integration of cfd and low-order models for combustion ... - IWR

integration of cfd and low-order models for combustion ... - IWR

integration of cfd and low-order models for combustion ... - IWR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISABE-2001-1088<br />

INTEGRATION OF CFD AND LOW-ORDER MODELS FOR COMBUSTION<br />

OSCILLATIONS IN AEROENGINES<br />

M. Zhu, A.P. Dowling <strong>and</strong> K.N.C. Bray<br />

Department <strong>of</strong> Engineering, University <strong>of</strong> Cambridge<br />

Cambridge CB2 1PZ, United Kingdom<br />

Tel: +44 1223 332600<br />

Fax: +44 1223 332662<br />

E-mail: mz101@eng.cam.ac.uk<br />

ABSTRACT<br />

The pressure oscillations within <strong>combustion</strong> chambers <strong>of</strong><br />

aeroengines are a major technical challenge to the development<br />

<strong>of</strong> high per<strong>for</strong>mance <strong>and</strong> <strong>low</strong> emission propulsion systems. The<br />

oscillations are driven by the resonant interaction between acoustic<br />

waves <strong>and</strong> unsteady <strong>combustion</strong>. The acoustic waves vary the<br />

air <strong>and</strong> fuel supplies <strong>and</strong> make the <strong>combustion</strong> unsteady. In return,<br />

unsteady <strong>combustion</strong> generates yet stronger waves. The<br />

resulting pressure waves can be so intense that they cause unbearable<br />

noise, vibration <strong>and</strong> even structural damage.<br />

In this paper, an approach integrating a one-dimensional linear<br />

stability analysis <strong>and</strong> computational fluid dynamics (CFD) is<br />

developed to predict the modes <strong>of</strong> oscillation in a combustor <strong>and</strong><br />

their frequencies <strong>and</strong> growth rates. Results from the CFD calculation<br />

provide the flame transfer function to describe unsteady<br />

heat release rate. Departure from ideal one dimensional f<strong>low</strong>s are<br />

described by shape factors <strong>and</strong> we describe a procedure through<br />

which they can be determined. Combined with this in<strong>for</strong>mation,<br />

<strong>low</strong>-<strong>order</strong> <strong>models</strong> can work out the possible oscillation modes<br />

<strong>and</strong> their initial growth rates. This work is a further development<br />

<strong>of</strong> our systematic investigation into the ‘rumble’ phenomenon,<br />

which occurs in aeroengine combustors at idle <strong>and</strong> sub-idle conditions<br />

<strong>and</strong> is typically in the range 50-120 Hz. However, the<br />

approach developed here can be used in more general situations<br />

<strong>for</strong> the analysis <strong>of</strong> any <strong>combustion</strong> oscillations.<br />

NOMENCLATURE<br />

a coefficient <strong>of</strong> IIR filter<br />

b coefficient <strong>of</strong> IIR filter<br />

c p heat capacity<br />

e total enthalpy<br />

E energy flux<br />

f momentum flux<br />

F non-dimensional shape factor defined in Eq. (8)<br />

H cross-section <strong>of</strong> combustor<br />

J 1<br />

non-dimensional shape factor defined in Eq. (11)<br />

J 2<br />

non-dimensional shape factor defined in Eq. (12)<br />

m mass flux<br />

p pressure<br />

q rate <strong>of</strong> heat release<br />

r radial coordinate<br />

R gas constant<br />

S source term<br />

t time<br />

T temperature<br />

u axial velocity<br />

v radial velocity<br />

x axial coordinate<br />

z complex number e iωT<br />

γ ratio <strong>of</strong> specific heats<br />

ε error<br />

ρ density<br />

ω complex frequency<br />

Superscripts<br />

¯ average over coherent harmonic variation<br />

coherent harmonic perturbation<br />

ˆ complex perturbation

1 INTRODUCTION<br />

The pressure oscillations that can occur within the <strong>combustion</strong><br />

chambers <strong>of</strong> aeroengines are a major technical challenge to<br />

the development <strong>of</strong> high per<strong>for</strong>mance <strong>and</strong> <strong>low</strong> emission propulsion<br />

systems. The oscillations are driven by the resonant interaction<br />

between acoustic waves <strong>and</strong> unsteady <strong>combustion</strong>. The<br />

acoustic waves vary the air <strong>and</strong> fuel supplies <strong>and</strong> make the <strong>combustion</strong><br />

unsteady. In return, unsteady <strong>combustion</strong> generates yet<br />

stronger waves. The pressure waves can become so intense that<br />

they cause unbearable noise, vibration <strong>and</strong> even structural damage.<br />

It is known that the <strong>combustion</strong> oscillation is a systemcoupled<br />

phenomenon, which involves the interaction <strong>of</strong> pressure<br />

waves, unsteady <strong>combustion</strong>, fuel/air supplies, <strong>and</strong> geometry <strong>of</strong><br />

combustors. In <strong>order</strong> to fully investigate the phenomenon, a combination<br />

<strong>of</strong> theoretical analysis, computational fluid dynamics<br />

<strong>and</strong> experimental work is needed. These techniques combine together<br />

to provide comprehensive in<strong>for</strong>mation to underst<strong>and</strong> <strong>combustion</strong><br />

oscillations <strong>and</strong> to develop control strategies.<br />

For aeroengines gas turbines, combustors with fuel spray atomizers<br />

are particularly susceptible to a <strong>low</strong> frequency oscillation<br />

at idle <strong>and</strong> sub-idle conditions. The frequency <strong>of</strong> this oscillation<br />

is typically in the range 50-120 Hz <strong>and</strong> is commonly<br />

called ‘rumble’. In recent years, a systematic program <strong>of</strong> work<br />

has been undertaken to investigate the ‘rumble’ phenomenon. In<br />

our study, CFD has been employed to calculate unsteady <strong>combustion</strong><br />

f<strong>low</strong>s at idle conditions. Through harmonic <strong>for</strong>cing <strong>of</strong><br />

the air or fuel supplies, the main source <strong>of</strong> the unsteady heat release<br />

has been identified [1]. Excitation by broad-b<strong>and</strong> signals<br />

gives fuller in<strong>for</strong>mation on the ‘flame transfer function’ between<br />

the rate <strong>of</strong> unsteady <strong>combustion</strong> <strong>and</strong> change in the air mass f<strong>low</strong><br />

rate [2]. In the primary zone, an increase in the inlet air mass f<strong>low</strong><br />

rate increases the turbulence scalar dissipation rate <strong>and</strong> hence the<br />

rate <strong>of</strong> <strong>combustion</strong>. The increase <strong>of</strong> air mass f<strong>low</strong> at the atomizer<br />

leads to a decrease in the inlet fuel droplet size. These smaller<br />

droplets evaporate quickly, increasing the gaseous mixture fraction<br />

in the recirculation zone with a recirculation time delay, <strong>and</strong><br />

this also influences the instantaneous rate <strong>of</strong> <strong>combustion</strong> <strong>and</strong> the<br />

location <strong>of</strong> the burning region. When the boundary conditions<br />

