Molybdenum - an extraordinary metal in high demand - IMOA

Molybdenum - an extraordinary metal in high demand - IMOA

Molybdenum - an extraordinary metal in high demand - IMOA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

®<br />

I M O A<br />

INTERNATIONAL MOLYBDENUM ASSOCIATION<br />

<strong>Molybdenum</strong> - <strong>an</strong> <strong>extraord<strong>in</strong>ary</strong> <strong>metal</strong> <strong>in</strong> <strong>high</strong> dem<strong>an</strong>d<br />

By H<strong>an</strong>s Imgrund <strong>an</strong>d Nicole K<strong>in</strong>sm<strong>an</strong>, International <strong>Molybdenum</strong> Association<br />

Ferromolybdenum (left); Roast<strong>in</strong>g molybdenite concentrate (right). Courtesy of Molymet, Chile<br />

A repr<strong>in</strong>t from the September 2007 issue of Sta<strong>in</strong>less Steel World<br />

International <strong>Molybdenum</strong> Association<br />

Rue Père Eudore Devroye 245, 1150 Brussels, Belgium<br />

Tel: +32 2 770 8878 · Fax: +32 2 770 8898<br />

e-mail: <strong>in</strong>fo@imoa.<strong>in</strong>fo · www.imoa.<strong>in</strong>fo

<strong>Molybdenum</strong> - <strong>an</strong> extraordi<br />

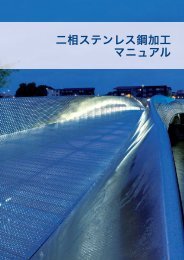

The US Air Force Memorial <strong>in</strong> Arl<strong>in</strong>gton, Virg<strong>in</strong>ia,<br />

USA, was designed by James Ingo Freed. It features<br />

three curved spires of welded, 19mm-thick,<br />

type 316 sta<strong>in</strong>less steel plate up to 82 metres <strong>in</strong><br />

height. Photo: Patrick McCafferty.<br />

20 S T A I N L E S S S T E E L W O R L D J U L Y / A U G U S T 2 0 0 7 www.sta<strong>in</strong>less-steel-world.net

Materials<br />

nary <strong>metal</strong> <strong>in</strong> <strong>high</strong> dem<strong>an</strong>d<br />

The recent nickel shortage has attracted a lot of attention. What is less known is that molybdenum<br />

too is <strong>in</strong> ever greater dem<strong>an</strong>d, with tighten<strong>in</strong>g supplies <strong>an</strong>d soar<strong>in</strong>g prices. A world-wide<br />

boom <strong>in</strong> <strong>in</strong>frastructure projects, especially those which have critical applications, has fuelled<br />

dem<strong>an</strong>d for this versatile <strong>metal</strong>. Sta<strong>in</strong>less Steel World asked Nicole K<strong>in</strong>sm<strong>an</strong> <strong>an</strong>d H<strong>an</strong>s Imgrund of<br />

the International <strong>Molybdenum</strong> Association to expla<strong>in</strong> the background <strong>an</strong>d <strong>in</strong>dicate what the future<br />

may hold. Their f<strong>in</strong>d<strong>in</strong>gs suggest that supplies will rema<strong>in</strong> tight <strong>in</strong> the short term, but that the<br />

long-term supply prospects are look<strong>in</strong>g good.<br />

MATERIALS<br />

By H<strong>an</strong>s Imgrund <strong>an</strong>d Nicole K<strong>in</strong>sm<strong>an</strong>, International <strong>Molybdenum</strong> Association<br />

Introductory<br />

In the last four years dem<strong>an</strong>d for<br />

molybdenum soared by 35 per cent.<br />

This surge comes ma<strong>in</strong>ly from a<br />

strong world-wide push to <strong>in</strong>vest <strong>in</strong><br />

<strong>in</strong>dustrial <strong>in</strong>frastructure: from a factory<br />

build<strong>in</strong>g boom <strong>in</strong> Ch<strong>in</strong>a to a<br />

rush to develop oilfields, m<strong>an</strong>y projects<br />

rely on the help of materials<br />

conta<strong>in</strong><strong>in</strong>g molybdenum.<br />

All this activity has trickled down to<br />

<strong>Molybdenum</strong> facts<br />

• About 25 per cent of all molybdenum<br />

produced is used to make<br />

moly-grade sta<strong>in</strong>less steel.<br />

• About 50 per cent is used for other<br />

iron-based <strong>metal</strong>s, such as construction<br />

steel, tool <strong>an</strong>d <strong>high</strong>-speed<br />

steel <strong>an</strong>d cast iron.<br />

• <strong>Molybdenum</strong> as <strong>an</strong> alloy<strong>in</strong>g element<br />

<strong>in</strong> steel is almost always used<br />

<strong>in</strong> comb<strong>in</strong>ation with other elements<br />

such as chromium, nickel, v<strong>an</strong>adium,<br />

tungsten or niobium.<br />

• Steel mills add molybdenum either<br />

as molybdenum oxide or ferromolybdenum.<br />

• The rema<strong>in</strong><strong>in</strong>g 25 per cent is purified<br />

<strong>an</strong>d used as moly <strong>metal</strong>, as <strong>an</strong><br />

alloy<strong>in</strong>g element <strong>in</strong> nickel <strong>an</strong>d other<br />

super alloys, as catalysts, lubric<strong>an</strong>ts,<br />

flame retard<strong>an</strong>ts, corrosion<br />

<strong>in</strong>hibitors <strong>an</strong>d pigments.<br />

• Super alloy producers use moly<br />

<strong>metal</strong> pellets as a <strong>high</strong>-purity alloy<strong>in</strong>g<br />

addition.<br />

<strong>an</strong> <strong>in</strong>crease <strong>in</strong> dem<strong>an</strong>d for the <strong>metal</strong><br />

