Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R<br />

<strong>IMER</strong> U.S.A. inc.<br />

Model 1106080<br />

HENCHMAN 2 <strong>HSM</strong><br />

MANUAL INSTRUCTION<br />

and<br />

PARTS LIST<br />

Manual Part. number 3225399 - 2005<br />

Machine serial N°<br />

Write in the serial n° of yuor machine here

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

Thank-you for purchasing a <strong>Henchman</strong> 2<strong>HSM</strong> from an Imer U.S.A. dealwidther. Your decision<br />

is an intelligent one.<br />

There is no other mortar mixer in the world which delivers the benefits and features of the<br />

<strong>Henchman</strong> 2 <strong>HSM</strong>.<br />

- Extremely rigid, mig welded bar steel frame.<br />

.<br />

- 8 H.P. Honda with low oil alert.<br />

- Full width fenders.<br />

- Torsion Bar suspension.<br />

- Advance paddle design, excellent mixing and discharge action.<br />

At Imer U.S.A. we continually search for ways to better serve our customers. Should you have<br />

an idea or thought to share with us regarding this product we would appreciate hearing from<br />

you. Our motto is "Tools and Services for the 21st Century" . We look forward to delivering<br />

the goods.<br />

Thank you again for your purchase.<br />

Mace T. Coleman, Jr.<br />

President, Imer U.S.A., Inc.<br />

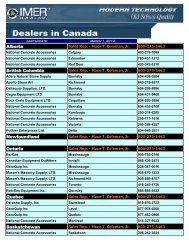

<strong>IMER</strong> WEST<br />

207 Lawrence Avenue<br />

So. San Francisco, CA 94080<br />

Tel 650 - 872 - 2200<br />

Fax 650 - 873 - 6482<br />

<strong>IMER</strong> EAST<br />

221 Westhampton Place<br />

Capitol Heights, MD 20743<br />

Tel 301 - 336 - 3700<br />

Fax 301 - 336 - 6687<br />

- 2 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

Table of Contents<br />

<strong>IMER</strong> U.S.A., INC.<br />

HENCHMAN 2<strong>HSM</strong><br />

INSTRUCTION MANUAL<br />

NOTE: Please read this manual before beginning to<br />

assemble or operate this piece of equipment.<br />

ASSEMBLY ........................................................................................ 5<br />

IMPORTANT NOTES AND ADVICE .................................................. 6<br />

OPERATING INSTRUCTIONS ........................................................... 8<br />

MAINTENANCE.................................................................................. 9<br />

BASIC TROUBLE SHOOTING - TECHNICAL SPECIFICATIONS ... 11<br />

SPARE PARTS........................................................................................12<br />

- 3 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

8<br />

5<br />

7<br />

6<br />

4<br />

2<br />

A<br />

A<br />

1<br />

3<br />

9<br />

FIG.1<br />

1) MESCOLATORE AD ASSE ORIZZONTALE<br />

2) GRIGLIA DI CARICO<br />

3) DUMP WHEEL<br />

4) SCOCCA PORTANTE SU RUOTE<br />

5) SICUREZZA GRIGLIA MESCOLATORE<br />

6) MOTORE DIESEL<br />

7) SERBATOIO CARBURANTE<br />

8) SERBATOIO OLIO<br />

9) TIMONE<br />

- 4 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

ASSEMBLY<br />

+<br />

TOWING<br />

Essentially the <strong>Henchman</strong> 2hsm is f ully assembled and ready to operate when it leaves the assembly<br />

facility here at Imer U.S.A. However, there are a couple items which should always be checked before<br />

towing the <strong>Henchman</strong> 2<strong>HSM</strong><br />

1. Make sure each tire is inflated to 62 PSI (cold), and check the oil level of the Honda motor.<br />

2. Make certain that the tow bar is properly anchored and its tow chain is in place. It is also important<br />

to loop the tow chain around the tow bar several times before connecting it to a vehicle.<br />