<strong>of</strong> the combustor are modified to describe the inlet air <strong>and</strong> fuel<br />

supplies <strong>and</strong> to include a downstream nozzle, the self-excited oscillations<br />

are established [3]. The causes <strong>of</strong> the oscillation have<br />

been identified: pressure variations in the combustor chamber alter<br />

the inlet air <strong>and</strong> fuel spray characteristics, <strong>and</strong> thereby change<br />

the rate <strong>of</strong> <strong>combustion</strong> <strong>and</strong> generate ‘hot spots’, which convect<br />

downstream. As these ‘hot spots’ accelerate through the downstream<br />

nozzle, an upstream propagating acoustic wave is generated,<br />

which at certain discrete frequencies rein<strong>for</strong>ces the pressure<br />

oscillation.<br />

Although CFD provides a powerful tool to underst<strong>and</strong> <strong>combustion</strong><br />

oscillations, there are two drawbacks to relying entirely<br />

on this method. One is that the calculations are very timeconsuming,<br />

<strong>and</strong> it is not feasible to investigate a wide range <strong>of</strong><br />

combustor geometries <strong>and</strong> f<strong>low</strong> conditions. The second is that<br />

the calculations are carried out in the time domain. An unstable<br />

operating condition is recognized by tracking the time evolution<br />

until a self-excited oscillation is established. Long simulation<br />

times are necessary to demonstrate stability. These time domain<br />

calculations provide detailed in<strong>for</strong>mation on the f<strong>low</strong> motion, but<br />

there is no direct in<strong>for</strong>mation on the damping factor. The latter<br />

is very useful in determining how close an operating point is to a<br />

instability boundary <strong>and</strong> in developing control strategies. These<br />

self-excited oscillations involve an almost one-dimensional interaction,<br />

consisting <strong>of</strong> the convection <strong>of</strong> ‘hot spots’ downstream<br />

<strong>and</strong> upstream propagation <strong>of</strong> a plane acoustic wave. We might<br />

there<strong>for</strong>e hope to describe it much more quickly through a onedimensional<br />

analysis. Moreover, the stability can be investigate<br />

the linearized equations <strong>of</strong> motion, where one is interested in<br />

whether disturbances with time dependence e iωt grow or decay<br />

with time.<br />

In this paper, a one-dimensional linear stability analysis <strong>and</strong><br />

CFD are integrated to study <strong>combustion</strong> oscillations. With this<br />

approach, CFD simulation <strong>and</strong> stability analysis work together to<br />

provide comprehensive in<strong>for</strong>mation on the mechanism <strong>of</strong> <strong>combustion</strong><br />

oscillation. Results from the CFD calculation provide<br />

the flame transfer function to describe unsteady heat release rate.<br />

Departure from ideal one dimensional f<strong>low</strong>s are described by<br />

shape factors <strong>and</strong> we describe a procedure through which they<br />

can be determined. Combined with this in<strong>for</strong>mation, <strong>low</strong>-<strong>order</strong><br />

<strong>models</strong> can work out the possible oscillation modes <strong>and</strong> their initial<br />

growth rates. This work is a further development <strong>of</strong> our systematic<br />

investigation into the ‘rumble’ phenomenon, which occurs<br />

in aeroengine combustors at idle <strong>and</strong> sub-idle conditions <strong>and</strong><br />

is typically in the range 50-120 Hz. However, the approach developed<br />

here can be used in more general situations <strong>for</strong> the analysis<br />

<strong>of</strong> any <strong>combustion</strong> oscillations. In the next section, the areaaveraged<br />

equations <strong>for</strong> a quasi-one-dimensional stability analysis<br />

are derived through integrating the equations <strong>of</strong> motion. Three<br />

non-dimensional shape factors are defined to account the effects<br />

<strong>of</strong> non-uni<strong>for</strong>mity in the radial direction. In section 3, based on<br />

the integrated equations, the equations <strong>for</strong> mean f<strong>low</strong> <strong>and</strong> linear<br />

perturbations are derived from these area-averaged equations.<br />

The determination <strong>of</strong> the flame transfer function <strong>and</strong> shape factors<br />

from a single <strong>for</strong>ced CFD calculation are briefly introduced.<br />

In section 4, we integrate the <strong>models</strong> from this CFD calculation<br />

with the linear perturbation equations. The results are compared<br />

with those from CFD calculation per<strong>for</strong>med with the same inlet<br />

boundary conditions. The sensitivities <strong>of</strong> the shape factor perturbations<br />

are also investigated. Finally, the conclusions are presented<br />

in section 5.<br />

2 INTEGRATED EQUATIONS<br />

As the ‘rumble’ problem we consider here is a <strong>low</strong> frequency<br />

oscillation <strong>and</strong> the wavelengths are long in comparison

©<br />

©<br />

©<br />

©<br />

©<br />

¢<br />

©<br />

¢<br />

©<br />

©<br />

©<br />

©<br />

¢<br />

©<br />

©<br />

¢<br />

¢<br />

©<br />

<br />

¡<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

with the combustor diameter, only plane acoustic waves carry<br />

energy. There<strong>for</strong>e, it is reasonable to consider one-dimensional<br />

disturbance in stability analysis. The f<strong>low</strong>s we consider are axisymmetric<br />

<strong>and</strong> the ensemble averaged equations can be written<br />

in two-dimensional <strong>for</strong>m. With the assumption <strong>of</strong> negligible<br />

molecular transport, <strong>and</strong> negligible Reynolds stresses <strong>and</strong> fluxes,<br />

the ensemble averaged conservation equations are<br />

In Eq. (6), the non-uni<strong>for</strong>m influences <strong>of</strong> momentum transport<br />

in the radial direction are considered through a shape factor<br />

F, which is defined as<br />

F ¢ x¦ t£¥¤<br />

u 2 <br />

2<br />

¤<br />

u<br />

ρ H <br />

r<br />

rρu 2 dr<br />

r<br />

r<br />

rρudr 2<br />

§ (8)<br />

r<br />

<br />

<br />

∂ ¢<br />

ρu£<br />

∂t<br />

∂ρ<br />

∂t<br />

∂ ¡<br />

ρu 2 £<br />

∂x<br />

∂ ¡<br />

∂x<br />

∂ ¢<br />

ρe<br />

∂t t £<br />

∂ ¡ ¢<br />

ρu£<br />

∂x<br />

¡ 1<br />

r<br />

ρue£<br />

∂<br />

∂r<br />

¡ 1<br />

r<br />

∂<br />

∂r<br />

rρv£¥¤ 0 ¦ (1)<br />

¡ rρuv£<br />

¡<br />

rρve£¥¤ §<br />

∂ p<br />

∂x 0 (2)<br />

1 ∂<br />

r ∂r<br />

q (3)<br />

Here <strong>and</strong> be<strong>low</strong>, we define p, q <strong>and</strong> ρ as Reynolds ensemble<br />

averages <strong>and</strong> u, v, T etc as Favre ensemble averages over turbulent<br />

f<strong>low</strong> fluctuations at x¦ r¦ t£ given . t is the time. x <strong>and</strong> r<br />

are the spatial coordinates in the axial <strong>and</strong> radial direction, respectively,<br />