<strong>an</strong>d the tr<strong>an</strong>sformation of a market<br />

that had been stagn<strong>an</strong>t for nearly 20<br />

years. <strong>Molybdenum</strong> has diverse appeal:<br />

it is used <strong>in</strong> pipel<strong>in</strong>es, to improve<br />

strength to tr<strong>an</strong>sport oil <strong>an</strong>d<br />

gas under <strong>high</strong> pressure; <strong>in</strong> process<strong>in</strong>g<br />

vessels <strong>in</strong> the chemical <strong>in</strong>dustry,<br />

to withst<strong>an</strong>d corrosion <strong>in</strong> <strong>an</strong> array<br />

of solutions; <strong>an</strong>d even <strong>in</strong> sculptures,<br />

such as the US Air Force Memorial,<br />

which is located just across the river<br />

from Wash<strong>in</strong>gton, DC, to keep their<br />

f<strong>in</strong>ish sh<strong>in</strong>y for a long time.<br />

The global <strong>in</strong>terest <strong>in</strong> go<strong>in</strong>g “green”<br />

has also had <strong>an</strong> impact: as more<br />

comp<strong>an</strong>ies reduce pl<strong>an</strong>t waste by recycl<strong>in</strong>g<br />

their waste streams with<strong>in</strong><br />

factory walls, moly-grade sta<strong>in</strong>less<br />

steels h<strong>an</strong>dle the <strong>high</strong>er corrosiveness<br />

that comes with <strong>high</strong>er concentration<br />

of aggressive subst<strong>an</strong>ces.<br />

Compounds of the element that allows<br />

steels to resist <strong>high</strong> temperatures<br />

<strong>an</strong>d sta<strong>in</strong>less steels to resist corrosive<br />

environments c<strong>an</strong> also work<br />

as <strong>an</strong> effective lubric<strong>an</strong>t, as a catalyst<br />

for the production of oil products or<br />

as a pigment to make or<strong>an</strong>ge pa<strong>in</strong>t.<br />

How molybdenum <strong>metal</strong> is<br />

used<br />

The most import<strong>an</strong>t properties of<br />

pure molybdenum <strong>metal</strong> <strong>an</strong>d molybdenum<br />

alloys are their <strong>high</strong> melt<strong>in</strong>g<br />

po<strong>in</strong>t (<strong>in</strong> the order of 2600°C), <strong>high</strong><br />

temperature resist<strong>an</strong>ce, <strong>high</strong> wear resist<strong>an</strong>ce<br />

<strong>an</strong>d good corrosion resist<strong>an</strong>ce.<br />

These products are often used<br />

<strong>in</strong> applications that require <strong>high</strong><br />

strength at <strong>high</strong> temperature, while<br />

their coefficient of exp<strong>an</strong>sion <strong>an</strong>d<br />

thermal conductivity also make<br />

them valuable to the electronics <strong>in</strong>dustry.<br />

Products made of molybdenum<br />

<strong>metal</strong> <strong>an</strong>d molybdenum base<br />

alloys <strong>in</strong>clude <strong>metal</strong> powder, wire,<br />

sheet, bar <strong>an</strong>d specialised powders.<br />

The price for molybdenum has spiked recently but was at low levels for much of the last 25 years.<br />

(Source: Metals Week)<br />

www.sta<strong>in</strong>less-steel-world.net S T A I N L E S S S T E E L W O R L D S E P T E M B E R 2 0 0 7 21

Materials<br />

Examples of the <strong>metal</strong>’s uses <strong>in</strong>clude<br />

parts of <strong>in</strong>dustrial furnaces,<br />

support wire for tungsten filaments<br />

<strong>in</strong> light bulbs, glass melt<strong>in</strong>g equipment,<br />

electronic equipment, <strong>an</strong>d<br />

<strong>metal</strong> <strong>an</strong>d plastic form<strong>in</strong>g equipment.<br />

One example of a <strong>metal</strong>form<strong>in</strong>g<br />

product is a pierc<strong>in</strong>g plug.<br />

It is made of TZM (a molybdenum<br />

alloy, dispersion-strengthened with<br />

tit<strong>an</strong>ium carbide <strong>an</strong>d zirconium oxide)<br />

<strong>an</strong>d used for the production of<br />

sta<strong>in</strong>less steel tub<strong>in</strong>g. Such pierc<strong>in</strong>g<br />

plugs are made of TZM because<br />

they must have <strong>high</strong> strength <strong>an</strong>d<br />

<strong>high</strong> wear resist<strong>an</strong>ce at the <strong>high</strong><br />

