What you should know about transport and unloading - Isopa

What you should know about transport and unloading - Isopa

What you should know about transport and unloading - Isopa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

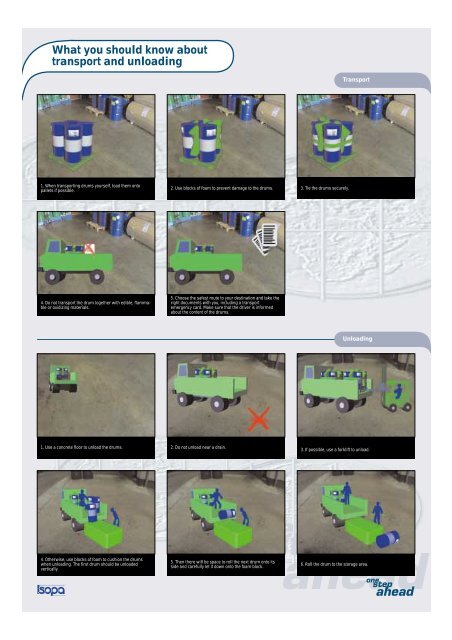

<strong>What</strong> <strong>you</strong> <strong>should</strong> <strong>know</strong> <strong>about</strong><br />

<strong>transport</strong> <strong>and</strong> <strong>unloading</strong><br />

Transport<br />

1. When <strong>transport</strong>ing drums <strong>you</strong>rself, load them onto<br />

pallets if possible.<br />

2. Use blocks of foam to prevent damage to the drums.<br />

3. Tie the drums securely.<br />

4. Do not <strong>transport</strong> the drum together with edible, flammable<br />

or oxidizing materials.<br />

5. Choose the safest route to <strong>you</strong>r destination <strong>and</strong> take the<br />

right documents with <strong>you</strong>, including a <strong>transport</strong><br />

emergency card. Make sure that the driver is informed<br />

<strong>about</strong> the content of the drums.<br />

Unloading<br />

1. Use a concrete floor to unload the drums.<br />

2. Do not unload near a drain.<br />

3. If possible, use a forklift to unload.<br />

4. Otherwise, use blocks of foam to cushion the drums<br />

when <strong>unloading</strong>. The first drum <strong>should</strong> be unloaded<br />

vertically.<br />

5. Then there will be space to roll the next drum onto its<br />

side <strong>and</strong> carefully let it down onto the foam block.<br />

6. Roll the drum to the storage area.

<strong>What</strong> <strong>you</strong> <strong>should</strong> <strong>know</strong> <strong>about</strong> storage<br />

<strong>and</strong> drum decontamination<br />

Storage<br />

1. The temperature in the storage area must be between<br />

15°C <strong>and</strong> 40°C. The storage area must be well ventilated.<br />

2. A fire extinguisher must be readily available in the storage<br />

area. If possible, this <strong>should</strong> be a foam extinguisher.<br />

3. Do not stack the drums higher than three levels.<br />

4. Leave enough space between the stacks for visual<br />

inspection.<br />

5. Do not leave the drums in a horizontal position.<br />

Make sure each drum is resting on its base.<br />

Drum decontamination<br />

1. Emptying <strong>and</strong> decontamination of drums must be<br />

carried out in a restricted area. The drum must be<br />

drip-free. Product labels <strong>should</strong> NOT be removed.<br />

2. Wear a breathing mask, goggles, boots <strong>and</strong> long sleeves<br />

while carefully putting the decontamination solution into<br />

the drum.<br />

3. Close the drum completely.<br />

4. Roll the drum at least four times so that the<br />

decontaminant reaches all parts of the drum.<br />

5. Slightly open bung to release the pressure. Leave the<br />

drum like this for at least two days.

<strong>What</strong> <strong>you</strong> <strong>should</strong> <strong>know</strong> <strong>about</strong> working<br />

with TDI (toluene diisocyanates)<br />

Working with TDI<br />

1. Make sure that fire extinguishers, tap water, hoses <strong>and</strong><br />

shower bath are readily accessible.<br />

2. Make sure that ventilation is working well in the production<br />

<strong>and</strong> storage areas.<br />

3. Make sure the TDI is at the right temperature.<br />

4. While working on the production line, wear a breathing<br />

mask, goggles, gloves, long sleeves <strong>and</strong> boots.<br />

5. Use a pump to empty the drums.<br />

6. During production, take regular measurements of<br />

TDI concentrations in the air. If <strong>you</strong> inhale high concentrations<br />

immediately seek medical attention.<br />

7. When storing foam, make sure there is enough space<br />

between each block because high temperatures can<br />

develop. Regularly check the temperature of the foam.<br />

8. Keep storage areas free of scrap foam <strong>and</strong> other flammable<br />

material.

<strong>What</strong> <strong>you</strong> <strong>should</strong> <strong>know</strong> <strong>about</strong><br />

a minor spill<br />

A minor spill<br />

1. A minor spillage can be dealt with on the spot.<br />

2. Take positive action. Inform the relevant members of the<br />

staff <strong>and</strong> evacuate the area.<br />

3. Put on full protective clothing, including coveralls, boots,<br />

goggles, gloves <strong>and</strong> breathing mask.<br />

4. Roll the leaking drum to prevent further spillage <strong>and</strong><br />

seal it with tape.<br />

5. Roll the damaged drum into the oversized drum, turn it<br />

onto its base <strong>and</strong> seal it loosely.<br />

6. Prevent spreading by covering the spillage with s<strong>and</strong> or<br />

other absorbent material.<br />

7. After putting s<strong>and</strong> or other absorbent material on the spillage,<br />

put decontamination solution on the affected area <strong>and</strong><br />

then leave it for <strong>about</strong> 30 minutes. The main components of<br />

decontamination solution are water, soap <strong>and</strong> glycol.<br />

8. Place the absorbent material into a waste container or<br />

an empty drum using a shovel.<br />

9. Clean the immediate area around the spillage with<br />

decontamination solution <strong>and</strong> wash down with water.<br />

10. The decontaminated absorbent must be <strong>transport</strong>ed to<br />

a safe place <strong>and</strong> disposed of safely.<br />

11. Rinse <strong>you</strong>rself with water. When there is a major spill,<br />

or a spill in a public area, call the emergency number of<br />

<strong>you</strong>r supplier or distributor.