3. Make sure the engine canopy door is latched shut.<br />

4. Make certain that the hitch system on your car or truck is compatible to the tow bar tongue.<br />

5. Finally, local laws and ordinances vary from state to state regarding the registration of towable<br />

construction equipment, check and see if a license plate is required. Call your local Department of<br />

Motor Vehicles for the proper procedure to follow.<br />

NOTE<br />

State law may also require a tail light assembly.<br />

Check with your local Department of Motor Vehicles for the proper procedure to follow.<br />

- 5 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

IMPORTANT NOTES AND ADVICE<br />

Do's and Don'ts on the Safe Use<br />

of the <strong>Henchman</strong> 2<strong>HSM</strong><br />

In the interest of safety, whoever uses the <strong>Henchman</strong> 2<strong>HSM</strong> should first read this manual and become<br />

familiar with all of the important safety notes. Failure to follow this advice may result in injury to<br />

yourself and others.<br />

WHAT TO DO !<br />

- Carefully read and understand these instructions before operating the mixer.Read the Honda manual too.<br />

- Always turn off the engine and disconnect the spark plug wire before cleaning or maintaining the mixer.<br />

Mixers powered by electric motors should be unplugged from their power source before servicing is<br />

performed.<br />

- Make sure the safety guards are always in place.<br />

- When using the machine always wear safety boots with reinforced toe-caps, safety glasses, gloves,<br />

hard hat, and clothing with the appropriate fit. Loose clothing can cause injury should it become entangled<br />

with the mixer.<br />

- Practice starting and stopping the machine.<br />

- Keep the mixer clean and free of debris build-up.<br />

- Periodically inspect your mixer for abnormal wear or damage.<br />

- Always stop the engine before adding fuel.<br />

- Do not operate the mixer while under the influence of drugs or alcohol.<br />

- Always operate the mixer on a level surface.<br />

- 6 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

IMPORTANT NOTES AND ADVICE<br />

WHAT NOT TO DO !<br />

DO NOT<br />

Place your hands or any other object inside the mixer drum while it is running.<br />

DO NOT<br />

Operate the mixer on a surface that is UNEVEN.... if the <strong>Henchman</strong> is placed on an incline, it can fall<br />

over or roll away.<br />

DO NOT<br />

Clean, assemble or work on the mixer while it is plugged in !<br />

DO NOT<br />

Operate the mixer with the guard lifter disconnected or the guard removed.<br />

DO NOT<br />

Operate the mixer in or around water puddles !<br />

DO NOT<br />

Leave the mixer unattended !<br />

DO NOT<br />

Allow other persons around the mixer while it is operating<br />

DO NOT<br />

Operate the <strong>Henchman</strong> 2<strong>HSM</strong> if you are uncertain as to how to run the machine.... Contact your local<br />

Imer Distributor or call Imer U.S.A. at 800 - 275 - 5463<br />

DO NOT<br />

Operate the mixer while under the influence of drugs or alcohol !<br />

WE WANT SAFE AND EFFICIENT<br />

PRODUCTION/OPERATION<br />

FOR ALL OUR CUSTOMERS !<br />

- 7 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

OPERATING INSTRUCTIONS<br />

1. Before starting the engine read the Honda manual provided and become familiar with the GX240<br />

powerplant. Especially important is to check the oil level daily and change it monthly. Additionally,<br />

cleaning the air filter weekly ensures consistently good performance.<br />

2. Operate the the <strong>Henchman</strong> 2<strong>HSM</strong> on a level surface.<br />

LOADING POSITION<br />

DUMPING POSITION<br />

3. To put the drum in the loading position rotate the dump wheel until the desired drum position is<br />

achieved.<br />

4. Start the engine and set the throttle at 3/4 to full on.<br />

FIG.2<br />

5. Now add 1/2 of the water which will be required, add half aggregates, the total cement or lime, and<br />

then the balance of the sand and water. Mix for the proper lenght of time untill an homogeneous<br />

mix is obtained.<br />

BE CAREFUL ! Always wear splash goggles when operating the mixer. Failure<br />

to do so will allow foreign particles to enter the eyes.<br />

BE CAREFUL ! Do not operate the mixer with the guard lifter disconnected or<br />