<strong>and</strong> u <strong>and</strong> v are the corresponding gas phase ¢ velocity<br />

components; p is the pressure. e t is the internal <strong>and</strong> mechanical<br />

energy e t ¤<br />

1<br />

c v T<br />

2 u2 α , <strong>and</strong> e is the total enthalpy given by<br />

¡ ¡<br />

e ¤ e t ¤ ρ p¨<br />

1<br />

c p T<br />

2 u2 α. In this work, the direct effects <strong>of</strong><br />

the droplet evaporation <strong>and</strong> transportation are neglected from the<br />

mass <strong>and</strong> momentum equations, but they influence q, the ¡ instantaneous<br />

rate <strong>of</strong> heat release/volume.<br />

The one-dimensional equations can be obtained by the integrating<br />

the Eqs. (1)-(3) over the cross-section. With the assumption<br />

<strong>of</strong> frictionless slip f<strong>low</strong>s at walls without heat transfer, the<br />

quantities integrated f<strong>low</strong> equations across the width <strong>of</strong> a combustor<br />

can be written as<br />

φ ¤<br />

<br />

1<br />

H<br />

r<br />

r<br />

rφ dr ¦ <strong>and</strong> © ψ¤<br />

1<br />

ρ H<br />

r<br />

r<br />

rρψ dr ¦ (4)<br />

where φ represents ρ <strong>and</strong> q, <strong>and</strong> ψ represents u, v, u 2 , e t <strong>and</strong><br />

e. H © x£¤<br />

r<br />

r rdr, is the cross-sectional area <strong>of</strong> the combustor,<br />

<strong>and</strong> is uni<strong>for</strong>m in this study. Integrating Eqs. (1)-(3), onedimensional<br />

conservation equations can be written ¢ as<br />

∂ ¡ 1 ρ ∂<br />

H © © u¤ S ρ<br />

m (5)<br />

¦<br />

∂t H ∂x <br />

¡ ∂ 1 ∂ 2 d p ¡<br />

u ρ<br />

ρ u HF¤ S<br />

∂t H ∂x dx f<br />

(6) ¦<br />

<br />

<br />

¡ ∂<br />

1 ∂<br />

e ρ<br />

∂t t <br />

e ρ H¤ q S u<br />

e (7) §<br />

H <br />

∂x<br />

where S m , S f<br />

<strong>and</strong> S e are the sources terms <strong>of</strong> mass, momentum<br />

<strong>and</strong> energy due to the primary <strong>and</strong> secondary air injections, respectively.<br />

For the total energy <strong>and</strong> total enthalpy, the integrated variable can<br />

be written as<br />

©<br />

e t ¤ c v T<br />

e¥¤ c p<br />

©<br />

1 2 © ¡<br />

F <strong>and</strong> ¦ (9)<br />

u<br />

2<br />

T J 1<br />

¡ 1<br />

2<br />

u 2 J 2<br />

§ (10)<br />

The dimensionless shape factors J 1<br />

<strong>and</strong> J 2<br />

are used to describe<br />

the non-uni<strong>for</strong>m influences <strong>of</strong> the enthalpy <strong>and</strong> kinetic energy<br />

transports in the radial direction, <strong>and</strong> are defined as<br />

¢<br />

J 1<br />

t£¥¤ x¦<br />

¢<br />

J 2<br />

t£¥¤ x¦<br />

c p uT<br />

¦ (11)<br />

<strong>and</strong>¦<br />

c p T u <br />

u 3 ¨<br />

u 3 ¦ (12)<br />

respectively. Although the heat capacity c p <strong>and</strong> state equation coefficient<br />

R are not uni<strong>for</strong>m within <strong>combustion</strong> chamber as <strong>combustion</strong><br />

alters the components <strong>of</strong> f<strong>low</strong>, we find from our later results<br />

that it is accurate enough to treat them as constants.<br />

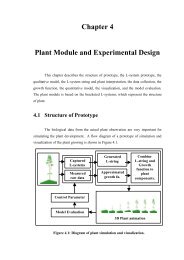

The shape factors (F, J 1<br />

<strong>and</strong> J 2<br />

) <strong>and</strong> the heat release rate<br />

can be obtained from a single CFD <strong>for</strong>cing q calculation. As<br />

in our previous work, the CFD calculation has been conducted<br />

in the idealized 2D axisymmetric annular combustor shown in<br />

Fig. 1. Fuel <strong>and</strong> air are injected through inlets 1 <strong>and</strong> 2 <strong>and</strong> dilution<br />

air through ports 3-10. The boundary conditions are specified<br />

to be representative <strong>of</strong> an aero-engine at idle. A contour<br />

plot <strong>of</strong> a typical mean temperature distribution is shown in Fig. 2<br />

<strong>for</strong> cross-reference in fol<strong>low</strong>ing discussion. More in<strong>for</strong>mation<br />

on the CFD algorithm <strong>and</strong> boundary conditions can be found in<br />

reference [1, 3].<br />

After a steady solution was achieved, the mean ¢<br />

values ¢<br />

<strong>of</strong><br />

F , J x£ 1<br />

<strong>and</strong> x£ J 2<br />

were calculated according to Eqs. (8), x£ (11)<br />

<strong>and</strong> (12), respectively. The results are shown in Figs. 3, 4 <strong>and</strong><br />

5, respectively. These non-dimensional shape factors ¢ would be<br />

unity if the axial velocity <strong>and</strong> the transported properties were ideally<br />

uni<strong>for</strong>m, i.e. independent <strong>of</strong> radius r. From Fig. 3, it can be<br />

seen that ¯F is large at the combustor inlet <strong>and</strong> outlet due to the<br />

high f<strong>low</strong> velocities that occur near the injectors <strong>and</strong> open exit,<br />

with virtually stagnant f<strong>low</strong> outside the main stream. Elsewhere<br />

in the combustor, the f<strong>low</strong> is relatively uni<strong>for</strong>m, thus ¯F is closer<br />

to unity. The shape factor J 1<br />

is determined not only by f<strong>low</strong> velocity,<br />

but also by the temperature distribution. Its mean value is

©<br />

©<br />

©<br />

¡<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

<br />

<br />

© ¢<br />

©<br />

©<br />

¢<br />

¢<br />

©<br />

©<br />

©<br />

¢<br />

¢<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

<br />

©<br />

©<br />

©<br />

¢<br />

©<br />

©<br />

©<br />

©<br />

©<br />

<br />

©<br />

¢<br />

©<br />

©<br />

©<br />

©<br />

©<br />

<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

(<br />

©<br />

©<br />

©<br />

©<br />

¢<br />

<br />

¢<br />

©<br />

©<br />

©<br />

©<br />

¡<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

©<br />

¦<br />

shown in Fig. 4. It is interested to see that J¯<br />

1<br />

is less than unity in<br />

the upstream section because here the higher temperature region<br />

is located in the recirculation zone where the velocity is stagnated<br />

or very small. Downstream <strong>of</strong> the <strong>combustion</strong> zone the<br />

hot <strong>low</strong> density gas is differentially accelerated by the pressure<br />

gradient <strong>and</strong> J¯<br />

1<br />

increases to values greater than unity. As a consequence,<br />

we can see that J¯<br />

1<br />

is continuously increased in Fig. 4.<br />

The small steps in Figs. 3-5 correspond to the effects <strong>of</strong> the primary<br />

<strong>and</strong> secondary air injections. The explanation <strong>for</strong> the shape<br />

factor J 2<br />

, which is shown in Fig. 5, is similar to that <strong>for</strong> Fig. 3.<br />

