You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

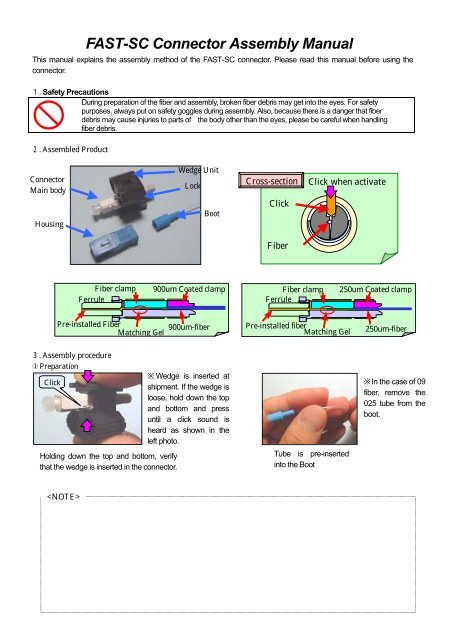

<strong>FAST</strong>-<strong>SC</strong> <strong>Connector</strong> <strong>Assembly</strong> <strong>Manual</strong><br />

This manual explains the assembly method of the <strong>FAST</strong>-<strong>SC</strong> connector. Please read this manual before using the<br />

connector.<br />

Safety Precautions<br />

During preparation of the fiber and assembly, broken fiber debris may get into the eyes. For safety<br />

purposes, always put on safety goggles during assembly. Also, because there is a danger that fiber<br />

debris may cause injuries to parts of the body other than the eyes, please be careful when handling<br />

fiber debris.<br />

Assembled Product<br />

<strong>Connector</strong><br />

Main body<br />

Housing<br />

Wedge Unit<br />

Lock<br />

Boot<br />

Cross-section<br />

Click<br />

Click when activate<br />

Fiber<br />

Fiber clamp<br />

Ferrule<br />

900um Coated clamp<br />

Fiber clamp<br />

Ferrule<br />

250um Coated clamp<br />

Pre-installed Fiber<br />

900um-fiber<br />

Matching Gel<br />

Pre-installed fiber<br />

Matching Gel<br />

250um-fiber<br />

<strong>Assembly</strong> procedure<br />

Preparation<br />

Click<br />

Holding down the top and bottom, verify<br />

that the wedge is inserted in the connector.<br />

Wedge is inserted at<br />

shipment. If the wedge is<br />

loose, hold down the top<br />

and bottom and press<br />

until a click sound is<br />

heard as shown in the<br />

left photo.<br />

Tube is pre-inserted<br />

into the Boot<br />

In the case of 09<br />

fiber, remove the<br />

025 tube from the<br />

boot.<br />

Fiber tip processing (Using the stripper and fiber cutter, fiber tip measurements on the right picture is achieved.)<br />

No gap<br />

Stripped<br />

Stripping Fiber cleaning Marking Screening Cut fiber with reference to the procedure<br />

0.25mm-fiber<br />

Coating part<br />

Marking<br />

Fiber<br />

10mm 10mm<br />

0.9mm-fiber<br />

Marking Coating part Fiber<br />

7mm 13mm<br />

Fiber Insertion and Hold<br />

Insert fiber slowly into the opening from back of<br />

connector main body. Insert fiber until marking is<br />

hidden and connection is made. Maintain the fiber<br />

connection while the fiber is bent.<br />

Marking Position<br />

Marking<br />

Connecting fiber<br />

Wedge Removal<br />

Press side of wedge when fiber is bent to remove<br />

wedge.<br />

Pre-installed fiber<br />

Wedge Removal Press side of wedge when fiber is bent to remove wedge<br />

0.25mm-fiber<br />

0.9mm-fiber<br />

Grip at about 10mm position.<br />

Approx.10mm<br />

Approx.10mm<br />

Press<br />

Grip at about 10mm position<br />

Fiber is not bent (Maintain<br />

connection force on fiber<br />

Press side of holder when fiber is<br />

connected.<br />

Press<br />

Press<br />

Press<br />

When fiber is bent<br />

Press side of wedge<br />

Wedge Structure<br />

Wedge<br />

Housing assembly Remove the lock and wedge, insert the housing and boot to complete<br />

Complete<br />

025mm-fiber<br />

Remove<br />

0.9mm-fiber<br />

Failure Checkpoint<br />

Condition Possible Cause Check point Picture<br />

Do not know where Marking is not done Marking is done following picture<br />

to insert fiber until therefore insertion 3..<br />

Marking<br />

depth is unclear.<br />

It is possible to insert fiber until<br />

Marking<br />

the marking is hidden.<br />

Connecting fiber<br />

Marking can reach up to 2mm<br />

into the opening at the rear of<br />

<br />

the connector<br />

Pre-Installed fiber<br />

Correct fiber insertion state<br />

Fiber cannot be<br />

inserted to the<br />

position of the<br />

marking.<br />

Wedge unit is<br />

removed but not reinstall<br />

back properly<br />

Wedge is not<br />

inserted<br />

Direction of wedge<br />

unit is wrong.<br />

The wedge is inserted into the<br />

connector following .<br />

The wedge unit and connector<br />

are direction-orientated refer to<br />

picture on right<br />

<br />

-<br />

<br />

Direction of lock is<br />

wrong<br />

The wedge unit and lock are<br />

direction-orientated refer to<br />

picture on right<br />