the guard removed. Do Not put your shovel or your hands inside the drum !<br />

- 8 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

6. To put the drum in the discharge position rotate the dump wheel untill the desired drum position is<br />

achieved.<br />

7. During the loading, mixing, and discharge cycle it is important to keep the mixer running at all times.<br />

8. Always prepare your work site to have a level ground surface, the Mixer must be stable as you load and<br />

discharge the drum.<br />

9. If no more mortar mixer is to be mixed in the next hours, the mixer should be cleaned inside and outside.<br />

To clean the mixer shut the engine off, keep drum guard with guard lifter connected, spray mixer with water untill<br />

it is cleaned, discharge the debris. Do not beat on the drum with a showel, hammer or other device to break up<br />

accumulations of dried mix, s this will dent and damage the drum and void the warranty.<br />

Lubrication<br />

MAINTENANCE<br />

1. All the components on the mixer which engage or move back and forth should be lubricated with grease<br />

on a weekly basis (fig3). Grease on a daily basis using any Grade #1 lithium base grease, the drum<br />

shaft seals.<br />

LUBRICATE ON A<br />

WEEKLY BASIS<br />

FIG.3<br />

2. Essentially the gearbox is sealed for life.The quality of the gears and the lubricant are such that changing<br />

the oil is not necessary. If you want to change the oil,see your dealer or call <strong>IMER</strong> U.S.A directly for<br />

instruction.<br />

3. One a year remove the cast cap from the top half of the dump gear assembly and grease it up good.<br />

(Part 4 page 16)<br />

Belt Tension<br />

1. The mixer has two belts in the canopy. The belts are properly adjusted before leaving our factory,<br />

however, it is a good idea to check their tension before operating the mixer. Then, when one belt<br />

becomes loose, tighten it back to this original condition.<br />

- 9 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

NOTE<br />

The belts will stretch the most during the first few hours of<br />

operation .... check them frequently, and always kill the<br />

motor and disconnect the spark plug wire before touching<br />

the belts. Or, if your machine has an electric motor, unplug<br />

it from the power source before adjusting the behs.<br />

2.To tighten the belt inside the canopy loosen the bolts which anchor the motor mount plate to<br />

the mixer frame. This allows the motor mount plate to slide down the frame, which in turn<br />

tightens the belt.The belt should have 1/4" to 3/8" of play. Now re-tighten the bolts which<br />

anchor the motor mount plate.<br />

NOTE<br />

It is very important to keep the engine pulley and the<br />

drive pulley in line with one another. Failure to<br />

maintain this alignment will cause the belt to twist and<br />

then break.<br />

MISC.<br />

Every month check all the mixer's mounting hardware to<br />

ensure all the nuts and bolts are properly tightened.<br />

Wheel Bearings<br />

1. The wheel bearings should be cleaned and repacked every 6 months to 1 year. The interval being<br />

dependant upon the amount of time the machine is towed, and under what conditions. This<br />

maintenance procedure is the same as that for automotive wheel bearings.<br />

Engine<br />

Read the Honda manual carefully ... and follow their instructions.<br />

Changing the oil and cleaning the air filter frequently ensure a reliable and long lasting motor.<br />

When you may need Honda Engine Service or Warranty Assistance, take the machine to your local Honda<br />

power equipment dealer, they will honor the warranty throughout America.<br />

NOTE<br />

It is always a good idea to check the oil level in the<br />

engine crankcase at the start of each working day.<br />

Clean oil at the correct level makes for a engine that<br />

will last and last.<br />

Mixer’s drum disassembly and re-assembly<br />

In case it’s necessary to remove the drum, to change the shaft seals, it’s necessary.<br />

