Download - Vinnova

Download - Vinnova

Download - Vinnova

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

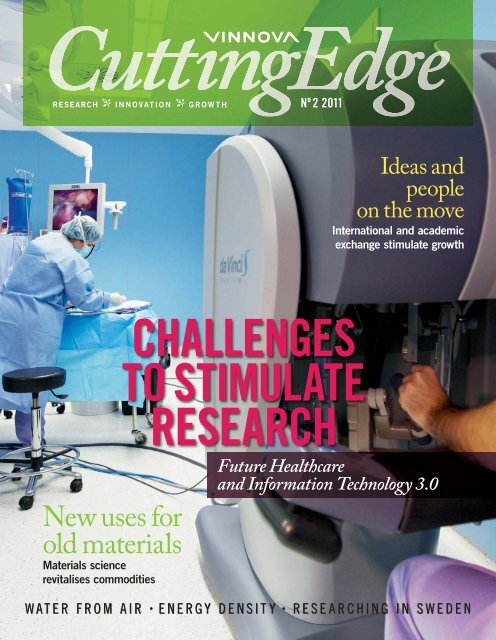

RESEARCH • INNOVATION • GROWTH No 2 2011<br />

<br />

people<br />

<br />

International and academic<br />

exchange stimulate growth<br />

CHALLENGES<br />

TO STIMULATE<br />

RESEARCH<br />

<br />

<br />

Materials science<br />

revitalises commodities<br />

Future Healthcare<br />

and Information Technology 3.0<br />

WATER FROM AIR ENERGY DENSITY RESEARCHING IN SWEDEN

EDITORIAL<br />

Challenges<br />

drive<br />

innovation<br />

Innovation is increasingly<br />

recognised as a key determinant<br />

of competitiveness, prosperity<br />

and sustainable development.<br />

Sweden is frequently ranked among<br />

the most innovative countries in the<br />

world and is also home to many large<br />

and successful multinational<br />

companies. As a proportion<br />

of its GDP, Sweden is also a<br />

world leader for investing<br />

in research and development.<br />

VINNOVA has identified<br />

four areas, or challenges, as<br />

starting points for future<br />

initiatives that will serve as drivers of<br />

innovation and sustainable growth:<br />

Information Society 3.0, Future<br />

healthcare, Competitive production<br />

and Sustainable attractive cities.<br />

This magazine presents two of<br />

these challenges and other examples<br />

of research and innovation conducted<br />

in Sweden with the support<br />

of VINNOVA and other<br />

research funding agencies.<br />

We hope it will be of<br />

interest to innovation<br />

actors around the world.<br />

Pleasant reading!<br />

Charlotte Brogren,<br />

Director General VINNOVA<br />

CONTENTS<br />

06 MATERIALS SCIENCE<br />

With both short- and long-term potential,<br />

material science – which investigates the relationship<br />

between the structure of materials and<br />

their observable properties – is enjoying a strong<br />

position in various industries within Sweden.<br />

From super-strong paper to lightweight boats, the<br />

applications for this field are endless.<br />

10 FUTURE HEALTHCARE<br />

The growing need for efficient healthcare solutions<br />

and services is prevalent in both established<br />

and growing economies worldwide. A variety of<br />

different factors have set the bar high for future<br />

care services, technical and medical solutions and<br />

efficient production. Early results are promising<br />

thanks in large measure to partnerships between<br />

industry, academia and research institutes.<br />

15 RESEARCHER EXCHANGE<br />

While there are more female researchers today<br />

than ever before, the research world remains rife<br />

with gender disparity. The VINNMER programme,<br />

an initiative inaugurated by VINNOVA, seeks to<br />

create gender balance in leadership roles for female<br />

researchers in academia, research institutes and<br />

industry.<br />

Publisher Charlotte Brogren, VINNOVA<br />

Editors Sanna Berg, VINNOVA Anders<br />

Nordner and Linas Alsenas, Appelberg<br />

Art Directors Ersan Curuklu and<br />

Markus Ljungblom, Appelberg<br />

Print Edita Västra Aros<br />

Paper Arctic Volume<br />

Cover photo Javier Larrea<br />

Address www.VINNOVA.se<br />

Phone +46 8 473 30 00<br />

ISSN 1650 – 3120<br />

Translation Jonathan Dellar<br />

19 INFORMATION SOCIETY 3.0<br />

The aim of VINNOVA’s vision for the Information<br />

Society 3.0 is not only to gain a competitive<br />

advantage internationally for Sweden, but to<br />

improve the world in which we live. Based on<br />

these challenges, investments are being made in<br />

needs-driven innovation and effective systems.<br />

2 VINNOVA-CUTTING EDGE No 2 2011

VINNOVA<br />

- bridging research and resources<br />

PHOTO: ISTOCKPHOTO<br />

FAMOUS SWEDISH INNOVATIONS<br />

Innovation is essential for meeting economic and social challenges and<br />

ensuring prosperity and quality of life. VINNOVA, the Swedish Governmental<br />

Agency for Innovation Systems, is investing in research to<br />

strengthen Sweden’s innovative capacity for competitiveness, sustainable<br />

development and growth.<br />

VINNOVA’s efforts range from programmes<br />

for R&D projects in small<br />

companies and universities, to<br />

long-term development of strong<br />

research and innovation environments<br />

that attract R&D investment and expertise<br />

from around the world.<br />

Most of these efforts are based on co-financing<br />

with industry, academia and the public sector<br />

to ensure maximum relevance and impact.<br />

Thus, VINNOVA works closely with companies,<br />

research environments and public actors as key<br />

drivers of innovation. VINNOVA has identified<br />

four areas, or challenges, as starting points for<br />

future initiatives that will serve as drivers of<br />

innovation and sustainable growth: Information<br />

society 3.0, Future healthcare, Competitive<br />

production and Sustainable attractive cities.<br />

VINNOVA’s opportunities for contributing to<br />

sustainable growth in Sweden are increasingly<br />

dependent on advanced international collaboration.<br />

A unique collaboration with China has been<br />

initiated for future mobile systems and VINNOVA<br />

has a bilateral programme with China’s Ministry<br />

of Science and Technology. Elsewhere, efforts<br />

are underway in India within the healthcare field<br />

and there is collaboration with the US on traffic<br />

safety research and in Japan on multidisciplinary<br />

biotechnology. These are just a few examples.<br />

VINNOVA has also been commissioned by the<br />

government to promote Swedish participation<br />

in R&D projects under the EU’s Framework<br />

Programmes.<br />

TO ENSURE THE QUALITY of its endeavours,<br />

VINNOVA systematically evaluates and analyses its<br />

efforts to ensure that they are making an impact<br />

and generating significant socio-economic value.<br />

For example, impact analyses have shown that<br />

public investment in traffic safety research saves<br />

thousands of lives and billions of Swedish kronor<br />

annually.<br />

At the same time, these analyses have also<br />

strengthened the Swedish automotive industry. The<br />

knowledge gained through this and other impact<br />

analyses provides a basis for policy efforts and a<br />

foundation for directing new investment towards<br />