roll<strong>in</strong>g temperature of sta<strong>in</strong>less steel<br />

(see photo.)<br />

Mak<strong>in</strong>g a better sta<strong>in</strong>less<br />

steel<br />

<strong>Molybdenum</strong> is added to sta<strong>in</strong>less<br />

steels to <strong>in</strong>crease corrosion resist<strong>an</strong>ce.<br />

About 10 per cent of sta<strong>in</strong>less<br />

steel production conta<strong>in</strong>s molybdenum,<br />

of which the content averages<br />

about 2 per cent. Traditionally the<br />

most import<strong>an</strong>t moly-grade sta<strong>in</strong>less<br />

steel is the austenitic type 316 (18%<br />

Cr, 10% Ni <strong>an</strong>d 2 or 2.5% Mo),<br />

which represents about 7 per cent of<br />

global sta<strong>in</strong>less steel production. In<br />

recent years moly-grade ferritics<br />

have grown fast. These <strong>in</strong>clude<br />

types 444 (18% Cr, 2% Mo), 436<br />

(18% Cr, 1.25% Mo) <strong>an</strong>d 434 (17%<br />

Cr <strong>an</strong>d 1% Mo). The comb<strong>in</strong>ed tonnage<br />

of moly-grade ferritics has<br />

jumped from 47,000 metric tons <strong>in</strong><br />

2002 to 366,000 tons <strong>in</strong> 2005, accord<strong>in</strong>g<br />

to the International<br />

Sta<strong>in</strong>less Steel Forum. Their percentage<br />

of total sta<strong>in</strong>less production has<br />

grown from 0.3 per cent to 1.7 per<br />

cent <strong>in</strong> just three years. Duplex<br />

sta<strong>in</strong>less steels have also been grow<strong>in</strong>g<br />

strongly to <strong>an</strong> estimated<br />

200,000 metric tons <strong>in</strong> 2006.<br />

TZM pierc<strong>in</strong>g plug for the production (roll<strong>in</strong>g) of<br />

sta<strong>in</strong>less steel tubes (courtesy of Pl<strong>an</strong>see).<br />

This sculpture right next to the oce<strong>an</strong> shows corrosion sta<strong>in</strong><strong>in</strong>g on type 304 sta<strong>in</strong>less steel due to<br />

<strong>in</strong>correct grade selection <strong>in</strong> a dem<strong>an</strong>d<strong>in</strong>g environment.<br />

Industrial sectors<br />

The most import<strong>an</strong>t uses of molygrade<br />

sta<strong>in</strong>less steel are <strong>in</strong>dustrial.<br />

The chemical <strong>an</strong>d petrochemical, oil<br />

<strong>an</strong>d gas, paper, power, water, food<br />

<strong>an</strong>d pharmaceutical <strong>in</strong>dustries use<br />

process<strong>in</strong>g equipment made of molygrade<br />

austenitic <strong>an</strong>d duplex sta<strong>in</strong>less<br />

steels.<br />

Moly-grade sta<strong>in</strong>less steel is also used<br />

<strong>in</strong> architectural applications. The correct<br />

selection of sta<strong>in</strong>less steel <strong>in</strong><br />

these applications is essential to avoid<br />

unpleas<strong>an</strong>t surprises, for <strong>in</strong>st<strong>an</strong>ce<br />

where a moly-free grade was used<br />

next to the oce<strong>an</strong> (see photo).<br />

Because the sta<strong>in</strong>less steel selected<br />

here is not corrosion-resist<strong>an</strong>t enough<br />

for this difficult environment, this<br />

sculpture has to be cle<strong>an</strong>ed from superficial<br />

corrosion sta<strong>in</strong><strong>in</strong>g every year.<br />

The US Air Force Memorial, us<strong>in</strong>g a<br />

moly-grade type 316 sta<strong>in</strong>less steel<br />

(which conta<strong>in</strong>s 2 per cent molybdenum)<br />

will most likely not have this<br />

problem (see photo).<br />

Mak<strong>in</strong>g a stronger alloy steel<br />

<strong>Molybdenum</strong> enh<strong>an</strong>ces hardenability,<br />

strength <strong>an</strong>d toughness, <strong>an</strong>d elevates<br />

the temperature resist<strong>an</strong>ce of<br />

constructional steels. It is often used<br />

<strong>in</strong> comb<strong>in</strong>ation with chromium<br />

<strong>an</strong>d/or nickel <strong>an</strong>d other alloy<strong>in</strong>g elements,<br />

with the molybdenum content<br />

typically r<strong>an</strong>g<strong>in</strong>g from 0.2 to<br />

1.2 per cent. Moly-grade steel categories<br />

<strong>in</strong>clude heat-treatable eng<strong>in</strong>eer<strong>in</strong>g<br />

steels, case-hardened steels,<br />

<strong>high</strong>-temperature steels, oil country<br />

tubular goods <strong>an</strong>d HSLA (High<br />

Strength, Low Alloy) steels. These<br />

grades are used <strong>in</strong> all k<strong>in</strong>ds of eng<strong>in</strong>eered<br />

products for automotive,<br />

shipbuild<strong>in</strong>g, aircraft <strong>an</strong>d aerospace<br />

<strong>in</strong>dustries; drill<strong>in</strong>g, m<strong>in</strong><strong>in</strong>g <strong>an</strong>d pro-<br />

www.sta<strong>in</strong>less-steel-world.net S T A I N L E S S S T E E L W O R L D S E P T E M B E R 2 0 0 7 23