The difference is that J¯<br />

2<br />

is much larger at the two boundaries due<br />

to the third power <strong>of</strong> velocity in Eq. (12) <strong>for</strong> the kinetic energy<br />

transport.<br />

state, the relationships <strong>for</strong> f<strong>low</strong> variables can be written as [4]<br />

u¤ ¯<br />

p¤ ¯<br />

ρ¤ ¯<br />

T ¤ ¯<br />

γJ¯<br />

¯<br />

1<br />

f <br />

2γFJ¯<br />

1<br />

1£ γ J ¯ ¯<br />

2<br />

m <br />

γ 2 ¯<br />

J 2 1<br />

¯ f<br />

2 ¡<br />

2<br />

¢<br />

J¯<br />

2<br />

γ 2<br />

1£ 2 ¯F J¯<br />

1<br />

γ γ <br />

¢ <br />

2γ ¯F J¯<br />

1<br />

1£ γ J ¯ ¯<br />

2<br />

m<br />

¯<br />

¯ © m 1£<br />

1<br />

¯ 2 E<br />

(20)<br />

m u ¦ ¯F£¨<br />

£!¦ u m¨<br />

ρ p"¨ £§<br />

¯f ¯ H (21)<br />

¯ H ¯<br />

(22)<br />

¯ R ¯<br />

(23)<br />

3 LINEAR STABILITY ANALYSIS<br />

To consider linear perturbations <strong>of</strong> one-dimensional f<strong>low</strong>s,<br />

it is convenient to write the governing equations in terms <strong>of</strong> flux<br />

quantities. Here the mass, momentum, <strong>and</strong> energy fluxes are defined<br />

as<br />

m ¢ x¦ t£¥¤<br />

f ¢ x¦ t£¤<br />

E ¢ x¦ t£¥¤<br />

r<br />

rρu dr ¤ H © ρ<br />

r<br />

r<br />

r p ρu 2 dr ¤ H ¢© ¡ ©<br />

p ρ<br />

£ ¡ ¢<br />

r<br />

r<br />

rρu c p T u 2¨ 2£ dr ¤<br />

¡ ¢<br />

r<br />

u¦ (13)<br />

ρ<br />

u<br />

u 2 F£¦ (14)<br />

e H ¦ (15)<br />

respectively.<br />

As the linear perturbation theory is considered here, it is sufficient<br />

to investigate perturbation to the mean f<strong>low</strong> with time dependence<br />

e iωt . The sign <strong>of</strong> imaginary part <strong>of</strong> ω determines the<br />

stability, while Re(ω) gives the frequency <strong>of</strong> the mode. Now time<br />

mean values will be denoted by the overbar <strong>and</strong> f<strong>low</strong> quantities<br />

can be expressed as<br />

φ ¢ x¦ t£¤ ¯φ ¢ x£<br />

φ ¢ x¦ t£¦ (16)<br />

where the fluctuating component x¦ t£¤ φ Re ˆφ ¢ x£ e iωt £ Compared<br />

with Eqs. (5)-(7), the conservation equations <strong>for</strong> steady<br />

f<strong>low</strong> can be written as<br />

¢ ¢<br />

d<br />

dx ¯ m¥¤<br />

d<br />

dx ¯ ¤ f<br />

d<br />

dx ¯<br />

¯ S m ¦ (17)<br />

p ¯<br />

dH<br />

dx<br />

E¥¤ H ¯ © q ©<br />

¯ ¡<br />

S f<br />

(18)<br />

¦<br />

¯ ¡<br />

S e (19)<br />

§<br />

With the definition <strong>of</strong> Eqs. (13)-(15) <strong>and</strong> the equation <strong>of</strong><br />

where γ is the ratio <strong>of</strong> specific heat capacities.<br />

For unsteady parts <strong>of</strong> the mass flux, momentum flux <strong>and</strong> energy<br />

flux, we have<br />

¢<br />

¤ f H <br />

ρ ¯<br />

2 ¯ ρ ©<br />

¤ ¢ © ρ m u H ¯<br />

© ©<br />

H E m ¤ <br />

1<br />

2 ¯ ¡ 2 ¢<br />

u J2<br />

¯ © ¡<br />

ρ<br />

u u ¯<br />

£¦ u<br />

¡ ©<br />

ρ £ ¡ u<br />

(24)<br />

¯<br />

¯F<br />

u ¯<br />

2 ¡ © F #¦ (25)<br />

p<br />

c p<br />

T ¯ J¯<br />

¡ 1<br />

1<br />

2 ¯ u<br />

ρ ¯<br />

u £ ¯<br />

2 J¯<br />

2<br />

£<br />

©<br />

c p T<br />

J¯<br />

¡<br />

1<br />

c p<br />

T¯<br />

¡<br />

J 1<br />

u ¯<br />

u<br />

¯ J 2<br />

£$§ (26)<br />

With the state equation, the perturbation <strong>of</strong> f<strong>low</strong> variables can be<br />

written as<br />

u<br />

ρ ¤<br />

0§ 5 γ 1£ ¯ ¡<br />

J 2 ¢ <br />

¤&%<br />

1£ γ<br />

2HR c p<br />

γ 1£ ¯ J 2<br />

m<br />

H ¯ u<br />

¤ p<br />

¤ T ¯<br />

¢<br />

T ©<br />

©<br />

u m u<br />

E u p ρ' u ©<br />

¯F J¯<br />

¯<br />

2<br />

1<br />

J¯<br />

¯<br />

1<br />

f<br />

2HR c p<br />

¯ J 1 H ¯ ¯ ¯<br />

ρ ¯<br />

ρ ¯<br />

ρ ¯<br />

f ¯F ¯ u<br />

¢<br />

p<br />

p ¯<br />

u ¯<br />

u<br />

u ¯<br />

u ¯<br />

m<br />

3 ¯<br />

J 1<br />

¨*% F H ¯ p ¯ ¡<br />

J 1 )( <br />

2<br />

<br />

¯F ¯ J 1<br />

ρ ¯<br />

3<br />

J2<br />

¡<br />

u ¯<br />

¦ (27)<br />

¦ (28)<br />

¯ © ¡ ©<br />

u £' m<br />

H<br />

m ¯<br />

u ¯ F<br />

2 ¡<br />

¦ (29)<br />

ρ<br />

£§<br />

¯ ρ<br />

(30)<br />

For linear disturbances whose time dependence is proportional<br />

to e iωt , the equations <strong>for</strong> the perturbations <strong>of</strong> mass flux,

©<br />

¢<br />

©<br />

©<br />

©<br />

©<br />

¢<br />

©<br />

©<br />

<br />

x¦<br />

¢<br />

©<br />

¢<br />

©<br />

©<br />

©<br />

¡<br />

¡<br />

¡<br />

<br />

©<br />

¢<br />

¤<br />

©<br />

momentum flux <strong>and</strong> energy flux can be written as<br />

d ˆ ©<br />

m<br />

dx<br />

d ˆ f<br />

dx<br />

d<br />

ʤ<br />

dx<br />

iωH ˆ ©<br />

ρ*¦ (31)<br />

¤<br />

iω ˆ ©<br />

m ¤<br />

q+ ˆ<br />

ρ ¯<br />

c v<br />

ˆ<br />

© ¡<br />

p<br />

iωH<br />

© ¢<br />

ρ ˆ<br />

<br />

T ˆ<br />

¯ © ¡<br />

dH<br />

dx (32)<br />

¦ ¡<br />

c v T¯<br />

1<br />

2 ¯ 2 u ¯F£<br />

u ˆ ¯F 1 u<br />

2 ¯ 2 ˆF£#§ (33)<br />

¡ u<br />

The unsteady heat release rate is the main driving <strong>for</strong>ce <strong>of</strong><br />