areas where it will have the greatest impact. •<br />

THE PROPELLER – JOHN ERICSSON<br />

In 1839, Swedish inventor John<br />

Ericsson introduced practical<br />

screw propulsion. The screw<br />

propeller had greater efficiency,<br />

was more compact and required a less complex<br />

power transmission system than its rivals. In<br />

addition to the propeller, Ericsson also invented<br />

the hot air engine and a solar machine. Ericsson<br />

realised the majority of his inventions in England<br />

and the USA.<br />

THE ZIPPER – GIDEON SUNDBÄCK<br />

In 1914, Gideon Sundbäck patented<br />

the classic zipper consisting<br />

of two cotton ribbons with metal<br />

teeth and a slider that closes and<br />

opens the zipper. The zipper has basically looked<br />

the same ever since. Sundbäck worked as an<br />

electrical engineer and had an international<br />

career eventually working for Westinghouse in<br />

the USA.<br />

THE TETRA CLASSIC – ERIK WALLENBERG<br />

In 1944, researcher Erik Wallenberg<br />

invented a paper carton in the<br />

shape of a triangular pyramid used<br />

for storing and transporting milk.<br />

The product, called Tetra Classic, was patented<br />

and became the starting point for Tetra Pak, the<br />

global packaging company established in 1951<br />

by Ruben Rausing.<br />

THE PACEMAKER – RUNE ELMQVIST<br />

On October 1958, the first successful<br />

pacemaker was implanted<br />

in a human body at Karolinska<br />

Institutet in Stockholm. The innovator<br />

was Rune Elmqvist, engineer and doctor.<br />

Elmqvist was development manager at Elema-<br />

Schönander which today is a part of St. Jude<br />

Medical, a global company developing medical<br />

technology and services.<br />

VINNOVA-CUTTING EDGE No 2 2011<br />

3

IN SHORT<br />

Swedish invention<br />

SOLVES WATER PROBLEM<br />

Uppsala-based company Airwatergreen has<br />

developed a patent-pending technology which<br />

can cost-effectively condense water out of<br />

air. A version of the Airwaterwell product is<br />

currently being tested in Uppsala University's<br />

library.<br />

Today’s limited supply of fresh water sources<br />

is a problem. With Airwaterwell, fresh water<br />

can be produced anywhere, with just air and<br />

sunlight.<br />

The technology is simple, which translates<br />

into a long service life and cheap manufacturing<br />

costs. It can also be packaged in<br />

various ways. For example, it can be used as<br />

a humidifier or sold for water production to<br />

private individuals and homeowners. Within<br />

two years, Airwatergreen may have developed<br />

the technology to construct a large-scale<br />

demonstration plant.<br />

SWEDISH OYSTERS<br />

HAVE GREAT POTENTIAL<br />

Kent<br />

Berntsson<br />

THE SWEDISH COAST is ideal<br />

for cultivating the Rolls-Royce of<br />

oysters, the Flat Oyster. France,<br />

Holland and Spain farmed these<br />

delicacies up until the 1950s, but<br />

when parasites wiped out their entire stock<br />

they turned instead to Giant Pacific Oysters<br />

from Japan. The low water temperatures in<br />

Sweden make it hard for parasites to take<br />

hold, so the Flat Oysters there have managed<br />

to avoid infection.<br />

European demand for the scarce Flat Oyster<br />

is very great. Fortunately, the waters off Bohuslän<br />

on Sweden's west coast have high salt<br />

content levels and are uncommonly nutritious,<br />

so the oysters grow quickly.<br />

“Our conditions are unique; the water contains<br />

nutrients and phytoplankton, which means<br />

we can produce 50,000 tonnes of oysters<br />

or mussels per year,” says Kent Berntsson,<br />

Production Manager and one of the founders of<br />

oyster cultivators Ostrea. “The potential exports<br />

are worth billions of Swedish crowns.”<br />

One challenge to cultivation is the great<br />

variation in the sea’s production of larvae, so<br />

Ostrea has built a special hatchery. Breeding<br />

oysters are brought from the seas off the Koster<br />

Islands to propagating tanks here. However,<br />

the process is very delicate and only 0.25 percent<br />

of the larvae become full-sized oysters.<br />

Ostrea wants to change this. If it is to succeed,<br />

it will require greater control over the saltwater<br />

and food in the hatchery. The company<br />

anticipates that the larvae that have been put<br />

out will yield half a million oysters by 2014. Due<br />

to its measures this year, Ostrea is estimating<br />

a harvest of 3 million oysters in 2015, at which<br />

point a further 40 people will need to be hired.<br />

PHOTO: GETTYIMAGES<br />

PHOTO: OSTREA<br />

4<br />

VINNOVA-CUTTING EDGE No 2 2011

Future boat imitates dolphin flipper<br />

Compared with a propeller that revolves rapidly at high<br />

revs, a dolphin’s flippers go back and forth at a relatively<br />

slow rate. Using this energy-efficient process, a dolphin<br />

can top 30 knots at one horsepower. Now this principle is<br />

being transferred to boat engines that are being driven by<br />

flippers instead of a propeller.<br />

“If we can get this working as well as it does in nature,<br />

there’ll be a whole new industry with loads of jobs,” says<br />

Johan Lund, CEO of Dolprop Industries. “Our challenge is<br />

to show that it really works.”<br />

Dolprop was formed in 2007 and last year received a<br />

grant from VINNOVA. Backed up by a patented invention,<br />

it is now a case of developing the technology all the way to<br />

the finished product.<br />

The company has constructed a test pool on Ekerö<br />

island in Sweden’s Lake Mälaren. In the 5 m x 2.5 m cylindrical<br />

pool, water streams around a permanent rig. Here,<br />

drive devices in different materials, sizes and designs<br />

are tested out. Stage one is to develop electric-powered<br />

outboards for smaller motorboats and sail craft.<br />

At a time when increasing numbers of people are<br />

searching for environmentally friendly alternatives,<br />

Lund believes there is a market for small, highperformance<br />

electric motors. If all goes<br />

according to plan, the first of them<br />

will be launched onto the market<br />

in 2012.<br />

Illustration Thomas Jemt<br />

BENEFITS OF FLIPPER DRIVE<br />

SAFER: Propeller accidents are avoided as the propeller is replaced with a soft flipper.<br />

QUIETER: The noise created by a propeller rotating at a high speed disappears. Dolprop’s patented Fluke<br />

