Training Manual - Potter Electric Signal Company, LLC

Training Manual - Potter Electric Signal Company, LLC

Training Manual - Potter Electric Signal Company, LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

#2. Wet System With An Alarm Check Valve:<br />

This type of system has an alarm check valve, the valve is basically a check valve with an alarm port. The main<br />

purpose of the alarm check valve is to ring a mechanical bell called a water motor gong. The valve should, (if<br />

properly maintained), help hold the system pressure steady and reduce the possibility of false alarms. Under<br />

normal circumstances, the clapper of the valve is closed, blocking the alarm port, maintaining the system<br />

pressure, and preventing the sprinkler system water from leaking back into the city supply. When a sprinkler<br />

opens due to fire, or there is a large surge in the city pressure, the clapper of the valve opens. The alarm port is<br />

now exposed to the incoming water supply. When the pressure at the switch reaches 6 psi, the pressure switch<br />

trips, or the retard time starts on the pressure switch with built in retard. This alarm port may be piped to the<br />

outside of the building through a water motor gong.<br />

These systems can use a vane type flow switch with a retard or they can use a pressure type flow switch. The<br />

pressure type flow switch would be installed on the alarm port, in line with a water motor gong if one is being<br />

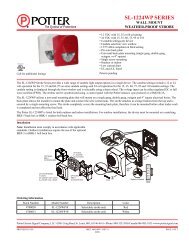

used. The pressure switch must either be installed on top of a retard chamber, (see Fig. 3), or a pressure switch<br />

with a built in retard, (see Fig. 4), must be used to prevent false alarms due to water surges. There must be an<br />

automatic drain on this line to allow the water to drain and the pressure to drop back to zero so the pressure<br />

switch can reset after a surge or activation of the alarm valve.<br />

Pressure type flow switches can be installed without disabling the sprinkler system. Since they are installed on<br />

the alarm port, there is no pressure or water present under normal circumstances. The sprinkler system does not<br />

have to be drained, they can be installed without shutting off the water supply. Therefore the sprinkler system is<br />

never out of service.<br />

Retard chambers are metal containers that fill with water when there is a surge in city pressure. They absorb<br />

the pressure increase thereby allowing the pressure switch to only operate in an actual alarm condition. There<br />

is an automatic drain at the bottom of the chamber to allow the surge to drain out. Retard chambers require<br />

maintenance to make sure that the drain stays clear and doesn’t get clogged with rust or corrosion. If a surge<br />

does not drain from the retard chamber before another surge happens, the retard chamber may fill causing the<br />

pressure switch to send a false alarm.<br />

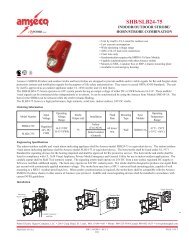

Fig. 3<br />

Pressure Type Flow Switch Installed On Top Of Retard Chamber<br />

WATER<br />

PRESSURE<br />

GAUGE<br />

(SYSTEM<br />

PRESSURE)<br />

BY-PASS LINE<br />

CHECK VALVE USED TO<br />

BUILD SYSTEM PRESSURE<br />

FROM SMALL SURGES<br />

WATER PRESSURE GAUGE<br />

(CITY PRESSURE)<br />

TAMPER<br />

DEVICE<br />

OSYSU<br />

OSY CONTROL VALVE (OPEN)<br />

(OPEN)<br />

(OPEN)<br />

RISER TO<br />

SPRINKLER HEADS<br />

CHECK<br />

WATER BY-PASS<br />

TEST VALVE<br />

(CLOSED)<br />

ANY SHUT-OFF VALVE IN<br />

LINE WITH A PRESSURE<br />

SWITCH IS REQUIRED TO BE<br />

SUPERVISED PER NFPA 72<br />

DRAIN<br />

VALVE<br />

(CLOSED)<br />

RBVS<br />

CHECK<br />

VALVE<br />

STRAINER<br />

WATERFLOW<br />

SWITCH<br />

PS10-1<br />

PS10-2<br />

DRIP<br />

CUP<br />

TO WATER<br />

MOTOR<br />

GONG<br />

RETARD<br />

CHAMBER<br />

DRAIN<br />

A pressure switch with a built in retard allows the system to remain operational at all times, and eliminates the<br />

maintenance required on the retard chamber. An automatic drain is still required to relieve the pressure on the line.<br />

WATER PRESSURE FROM<br />

CITY MAINS<br />

DRAIN<br />

PIPE<br />

Note: All water control valves shall be supervised per NFPA13 2010 8.16.1.1.2.1. Pressure type flow switches<br />

must be installed before any shut-off valve, or such valve must be electronically supervised.<br />

Note:<br />

Unless excess pressure is pumped into system, the waterflow device should have a retard per NFPA 72 2010<br />

17.12. There shall be no shut-off valve in line to a pressure type waterflow switch, unless the shut-off is<br />

electrically supervised. The <strong>Potter</strong> Model RBVS is designed to electrically supervise ball valves.<br />

18 19