<strong>combustion</strong> instability, <strong>and</strong> when predicting <strong>combustion</strong> oscillations,<br />

it is important to describe the coupling between this rate <strong>of</strong><br />

heat release <strong>and</strong> the f<strong>low</strong>. Many <strong>models</strong> <strong>for</strong> flame transfer functions<br />

have been described in the literature [4, 5]. In our recent<br />

work, a method <strong>for</strong> calculating flame transfer functions with CFD<br />

has been developed. Here, CFD was used to calculate the unsteady<br />

f<strong>low</strong> in the combustor. Through calculations <strong>of</strong> the <strong>for</strong>ced<br />

unsteady <strong>combustion</strong> resulting from a specified time-dependent<br />

variation in the air supply, we were able to obtain in<strong>for</strong>mation<br />

on the transfer function between rate <strong>of</strong> heat release <strong>and</strong> the air<br />

f<strong>low</strong> rate through the atomizer. For one-dimensional analysis, the<br />

heat release rate is obtained by <strong>integration</strong> across the combustior<br />

section. The ARX model is used in the transfer function calculation<br />

[6]. This means the transfer function at axial position x is<br />

written in the <strong>for</strong>m <strong>of</strong> an IIR filter, with additional noise, i.e.<br />

q<br />

x¦ nT £¥¤<br />

1<br />

¢ I,<br />

∑ a i x£ m a x¦<br />

<br />

0 i-<br />

K<br />

∑<br />

¢<br />

b k<br />

x£<br />

1 k-<br />

q<br />

n i N£ T<br />

n <br />

k£ T<br />

ε ¢ nT £§ (34)<br />

The error ε ¢ t£ is assumed to be uncorrelated to q ¢ x¦ t£ <strong>and</strong> independent<br />

<strong>of</strong> frequency. The input signal we used in this work<br />

is the sum <strong>of</strong> sinusoidal signals, be<strong>for</strong>e normalization it can be<br />

written as<br />

¢<br />

m a £¤ nT<br />

K<br />

∑<br />

k- 1<br />

sin ¢ π ¢ n 1£ ω k<br />

t ¡ 2πw ¢ k££¦<br />

<strong>and</strong> n ¤ 1 . .. N ¦ (35)<br />

where K is the number <strong>of</strong> sinusoids which are equally spread<br />

over the passb<strong>and</strong>. ω 1<br />

<strong>and</strong> ω 2<br />

are the <strong>low</strong>er <strong>and</strong> upper limits <strong>of</strong><br />

¡<br />

the passb<strong>and</strong>, <strong>and</strong> ω k<br />

¤ ω 1<br />

k ω 2<br />

ω 1<br />

K¦ k ¤ 1 . . . K. w ¢ k£<br />

£¨<br />

describes the phase <strong>of</strong> the kth sinusoid at ¢ t 0 <strong>and</strong> is a ¤<br />

r<strong>and</strong>om<br />

number chosen from a uni<strong>for</strong>m distribution on the interval<br />

¢ ¢<br />

. After the 0¦ 1 a i<br />

x£ <strong>and</strong> b k<br />

are obtained, the x£ frequency domain<br />

transfer function <strong>of</strong> the flame model can be written as<br />

H ¢ ω ¦ x£¤<br />

q ˆ<br />

ω ¦ x£<br />

ˆm a<br />

¢<br />

ω£<br />

1 ¢ I,<br />

∑ a i<br />

x£ z i , i- 0<br />

K ¢<br />

1 ∑ b k<br />

x£ z k , § (36)<br />

1 k-<br />

The integrated mean heat release rate is shown in Fig. 6. The<br />

flame transfer functions at 50 Hz, calculated with I¦ K ¤ 10 <strong>and</strong><br />

I¦ K ¤ 30 are shown in Fig. 7. The transfer functions <strong>of</strong> the shape<br />

factors can be calculated with the same method.<br />

4 RESULTS AND DISCUSSION<br />

The mean values <strong>of</strong> mass, momentum <strong>and</strong> energy fluxes can<br />

be calculated through <strong>integration</strong> <strong>of</strong> Eqs. (17)-(19) with appropriate<br />

inlet boundary conditions. The results are shown in Figs. 8-<br />

10 are with inlet boundary conditions derived from the CFD results<br />

to aid comparison in this paper. In these figures, three steps<br />

are clearly demonstrated, which correspond to the contributions<br />

from the primary <strong>and</strong> secondary air injections. In current study,<br />

the source terms S m , S f<br />

<strong>and</strong> S e are kept as constants in both the<br />

CFD <strong>and</strong> in the linear analysis. The mean values <strong>of</strong> f<strong>low</strong> variables<br />

can be obtained according to Eqs. (20)-(23). The mean values<br />

<strong>of</strong> temperature <strong>and</strong> velocity are shown in Figs 11 <strong>and</strong> 12, respectively.<br />

From Figs. 8-12, we can see that the mean f<strong>low</strong> results<br />

from one-dimensional analysis are in good agreement with those<br />

from CFD calculations. From Fig. 11, it can be seen that the integrated<br />

temperature is much <strong>low</strong>er than that within <strong>combustion</strong><br />

zone. This is because, at this idle condition, the temperature <strong>of</strong><br />

most <strong>of</strong> the air within combustor is relatively <strong>low</strong>, although the<br />

local temperature can be as high as 2000 K. For the integrated<br />

velocity, as shown in Fig. 12, three steps due to additional air<br />

injected are clearly demonstrated. The decrease fol<strong>low</strong>ing each<br />

step in mean velocity is the subsequence <strong>of</strong> the relatively high<br />

density <strong>of</strong> the cool f<strong>low</strong> in the recirculation induced by the f<strong>low</strong><br />

injection.<br />

The aim <strong>of</strong> this study is to develop a method whereby a linear<br />

stability analysis can provide a useful tool to predict ‘rumble’.<br />

Our first calculation involved keeping the shape factors<br />

constant (independent <strong>of</strong> time) <strong>and</strong> using the flame transfer functions<br />

identified from CFD calculation. In the one-dimensional<br />

analysis, the flame transfer function ˆ describes the relationship<br />

between the unsteady heat release rate with inlet oscilla-<br />

q<br />

tions. We found that this approach led to one-dimensional disturbances<br />

which were significantly different from the area-averaged<br />

CFD results. There<strong>for</strong>e, it is necessary to investigate the sensitivities<br />

<strong>of</strong> the results to the time dependence <strong>of</strong> the three nondimensional<br />

shape factors. In Eq. (11), the non-dimensional<br />

shape factor J 1 describes the effects <strong>of</strong> oscillation on the shape

factor describing nonuni<strong>for</strong>mity <strong>of</strong> the enthalpy transport in the<br />

axial direction. According to the definition, it is determined by<br />

both axial velocity <strong>and</strong> temperature. That means it also has an<br />

influence on the transport <strong>of</strong> the entropy wave. It is evident from<br />