Propulsion Device replaces the propeller with a flipper.<br />

MICROWAVES SHRINK FOOD WASTE<br />

Food waste is bulky and can smell bad if not<br />

dealt with properly. Correct handling is a challenge<br />

on ships and oil platforms where space<br />

is limited and there are few opportunities to<br />

dispose of the waste. It was these conditions<br />

that led Stena Metall, in partnership with<br />

the industrial company GISIP, to develop a<br />

microwave-based technology for the rapid drying<br />

and sterilisation of food waste.<br />

Using microwave ovens the size of fridges, the<br />

aim is to reduce the weight of the waste by 85<br />

percent. GISIP has conducted a pilot project and<br />

the results are positive.<br />

”The principle is the same as with a normal<br />

microwave oven,” says Carina Pettersson, project<br />

manager at Stena Metall. “The difference is we<br />

are using a vacuum process in which the water is<br />

condensed out and the waste dries rapidly and<br />

effectively.”<br />

By-products of the process include an odourless<br />

powder that can be used as fuel, fertiliser<br />

and animal fodder, and excess warmth that can<br />

be used for heating.<br />

NDER<br />

INNOVATION<br />

& GENDER<br />

Dried food waste is turn into fish fodder.<br />

PHOTO: SHUTTERSTOCK<br />

INNOVATION<br />

& GENDER<br />

INNOVATION is really about questioning what is<br />

taken for granted – challenging the norm – and<br />

finding new pathways to things. In challenging<br />

the norm, we need a critical perspective and<br />

undoubtedly a gender perspective can be helpful.<br />

Read more: www.VINNOVA.se/InnovationGender<br />

VINNOVA-CUTTING EDGE No 2 2011<br />

5

MATERIALS SCIENCE //<br />

NEW MATERIALS<br />

create competitive industry<br />

As the challenge to Swedish export products from recently industrialised<br />

countries gets tougher, companies must find new<br />

competitive advantages. This is where materials science can<br />

play a vital role. BY ÅKE R MALM PHOTO ISTOCKPHOTO<br />

The picture of Sweden’s position in<br />

materials science is also true of its<br />

basic industry.<br />

“We are strong in steel and cellulose<br />

materials,” says Professor Lars Berglund,<br />

head of the Royal Institue of Technology's<br />

Biocomposites Research Division.<br />

He leads a long-term project seeking to<br />

develop new materials based on forest products.<br />

The objective is to strengthen the Swedish<br />

forest industry’s position when competing with<br />

countries offering raw materials based on fastgrowing<br />

woods.<br />

“If your products are very simple, it’s easier<br />

for eucalyptus to compete,” he says. “If you add<br />

knowledge and technology, it’s a different matter.”<br />

THE PROJECT RESULTS include super-strong<br />

paper and something called aerogel, an incredibly<br />

light material useful as thermal insulation.<br />

Both are based on nanotechnology in which the<br />

researchers manipulate material structure at just<br />

above the atomic level.<br />

“Nanostructured material is a very important<br />

area,” Berglund says. “It’s incredibly knowledgeintensive,<br />

and we’re able to make great strides<br />

with properties.”<br />

Materials science has enjoyed a strong position<br />

within the Swedish engineering industry,<br />

but Berglund feels companies are moving more<br />

in the direction of applications and less towards<br />

new development. He also sees a structural<br />

change, with smaller companies taking<br />

an increasingly larger role. These are high-tech<br />

companies with niche knowledge, such as in the<br />

biomedical field.<br />

IN THE SHORT-TERM, materials science is about<br />

finding new applications or products for existing<br />

materials. Perhaps steel in a vehicle can be<br />

replaced with composites to save weight and<br />

fuel, or constituents made from renewable raw<br />

materials can substitute for plastic.<br />

An example is the research project Lightweight<br />

Construction Applications at Sea (LÄSS)<br />

which was started in order to strengthen the<br />

Swedish shipbuilding industry. Amongst other<br />

things, it has helped Kockums, the marine construction<br />

firm, develop competitive vessels and<br />

marine superstructures in composite materials.<br />

“It’s not a matter of us teaching Kockums how<br />

to build ships,” says Tommy Hertzberg of the SP<br />

Technical Research Institute of Sweden, which<br />

has been coordinating the project. “However,<br />

LÄSS has shown what is important and helped<br />

influence the authorities, Swedish Maritime<br />

Administration and others.”<br />

So in the field of materials science, to which<br />

countries should Sweden measure itself? According<br />

to Lars Berglund, the Asian countries<br />

are rapidly gaining ground, but the strongest<br />

research milieus are still in the US.<br />

“They don’t have individual materials science<br />

departments dealing solely with metals or plastics,”<br />

Berglund says. “Rather, they have multidisciplinary<br />

departments covering all types of<br />

materials. We don’t have that in Sweden.”<br />

IN BRIEF<br />

Materials science is the creation and application<br />

of knowledge that relates composition and<br />

materials processes to the structure, properties<br />

and functions of the material.<br />

6<br />

VINNOVA-CUTTING EDGE No 2 2011

Nanocellulose creating new packaging<br />

Nanocellulose allows plastic and aluminium to be replaced with<br />

renewable materials in some packaging. The knowledge centre<br />

BiMaC Innovation is currently working on scaling up production<br />

to an industrial level.<br />

BY ÅKE R MALM<br />

PHOTOS ISTOCKPHOTO, BIMAC<br />

PAPER HAS TWO important properties that<br />

limit its use in packaging: it cannot be moulded<br />

because it is not ductile, and it absorbs water.<br />

Thus fluids are often packed in plastic bottles or<br />

cartons with protective layers of polythene and<br />

aluminium, materials that are not renewable.<br />

BiMaC Innovation is developing methods to<br />

replace these with nanomaterial-based barriers,<br />

alternatives that are also biodegradable.<br />

“The focus is on the borderland between new<br />

and traditional packaging materials,” says Professor<br />

Tom Lindström, program director at BiMaC<br />

Innovation.<br />

This substance known as nanocellulose has a<br />

key role in changing the properties of paper in<br />

various ways. In simple terms, nanocellulose can<br />

be described as fibres broken down into their<br />

constituents, or fibrils, which are then concentrated<br />

into a form of gel. Using this as an additive,<br />

the researchers at BiMaC have shaped paper into<br />

three-dimensional shapes just like a bottle. Other<br />

projects have shown how nanocellulose can be<br />

used to create barrier layers against oxygen and<br />

water vapour or for making a foam that serves the<br />

same protective function as styrofoam.<br />

“There is major industrial interest in the nanocellulose<br />

development,” says Lindström. “At the<br />

moment, it’s most intense in the forest industry.”<br />

The demonstrator project is now concluded<br />

and the pilot plant for producing 100 kg of nanocellulose<br />

a day has ben put into operation at the<br />

research institute Innventia, where Lindström<br />

also works.<br />

“We’re quite busy making a commercial nanocellulose<br />

product,” he says.<br />

LINDSTRÖM BELIEVES that within two or three<br />

years it may be possible to start projects for<br />

major plants. At the same time, he is attempting<br />

to partner Innventia and BiMaC Innovation<br />

with industry under the umbrella of a larger EU<br />

project. The objective is to build a factory that can<br />

produce 2,000 tonnes of nanocellulose per year.<br />

“We want applications that can be integrated<br />

into pulp and paper factories,” Lindström says.<br />

ASSIGNMENT:<br />

Stopping bacteria in hygiene products<br />

BY ÅKE R MALM PHOTO HÅKAN FLANK<br />

IN BRIEF<br />

PURPOSE: To develop antibacterial cellulose<br />

fibres for use mainly in hygiene products.<br />

PARTICIPANTS: The Department of Fibre and<br />

Polymer Technology at the Royal Institute of Technology,<br />

BASF, SCA and Karolinska Institutet.<br />

RESEARCHERS at Royal Institute of Technology<br />

in Stockholm (KTH) have developed<br />

a new method of coating cellulose fibres<br />

with antibacterial polymers. Benefits should<br />

include better hygiene products.<br />

SCA had the fibres, BASF the antibacterial<br />

polymers, and the researchers at KTH the<br />

ideas and ambition to bring them together.<br />

This was the basis of a research project<br />

which, with VINNOVA’s support, will yield<br />

new antibacterial materials.<br />

“If you can find the right concept the<br />

market is enormous, especially in the<br />

hygiene sector,” says Monica Ek. She and<br />

Lars Wågberg are jointly leading the project<br />

at KTH’s Department of Fibre and Polymer<br />

Technology.<br />

Developed in partnership with doctoral<br />

student Josefin Illergård, their method is<br />

based on attaching antibacterial polymers<br />

to cellulose fibres in a water-based medium,<br />

without the dangerous solvents that had<br />

previously been necessary.<br />

“We’ve done a lot of work on the choice<br />

of polymers, designing their appearance –<br />

and with antibacterial testing,” says Ek.<br />

The result is a patent describing which<br />

polymers should be used to obtain the<br />

antibacterial effect. Work is now under way<br />

to discover exactly what causes it whilst trials<br />

involving real products have begun.<br />

“The clever thing about this method is<br />

that if we can get it to work, it can be used in<br />

