TAKES CONTROL - International Rectifier

TAKES CONTROL - International Rectifier

TAKES CONTROL - International Rectifier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

POWER<br />

ELECTRONICS<br />

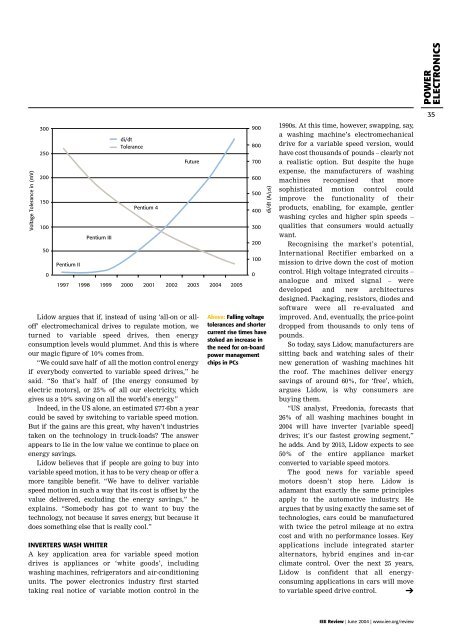

Voltage Tolerance in (mV)<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Pentium II<br />

Pentium III<br />

di/dt<br />

Tolerance<br />

Pentium 4<br />

Future<br />

1997 1998 1999 2000 2001 2002 2003 2004 2005<br />

Lidow argues that if, instead of using ‘all-on or alloff’<br />

electromechanical drives to regulate motion, we<br />

turned to variable speed drives, then energy<br />

consumption levels would plummet. And this is where<br />

our magic figure of 10% comes from.<br />

“We could save half of all the motion control energy<br />

if everybody converted to variable speed drives,” he<br />

said. “So that’s half of [the energy consumed by<br />

electric motors], or 25% of all our electricity, which<br />

gives us a 10% saving on all the world’s energy.”<br />

Indeed, in the US alone, an estimated £77.6bn a year<br />

could be saved by switching to variable speed motion.<br />

But if the gains are this great, why haven’t industries<br />

taken on the technology in truck-loads? The answer<br />

appears to lie in the low value we continue to place on<br />

energy savings.<br />

Lidow believes that if people are going to buy into<br />

variable speed motion, it has to be very cheap or offer a<br />

more tangible benefit. “We have to deliver variable<br />

speed motion in such a way that its cost is offset by the<br />

value delivered, excluding the energy savings,” he<br />

explains. “Somebody has got to want to buy the<br />

technology, not because it saves energy, but because it<br />

does something else that is really cool.”<br />

INVERTERS WASH WHITER<br />

A key application area for variable speed motion<br />

drives is appliances or ‘white goods’, including<br />

washing machines, refrigerators and air-conditioning<br />

units. The power electronics industry first started<br />

taking real notice of variable motion control in the<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

di/dt (A/µs)<br />

Above: Falling voltage<br />

tolerances and shorter<br />

current rise times have<br />

stoked an increase in<br />

the need for on-board<br />

power management<br />

chips in PCs<br />

1990s. At this time, however, swapping, say,<br />

a washing machine’s electromechanical<br />

drive for a variable speed version, would<br />

have cost thousands of pounds – clearly not<br />

a realistic option. But despite the huge<br />

expense, the manufacturers of washing<br />

machines recognised that more<br />

sophisticated motion control could<br />

improve the functionality of their<br />

products, enabling, for example, gentler<br />

washing cycles and higher spin speeds –<br />

qualities that consumers would actually<br />

want.<br />

Recognising the market’s potential,<br />

<strong>International</strong> <strong>Rectifier</strong> embarked on a<br />

mission to drive down the cost of motion<br />

control. High voltage integrated circuits –<br />

analogue and mixed signal – were<br />

developed and new architectures<br />

designed. Packaging, resistors, diodes and<br />

software were all re-evaluated and<br />

improved. And, eventually, the price-point<br />

dropped from thousands to only tens of<br />

pounds.<br />

So today, says Lidow, manufacturers are<br />

sitting back and watching sales of their<br />

new generation of washing machines hit<br />

the roof. The machines deliver energy<br />

savings of around 60%, for ‘free’, which,<br />

argues Lidow, is why consumers are<br />

buying them.<br />

“US analyst, Freedonia, forecasts that<br />

26% of all washing machines bought in<br />

2004 will have inverter [variable speed]<br />

drives; it’s our fastest growing segment,”<br />

he adds. And by 2013, Lidow expects to see<br />

50% of the entire appliance market<br />

converted to variable speed motors.<br />

The good news for variable speed<br />

motors doesn’t stop here. Lidow is<br />

adamant that exactly the same principles<br />

apply to the automotive industry. He<br />

argues that by using exactly the same set of<br />

technologies, cars could be manufactured<br />

with twice the petrol mileage at no extra<br />

cost and with no performance losses. Key<br />

applications include integrated starter<br />

alternators, hybrid engines and in-car<br />

climate control. Over the next 25 years,<br />

Lidow is confident that all energyconsuming<br />

applications in cars will move<br />

to variable speed drive control. ➔<br />

35<br />

IEE Review | June 2004 | www.iee.org/review