Fig. 13 that the position <strong>of</strong> maximum amplitude <strong>of</strong> J 1 is in the<br />

recirculation zone. This can be explained by the fact that fluctuation<br />

in the inlet air not only alters the fuel vapor distribution in<br />

this region, it also alters the vorticity, <strong>and</strong> thus effects the radial<br />

distribution <strong>of</strong> enthalpy. The results <strong>of</strong> neglecting J 1 on temperature<br />

<strong>and</strong> velocity perturbation are shown in Figs. 14 <strong>and</strong> 15,<br />

respectively. It is seen that there is large difference in the unsteady<br />

temperature <strong>and</strong> velocity distributions predicted with <strong>and</strong><br />

without consideration <strong>of</strong> J 1 , particularly in <strong>combustion</strong> region.<br />

From Fig. 15, we can see that there is large difference in the<br />

phase <strong>of</strong> downstream fluctuation in velocity. This difference can<br />

lead to a large error downstream boundary condition <strong>and</strong> lead to<br />

significantly different resonant frequencies. There<strong>for</strong>e, it is important<br />

to include the fluctuation <strong>of</strong> J 1<br />

in any stability analysis.<br />

In fact, from our previous work, it is clear that the mechanism<br />

<strong>of</strong> rumble involves the resonant interaction <strong>of</strong> the entropy <strong>and</strong><br />

acoustic waves. The effects <strong>of</strong> changes in the radial distribution<br />

<strong>of</strong> axial transport <strong>of</strong> enthalpy <strong>and</strong> hence <strong>of</strong> entropy are described<br />

by the non-dimensional factor Jˆ<br />

1<br />

. We see that in the prediction<br />

<strong>of</strong> entropy wave, it is not sufficient to treat the shape function<br />

J 1<br />

as steady. An adjustment is needed to cope with time variations<br />

in radial non-uni<strong>for</strong>mity, particularly due<br />

¢<br />

to the changing<br />

strength <strong>of</strong> the recirculation vortex. Fortunately, J 1<br />

x¦ t£ ¢ is ¢ influenced<br />

primarily by the inlet air f<strong>low</strong> rate <strong>and</strong> Jˆ<br />

1<br />

ω ¦ x£¨ ˆm a ω£ can<br />

be identified from a single <strong>for</strong>ced CFD calculation as described<br />

in section 3.<br />

In Eq. (8), F represents the variation <strong>of</strong> momentum flux<br />

when the oscillations changes the nonuni<strong>for</strong>mity <strong>of</strong> the axial velocity.<br />

The magnitude <strong>and</strong> phase <strong>of</strong> the relationship between<br />

F <strong>and</strong> inlet air mass f<strong>low</strong> rate are shown in Fig. 16. It is seen<br />

x¦ t£<br />

that there are three peaks in the magnitude plot. Comparison with<br />

the f<strong>low</strong> field contours shows that these ¢ three peaks correspond<br />

to the jets induced by inlets 1 <strong>and</strong> 2, the <strong>combustion</strong> recirculation<br />

zone <strong>and</strong> the downstream contraction, respectively. It means<br />

that the oscillation alters the size or intensity <strong>of</strong> the jets or vortex,<br />

there<strong>for</strong>e the axial uni<strong>for</strong>mness <strong>of</strong> momentum transport. A similar<br />

conclusion can be drawn about the non-dimensional factor<br />

J 2<br />

, which represents the effect <strong>of</strong> oscillation on the uni<strong>for</strong>mness<br />

<strong>of</strong> kinetic energy in the radial direction. The comparison <strong>of</strong> the<br />

results from a one-dimensional analysis with <strong>and</strong> without considering<br />

F <strong>and</strong> J 2<br />

are shown in Figs. 17 <strong>and</strong> 18. It is seen that,<br />

although there are some differences, they are small <strong>and</strong> the predicted<br />

the magnitude <strong>and</strong> phase <strong>of</strong> the f<strong>low</strong> parameters are quite<br />

comparable. Figures 19 <strong>and</strong> 20 give time traces <strong>of</strong> shape factors<br />

J 1<br />

<strong>and</strong> F at the typical location <strong>for</strong> <strong>for</strong>cing at a frequency<br />

50 Hz. It is seen that, in each position, the ratios <strong>of</strong> magnitude<br />

<strong>of</strong> oscillation to mean value <strong>for</strong> J 1<br />

<strong>and</strong> F are <strong>of</strong> the same <strong>order</strong>.<br />

However, as we discussed above, the influence <strong>of</strong> J 1<br />

on the<br />

one-dimensional f<strong>low</strong> parameters is much greater than that <strong>of</strong> F.<br />

This rein<strong>for</strong>ces our argument that the unsteady entropy transport<br />

is more important that those <strong>of</strong> momentum <strong>and</strong> kinetic energy.<br />

Hence in a simplified analysis, it is justified to neglect any unsteadiness<br />

in the shape factors F <strong>and</strong> J 2<br />

, although it should be<br />

retained in J 1<br />

.<br />

5 CONCLUSIONS<br />

In this work, a new approach is developed to give predications<br />

<strong>for</strong> instability onset <strong>and</strong> the frequencies <strong>of</strong> oscillation.<br />

This is based on integrating CFD <strong>and</strong> <strong>low</strong>-<strong>order</strong> <strong>models</strong>. The<br />

CFD provides the transfer function between the heat release<br />

rate per unit length <strong>and</strong> air f<strong>low</strong> rate through the atomizer by<br />

time-dependent calculations <strong>of</strong> the <strong>combustion</strong> processes with<br />

specified <strong>for</strong>ced inlet boundary conditions. At the same time<br />

the transfer functions between non-dimensional shape factors<br />

<strong>and</strong> inlet air f<strong>low</strong> rate can be calculated. By integrating the<br />

ensemble-averaged conservation equations <strong>of</strong> motion, quasi-onedimensional<br />

equations <strong>for</strong> a linear stability analysis are derived.<br />

The effects <strong>of</strong> any radial non-uni<strong>for</strong>mity on transport <strong>of</strong> f<strong>low</strong> parameters<br />

are considered by shape factors, which can be obtained<br />

from the same CFD calculation. F<strong>low</strong> quantities can be determined<br />

quickly <strong>and</strong> straight<strong>for</strong>wardly by solving the mean f<strong>low</strong><br />

<strong>and</strong> the linear perturbation equations. The amplitude <strong>and</strong> phase<br />

relationships <strong>of</strong> temperature <strong>and</strong> velocity perturbations, which<br />

play an important role in the downstream boundary condition,<br />

have been compared with CFD results <strong>for</strong> the same inlet boundary<br />

conditions. The results show good agreement. To simplify<br />

the perturbation analysis, the sensitivity to the non-dimensional<br />

shape factors was also investigated. It is shown that the inclusion<br />

<strong>of</strong> factor J 1<br />

, which represents the effect <strong>of</strong> radial nonuni<strong>for</strong>mity<br />

on enthalpy transport, is important if the <strong>combustion</strong> oscillations<br />

are to be predicted correctly. The shape factors F <strong>and</strong> J 2 , which<br />

represent the momentum <strong>and</strong> kinetic energy transports, can be<br />

neglected in the linear analysis <strong>of</strong> <strong>combustion</strong> oscillation. The<br />

strategy outlined here can be expected to have useful practical<br />

applications if the flame transfer function <strong>and</strong> the shape factors,<br />

determined from a small number <strong>of</strong> detailed CFD calculations,<br />

can subsequently be applied to linear stability analyses under a<br />

wider range <strong>of</strong> conditions. In the future, we will use the method<br />

developed here to predict the instability onset <strong>and</strong> the frequencies<br />