many different types of material,” says Ek.<br />

“It may even work on textiles as well.”<br />

In the long run, this means antibacterial<br />

polymers may find uses beyond the hygiene<br />

field. Perhaps in sports clothing or wound<br />

dressings, areas that currently use other<br />

agents against bacteria.<br />

“The current commercial market mainly<br />

consists of silver products, but the problem<br />

with silver is that it doesn’t stay put and can<br />

leak out,” says Ek.<br />

VINNOVA-CUTTING VINNOVA-NYTT EDGE OKTOBER No 2 2010 2011<br />

7

MATERIALS SCIENCE //<br />

Light marine materials<br />

GET HEFTIER ROLE<br />

The LÄSS research project has<br />

broken new ground for the use<br />

of aluminium and composites<br />

in marine designs. This is as<br />

much a matter of materials science<br />

as classification law.<br />

BY ÅKE R MALM<br />

PHOTO KOCKUMS<br />

“Cut the weight by at least 30 percent.” That<br />

was one of the objectives when Tommy Hertzberg<br />

at the SP Technical Research Institute<br />

of Sweden started a research project in 2005 -<br />

Lightweight Construction Applications at Sea,<br />

or LÄSS - to increase the use of light materials<br />

within the shipbuilding industry. The aim was to<br />

give Swedish companies competitive advantages<br />

through increased knowledge of aluminium<br />

composites in vessel design. Its advantages included<br />

a drastic reduction in the fuel consumption<br />

of a vessel.<br />

THE WORK WAS based on several different types<br />

of vessel, including a car ship with an aluminium<br />

superstructure and a high-speed ferry made<br />

entirely of composites.<br />

“Basically, this meant we designed the vessels<br />

for these lightweight materials,” says Hertzberg.<br />

“Then we demonstrated how much could be<br />

saved, how much it cost and the scale of its environmental<br />

impact.”<br />

Maritime construction is mainly governed by<br />

various regulations, with compliance controlled<br />

by classification companies such as Lloyds<br />

and Det Norske Veritas (DNV). In addition to<br />

material strength, the rules lay down major requirements<br />

for fire resistance. The fire properties of<br />

aluminium were already documented, but not<br />

those of the composite material, so this required<br />

large-scale fire testing.<br />

“We verified their suitability, and various<br />

certificates now exist that indicate that these<br />

materials can be used in construction,” Hertzberg<br />

says.<br />

When LÄSS concluded in 2008, the analysis<br />

showed that the typical weight reduction due to<br />

changing construction materials was 50 percent<br />

or more. The payback period for investment in<br />

lightweight materials varies depending on the<br />

type of vessel, but in all cases studied by LÄSS it<br />

was estimated at less than five years.<br />

THE RESULTS OF LÄSS are now starting to be<br />

visible in the form of various partnerships in the<br />

industry, such as the Composite Superstructure<br />

Concept. This is a joint venture in which marine<br />

and naval technology company Kockums and<br />

the Swedish company DIAB are collaborating<br />

with Thermal Ceramics in England. Kockums<br />

can also point to a very definite example – at<br />

Östersjön.<br />

“We recently delivered the first working craft<br />

in the world built of carbon fibre and classified<br />

under DNV’s rules,” says Lars Tedehammar,<br />

senior vice-president for Kockums Surface Vessel<br />

Division.<br />

THE CLIENT IS Fintry Marine Design in Switzerland<br />

and the vessel, of the CarboCat type, is<br />

now in service at the windfarm off Rostock.<br />

According to the initial reports to Tedehammar,<br />

the fuel consumption is around half that of a<br />

corresponding aluminium design.<br />

IN BRIEF<br />

PURPOSE: To increase knowledge of light<br />

materials in marine construction; to increase<br />

the competitiveness of the Swedish shipping<br />

industry; to make shipping more efficient.<br />

PARTICIPANTS: Universities, research bodies,<br />

shipbuilders, shipping companies, materials<br />

manufacturers, authorities and classification<br />

companies. Thirty participants in total.<br />

8<br />

VINNOVA-CUTTING EDGE No 2 2011

IN SHORT<br />

Green<br />

POWER<br />

Illustration Alexander Rauscher<br />

A battery consisting only of combustible material<br />

and which could be virtually any shape or size<br />

may become a reality in the future. The Nanotechnology<br />

and Functional Materials Department<br />

of the Ångström Laboratory at Uppsala University<br />

has been working for a long time with cellulose<br />

from green algae in its biotechnology work. During<br />

a project in which Professor Maria Strømme<br />

and her research colleagues investigated the<br />

behaviour of algae cellulose in water, they found<br />

that the cellulose could also serve as a constituent<br />

of batteries.<br />

Separator<br />

Filter paper saturated with<br />

elektrolyte<br />

Anode<br />

Conductive paper<br />

made of algae cellulose<br />

Collector<br />

Graphite foil<br />

Cathode<br />

Conductive paper<br />

made of algae cellulose<br />

Green algae cellulose has a large surface area<br />

which has good electrochemical properties when<br />

coated with a conductive polymer. The algae battery<br />

is very environmentally friendly, as it consists<br />

solely of nanostructured cellulose from green<br />

algaes, a conductive polymer and a saltwater<br />

electrolyte.<br />

In September 2011, tests of the first prototype of<br />

the algae battery commenced in an environmentally<br />

friendly TV remote developed by Motorola.<br />

Glass facades generate electricity.<br />

LEAVES<br />

OF GLASS<br />

NLAB SOLAR is developing solar cells for<br />

buildings to imitate a plant’s way of converting<br />

sunlight into energy. But instead of chlorophyll,<br />

titanium dioxide is used by transparent<br />

solar cells to convert the sun’s rays into electricity.<br />

The objective is to cover the glass facades<br />

of buildings with these cells to generate<br />

electricity and protect against harmful rays.<br />

NLAB Solar’s cells are a further development<br />

of technology originally produced by Michael<br />

Grätzel in Switzerland. While a variety of<br />

manufacturers around the world are currently<br />

producing ‘Grätzel solar cells,’ NLAB’s cells<br />

are equipped with an additional reflective layer<br />

inside. This difference means that NLAB’s<br />

solar cells are significantly more efficient than<br />

those of their competitors. Previously, the best<br />

cells had an efficiency of just over 10 percent,<br />

and those intended for covering glass facades<br />

on buildings seldom put out more than three<br />

or four percent of the incident solar energy.<br />

“We’ve succeeded in turbo-charging our solar<br />

cells,” says Giovanni Fili, CEO of NLAB Solar.<br />

“Because of their reflective surface, the efficiency<br />

of our transparent cells is 37 percent<br />

higher than those of our competitors.”<br />

According to Fili, the company has overcome<br />

its main obstacles in terms of solar cell<br />

technology and is concentrating instead on<br />

optimising the industrial process.<br />

“Thanks to the support we have received from<br />

VINNOVA’s programme ‘Green nanotechnology<br />

for the environmental field,’ we have been<br />

able to put the theoretical knowledge we’ve<br />

have had for many years into a technology that<br />

works industrially,” says Fili. “The support has<br />

also brought increased interest from industry,<br />

and we’ve been able to get a large grant from<br />

the European Union to build a production<br />

plant; we’ll soon show that industrial production<br />

of facade glass with built-in solar cells is<br />

possible.”<br />

VINNOVA-CUTTING EDGE No 2 2011<br />

9

FUTURE HEALTHCARE //<br />

A range of different factors have set<br />

the bar high for future care services,<br />

technical and medical solutions and<br />

efficient production, and they must<br />

not be developed at the expense of<br />

the environment.<br />

BY KATARINA AHLFORT<br />

PHOTO JAVIER LARREA/SCANPIX<br />

HEA<br />

FUTURE 10 VINNOVA-NYTT VINNOVA-CUTTING OKTOBER EDGE 2010 No 2 2011

VVINNOVA HAS IDENTIFIED four areas,<br />

or challenges, as starting points<br />

for future initiatives. One of these<br />

challenges - Future Healthcare - may<br />

be extremely important to Swedish competitiveness<br />

internationally.<br />

“Some future care needs are directly linked<br />

to demographics,” says Maria Landgren, chief<br />

strategy officer within health at VINNOVA. “In<br />

the west of Sweden, we have a growing number<br />

of elderly and sick people, as well as more<br />

elderly people who are healthy but in need of<br />

more primary care.”<br />

As the number of younger people available<br />

for gainful employment decreases, the need for<br />

efficiency within healthcare grows.<br />

“We have to run care in a smarter fashion,<br />

perhaps by starting with the patient’s needs,<br />

using innovative IT solutions, new work<br />

processes or new solutions for smarter home<br />

healthcare,” says Landgren.<br />

Growing economies such as Brazil are also<br />

finding a greater demand for efficient healthcare<br />

services and an ever-increasing need for<br />

new solutions in the care field.<br />

THE RESEARCH COMMUNITY sees major opportunities<br />

for exporting Swedish healthcare<br />

innovations.<br />

“For example, our advanced infrastructure<br />

gives us a bird’s-eye view of the care situation,”<br />

Landgren says. “This includes our care quality<br />

register which holds personal and register data<br />

on the national population.”<br />

