best available technologies. Social sustainability as<br />

practiced by Eldorado is also more than empty words in an <strong>annual</strong> <strong>report</strong>. The company is reaching out to the local<br />

communities with projects combatting child abuse, improving the schools, and supporting local programs that are far<br />

removed from the business of making pulp.<br />

The Eldorado mill is one of the largest private investments in Brazil. At its height, there were close to 8,000 construction<br />

workers in the area and the mill provides permanent employment to thousands when the forestry operations are<br />

taken into account.<br />

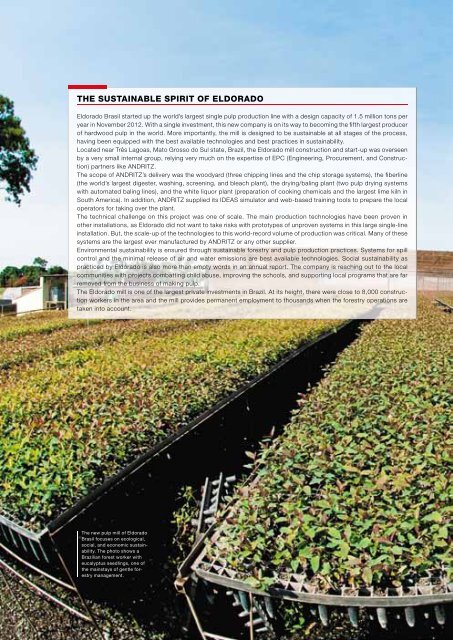

The new pulp mill of Eldorado<br />

Brasil focuses on ecological,<br />

social, and economic sustainability.<br />

The photo shows a<br />

Brazilian forest worker with<br />

eucalyptus seedlings, one of<br />

the mainstays of gentle forestry<br />

management.