<strong>of</strong> oscillation. We anticipate the results will be useful to<br />

underst<strong>and</strong> the <strong>combustion</strong> oscillation <strong>and</strong> be helpful in the development<br />

<strong>of</strong> control strategies.<br />

ACKNOWLEDGMENT<br />

This work was funded by the Engineering <strong>and</strong> Physical<br />

Sciences Research Council, Rolls-Royce <strong>and</strong> European<br />

Union GROWTH Program, Research project “ICLEAC: Instability<br />

Control <strong>of</strong> Low Emission Aero Engine Combustors”

1<br />

2<br />

/<br />

0<br />

Contract(G4RD-CT2000-0215), whose support are gratefully<br />

acknowledged.<br />

3 4 5<br />

REFERENCES<br />

[1] M. Zhu, A.P. Dowling <strong>and</strong> K.N.C. Bray. Combustion oscillations<br />

in burners with fuel spray atomiser. ASME paper<br />

98–GT–302, Indianapolis, Indiana, June 1999. ASME International<br />

Gas Turbine <strong>and</strong> Aeroengine Congress <strong>and</strong> Exhibition.<br />

[2] M. Zhu, A.P. Dowling <strong>and</strong> K.N.C. Bray. Flame transfer function<br />

calculations <strong>for</strong> <strong>combustion</strong> oscillations. ASME paper<br />

2000–GT–374, New Orleans, Louisiana, June 2001. ASME<br />

International Gas Turbine <strong>and</strong> Aeroengine Congress <strong>and</strong> Exhibition.<br />

[3] M. Zhu, A.P. Dowling <strong>and</strong> K.N.C. Bray. Self-excited Oscillations<br />

in Combustors with Spray Atomisers. ASME paper<br />

2000–GT–108, Munich, Germany, May 2000. ASME International<br />

Gas Turbine <strong>and</strong> Aeroengine Congress <strong>and</strong> Exhibition.<br />

[4] A. P. Dowling, 1995, “The calculation <strong>of</strong> thermoacoustic oscillations”,<br />

Journal <strong>of</strong> Sound <strong>and</strong> Vibration, 180(4), pp. 557–<br />

581.<br />

[5] A. P. Dowling, 1997, “Nonlinear self-excited oscillations <strong>of</strong><br />

a ducted flame”, J. Fluid Mech., 346, pp. 271–290.<br />

[6] L. Ljung. System Identification Toolbox User’s Guide. The<br />

MathWorks Inc., 1991.<br />

r(m)<br />

0.27<br />

0.26<br />

0.25<br />

0.24<br />

0.23<br />

0.22<br />

0.21<br />

0.2<br />

0.19<br />

Figure 1.<br />

Schematic diagram <strong>of</strong> the geometry.<br />

6 7 /98<br />

0.18<br />

0 0.05 0.1 0.15 0.2<br />

x(m)<br />

/:/<br />

2000<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

FIGURES<br />

Figure 2. Contour plot <strong>of</strong> the mean temperature distribution<br />

chamber at idle conditions. The black line indicates the mean<br />

position <strong>of</strong> the stoichiometric curve <strong>and</strong> arrows denote the<br />

direction <strong>and</strong> magnitude <strong>of</strong> the mean velocity.<br />

4.5<br />

4<br />

3.5<br />

3<br />

mean F<br />

2.5<br />

2<br />

1.5<br />

1<br />

0 0.05 0.1 0.15 0.2 0.25<br />

axial coordinate x(m)<br />

Figure 3.<br />

The mean <strong>of</strong> dimensionless shape factor ¯F ¢ x£ , which is<br />

defined by Eq. (8).

1.6<br />

mean J 1<br />

1.5<br />

1.4<br />

1.3<br />

1.2<br />

1.1<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

| q |<br />

3.5 x 108<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

I,K = 10<br />

I,K = 30<br />

0<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

Figure 4.<br />

0.6<br />

0 0.05 0.1 0.15 0.2 0.25<br />

axial coordinate x(m)<br />

20<br />

18<br />

16<br />

¢<br />

The mean <strong>of</strong> dimensionless shape factor J¯<br />

1 , which is x£<br />

defined by Eq. (11).<br />

angle ( q ) deg.<br />

400<br />

300<br />

200<br />

100<br />

0<br />

I,K = 10<br />

I,K = 30<br />

mean J 2<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Figure 7.<br />

−100<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

The transfer function between the heat release rate per<br />

unit length <strong>and</strong> the air f<strong>low</strong> rate through the atomizer at a frequency<br />

50 Hz. Identification involves fitting the ARX model <strong>of</strong> Eq. (34), the<br />

I= ><br />

I= ><br />

solid lines indicate the result from the model K 10 <strong>and</strong> dash<br />

lines indicate that from the model K 30.<br />

Figure 5.<br />

0<br />

0 0.05 0.1 0.15 0.2 0.25<br />

axial coordinate x(m)<br />

The mean <strong>of</strong> dimensionless shape factor ¯ J 2 ; x< , which is<br />

defined by Eq. (12).<br />

13<br />

12<br />

11<br />

1D analysis<br />

CFD result<br />

5 x 107 x (m)<br />

q(x) w/m<br />

4.5<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

mean mass flux<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

1<br />

0.5<br />

0<br />

0 0.025 0.05 0.075 0.1 0.125 0.15 0.175 0.2 0.225<br />

Figure 6.<br />

The mean heat release rate ¯q ; x< per unit length <strong>of</strong><br />

combustor.<br />

Figure 8.<br />

3<br />

0 0.05 0.1 0.15 0.2<br />

axial coordinate x(m)<br />

The mean mass flux, where the solid lines indicate the<br />

result from a one-dimensional analysis <strong>and</strong> dash lines indicate that<br />

from the CFD calculation.