The register makes it possible to demonstrate<br />

the effectiveness of different care<br />

measures. Furthermore, Swedes generally have<br />

a positive attitude towards participating in research<br />

studies, and the healthcare industry has<br />

an IT maturity considered important in this<br />

context. However, there is still major untapped<br />

potential.<br />

EXAMPLES OF SWEDISH solutions within<br />

health and fitness are stem cell pharmacies,<br />

oats and rye in food products and robots in<br />

healthcare.<br />

“Above all, through the challenge, we are<br />

working preventively so that fewer people get<br />

sick or have accidents,” Landgren says. “This<br />

includes innovations for things like increased<br />

traffic safety. Sweden is among those countries<br />

with the lowest number of fatal traffic accidents<br />

in the world, thanks in large measure to Swedish<br />

innovations such as airbags, safer traffic<br />

crossings and other smart traffic solutions.”<br />

By cross-linking different sectors and<br />

research areas, VINNOVA is working broadly<br />

within four challenge areas.<br />

“For example, the healthcare challenge is<br />

linked to sustainable cities by the fact that<br />

emissions and noise can cause illness, which<br />

in turn is directly linked to the environmental<br />

issue,” says Landgren.<br />

“To date, health and environmental issues<br />

have not come together in new innovations, but<br />

we can see major potential here for collaborating<br />

in future research projects.”<br />

THCARE<br />

4CHALLENGES<br />

TO STIMULATE<br />

RESEARCH<br />

These four challenges will<br />

serve as drivers of innovation<br />

and sustainable growth:<br />

1 Future healthcare<br />

2 Competitive production<br />

3 Sustainable attractive cities<br />

4 Information society 3.0.<br />

Based on these challenges,<br />

investments are being made<br />

in needs-driven research,<br />

innovation and effective innovation<br />

systems.<br />

The challenges are drafted<br />

according to societal needs<br />

and demands.<br />

They are interdisciplinary<br />

between several industries,<br />

sectors and research fields<br />

and have the aim of discovering<br />

new growth potential.<br />

The initiatives should encourage<br />

inter-industrial and<br />

inter-sectoral collaborations<br />

between various actors.<br />

FURTHER READING:<br />

The largest product development<br />

unit in the Nordic region.<br />

Virtual worlds for pathologists<br />

and doctors.<br />

VINNOVA-CUTTING VINNOVA-NYTT EDGE OKTOBER No 2 2010 2011<br />

11

FUTURE HEALTHCARE //<br />

Where good ideas<br />

become products<br />

WORKING TOGETHER.<br />

The Actileg stair machine<br />

originated with SLL Innovation.<br />

Care provider and care<br />

recipient step together whilst<br />

talking. The result is mental as<br />

well as physical stimulation.<br />

INNOVATIVE<br />

PRODUCTS<br />

Examples of products<br />

already on the market that<br />

have contributed to the<br />

development of SLL Innovation<br />

include:<br />

• The Clean Lift system for<br />

sterile surgical washing.<br />

• The Actileg tandem stair<br />

machine for activation<br />

of blood circulation in<br />

elderly people.<br />

• The Respine mobile back<br />

support for people with<br />

whiplash injuries.<br />

• Stickstop, used by<br />

healthcare personnel for<br />

injections.<br />

Every day, healthcare staff think of good ideas for how their daily work can be<br />

simplified. These ideas are transformed into products by SLL Innovation.<br />

BY KATARINA AHLFORT<br />

PHOTO ROLF ANDERSSON ILLUSTRATION RESPINE<br />

”T<br />

HROUGH SLL INNOVATION, we aim to convert<br />

staff members’ ideas into new, innovative<br />

products that improve care,” says Olof<br />

Hillborg, development manager of the project<br />

at Danderyd Hospital outside Stockholm. All healthcare<br />

staff in Stockholm County Council who have an idea for<br />

improving the workplace can contact SLL Innovation.<br />

The project is a collaboration between Danderyd Hospital,<br />

Karolinska University Hospital and Healthcare Provision,<br />

Stockholm County.<br />

“We are also working with entrepreneurs and companies<br />

in the medical technology field who want to tap the clinical<br />

expertise in healthcare,” says Hillborg.<br />

The County Council covers half the costs for healthcare<br />

employees developing new ideas for innovations.<br />

What has been the staff response within healthcare?<br />

“Terrific,” says Hillborg. “A lot of people are coming<br />

to us with their ideas. The staff think it’s fantastic to get<br />

feedback and support from their employer.”<br />

So far, SLL Innovation has sold some 10 prototypes to<br />

medical technology companies, and the sales are gradually<br />

supplying financial compensation to both the hospital and<br />

the individual inventor.<br />

Six products are already on the market and some 10 innovations<br />

are heading for launch.<br />

“We see enormous export opportunities where Swedish<br />

healthcare products are concerned,” Hillborg says. “The<br />

quality of our healthcare system is considered among the<br />

best in the world, so obviously products from here have<br />

high potential.”<br />

His hopes for the future are to be able to extend the<br />

project and develop more innovations by having more<br />

project employees and thereby being able to accept more<br />

healthcare innovators throughout Sweden.<br />

“Through SLL Innovation, we have been able to build<br />

up the largest product development unit in the Nordic region,”<br />

Hillborg says. “We have 45,000 healthcare employees<br />

in Stockholm alone.”<br />

PROBLEM SOLVER. Respine’s<br />

portable neck support for people<br />

with neck and back problems.<br />

12 VINNOVA-CUTTING EDGE No 2 2011

KNIFELESS SURGERY<br />

Introducing the Swedish-innovated<br />

visualisation table for<br />

use in virtual post-mortems and<br />

preoperative planning.<br />

BY KATARINA AHLFORT<br />

PHOTOS SECTRA<br />

AFTER IMAGING BY computed<br />

tomography/MRI, a body can be<br />

examined on the visualisation table<br />

using detailed 3-D X-ray images.<br />

Doctors are now able to make diagnoses and<br />

carry out non-invasive post-mortems using the<br />

visualisation table.<br />

The table provides a three-dimensional overview<br />

of X-ray data enabling a doctor to make a<br />

detailed examination quickly and simply.<br />

By simply touching the screen the user can<br />

interact with 3-D volume rendering, and layers<br />

of skin and muscle can be hidden or shown as<br />

required.<br />

IMAGES CAN BE ZOOMED and rotated. By dragging<br />

a finger across the screen, it is possible to<br />

"cut" through sections of the body with a virtual<br />

scalpel. The visualisation table also allows groups<br />

of doctors to carry out complex examinations and<br />

manage large volumes of information without<br />

delay.<br />

Doctors from Linköping and Norrköping,<br />

in partnership with the medical technology<br />

company Sectra, have succeeded in transforming<br />

their complex innovation into a finished product<br />

for the clinical market in less than two years.<br />

Introduced in 2010 at the Radiological Society<br />

of North America fair in Chicago, the table is<br />

generally known as a “virtual visualisation table”<br />

and is used for post-mortems as well as medical<br />

analyses on living people.<br />

Which of the visualisation<br />

table’s applications has<br />

aroused the greatest interest?<br />

"The capability for rapid<br />

three-dimensional overview of<br />

Ulf Elmhester patient cases before the surgical<br />

team goes into theatre,” says Per Elmhester,<br />

product manager at Sectra. “This in turn reduces<br />

VIRTUAL WORLD. Using X-ray data and advanced<br />

image processing, examinations and post-mortems<br />

on bodies can be conducted on the visualisation table.<br />

risk to the patient as the team of doctors is better<br />

prepared."<br />

Are virtual medical images as reliable as<br />

traditional examination or post-mortem?<br />

“The images are just as reliable, albeit different,”<br />

Elmhester says. “Advanced visualisation<br />

means we can compensate to some extent for the<br />

information the doctor gets through odour and<br />

touch during a post-mortem, but naturally this<br />

information can’t be duplicated. However, during<br />

a digital examination it’s easier to detect details<br />

such as the entry angles of weapons like a knife<br />

or bullet. Also, examination by visualisation table<br />

means material evidence remains intact.”<br />

What is the future vision for the project?<br />

“We’re continuing to have a close dialogue<br />

with our reference groups in research and the<br />

medical profession to develop the visualisation<br />

table as new users arise," says Elmhester.<br />

VISUALISATION TABLE<br />

• The touch-screen measures 46 inches and<br />

displays three-dimensional images of living or<br />

deceased people.<br />

• Its purpose is to facilitate doctors’ daily clinical<br />

work in surgery and pathology.<br />

• Thanks in large measure to a partnership<br />

between industry, academia and research<br />

institutes, the project has received an early<br />

launch abroad.<br />

• Partnered with medical technology company<br />

Sectra, researchers created the finished<br />

product for the clinical market in less than two<br />

years.<br />

VINNOVA-CUTTING EDGE No 2 2011 13

IN SHORT<br />

RAPID DETECTION<br />

of resistant bacteria<br />

PHOTO: ROBOTDALEN<br />

SUBSTITUTE FOR CULTURING. Q-linea’s instrument can detect antibiotic-resistant bacteria in just<br />

three hours, a huge improvement on the traditional three-day detection method.<br />

