Comflex® Rubber Expansion Joints Engineering Guide

Comflex® Rubber Expansion Joints Engineering Guide

Comflex® Rubber Expansion Joints Engineering Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

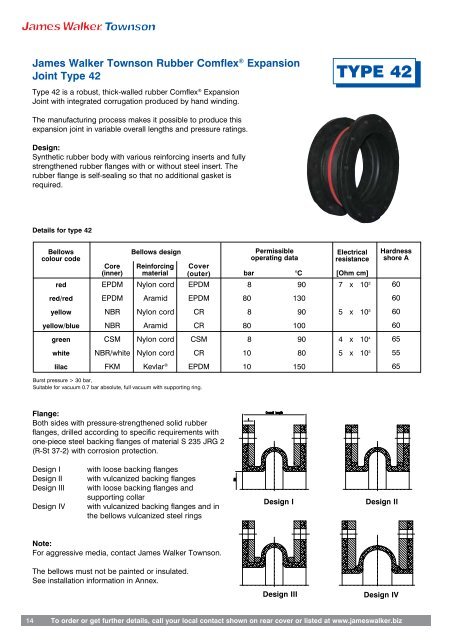

James Walker Townson <strong>Rubber</strong> Comflex ® <strong>Expansion</strong><br />

Joint Type 42<br />

Type 42 is a robust, thick-walled rubber Comflex ® <strong>Expansion</strong><br />

Joint with integrated corrugation produced by hand winding.<br />

TYPE 42<br />

The manufacturing process makes it possible to produce this<br />

expansion joint in variable overall lengths and pressure ratings.<br />

Design:<br />

Synthetic rubber body with various reinforcing inserts and fully<br />

strengthened rubber flanges with or without steel insert. The<br />

rubber flange is self-sealing so that no additional gasket is<br />

required.<br />

Details for type 42<br />

Bellows<br />

colour code<br />

red<br />

Core<br />

(inner)<br />

EPDM<br />

Bellows design<br />

Reinforcing<br />

material<br />

Nylon cord<br />

Cover<br />

(outer)<br />

EPDM<br />

Permissible<br />

operating data<br />

bar °C<br />

8 90<br />

Electrical<br />

resistance<br />

[Ohm cm]<br />

7 x 10 2<br />

Hardness<br />

shore A<br />

60<br />

red/red<br />

EPDM<br />

Aramid<br />

EPDM<br />

80 130<br />

60<br />

yellow<br />

NBR<br />

Nylon cord<br />

CR<br />

8 90<br />

5 x 10 3<br />

60<br />

yellow/blue<br />

NBR<br />

Aramid<br />

CR<br />

80 100<br />

60<br />

green<br />

CSM<br />

Nylon cord<br />

CSM<br />

8 90<br />

4 x 10 4<br />

65<br />

white<br />

NBR/white<br />

Nylon cord<br />

CR<br />

10 80<br />

5 x 10 3<br />

55<br />

lilac<br />

FKM<br />

Kevlar ®<br />

EPDM<br />

10 150<br />

65<br />

Burst pressure > 30 bar,<br />

Suitable for vacuum 0.7 bar absolute, full vacuum with supporting ring.<br />

Flange:<br />

Both sides with pressure-strengthened solid rubber<br />

flanges, drilled according to specific requirements with<br />

one-piece steel backing flanges of material S 235 JRG 2<br />

(R-St 37-2) with corrosion protection.<br />

Design I<br />

Design II<br />

Design III<br />

Design IV<br />

with loose backing flanges<br />

with vulcanized backing flanges<br />

with loose backing flanges and<br />

supporting collar<br />

with vulcanized backing flanges and in<br />

the bellows vulcanized steel rings<br />

Design I<br />

Design II<br />

Note:<br />

For aggressive media, contact James Walker Townson.<br />

The bellows must not be painted or insulated.<br />

See installation information in Annex.<br />

Design III<br />

Design IV<br />

14<br />

To order or get further details, call your local contact shown on rear cover or listed at www.jameswalker.biz