Training Manual - Potter Electric Signal Company, LLC

Training Manual - Potter Electric Signal Company, LLC

Training Manual - Potter Electric Signal Company, LLC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

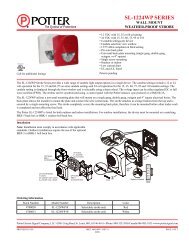

Fig. 10<br />

Valve Supervision (Tamper Switch)<br />

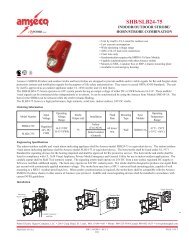

Selection Guide<br />

TYPE OF VALVE<br />

Installation of Waterflow Switches<br />

Read and follow the manufacturers instructions.<br />

Vane (Paddle) type: For use in wet pipe systems only!<br />

Vane type water flow switches can be installed in either vertical or horizontal sections of pipe. If they are<br />

installed in a horizontal section, they must be installed on the top half of the pipe. This is to prevent any debris<br />

in the pipe from falling into the throat area of the flow switch and affecting the paddle movement. They should<br />

never be installed on the bottom half of the pipe.<br />

OUTSIDE<br />

SCREW<br />

& YOKE<br />

(OS & Y)<br />

BUTTERFLY<br />

POST INDICATOR<br />

(PIV)<br />

(YARD OR WALL)<br />

BALL VALVE<br />

After shutting off the water to the system and draining it, drill the correct size hole for the flow switch. The hole<br />

should be de-burred and the inside of the pipe should be cleaned of any rust, scale or corrosion. Do not trim the<br />

paddle. The most likely area for a paddle to hang up is the area immediately upstream of the hole in the pipe,<br />

on the same side of the pipe as the hole. When water flows through the system, the paddle is pressed against the<br />

inside of the pipe.<br />

The flow switch should be centered in the pipe and the “U” bolt should be tightened evenly according to the<br />

manufacturer’s specifications. This will prevent the paddle from dragging on the inside of the pipe and prevent<br />

the flow switch from leaking.<br />

WALL<br />

When filling the system, first open any valves at the end of the system or branch lines. Slowly open the water<br />

supply valve, let the water flow out of the valves until it is flowing smoothly. This will prevent air from entering<br />

the system and help bleed any trapped air out of the system.<br />

Fig. 11<br />

COVER TAMPER SWITCH<br />

DO NOT LEAVE COVER OFF FOR<br />

EXTENDED PERIOD OF TIME<br />

OS & Y<br />

OUTSIDE SCREW<br />

& YOKE<br />

BUTTERFLY VALVE<br />

PIV<br />

POST INDICATOR VALVE<br />

WALL PIV<br />

WALL POST<br />

INDICATOR VALVE<br />

RBVS<br />

TIGHTEN NUTS<br />

ALTERNATELY<br />

OSYSU-1 ONE CONTACT<br />

OSYSU-2 TWO CONTACTS<br />

PCVS-1 ONE CONTACT<br />

PCVS-2 TWO CONTACTS<br />

DWG# 8704200-J1<br />

MOUNT ON PIPE SO<br />

ARROW ON SADDLE<br />

POINTS IN DIRECTION<br />

OF WATERFLOW<br />

ROLL PADDLE IN<br />

OPPOSITE DIRECTION<br />

OF WATERFLOW<br />

DIRECTION OF<br />

WATERFLOW<br />

DWG. #1146-1E<br />

30 31