ABOUT 10 BILLION courses of antibiotic<br />

treatment are given around the world each year.<br />

This intensive use of antibiotic therapy has resulted<br />

in antibiotic resistance in many bacteria<br />

(human pathogens). Part of the solution is to<br />

simply reduce the number of needless treatments.<br />

That’s where Q-linea comes in.<br />

Johan Widén, project manager of Q-linea, says,<br />

“With an investment of slightly more than five<br />

billion Swedish kronor in a development project,<br />

we can deliver an instrument to determine<br />

whether bacteria are resistant by detecting an<br />

incredibly small amount of DNA.”<br />

In combination with advanced molecular biological<br />

analysis, Q-linea’s patented technology<br />

is now opening up opportunities to change the<br />

treatment of patients. With this instrument, it<br />

is possible to quickly determine the need for<br />

antibiotic treatment and thus reduce unnecessary<br />

prescriptions. The analysis shows what<br />

sorts of antibiotics are required, thus reducing<br />

the number of incorrect penicillin treatments.<br />

PHOTO Q-LINEA<br />

ROBOTS SUPPORT HUMAN HEALTH<br />

Robots have long been important to large industrial<br />

companies. Now Robotdalen (Robot Valley), one of the<br />

efforts under VINNOVA’s VINNVÄXT programme, wants to<br />

take robot technology into undeveloped spheres, such as<br />

health robotics.<br />

The vision is to establish Robotdalen as a world-leading region<br />

for research, development and manufacturing within<br />

robotics, with an effective system for pushing innovations<br />

from concept to successful product.<br />

“Health robotics as an area has long gone unresearched, but<br />

the developments we’re seeing now are fantastic,” says Erik<br />

Lundqvist, General Manager of Robotdalen. “The challenges<br />

for society are increasing as the number of elderly people<br />

rises. If our healthcare systems are to cope with this increasing<br />

demand, we have to find ways of using technology to help<br />

people stay independent well into old age.”<br />

Swedish companies are not the only ones attracted to<br />

Robotdalen. Thanks to the opportunity the partnership<br />

offers to develop and test robots in the health sector, today<br />

there are also American and Japanese companies located<br />

in Robotdalen's home of Mälardalen, Sweden.<br />

www.robotdalen.se<br />

VINNOVA TAKES UP UN<br />

TRAFFIC SAFETY EFFORT<br />

EVERY YEAR, more than 1.3 million people die in traffic.<br />

Road accidents are a major and increasing cause of<br />

death around the world. For this reason, the UN adopted<br />

a 10-year focus on traffic safety earlier this year. In Sweden,<br />

the Swedish Transport Administration, Chalmers<br />

and VINNOVA have jointly decided to establish a Vision<br />

Zero Academy.<br />

Sweden is a world leader in traffic safety with just 2.8<br />

deaths per 100,000 inhabitants. This is a result of<br />

long-term, systematic traffic safety work, with major<br />

investments in measures such as median barriers, improved<br />

safety for children and vulnerable road users, and<br />

measures to prevent drunk driving.<br />

Vision Zero Academy can be developed into a global<br />

knowledge node, further strengthening Sweden’s leadership<br />

in the field. An international Vision Zero conference<br />

will be held in Sweden in 2012.<br />

MORE TRANSPLANTS<br />

with lung cleaning machine<br />

AT THE MOMENT, it is not unusual for seriously ill people<br />

to die waiting for a suitable lung donor. The problem is<br />

not simply a lack of organs but the fact that available ones<br />

may be damaged and unusable. Lungs are the hardest<br />

organs to find; 80 percent of all donated lungs normally<br />

have to be discarded due to inferior quality.<br />

Medical technology company Vivoline has<br />

developed a method for cleaning lungs,<br />

enabling more transplants to be carried out.<br />

“The method we’ve just begun commercialising<br />

is based on Professor Stig Steen’s<br />

research,” explains Peter Sebelius, CEO of<br />

Vivoline. “He discovered how to clean lungs<br />

and remove harmful fluid accumulations<br />

years ago, but a breakthrough for the technology<br />

was delayed because the method was<br />

too complex in practical terms. It relied on a heart-lung<br />

machine that was intended for other purposes.”<br />

Through a partnership between Steen and Vivoline, an entirely<br />

new machine is now on the market. Custom-built for<br />

cleaning lungs, it is much simpler for medical staff to use.<br />

www.vivoline.se<br />

14 VINNOVA-CUTTING EDGE No 2 2011

EXCHANGE //<br />

CROSS-BORDER.<br />

Researchers with international<br />

experience in academia<br />

as well as industry are the<br />

VINNMER programme’s target<br />

group.<br />

MOBILITY<br />

FUELLING PROGRESS<br />

The VINNMER programme, an initiative inaugurated by VINNOVA,<br />

seeks to create gender balance in leadership roles for female researchers<br />

in academia, research institutes and industry.<br />

BY KATARINA AHLFORT<br />

ILLUSTRATION SHUTTERSTOCK<br />

Through the VINNMER programme,<br />

managers of organisations, faculties<br />

and industry have the chance early<br />

on to detect and engage with female<br />

researchers who may become future leaders.<br />

“Due in no small measure to the high proportion<br />

of men in leadership functions, we need<br />

more diversity in researcher qualification services,”<br />

says Erik Litborn, Programme Manager<br />

of VINNMER at VINNOVA. “We also want to see<br />

greater representation of other cultures, competences<br />

and experience.”<br />

THOSE RESEARCHERS selected for the programme<br />

get half their salary paid by VINNMER and the<br />

remainder by the company or organisation that<br />

they are associated with, for a period of three<br />

years.“In academia, we seldom see long-term<br />

plans for researchers’ continued activity once<br />

the research funding ends,” continues Litborn.<br />

“Through this investment, early-stage research is<br />

combined with career development.”<br />

According to the programme board, a prerequisite<br />

for participation is that the employer also<br />

holds a continuous dialogue with the individual<br />

about future plans and appropriate career moves.<br />

“I’m hoping the programme will lead to more<br />

competent researchers being able to have careers<br />

and that the participants will serve to inspire<br />

and lead other researchers,” says Ulf Wahlberg,<br />

Vice President of Industry and Research Relations<br />

at Ericsson and a member of the VINNMER<br />

programme board.<br />

WAHLBERG STRESSES that the programme<br />

also provides industry with access to enhanced<br />

competence through strong research milieus,<br />

exceptional leaders and more young researchers<br />

choosing research careers.<br />

“Ultimately, it strengthens the international<br />

competitiveness of Sweden and Swedish businesses,”<br />

he says.<br />

International interest in the programme is<br />

substantial. The Norwegian counterpart to VIN-<br />

NOVA has virtually copied the programme design<br />

and in Austria, according to Litborn, a number of<br />

similar projects are underway.<br />

VINNMER is one of the first national programmes<br />

sponsored through the EU’s Marie<br />

Curie Actions research programme.<br />

Marie Curie Actions has contributed EUR 5<br />

million to the programme, spread over four years.<br />

The partnership means that, for the programme’s<br />

duration, the European Commission will provide<br />

40 percent of the funds granted in around 40 of<br />

the 100 or so current VINNMER projects.<br />

The Commission uses a peer-review system<br />

for a traditional evaluation of the programme,<br />

taking a scientific and administrative approach.<br />

ALAN CRAIG and Silvia Dürmeier, Programme<br />

Managers of the European Commission’s Research<br />

Executive Agency, recently visited Sweden<br />

to learn more about the programme.<br />

Craig confirmed that VINNMER is working<br />

well, in particular because calls for proposals are<br />

made in sufficient time for the money to be put to<br />

optimum use.<br />

“It’s a very positive thing that the emphasis<br />

is on encouraging women, a group underrepresented<br />

in research, to invest in a scientific career,”<br />

said Dürmeier.<br />

VINNOVA-CUTTING EDGE No 2 2011 15

EXCHANGE //<br />

Career boost<br />

follows research exchange<br />

How can we produce packaging for<br />

milk and soured milk with high waterrepellent<br />

properties? This was one<br />

of the questions underlying Rauni<br />

Seppänen’s research project.<br />

BY ANNICA HULTH<br />

PHOTO JENNY GAULITZ<br />

“W<br />

e’ve had a very good, smooth partnership,”<br />

says Rauni Seppänen of VINNMER, former<br />

researcher at the Institute for Surface<br />

Chemistry (YKI) in Stockholm.<br />

Having completed several years’ research<br />

at YKI, Seppänen wanted to learn more about the physical<br />