Materials<br />

These mill cutters are made of <strong>high</strong>-speed steel with 5 per cent Mo (courtesy of Boehler Edelstahl).<br />

cess<strong>in</strong>g <strong>in</strong>dustries; <strong>an</strong>d energy generation<br />

<strong>in</strong>dustries. Products <strong>in</strong>clude<br />

vessels, t<strong>an</strong>ks <strong>an</strong>d heat exch<strong>an</strong>gers,<br />

gears <strong>an</strong>d shafts, pip<strong>in</strong>g <strong>an</strong>d m<strong>an</strong>y<br />

more.<br />

Mak<strong>in</strong>g a longer-last<strong>in</strong>g tool<br />

steel<br />

<strong>Molybdenum</strong> contributes to secondary<br />

harden<strong>in</strong>g (<strong>in</strong> comb<strong>in</strong>ation with<br />

v<strong>an</strong>adium) <strong>in</strong> tool steels. It also separates<br />

the pearlite <strong>an</strong>d ba<strong>in</strong>ite reactions,<br />

<strong>an</strong>d therefore allows step<br />

quench<strong>in</strong>g. Products made of tool<br />

steels <strong>in</strong>clude h<strong>an</strong>d tools, knives<br />

<strong>an</strong>d saws, forg<strong>in</strong>g dies, pressure cast<strong>in</strong>g<br />

moulds <strong>an</strong>d mold<strong>in</strong>g plates. The<br />

typical molybdenum content <strong>in</strong> tool<br />

steels is around 0.8 per cent.<br />

<strong>Molybdenum</strong> contributes to secondary<br />

harden<strong>in</strong>g <strong>an</strong>d is <strong>an</strong> import<strong>an</strong>t<br />

constituent of the primary M6C carbide,<br />

which makes <strong>high</strong>-speed steels<br />

more wear-resist<strong>an</strong>t. Pr<strong>in</strong>cipal uses<br />

are for cutt<strong>in</strong>g tools <strong>an</strong>d saws for<br />

steel, cast <strong>an</strong>d non-ferrous materials,<br />

twist drills, mill<strong>in</strong>g cutters (see photo)<br />

<strong>an</strong>d push<strong>in</strong>g tools. The average<br />

molybdenum content <strong>in</strong> <strong>high</strong>-speed<br />

steels is around 5 per cent.<br />

<strong>Molybdenum</strong> m<strong>in</strong><strong>in</strong>g<br />

The ma<strong>in</strong> regions of molybdenum<br />

m<strong>in</strong><strong>in</strong>g <strong>in</strong>clude South America,<br />

North America <strong>an</strong>d Ch<strong>in</strong>a. These regions<br />

accounted for 93 per cent of<br />

global production <strong>in</strong> 2006, which<br />

was estimated to be 422 million<br />

pounds (192,000 metric tons).<br />

Roughly 60 per cent of molybdenum<br />

is produced as a by-product of<br />

<strong>an</strong>other m<strong>in</strong><strong>in</strong>g operation, most<br />

commonly copper production. The<br />

ore from copper m<strong>in</strong>es which also<br />

produce molybdenum usually conta<strong>in</strong>s<br />

between 0.5 <strong>an</strong>d 1.5 per cent<br />

copper (5 to 15 kg per metric ton of<br />

ore) <strong>an</strong>d between 0.01 <strong>an</strong>d 0.05 per<br />

cent molybdenum (0.1 to 0.5 kg/t).<br />

Major operations m<strong>in</strong>e more th<strong>an</strong><br />

50 million tons of ore per year, produc<strong>in</strong>g<br />

over 200,000 tons of copper<br />

<strong>an</strong>d between 5,000 <strong>an</strong>d 15,000 tons<br />

of moly. For every kilo of copper,<br />

between 20 <strong>an</strong>d 40 grams of moly is<br />

extracted.<br />

For these producers, it is a relatively<br />

<strong>in</strong>expensive step to extract molybdenum<br />

from the ore that is already<br />

ground up to take out copper. The<br />

revenues from molybdenum are<br />

usually less th<strong>an</strong> 10 per cent of total<br />

sales. Therefore, the molybdenum<br />

output does not necessarily<br />

follow the dem<strong>an</strong>d for molybdenum<br />

but the dem<strong>an</strong>d for copper.<br />

The moly output automatically <strong>in</strong>creases<br />

when the m<strong>in</strong>e <strong>in</strong>creases its<br />

copper production <strong>an</strong>d it falls when<br />

the m<strong>in</strong>e decreases its copper production<br />

because dem<strong>an</strong>d for copper<br />

falls.<br />

M<strong>in</strong><strong>in</strong>g for moly only (primary production)<br />

is much more expensive. A<br />

primary m<strong>in</strong>e <strong>in</strong> the West, with <strong>an</strong><br />