- to remove the canopy, the gear box, the drum paddles.<br />

- to remove the drum from the frame.<br />

- to remove the shaft supports.<br />

- 10 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

TECHNICAL SPECIFICATIONS<br />

HENCHMAN 2<strong>HSM</strong><br />

DRUM CAPACITY<br />

8 CU. FT.<br />

BATCH OUTPUT<br />

6 CU. FT.<br />

DRUM DIAMETER 24"<br />

DISCHARGE OUTLET HEIGHT 28"<br />

PNEUMATIC WHEELS<br />

62PSI<br />

POWER PLANTS 8 HP HONDA GX 240<br />

OVERALL OPERATING DIMENSIONS<br />

OVERALL STORAGE DIMENSIONS<br />

WEIGHT<br />

76"X49"X57"<br />

76"X49"X57"<br />

650 Lb<br />

*Capacity based upon usable volume<br />

Due to Imer U.S.A. 's commitment to<br />

Reasearch and Development,<br />

specifications are subject<br />

to change without notice.<br />

- 11 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

SPARE PARTS<br />

- 12 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

GENERAL STRUCTURE<br />

16<br />

16<br />

21<br />

22<br />

15<br />

24<br />

17<br />

23<br />

9<br />

3<br />

5<br />

13<br />

4<br />

14<br />

12<br />

10<br />

1<br />

2<br />

18<br />

6<br />

25<br />

27<br />

11<br />

20<br />

26<br />

7<br />

8<br />

19<br />

TAB 1<br />

- 13 -

T A B .3<br />

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

M IX IN G T A N K<br />

R if. C o d . D E S C R IP T IO N<br />

1 3 2 2 5 4 2 8 F R O N T U P P E R C U T<br />

2 3 2 2 5 9 8 6 F R A M E<br />

3 3 2 0 6 6 3 3 R E A R TA N K S U P P O R T<br />

4 3 2 0 9 0 0 9 F R O N T TA N K S U P P O R T<br />

5 3 2 2 5 3 6 9 M IX IN G M A C H IN E TA N K<br />

6 3 2 2 5 3 8 6 A X L E S U P P O R T<br />

7 2 2 4 8 2 1 6 A X L E<br />

8 2 2 11 4 0 7 W H E E L 4 .5 0 -1 0 4 F<br />

9 3 2 2 5 3 4 7 TA N K R E D U C T O R U N IT<br />

1 0 3 2 2 5 3 8 3 R H R E D U C T O R U N IT S U P P O R T<br />

11 T ILT IN G R E D U C T IO N U N IT<br />

1 2 3 2 2 5 4 5 9 E N G IN E S U P P O R T B R A C K E T<br />

1 3 2 2 7 5 7 5 2 E N G IN E (H O N D A G X 2 4 0 K 1 S X Q 4 )<br />

1 4 3 2 2 5 4 6 1 C L U T C H G X 2 4 0<br />

1 5 3 2 2 5 3 7 6 R E A R D O O R<br />

1 6 3 2 2 4 6 2 5 H IN G E<br />

1 7 2 2 3 3 6 0 0 H IN G E<br />

1 8 3 2 2 5 4 9 3 R H B R A C K E T M U D G U A R D S U P P O R T<br />

1 9 3 2 2 4 9 9 5 H O S E D R A W B A R<br />

2 0 3 2 0 6 0 11 M U D G U A R D<br />

2 1 3 2 2 5 3 8 2 E N G IN E B E LT G U A R D<br />

2 2 3 2 2 5 3 7 7 C A B D O O R<br />

2 3 3 2 2 5 3 9 0 M IX IN G M A C H IN E G R IL L<br />

2 4 3 2 2 5 3 9 1 TA N K D O O R O P E N IN G L E V E R<br />

2 5 3 2 2 5 4 9 4 L H B R A C K E T M U D G U A R D S U P P O R T<br />

2 6 3 2 2 5 3 9 5 D R A W B A R L O C K IN G P IN<br />

2 7 2 2 2 6 7 0 0 S P L IT P IN (A M A 3 5 /7 2 )<br />

- 14 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

1<br />

10<br />

