Clinch Fastening Systems

Clinch Fastening Systems

Clinch Fastening Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Autoriv Installation <strong>Systems</strong><br />

<strong>Clinch</strong> <strong>Fastening</strong> <strong>Systems</strong><br />

• Controls and operator interface ease tracking of<br />

installation problems<br />

– Micro-controller or PLC monitors fastener in all<br />

critical locations, ensuring fasteners are ready<br />

for setting<br />

– Heavy-duty LED panel displays system status<br />

and exact fault locations, permitting it to be<br />

dealt with directly and quickly<br />

– System interacts with press to stop process if<br />

an abnormality is sensed<br />

– Rotary operator panel with system layout and<br />

checks; can always be turned to the press<br />

operator<br />

• Press simulation unit can be created<br />

– Allows complete system check (punch head,<br />

signal exchange and feeding unit) outside the<br />

press<br />

– Feeding system and punch heads can also be<br />

checked manually<br />

Benefits<br />

• Shortens downtime for changeovers<br />

• Highly-accurate positioning<br />

• Eases troubleshooting<br />

• Helps prevent damage to press<br />

• Reduces potential for scrapped or reworked<br />

assemblies<br />

• Withstands demanding assembly environments<br />

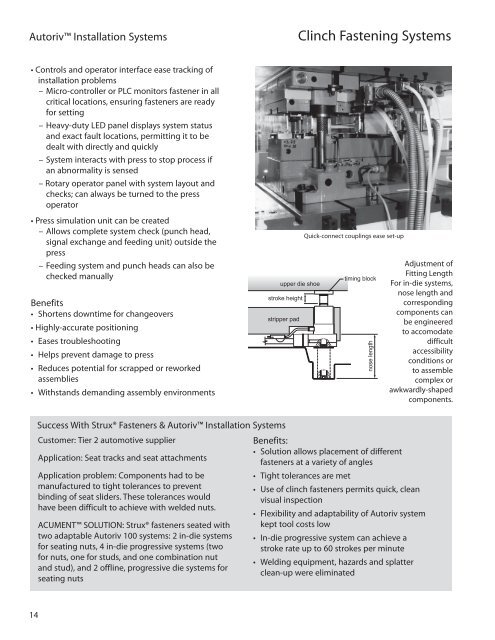

Quick-connect couplings ease set-up<br />

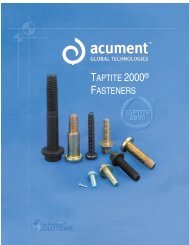

Adjustment of<br />

Fitting Length<br />

For in-die systems,<br />

nose length and<br />

corresponding<br />

components can<br />

be engineered<br />

to accomodate<br />

difficult<br />

accessibility<br />

conditions or<br />

to assemble<br />

complex or<br />

awkwardly-shaped<br />

components.<br />

Success With Strux® Fasteners & Autoriv Installation <strong>Systems</strong><br />

Customer: Tier 2 automotive supplier<br />

Benefits:<br />

• Solution allows placement of different<br />

Application: Seat tracks and seat attachments<br />

fasteners at a variety of angles<br />

Application problem: Components had to be<br />

• Tight tolerances are met<br />

manufactured to tight tolerances to prevent<br />

• Use of clinch fasteners permits quick, clean<br />

binding of seat sliders. These tolerances would<br />

visual inspection<br />

have been difficult to achieve with welded nuts.<br />

ACUMENT SOLUTION: Strux® fasteners seated with<br />

two adaptable Autoriv 100 systems: 2 in-die systems<br />

for seating nuts, 4 in-die progressive systems (two<br />

for nuts, one for studs, and one combination nut<br />

and stud), and 2 offline, progressive die systems for<br />

seating nuts<br />

• Flexibility and adaptability of Autoriv system<br />

kept tool costs low<br />

• In-die progressive system can achieve a<br />

stroke rate up to 60 strokes per minute<br />

• Welding equipment, hazards and splatter<br />

clean-up were eliminated<br />

14