ANDRITZ annual report 2012 - ANDRITZ Vertical volute pumps

ANDRITZ annual report 2012 - ANDRITZ Vertical volute pumps

ANDRITZ annual report 2012 - ANDRITZ Vertical volute pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ANDRITZ</strong> AUTOMATION<br />

59<br />

Electronic automation has changed the profile of workers<br />

needed to operate machines such as the drying line<br />

in Três Lagoas, with a clear shift from blue-collar<br />

to fewer, but more highly qualified white-collar<br />

positions. Quality control, fault finding, speed regulation<br />

– all work that would previously have been carried<br />

out by hand by a team of workers, is now overseen by<br />

a much smaller group via computer. “In emerging<br />

countries like Brazil, these positions are very<br />

highly valued – it is seen as an exciting opportunity<br />

to learn new skills,” Schiefer explains. By<br />

reducing the need for hands-on work on what can often<br />

be potentially dangerous machinery, automation has<br />

also greatly reduced the number of accidents at production<br />

sites.<br />

These same benefits from automation also help protect<br />

the environment. Fewer production stoppages reduce<br />

the need to carry out repeated machinery start-ups and<br />

shut-downs, which result in higher emissions. <strong>ANDRITZ</strong><br />

also incorporates emission tracking technology, enabling<br />

operators to see precisely how much energy they<br />

are using and what it costs – “a powerful tool in educating<br />

staff and raising awareness,” Schiefer comments.<br />

With restrictions on harmful emissions on the rise, this<br />

can also help companies adhere to environmental laws<br />

and guidelines, avoiding costly fines.<br />

Will man ever be totally replaced by machine? This is<br />

a question often asked, says Schiefer, but he thinks<br />

not, at least not in the foreseeable future. “The human<br />

element is vital for safety reasons. One of the major<br />

trends is looking toward utilizing web-based technology,<br />

which brings increased flexibility, allowing us to<br />

access data and control systems remotely via tablets. It<br />

will become less important for humans to be where the<br />

plant is, but they will remain involved in other ways.”<br />

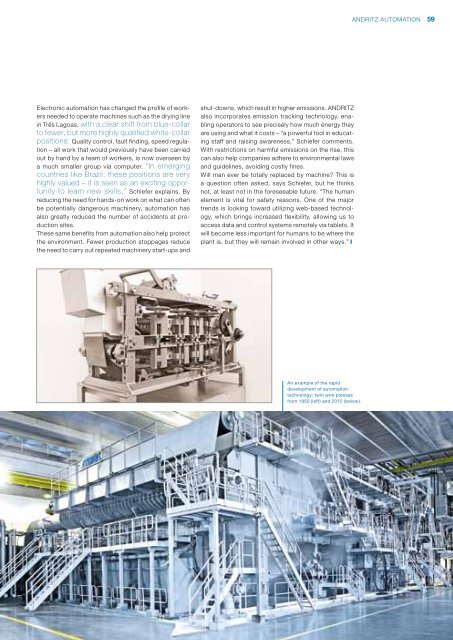

An example of the rapid<br />

development of automation<br />

technology: twin wire presses<br />

from 1950 (left) and <strong>2012</strong> (below).