<strong>an</strong>nual production capacity <strong>in</strong> the<br />

order of 10,000 tons of molybdenum<br />

(22 million lbs), takes <strong>an</strong> <strong>in</strong>vestment<br />

of several hundred million<br />

US dollars to open. Of the 40<br />

per cent molybdenum from primary<br />

m<strong>in</strong>es, 25 per cent is produced<br />

<strong>in</strong> Ch<strong>in</strong>a <strong>an</strong>d the CIS <strong>an</strong>d 15<br />

per cent <strong>in</strong> the West.<br />

Ore grades <strong>in</strong> primary m<strong>in</strong>es conta<strong>in</strong><br />

between 0.12 <strong>an</strong>d 0.20 per cent<br />

moly. Thus, the production of<br />

10,000 tons of Mo requires m<strong>in</strong><strong>in</strong>g<br />

<strong>an</strong>d mill<strong>in</strong>g <strong>in</strong> excess of 5 million<br />

tons of ore per year. The cost of this<br />

has to be borne by the revenue<br />

www.sta<strong>in</strong>less-steel-world.net S T A I N L E S S S T E E L W O R L D S E P T E M B E R 2 0 0 7 25

Materials<br />

from molybdenum alone. Therefore<br />

the production of primary molybdenum<br />

is signific<strong>an</strong>tly more costly<br />

th<strong>an</strong> the production of by-product<br />

molybdenum. The primary m<strong>in</strong>es<br />

are sw<strong>in</strong>g producers, i.e. they <strong>in</strong>crease<br />

their production when the<br />

market has <strong>high</strong>er dem<strong>an</strong>d for<br />

molybdenum <strong>an</strong>d decrease their<br />

production when the dem<strong>an</strong>d is<br />

down.<br />

The ch<strong>an</strong>g<strong>in</strong>g structure of<br />

the <strong>in</strong>dustry<br />

The bal<strong>an</strong>ce of molybdenum m<strong>in</strong><strong>in</strong>g<br />

has shifted over the years from<br />

ma<strong>in</strong>ly primary production to<br />

ma<strong>in</strong>ly by-product production. As<br />

copper comp<strong>an</strong>ies have <strong>in</strong>creased<br />

<strong>an</strong>d optimized the recovery of<br />

molybdenum, the amount of byproduct<br />

molybdenum produced has<br />

<strong>in</strong>creased signific<strong>an</strong>tly <strong>in</strong> the last 15<br />

years. Dur<strong>in</strong>g that same time, production<br />

<strong>in</strong> Ch<strong>in</strong>a <strong>an</strong>d the availability<br />

of Ch<strong>in</strong>ese molybdenum for export<br />

to the rest of the world have<br />

also <strong>in</strong>creased.<br />

Because of these structural ch<strong>an</strong>ges,<br />

the primary m<strong>in</strong>es <strong>in</strong> North<br />

America that have traditionally produced<br />

the bulk of molybdenum<br />

have decreased their production<br />

<strong>an</strong>d have become sw<strong>in</strong>g producers:<br />

these m<strong>in</strong>es are only able to <strong>in</strong>crease<br />

their production, or come<br />

back on-stream, when the market<br />

dem<strong>an</strong>d requires their more costly<br />

molybdenum. The by-product<br />

m<strong>in</strong>es, on the contrary, produce<br />

their lower-cost molybdenum along<br />

with copper to fill the dem<strong>an</strong>d for<br />

copper <strong>an</strong>d do not adjust much to<br />

the market conditions for molybdenum.<br />

Market conditions became difficult<br />

<strong>in</strong> 2001 <strong>an</strong>d 2002, when the molybdenum<br />

price dropped even further<br />

after be<strong>in</strong>g already low for most of<br />

the previous 20 years. The production<br />

of the primary m<strong>in</strong>es <strong>in</strong> North<br />

America was reduced to less th<strong>an</strong> 45<br />

million pounds per year, or less<br />

th<strong>an</strong> 15 per cent of global production.<br />

With this low production level,<br />

the sw<strong>in</strong>g producers, the primary<br />

North Americ<strong>an</strong> m<strong>in</strong>es, were no<br />

longer able to adjust their production<br />

sufficiently to absorb ch<strong>an</strong>ges,<br />

particularly strong <strong>in</strong>creases <strong>in</strong> dem<strong>an</strong>d.<br />

Production of Western primary m<strong>in</strong>es has decreased when prices <strong>an</strong>d dem<strong>an</strong>d were low for<br />

several years. Production from these m<strong>in</strong>es was only about 40 million lb <strong>in</strong> 2001 <strong>an</strong>d 2002.<br />

(Source: <strong>IMOA</strong>, Metals Week).<br />

Global molybdenum dem<strong>an</strong>d has <strong>in</strong>creased strongly <strong>in</strong> the last four years after be<strong>in</strong>g stagn<strong>an</strong>t for<br />

several years. (Source: <strong>IMOA</strong>, Metals Week).<br />

<strong>Molybdenum</strong> m<strong>in</strong>e production <strong>in</strong> Ch<strong>in</strong>a has dropped <strong>in</strong> 2005 as m<strong>in</strong>es were closed due to safety<br />

concerns (Source: <strong>IMOA</strong>)<br />

26 S T A I N L E S S S T E E L W O R L D S E P T E M B E R 2 0 0 7 www.sta<strong>in</strong>less-steel-world.net

Materials<br />

Comp<strong>an</strong>y M<strong>in</strong>e Location Type<br />

Mont<strong>an</strong>a/<br />

Gruppo Mexico<br />

Estimated <strong>an</strong>nual<br />

capacity<br />

(million lb Mo)<br />

Status<br />

Butte USA Cu by-product 8 Reopened 2004<br />

Quadra M<strong>in</strong><strong>in</strong>g Ltd. Rob<strong>in</strong>son USA Cu by-product 1 Started 2006<br />