|<br />

2.84 x 104<br />

mean momentum flux<br />

2.835<br />

2.83<br />

2.825<br />

2.82<br />

2.815<br />

2.81<br />

1D analysis<br />

CFD result<br />

mean velocity<br />

65<br />

60<br />

55<br />

50<br />

45<br />

40<br />

1D analysis<br />

CFD result<br />

2.805<br />

35<br />

2.8<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2<br />

axial coordinate x(m)<br />

Figure 9. The mean momentum flux, where the solid lines indicate<br />

the result from a one-dimensional analysis <strong>and</strong> dash lines indicate<br />

that from the CFD calculation.<br />

8 x 106<br />

30<br />

25<br />

Figure 12.<br />

20<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

axial coordinate x(m)<br />

Mean velocity, where the solid lines indicate the result<br />

from a one-dimensional analysis <strong>and</strong> dash lines indicate that from<br />

the CFD calculation.<br />

7<br />

6<br />

1D analysis<br />

CFD result<br />

mean energy flux<br />

5<br />

4<br />

1.8<br />

1.6<br />

3<br />

1.4<br />

2<br />

1.2<br />

1<br />

Figure 10.<br />

1<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2<br />

axial coordinate x(m)<br />

The mean energy flux, where the solid lines indicate the<br />

result from a one-dimensional analysis <strong>and</strong> dash lines indicate that<br />

from the CFD calculation.<br />

| J 1<br />

′<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

850<br />

800<br />

1D analysis<br />

CFD result<br />

0<br />

−20<br />

750<br />

−40<br />

700<br />

] deg.<br />

−60<br />

mean temperature<br />

650<br />

600<br />

angle [ J 1<br />

′<br />

−80<br />

−100<br />

550<br />

−120<br />

500<br />

−140<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

450<br />

Figure 11.<br />

400<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

axial coordinate x(m)<br />

Mean temperature, where the solid lines indicate the<br />

result from a one-dimensional analysis <strong>and</strong> dash lines indicate that<br />

from the CFD calculation.<br />

Figure 13. Magnitude <strong>and</strong> phase <strong>of</strong> the transfer function between<br />

shape factor J 1 <strong>and</strong> air f<strong>low</strong> rate through the atomizer at a<br />

frequency 50 Hz.

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

1800<br />

1600<br />

1400<br />

1200<br />

CFD result<br />

with J1 ′<br />

without J1 ′<br />

2.5<br />

2<br />

1000<br />

| T ′ |<br />

800<br />

600<br />

400<br />

| F ′ |<br />

1.5<br />

1<br />

200<br />

0.5<br />

0<br />

0<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

250<br />

200<br />

150<br />

CFD result<br />

with J1 ′<br />

without J1 ′<br />

0<br />

100<br />

−50<br />

angle [ T ′ ] deg.<br />

50<br />

0<br />

−50<br />

−100<br />

angle [ F ′ ] deg.<br />

−100<br />

−150<br />

−150<br />

−200<br />

−200<br />

−250<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

Figure 14. Magnitude <strong>and</strong> phase <strong>of</strong> the transfer function between<br />

the temperature <strong>and</strong> air f<strong>low</strong> rate through the atomizer at a<br />

frequency 50 Hz, where the solid lines indicate the result from the<br />

CFD calculation. The dash lines <strong>and</strong> dotted-dash lines indicate the<br />

results from one-dimensional analysis with <strong>and</strong> without J?1 ,<br />

respectively.<br />

Figure 16.<br />

−250<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

Magnitude <strong>and</strong> phase <strong>of</strong> the transfer function between<br />

shape factor F <strong>and</strong> air f<strong>low</strong> rate through the atomizer at a frequency<br />

50 Hz.<br />

450<br />

120<br />

400<br />

CFD result<br />

100<br />

CFD result<br />

with J1 ′<br />

without J1 ′<br />

350<br />

300<br />

with F ′ J2 ′<br />

without F ′ J2 ′<br />

80<br />

250<br />

| T ′ |<br />

200<br />

| u ′ |<br />

60<br />

150<br />

40<br />

100<br />

50<br />

20<br />

0<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

0<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

200<br />

150<br />

150<br />

CFD result<br />

100<br />

CFD result<br />

with J1 ′<br />

100<br />

with F ′ J2 ′<br />

without F ′ J2 ′<br />

without J1 ′<br />

50<br />

angle [ u ′ ] deg.<br />

50<br />

0<br />

−50<br />

−100<br />

−150<br />

angle [ T ′ ] deg.<br />

0<br />

−50<br />

−100<br />

−150<br />

−200<br />

−250<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

Figure 15.<br />

−200<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

Magnitude <strong>and</strong> phase <strong>of</strong> the transfer function between<br />

the velocity <strong>and</strong> air f<strong>low</strong> rate through the atomizer at a frequency<br />

50 Hz, where the solid lines indicate the result from the CFD<br />

calculation. The dash lines <strong>and</strong> dotted-dash lines indicate the<br />

results from one-dimensional analysis with <strong>and</strong> without J?1 ,<br />

respectively.<br />

Figure 17. Magnitude <strong>and</strong> phase <strong>of</strong> the transfer function between<br />

the temperature <strong>and</strong> air f<strong>low</strong> rate through the atomizer at a<br />

frequency 50 Hz, where the solid lines indicate the result from the<br />

CFD calculation. The dash lines <strong>and</strong> dotted-dash lines indicate the<br />

results from one-dimensional analysis with <strong>and</strong> F@ without <strong>and</strong> J@2 ,<br />

respectively.

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

35<br />

30<br />

25<br />

CFD result<br />

with F ′ J2 ′<br />

without F ′ J2 ′<br />

20<br />

| u ′ |<br />

15<br />

10<br />

5<br />

0<br />

140<br />

120<br />

100<br />

CFD result<br />

with F ′ J2 ′<br />

without F ′ J2 ′<br />

angle [ u ′ ] deg.<br />

80<br />

60<br />

40<br />

20<br />

2.255 x 105 p 0<br />

( x=0 ) Pa<br />

0<br />

−20<br />

2.25<br />

Figure 18.<br />

−40<br />

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 0.22<br />

Magnitude <strong>and</strong> phase <strong>of</strong> the transfer function between<br />

the velocity <strong>and</strong> air f<strong>low</strong> rate through the atomizer at a frequency<br />

50 Hz, where the solid lines indicate the result from the CFD<br />

calculation. The dash lines <strong>and</strong> dotted-dash lines indicate the<br />

results from one-dimensional analysis with <strong>and</strong> without F@ <strong>and</strong> J@2 ,<br />

2.25<br />

respectively.<br />

2.255 x 105 p 0<br />

( x=0 ) Pa<br />

2.245<br />

2.315<br />

2.295<br />

2.275<br />

1.124<br />

1.123<br />

1.122<br />

1.121<br />

1.12<br />

1.69<br />

1.68<br />

F( x 1<br />

, t )<br />

F( x 2<br />

, t )<br />

F( x 3<br />

, t )<br />

2.245<br />

0.78<br />

0.76<br />

0.74<br />

0.72<br />

0.7<br />

1.25<br />

J 1<br />

( x 1<br />

, t )<br />

J 1<br />

( x 2<br />

, t )<br />

1.67<br />

1.66<br />

1.65<br />

0.15 0.16 0.17 0.18 0.19 0.2 0.21<br />

Figure 20.<br />

Sinusoidal changes <strong>of</strong> the total pressure in the<br />

atomizer air inlet lead to oscillations in the non-dimensional shape<br />

factor F at x 1 A 0B 01m, x 2 A 0B 128m <strong>and</strong> x 3 A 0B 2m, respectively.<br />

1.24<br />

1.23<br />

1.22<br />

1.25<br />

1.24<br />

1.23<br />

1.22<br />

J 1<br />

( x 3<br />

, t )<br />

1.21<br />

0.15 0.16 0.17 0.18 0.19 0.2 0.21<br />

Figure 19. Sinusoidal changes <strong>of</strong> the total pressure in the<br />

atomizer air inlet lead to oscillations in the non-dimensional shape<br />

factor J 1 at x 1 A 0B 01m, x 2 A 0B 128m <strong>and</strong> x 3 A 0B 2m, respectively.