3<br />

16<br />

7<br />

15<br />

6<br />

3<br />

2<br />

9<br />

3<br />

8<br />

4<br />

3<br />

2<br />

13<br />

5<br />

11<br />

12 14<br />

Rif. Cod. DESCRIPTION<br />

1 3225388 REDUCTION UNIT CARTER<br />

2 3225387 REDUCTION UNIT FLANGE<br />

3 2204550 BEARING 6205<br />

4 2202871 PINION SHAFT<br />

5 3225403 REDUCTION UNIT EXIT SHAFT<br />

6 2202858 PINION Z11<br />

7 2202526 GEAR Z 58<br />

8 2202517 GEAR Z 53<br />

9 2207301 OIL SEAL RING 42X25X7<br />

10 3213282 BEARING 6208 SKF<br />

11 3213899 BEARING 6209 SKF<br />

12 3225352 OIL SEAL RING 75X45X10<br />

13 2222006 SCREW TE M8X30 Z<br />

14 3225404 BUSHING D=35mm<br />

15 3225405 PULLEY D=304mm<br />

16 2237256 SPACER M22<br />

- 15 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

4<br />

7<br />

8<br />

1<br />

7<br />

3<br />

6<br />

5<br />

2<br />

ID CODICE DESCRIZIONE Q.TA<br />

TAB.3<br />

DRUM REDUCTION UNIT<br />

1<br />

Rif.<br />

2229300<br />

Cod.<br />

LINGUETTA 6x6 x20<br />

DESCRIPTION<br />

1<br />

12 2227320 2229300 ANELLO 20 E TONGUE 6X6X20 1<br />

23 2204560 2227320 CUSCINETTO 6204 RING 20 E<br />

1<br />

3 2204560 BEARING 6204<br />

4<br />

4 3209429<br />

3209429<br />

COPERCHIO RIBALTAMENTO<br />

TILTING COVER<br />

1<br />

5 3208777 VOLANTE SALDATO STEERING-WHEEL 1<br />

6 3206748 HANDWHEEL MCP 28X88<br />

6 3206748 IMPUGN. MAN. GIREV. MCP 28X88<br />

7 3208770 TILTING BUSH<br />

1<br />

87 3208770 3208773 BOCCOLA RIBALTAMENTO WHEEL Z=32 M3<br />

1<br />

2<br />

8 3208773 RUOTA Z=32 M3 1<br />

- 16 -

<strong>IMER</strong> U.S.A. Inc.<br />

HENCHMAN 2 <strong>HSM</strong><br />

11<br />

13<br />

14<br />

15<br />

10<br />

4<br />

13<br />

12<br />

5<br />

7<br />

9<br />

6<br />

7<br />

6<br />

15<br />

8<br />

2<br />

8<br />

7<br />

1<br />

6<br />

6<br />

4<br />

MIXING MACHINE TANK<br />

Rif. Cod. DESCRIPTION<br />

1 3225369 MIXING MACHINE TANK<br />

2 3225410 HINGE FOR GRILL<br />

3 3225356 TITLING SIDE FLANGE<br />

4 2230550 GREASER 1/8" GAS<br />

5 3225357 GREASING BUSH 40X50X30<br />

6 3224315 SEAL D43<br />

7 3224311 SEAL FLANGE<br />

8 3225361 TORRINGTON BUSHING 40X48X40<br />

9 3225355 REDUCTION UNIT SIDE FLANGE<br />

10 3225362 OIL SEAL RING 50X35X7<br />

11 3225354 MIXING MACHINE TANK SHAFT<br />

12 3225396 LH BLADE<br />

13 3225397 CENTRAL LH BLADE<br />

14 3225395 RH BLADE<br />

15 3225398 CENTRAL RH BLADE<br />

7<br />

5<br />

3<br />

- 17 -

This is a contact addendum to our manuals<br />

Imer <strong>USA</strong> East<br />

221 Westhampton Pl<br />

Capitol Heights, MD 20743<br />

Phone: 301-336-3700<br />

Fax: 301-336-6687<br />

Order Fax:301-336-5811<br />

Imer <strong>USA</strong> West<br />

3654 Enterprise Ave<br />

Hayward, CA 94545<br />

www.imerusa.com<br />

800-275-5463