Taseko M<strong>in</strong>es Gibraltar C<strong>an</strong>ada Cu by-product 1 Reopened 2005<br />

Anglo Americ<strong>an</strong>/<br />

Falconbridge<br />

Amerigo (M<strong>in</strong>era<br />

Valle Central)<br />

Golden Phoenix<br />

M<strong>in</strong>erals<br />

Collahausi Chile Cu by-product 7 Started 2005<br />

- Chile Cu by-product 1 Started 2005<br />

Ashdown USA Primary 0.5 Started 2006<br />

Roxmark M<strong>in</strong>es Nortoba - Tyson C<strong>an</strong>ada Primary 1 Started 2006<br />

Table 1: Mloybdenum m<strong>in</strong>es recently started or reopened (source: Adams Metals)<br />

<strong>Molybdenum</strong> dem<strong>an</strong>d has<br />

<strong>in</strong>creased signific<strong>an</strong>tly<br />

As <strong>in</strong>dicated already, the uses for<br />

molybdenum-conta<strong>in</strong><strong>in</strong>g products<br />

are mostly <strong>in</strong>dustrial <strong>an</strong>d <strong>in</strong>clude energy<br />

generation, oil <strong>an</strong>d gas, chemical<br />

process<strong>in</strong>g, tr<strong>an</strong>sportation, m<strong>in</strong><strong>in</strong>g,<br />

mech<strong>an</strong>ical eng<strong>in</strong>eer<strong>in</strong>g, build<strong>in</strong>g<br />

<strong>an</strong>d construction <strong>an</strong>d fabrication.<br />

[Dem<strong>an</strong>d for molybdenum]<br />

M<strong>an</strong>y of these sectors have seen <strong>an</strong><br />

up cycle <strong>in</strong> <strong>in</strong>vestment <strong>in</strong> the last<br />

few years. High oil prices have boosted<br />

exploration <strong>an</strong>d brought new production<br />

facilities onl<strong>in</strong>e. The new<br />

fields often are more difficult to<br />

reach <strong>an</strong>d more difficult to tap.<br />

Higher temperatures, pressures <strong>an</strong>d<br />

concentrations result <strong>in</strong> a need for<br />

better (often molybdenum-alloyed)<br />

materials. Five to ten years ago, for<br />

example, ref<strong>in</strong>eries did not need to<br />

use much sta<strong>in</strong>less steel <strong>in</strong> their process<strong>in</strong>g.<br />

Today, the raw oil to be<br />

processed is becom<strong>in</strong>g <strong>in</strong>creas<strong>in</strong>gly<br />

aggressive, so sta<strong>in</strong>less steel equipment<br />

is becom<strong>in</strong>g more common.<br />

The general trend <strong>in</strong> the chemical<br />

<strong>an</strong>d petrochemical <strong>in</strong>dustries of <strong>in</strong>creas<strong>in</strong>g<br />

process temperatures <strong>an</strong>d<br />

pressures to <strong>in</strong>crease pl<strong>an</strong>t efficiency<br />

also favours the use of moly-grade<br />

materials. Similarly, environmentally<br />

friendly process<strong>in</strong>g, where effluents<br />

are recycled <strong>in</strong> the pl<strong>an</strong>t <strong>in</strong>stead<br />

of be<strong>in</strong>g released to the environment,<br />

<strong>in</strong>creases the need for<br />

moly-conta<strong>in</strong><strong>in</strong>g materials that c<strong>an</strong><br />

withst<strong>an</strong>d the <strong>high</strong>er concentrations<br />

of aggressive compounds.<br />

F<strong>in</strong>ally, the rapid exp<strong>an</strong>sion of the<br />

Ch<strong>in</strong>ese economy, creat<strong>in</strong>g a need<br />

for more <strong>in</strong>dustrial process<strong>in</strong>g<br />

pl<strong>an</strong>ts <strong>an</strong>d for <strong>in</strong>vestment <strong>in</strong> new<br />

<strong>in</strong>frastructure, has multiplied the<br />

use of moly-grade materials <strong>in</strong> that<br />

part of the world <strong>in</strong> just a few years.<br />

Therefore, molybdenum dem<strong>an</strong>d<br />

had a compounded <strong>an</strong>nual growth<br />

rate of 8 per cent between 2002 <strong>an</strong>d<br />

2006. Such market conditions have<br />

not been seen for decades. In fact,<br />

between 1990 <strong>an</strong>d 2006 the growth<br />

rate was only 3.3 per cent per year.<br />

To express this <strong>in</strong> weight: <strong>in</strong> the 12<br />

years between 1990 <strong>an</strong>d 2002 the<br />

dem<strong>an</strong>d for molybdenum <strong>in</strong>creased<br />

by 58 million pounds. In the last<br />

four years, between 2002 <strong>an</strong>d 2006,<br />

the dem<strong>an</strong>d <strong>in</strong>creased by 112 mil-<br />

Comp<strong>an</strong>y M<strong>in</strong>e Location Type<br />

Pl<strong>an</strong>ned <strong>an</strong>nual<br />

capacity<br />

(million lb Mo)<br />

Status<br />

Probable<br />

start-up<br />

Freeport / PD Cerro Verde Peru Cu by-product 8 Commission<strong>in</strong>g Q2 2007<br />