structure of cardboard packaging. For example, what<br />

happens when liquid penetrates at the edges where the<br />

packaging opens?<br />

One way of finding out is to use X-ray tomography;<br />

this gives highly realistic, three-dimensional images of the<br />

paper’s structure.<br />

The X-ray equipment was located at Jyväskylä University<br />

in Finland. Four companies were linked to the project: two<br />

cardboard manufacturers and two chemical companies.<br />

Once at Jyväskylä, Seppänen met a doctoral student who<br />

wanted to get involved in the studies and after the two got<br />

to know each other, the project really took off.<br />

“There was a real snowball effect. She’s a physicist and<br />

I’m a surface chemist, so this was a meeting of two worlds.<br />

She’s now passed her doctorate and is planning to continue<br />

her research at YKI,” says Seppänen.<br />

Thanks to this project, Seppänen spent three months at<br />

Tokyo University studying surface treatment of cellulose<br />

fibres.<br />

In December, Seppänen moved from the strictly academic<br />

world and started work as a research and development<br />

specialist at Holmen Paper. Fresh challenges await her<br />

in this industry, like developing paper that works optimally<br />

in the printing process. Her research goes on.<br />

“Once a researcher, always a researcher. Now I’m the<br />

customer, the one commissioning research. Obviously, I’ll<br />

benefit from my experience at YKI,” she concludes.<br />

CAREERIST. After many years as a<br />

researcher at the Institute of Surface<br />

Chemistry, Rauni Seppänen<br />

has taken the step into industry.<br />

PACKAGING TECHNOLOGY<br />

PURPOSE: To increase understanding of the<br />

importance of surface chemistry and structure<br />

in food packaging made of cardboard.<br />

PARTICIPANTS: Institute of Surface<br />

Chemistry, Jyväskylä University, Tokyo<br />

University, Korsnäs, Stora Enso, Hercules and<br />

Kemira.<br />

FUNDING: Contributions were made through<br />

VINNMER (half salary for three years), Jyväskylä<br />

University (research instruments and<br />

a doctoral student) and companies (cash and<br />

benefits).<br />

16 VINNOVA-CUTTING EDGE No 2 2011

Through her research, Nazanin Emami can help increase<br />

the life of orthopaedic implants.<br />

LESS PAIN<br />

and lower care costs<br />

BIOTRIBOLOGY. Wear, lubrication<br />

and friction in hip and knee<br />

joints are the primary interests of<br />

Nazanin Emami and her<br />

research group.<br />

BY KATARINA AHLFORT<br />

PHOTO SHUTTERSTOCK<br />

In 2007 when Nazanin Emami, a lector<br />

at Luleå University of Technology, did<br />

her post-doctorate in biotribology in<br />

Australia 2007, she wondered how many<br />

of her future ambitions would be realised.<br />

“We are reducing human suffering as well<br />

as saving billions of kronor in care costs by<br />

developing more sustainable implant materials.<br />

This means many patients can avoid repeated,<br />

serious operations,” says Emami.“I applied to the<br />

VINNMER programme and when I was eventually<br />

successful, many of my Australian colleagues<br />

observed that ‘Sweden is a wonderful country for<br />

researchers,’” she says.<br />

BUT THE COMPETITION amongst programme<br />

applicants was stiff.<br />

“The VINNMER grant paid 50 percent of my<br />

salary; in other words 50 percent freedom to do<br />

research for a three-year period. That’s a freedom<br />

normally only available to research assistants. As<br />

a senior researcher, there’s seldom such a scope,”<br />

says Emami.<br />

Biotribology research aims to reduce friction<br />

and improve lubrication for implants in the body.<br />

“For over 40 years, hip and knee implant<br />

surgery has been one of the greatest orthopaedic<br />

success stories. But implants that ought to last a<br />

lifetime are in reality only lasting around 15 years,”<br />

she says.<br />

FOR YOUNG PEOPLE, implant changes are generally<br />

required and that means comprehensive<br />

surgeries.<br />

“We hope to be to reduce the number of<br />

painful procedures. The primary target group for<br />

my research is younger patients, such as teenagers<br />

who have been injured in car accidents or people<br />

in their 40s affected by rheumatic problems. They<br />

should be able to jump and bounce around and<br />

have an active life.”<br />

Emami’s research has already resulted in four<br />

“Implants which<br />

ought to last a<br />

lifetime in reality<br />

are lasting only 10 to 15<br />

years.”<br />

Nazanin Emami<br />

new jobs as she has employed three doctoral<br />

students into the research group.<br />

“We’re well underway where it concerns<br />

strengthening polymeric materials with nanoparticles,”<br />

she says. “Of the four others in the<br />

group three are women, which is a positive thing<br />

given the otherwise male-dominated tribology<br />

research group at Luleå University of Technology.”<br />

The research is multidisciplinary; the researchers<br />

at Luleå are collaborating with medical<br />

orthopaedists both in Sweden and abroad. The<br />

programme has confirmed the group’s initiatives<br />

in the field of biotribology and has made it possible<br />

to build bridges, with research institutes in<br />

Australia, Portugal and Great Britain participating<br />

in sub-projects.<br />

IMPLANTS<br />

• At Luleå University of Technology, three<br />

projects are under way within the field of<br />

biotribology. The emphasis is on hip and<br />

knee implants.<br />

• Projects are being conducted in partnership<br />

with the Center for Medical Technology and<br />

Physics at Luleå University, Leeds University<br />

in Great Britain, the University of Aveiro<br />

in Portugal and a number of companies.<br />

VINNOVA-CUTTING EDGE No 2 2011<br />

17

IN SHORT<br />

RESEARCH<br />

GOES VIRAL<br />

The biotech company Vironova<br />

deals almost exclusively with viruses.<br />

It has developed a special method for<br />

automatic analysis of different types<br />

of viruses and other nanoparticles,<br />

which, it is hoped, will contribute to<br />

the development of more effective<br />

drugs against the flu and herpes.<br />

“In recent years, we’ve been aware<br />

of a much greater interest in viruses;<br />

both those that are potentially dangerous<br />

and those which produce more<br />

common symptoms of illness,” says<br />

Heather Marshall-Heyman, Project<br />

Coordinator at Vironova.<br />

Vironova was born when its founder,<br />

Mohammed Homman, was conducting<br />

research at Karolinska Institutet<br />

in Sweden. Homman realised that<br />

there was a need for the digitisation<br />

and automatic identification of<br />

viruses.<br />

The company’s 15 employees are<br />

involved in a number of research projects;<br />

clients include pharmaceutical<br />

companies, which mostly purchase<br />

virus safety and nanoparticle analysis<br />

services.<br />

Vironova also collaborates with a<br />

range of European researchers linked<br />

to academic institutions and companies.<br />

For example, Vironova’s researchers<br />

are leading the Minitema project<br />

under the European Commission’s<br />

Eurostars programme. The project’s<br />

objective is to develop the world’s<br />

first portable transmission electron<br />

microscope for identifying viruses<br />

and characterising other biological<br />

nanoparticles. This project ranked<br />

second out of 110 eligible Eurostars<br />

applications from companies and<br />

universities around Europe.<br />

“For a small company like Vironova,<br />

it’s very important to have financial<br />

support,” says Marshall-Heyman.<br />

“But it’s not just the money that helps<br />

us. Thanks to VINNOVA’s knowledgeable<br />

staff we’ve gained valuable<br />

advice which has helped us develop<br />

our projects.”<br />

RESEARCHING,<br />

LIVING AND<br />

WORKING IN<br />

SWEDEN<br />

NEW WEBSITE FACILITATES<br />

RESEARCHERS’ MOBILITY<br />

The new website EURAXESS Sweden aims<br />

to make researcher mobility easier in Europe. It<br />

contains information for researchers moving to<br />

Sweden, such as explanations of visa procedures,<br />

tax and social insurance issues and how to live<br />

and work in Sweden. There is also information<br />

about research posts advertised by universities<br />

and research faculties in the country. A separate<br />

section has information on fellowships and grants<br />

and aims to help researchers find research funding<br />

in Sweden and elsewhere in Europe.<br />

This new website is part of the European network<br />

EURAXESS established by the European Commission<br />

and consisting of 200 centres in more<br />

than 30 countries. All services provided through<br />

EURAXESS are free of charge. In Sweden,<br />

EURAXESS is located at VINNOVA in partnership<br />

with the Swedish Research Council, the Swedish<br />

Council for Working Life and Social Research and<br />

