Training Manual - Potter Electric Signal Company, LLC

Training Manual - Potter Electric Signal Company, LLC

Training Manual - Potter Electric Signal Company, LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

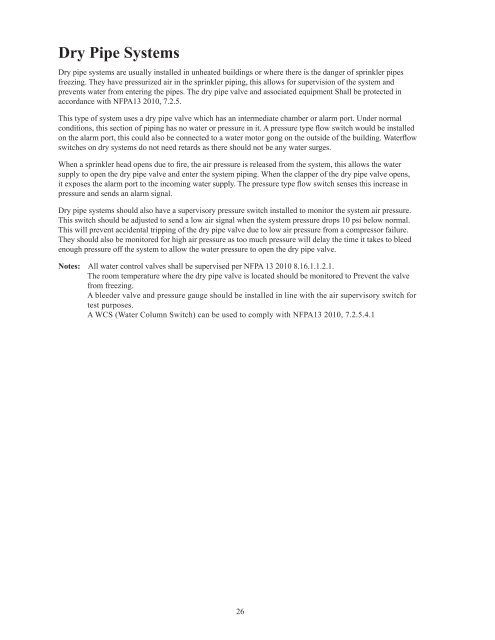

Dry Pipe Systems<br />

Dry pipe systems are usually installed in unheated buildings or where there is the danger of sprinkler pipes<br />

freezing. They have pressurized air in the sprinkler piping, this allows for supervision of the system and<br />

prevents water from entering the pipes. The dry pipe valve and associated equipment Shall be protected in<br />

accordance with NFPA13 2010, 7.2.5.<br />

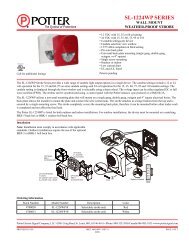

Fig. 7<br />

TO WATER<br />

MOTOR GONG<br />

Dry Pipe Valve System<br />

Waterflow Alarm Installation<br />

RISER TO<br />

SPRINKLER HEADS<br />

This type of system uses a dry pipe valve which has an intermediate chamber or alarm port. Under normal<br />

conditions, this section of piping has no water or pressure in it. A pressure type flow switch would be installed<br />

on the alarm port, this could also be connected to a water motor gong on the outside of the building. Waterflow<br />

switches on dry systems do not need retards as there should not be any water surges.<br />

When a sprinkler head opens due to fire, the air pressure is released from the system, this allows the water<br />

supply to open the dry pipe valve and enter the system piping. When the clapper of the dry pipe valve opens,<br />

it exposes the alarm port to the incoming water supply. The pressure type flow switch senses this increase in<br />

pressure and sends an alarm signal.<br />

Dry pipe systems should also have a supervisory pressure switch installed to monitor the system air pressure.<br />

This switch should be adjusted to send a low air signal when the system pressure drops 10 psi below normal.<br />

This will prevent accidental tripping of the dry pipe valve due to low air pressure from a compressor failure.<br />

They should also be monitored for high air pressure as too much pressure will delay the time it takes to bleed<br />

enough pressure off the system to allow the water pressure to open the dry pipe valve.<br />

Notes: All water control valves shall be supervised per NFPA 13 2010 8.16.1.1.2.1.<br />

The room temperature where the dry pipe valve is located should be monitored to Prevent the valve<br />

from freezing.<br />

A bleeder valve and pressure gauge should be installed in line with the air supervisory switch for<br />

test purposes.<br />

A WCS (Water Column Switch) can be used to comply with NFPA13 2010, 7.2.5.4.1<br />

WATERFLOW<br />

SWITCH<br />

PS10-1<br />

PS10-2<br />

RBVS<br />

WATER BY-PASS<br />

TEST VALVE<br />

(CLOSED)<br />

PETCOCK<br />

(OPEN)<br />

CHECK<br />

BALL<br />

DRIP<br />

VALVE<br />

WATER<br />

PRESSURE<br />

GAUGE<br />

AIR SUPPLY<br />

VALVE<br />

(OPEN)<br />

CHECK<br />

AIR<br />

PRESSURE<br />

WATER LEVEL<br />

BVL BLEEDER<br />

TEST VALVE<br />

(OPEN)<br />

AIR PRESSURE<br />

SUPERVISORY<br />

PS40-1<br />

PS40-2<br />

AIR SUPPLY<br />

AIR<br />

PRESSURE<br />

GAUGE<br />

PRIMING<br />

CHAMBER<br />

SHUT-OFF<br />

VALVE<br />

(CLOSED)<br />

INTERMEDIATE<br />

CHAMBER<br />

DRAIN VALVE (CLOSED)<br />

TAMPER<br />

DEVICE<br />

OSYSU<br />

DRIP<br />

CUP<br />

OS & Y<br />

CONTROL<br />

VALVE<br />

(OPEN)<br />

CHECK<br />

Note:<br />

Per NFPA72 2010 23.8.5.10.4, there shall be<br />

no shut-off valve in line to a pressure type<br />

waterflow switch, unless the shut-off ball<br />

valve is electrically supervised with <strong>Potter</strong><br />

Model RBVS (Retrofit Ball Valve Switch).<br />

WATER PRESSURE<br />

FROM CITY MAINS<br />

DRAIN<br />

PIPE<br />

DWG# 8704200-4A<br />

26 27