Roca M<strong>in</strong>es Max Moly C<strong>an</strong>ada Primary 5 Under Construction Q3 2007<br />

Alumbrera<br />

Bajo de la<br />

Alumbrera<br />

Argent<strong>in</strong>a Cu by-product 5 Under Construction Q4 2007<br />

BHP P<strong>in</strong>to Valley USA Cu by-product 3 Under Construction Q4 2007<br />

Mercator M<strong>in</strong>eral Park USA Cu by-product 10 Under Construction Q2 2008<br />

Ad<strong>an</strong>ac Ruby Creek C<strong>an</strong>ada Primary 10<br />

Moly M<strong>in</strong>es<br />

Ltd.<br />

Sp<strong>in</strong>fex Ridge Australia Cu by-product 20<br />

Grupo Mexico C<strong>an</strong>enea Mexico Cu by-product 10<br />

Freeport / PD Climax USA Primary 20 to 30<br />

Idaho General Mount Hope USA Primary 30<br />

Thompson Cree Davison C<strong>an</strong>ada Primary 8<br />

Table 2. Likely molybdenum m<strong>in</strong>e projects (source: Adams Metals)<br />

Feasability complete;<br />

contract<strong>in</strong>g<br />

Complet<strong>in</strong>g<br />

feasability<br />

Complet<strong>in</strong>g<br />

feasability<br />

Restarted -<br />

conditionally approved<br />

Complet<strong>in</strong>g<br />

feasability<br />

Start<strong>in</strong>g feasability<br />

study<br />

Q2 2009<br />

Q3 2009<br />

Q3 2009<br />

2010<br />

2011<br />

2012<br />

28 S T A I N L E S S S T E E L W O R L D S E P T E M B E R 2 0 0 7 www.sta<strong>in</strong>less-steel-world.net

Materials<br />

Ch<strong>in</strong>a 43%<br />

lion pounds, from 310 million<br />

pounds to 422 million pounds. This<br />

is over 35 per cent of the total dem<strong>an</strong>d<br />

<strong>in</strong> 2002 <strong>an</strong>d 2.5 times as<br />

much as the primary m<strong>in</strong>e production<br />

<strong>in</strong> the same year. This situation<br />

has created a major stra<strong>in</strong> on the<br />

supply of molybdenum.<br />

<strong>Molybdenum</strong> supply<br />

M<strong>in</strong><strong>in</strong>g operations take m<strong>an</strong>y years<br />

to develop <strong>an</strong>d start. Feasibility<br />

studies, environmental impact studies,<br />

negotiation with local residents<br />

<strong>an</strong>d f<strong>in</strong><strong>an</strong>c<strong>in</strong>g are just part of the<br />

process needed to start a new m<strong>in</strong>e<br />

or restart a mothballed one. Because<br />

of this, <strong>metal</strong> production c<strong>an</strong>not be<br />

quickly <strong>in</strong>creased when dem<strong>an</strong>d <strong>in</strong>creases<br />

sharply.<br />

Of course, there is some flexibility<br />

to <strong>in</strong>crease production <strong>in</strong> exist<strong>in</strong>g<br />

m<strong>in</strong>es, but that flexibility is limited<br />

to a few percentage po<strong>in</strong>ts. The<br />

sharp rise <strong>in</strong> dem<strong>an</strong>d after 2002<br />

overwhelmed the sw<strong>in</strong>g producers,<br />

who had seen their bus<strong>in</strong>ess shr<strong>in</strong>k<strong>in</strong>g<br />

cont<strong>in</strong>uously dur<strong>in</strong>g the five<br />

preced<strong>in</strong>g years. At the same time,<br />

molybdenum production <strong>in</strong> Ch<strong>in</strong>a<br />

was not able to compensate for this<br />

limitation. Its production actually<br />

decreased <strong>in</strong> 2005, ma<strong>in</strong>ly because<br />

the Ch<strong>in</strong>ese government had to<br />

close some m<strong>in</strong>es due to safety concerns.<br />

The problem was further compounded<br />

by limited roast<strong>in</strong>g capacities.<br />

Roast<strong>in</strong>g is a necessary step to ref<strong>in</strong>e<br />

molybdenum. Accord<strong>in</strong>g to estimates<br />

by Climax <strong>Molybdenum</strong> (presented<br />

at the 2005 Ry<strong>an</strong>’s Notes<br />

CIS & Mongolia 8%<br />

South America 16%<br />

North America 33%<br />

Global molybdenum reserves total 19 million tons <strong>an</strong>d are ma<strong>in</strong>ly situated <strong>in</strong> Ch<strong>in</strong>a <strong>an</strong>d North<br />