the Swedish Research Council Formas.<br />

www.euraxess.se<br />

18 VINNOVA-CUTTING EDGE No 2 2011

INFORMATION SOCIETY 3.0 //<br />

Contributing to a better world and creating more<br />

jobs are at the centre of VINNOVA’s vision for the<br />

challenge of Information Society 3.0.<br />

BY LISA BJERRE PHOTO ISTOCKPHOTO, APPLE<br />

FUTURE 3.0<br />

”C<br />

reating growth in Sweden<br />

and a better world<br />

— this is essentially the<br />

thrust of VINNOVA’s four<br />

challenges.” So says Peter Eriksson,<br />

VINNOVA’s chief strategy officer for<br />

industrial development.<br />

For the Information Society 3.0<br />

challenge, a better world may find<br />

expression by building an identity or<br />

by digitalising physical products.<br />

THIS SIMPLIFIES everyday life and<br />

improves the environment. But<br />

Eriksson really doesn’t want to say<br />

too much.“Information Society 3.0 is<br />

an open invitation,” he says. “It’s not<br />

our role to talk about what should be<br />

done.”<br />

The projects that VINNOVA will focus<br />

on are initiatives in which several parties<br />

that do not normally cooperate are<br />

required to work together. The idea is<br />

to bring together resources and actors<br />

to create something new.<br />

“We’re looking for ideas that would<br />

be very good if implemented but that<br />

are difficult to implement today,” says<br />

Eriksson. Although Eriksson does not<br />

want to steer the ideas, he offers an<br />

example of how Information Society<br />

3.0 can work with other challenges<br />

identified by VINNOVA, such as Future<br />

Healthcare. “Where can I find the<br />

nearest outpatient care provider in<br />

Sweden?” he asks. “I can’t currently<br />

get an answer to that question, but<br />

imagine if I could find it in a mobile<br />

application. There are many services<br />

that ought to exist but don’t yet.”<br />

A SUCCESSFUL INFORMATION Society<br />

3.0 should not only make the world a<br />

better place, it should also strengthen<br />

Sweden’s competitiveness. Eriksson<br />

believes that Sweden is a good test<br />

market and that the country is about<br />

the right size to succeed in linking<br />

together various actors. Business<br />

ideas that succeed here also have good<br />

prospects of being exported.<br />

“When it comes to using digital<br />

services, Sweden tops the list. We’re in<br />

a good position and it’s easier to win<br />

when you’re already far ahead. Now it’s<br />

about utilising our position.”<br />

This outlook is confirmed by Ilia<br />

Katardjiev, a professor at the<br />

WISENET research centre supported<br />

by VINNOVA.<br />

“WISENET is a basis for new export<br />

companies looking after our research<br />

results,” Katardjiev says. “We are working<br />

with small companies that have<br />

good growth opportunities. We’ll be<br />

creating a lot of jobs.”<br />

4 CHALLENGES TO STIMULATE RESEARCH<br />

These four challenges will serve as drivers of innovation and sustainable growth:<br />

1 Future healthcare 2 Competitive production 3 Sustainable attractive cities 4 Information society 3.0<br />

Based on these challenges, investments are being made in needs-driven reseacrh innovation and in effective innovation systems.<br />

The challenges are drafted according to societal need and demand. They are interdisciplinary between several industries, sectors<br />

and research fields and have the aim of discovering new growth potential.<br />

The initiatives should encourage inter-industrial and inter-sectoral collaborations between various actors.<br />

›<br />

VINNOVA-CUTTING VINNOVA-NYTT EDGE OKTOBER No 2 2010 2011 19

INFORMATION SOCIETY 3.0 //<br />

The researchers at Mobile Life<br />

Centre take games seriously. New<br />

business opportunities are hiding<br />

underneath the enjoyment.<br />

BY LISA BJERRE<br />

PHOTOS ISTOCKPHOTO<br />

TEXT ANDERS NORDNER<br />

Information Society 3.0 is one of four<br />

challenges VINNOVA will be working<br />

on in the next few years. The following<br />

are predictions made by VINNOVA<br />

Chief Strategy Officer Jonas Wallberg<br />

about the effects of information and<br />

communications technology (ICT)<br />

in various areas at different times in<br />

future.<br />

SERIOUS<br />

about<br />

GAMES<br />

ICT – CURRENT AND FUTURE ›› ››<br />

IN 10 YEARS’ TIME:<br />

ICT is used increasingly to mitigate or<br />

avoid undesirable effects and to help<br />

and support people.<br />

Ex 1. Services emerge that allow you to<br />

use your mobile phone to set the washing<br />

machine for a washload to be ready<br />

when you get home, check that the coffee<br />

machine has been switched off and<br />

ensure the freezer door is closed.<br />

Ex 2. Using communication services<br />

and close-proximity physical sensors,<br />

you can monitor your own health and<br />

send data, perhaps to a healthcare<br />

centre. Robots are an increasingly<br />

important home health aid.<br />

Ex 3. Vehicles have systems to reduce<br />

the harmful effects of accidents, such<br />

as automatic braking for road obstacles<br />

and elevating bonnets to avoid personal<br />

injury in collisions between cars and<br />

pedestrians.<br />

IN 20 YEARS’ TIME:<br />

ICT developments are<br />

used to repair humans<br />

and automate certain functions in<br />

society which we currently have to<br />

control for ourselves.<br />

Ex 1. When we leave home, the coffee<br />

machine goes off and the freezer<br />

door closes. The washing machine<br />

starts up when the electricity is cheap<br />

or when the electricity service<br />

20 VINNOVA-CUTTING EDGE No 2 2011

MOBILE LIFE CENTRE<br />

WORKS WITH: Design-orientated research in<br />

mobile services.<br />

NUMBER OF EMPLOYEES: 35<br />

START YEAR: 2007. VINNOVA funding up to<br />

2017.<br />

Democracy, streamlining and revolution.<br />

IT and the Internet can be used<br />

for many meaningful ends, but perhaps<br />

the thing closest to our hearts is<br />

having fun.<br />

“If you look at the products that have been<br />

successful in recent years, you can see how people<br />

are bored and doing everything possible to have<br />

more fun. It’s about socialising and about amusements,<br />

entertainments and games.”<br />

These are the words of Oskar Juhlin, head of<br />

Mobile Life, the VINN Excellence centre supported<br />

by VINNOVA. The purpose of the centre<br />

is to help Swedish industry develop this type<br />

of mobile technology and to understand the<br />

consumers’ interests.<br />

“I can’t emphasise how important it is that we<br />

understand this, but in Sweden we find it difficult<br />

supplier considers it suitable to avoid<br />

demand spikes in residential areas.<br />

Ex 2. Electronics are integrated with<br />

human functions, such as prostheses or<br />

portable miniaturised aid systems, such<br />

as dialysis equipment.<br />

Ex 3. Using sensors, vehicle systems<br />

can predict a collision and prepare the<br />

vehicle to mitigate its effects as far as<br />

possible.<br />

››<br />

to take non-serious things seriously.<br />

They’re often way down our<br />

agenda.”<br />

“If we underestimate games<br />

and the somewhat nebulous<br />

(from an external perspective)<br />

Oskar Juhlin<br />

activities in which mobile users<br />

engage, we miss a great many business opportunities,”<br />

Juhlin says, citing Facebook and the<br />

games developer Zynga as examples. Amongst<br />

other things, Zynga is behind the globally successful<br />

Facebook game FarmVille.<br />

GAMES ARE WORTH taking seriously because<br />

they can generate successful business. “We have<br />

to understand what’s important in people’s lives,”<br />

says Juhlin.<br />

One area to which Mobile Life has devoted its<br />

IN 50 YEARS’ TIME:<br />

Imagination and vision merge.<br />

Information and communications<br />

technology helps increase our capacity<br />

and our experiences. Our<br />

consciousness is on computer<br />

and maybe we can make security<br />

backups of our minds.<br />

Ex 1.ICT helps<br />

optimise energy<br />

consumption and various ways of recycling<br />

and utilising people’s movements<br />

or temperature differences to<br />

extract energy.<br />

Ex 2. The computational<br />

capacity of computers has<br />

reached a level allowing us to<br />

understand how the brain<br />

functions. Maybe we can<br />

cure diseases related<br />

efforts is 'unique games. 'These are mobile games<br />

based on your situation and the people you meet<br />

— a kind of role-play held outdoors, with experiences<br />

enhanced by technology. When you look at<br />

your mobile, elements of your surroundings are<br />

included in the game. Mobile Life has collaborated<br />

on this project with Nokia and games firm<br />

Company P.<br />

ANOTHER AREA THAT engaged the researchers<br />

was using GPS to study the interaction between<br />

hunters and dogs. The idea was to use what was<br />

learned to develop mobile services that all pet<br />