America (source: US Geological Survey 2006).<br />

Conference), the Western roasters<br />

were runn<strong>in</strong>g at a capacity utilization<br />

rate of 77 per cent <strong>in</strong> 2003, which<br />

moved up to 94 per cent <strong>in</strong> 2004 <strong>an</strong>d<br />

reached 100 per cent <strong>in</strong> 2005.<br />

This comb<strong>in</strong>ation of circumst<strong>an</strong>ces<br />

led to the current - <strong>an</strong>d unexpected<br />

- tight supply of molybdenum.<br />

About the authors<br />

Dr. H<strong>an</strong>s Imgrund<br />

works as a part-time<br />

consult<strong>an</strong>t to <strong>IMOA</strong>.<br />

A Germ<strong>an</strong> national,<br />

he studied<br />

<strong>metal</strong>lurgy at the<br />

Clausthal Bergakademie <strong>an</strong>d the<br />

Technical University <strong>in</strong> Berl<strong>in</strong>. He<br />

started his career <strong>in</strong> the moly<br />

bus<strong>in</strong>ess <strong>in</strong> 1973 as a development<br />

eng<strong>in</strong>eer of Climax <strong>Molybdenum</strong><br />

Comp<strong>an</strong>y.<br />

He worked as Vice President Sales<br />

<strong>an</strong>d Market<strong>in</strong>g for Climax <strong>an</strong>d for<br />

Cyprus M<strong>in</strong>es Corporation from 1981<br />

until his retirement from Climax <strong>in</strong><br />

2003.<br />

He was actively <strong>in</strong>volved <strong>in</strong> the<br />

foundation of <strong>IMOA</strong> <strong>an</strong>d has served<br />

on <strong>IMOA</strong>’s Executive Committee s<strong>in</strong>ce<br />

its <strong>in</strong>ception <strong>in</strong> 1989.<br />

High dem<strong>an</strong>d leads to m<strong>in</strong>e<br />

<strong>an</strong>d roast<strong>in</strong>g exp<strong>an</strong>sions<br />

The tight supply situation <strong>an</strong>d the<br />

cont<strong>in</strong>ued <strong>high</strong> prices of molybdenum<br />

over the last four years have<br />

prompted m<strong>an</strong>y m<strong>in</strong><strong>in</strong>g comp<strong>an</strong>ies<br />

to develop new molybdenum m<strong>in</strong><strong>in</strong>g<br />

<strong>an</strong>d roast<strong>in</strong>g facilities. Projects<br />

have become possible that would<br />

not have been profitable at the low<br />

molybdenum prices previously seen.<br />

New operations that opened <strong>in</strong> the<br />

Americas s<strong>in</strong>ce 2003 have added <strong>an</strong><br />

estimated <strong>an</strong>nual capacity of almost<br />

20 million pounds. Production <strong>in</strong><br />

Ch<strong>in</strong>a also <strong>in</strong>creased by some 20<br />

million pounds <strong>in</strong> 2006.<br />

Additionally, m<strong>an</strong>y new projects are<br />

under consideration <strong>an</strong>d <strong>in</strong> various<br />

pl<strong>an</strong>n<strong>in</strong>g <strong>an</strong>d construction stages. A<br />

shortlist c<strong>an</strong> be found <strong>in</strong> table 2,<br />

provided by Terry Adams of Adams<br />

Metals Ltd. The lead times for some<br />

of these projects are very long.<br />

Accord<strong>in</strong>g to Mr Adams there are<br />

around 500 other molybdenum<br />

projects <strong>in</strong> discussion with vary<strong>in</strong>g<br />

probabilities of completion.<br />

Roast<strong>in</strong>g capacity should also be<br />

grow<strong>in</strong>g soon as capacities <strong>in</strong> the<br />

Western world are projected to <strong>in</strong>crease<br />

from today’s 340 million<br />

pounds to 410 million pounds by<br />

2010.<br />

For the long term, known reserves<br />

for molybdenum amount to 19 million<br />

metric tons, accord<strong>in</strong>g to the<br />

US Geological Survey of 2006. This<br />

would be sufficient for 100 years at<br />

present dem<strong>an</strong>d levels, provid<strong>in</strong>g us<br />

with a corrosion-free future for<br />

m<strong>an</strong>y years to come.<br />

Dr. Nicole K<strong>in</strong>sm<strong>an</strong><br />

is the Technical<br />

Director of the<br />

International<br />

<strong>Molybdenum</strong><br />

Association (<strong>IMOA</strong>).<br />

A Swiss citizen, she studied<br />

mech<strong>an</strong>ical eng<strong>in</strong>eer<strong>in</strong>g <strong>an</strong>d<br />

<strong>metal</strong>lurgy at the Swiss Federal<br />

Institute of Technology <strong>in</strong> Zurich (ETH)<br />

<strong>an</strong>d bus<strong>in</strong>ess adm<strong>in</strong>istration at<br />

Carnegie Mellon University <strong>in</strong><br />

Pittsburgh, USA. In 1995 she started<br />

her career as a market development<br />

m<strong>an</strong>ager at TMR <strong>in</strong> Pittsburgh, a<br />

consult<strong>in</strong>g comp<strong>an</strong>y focus<strong>in</strong>g on<br />

technical consult<strong>in</strong>g <strong>in</strong> sta<strong>in</strong>less steel.<br />

S<strong>in</strong>ce 2002 she is Technical Director<br />

of <strong>IMOA</strong>, <strong>in</strong> charge of the market<br />

development programme of the<br />

association.<br />

www.sta<strong>in</strong>less-steel-world.net S T A I N L E S S S T E E L W O R L D S E P T E M B E R 2 0 0 7 31