Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tube test seals<br />

Special duty products<br />

Tube test seals<br />

High-pressure hydrostatic testing<br />

We manufacture two types of seal<br />

that are specifically designed to<br />

operate with tube testing machines<br />

that repeatedly seal and release the<br />

tube ends as part of the hydrostatic<br />

testing process.<br />

The quality of such seals is a crucial<br />

factor in the reliability of the machines’<br />

operation; our tube test seals therefore<br />

provide the highest levels of performance.<br />

Other designs are available on request.<br />

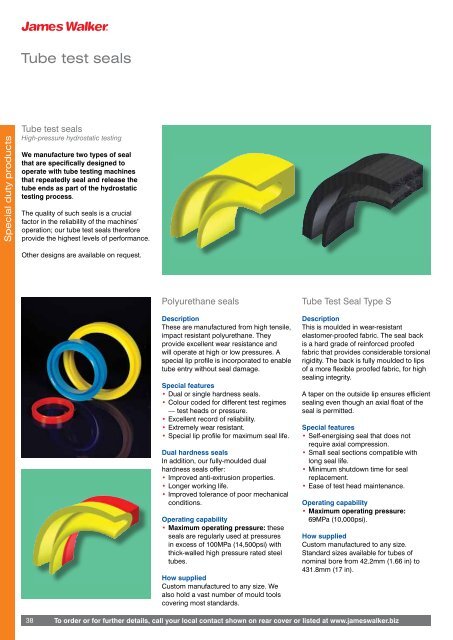

Polyurethane seals<br />

Description<br />

These are manufactured from high tensile,<br />

impact resistant polyurethane. They<br />

provide excellent wear resistance and<br />

will operate at high or low pressures. A<br />

special lip profile is incorporated to enable<br />

tube entry without seal damage.<br />

Special features<br />

• Dual or single hardness seals.<br />

• Colour coded for different test regimes<br />

— test heads or pressure.<br />

• Excellent record of reliability.<br />

• Extremely wear resistant.<br />

• Special lip profile for maximum seal life.<br />

Dual hardness seals<br />

In addition, our fully-moulded dual<br />

hardness seals offer:<br />

• Improved anti-extrusion properties.<br />

• Longer working life.<br />

• Improved tolerance of poor mechanical<br />

conditions.<br />

Operating capability<br />

• Maximum operating pressure: these<br />

seals are regularly used at pressures<br />

in excess of 100MPa (14,500psi) with<br />

thick-walled high pressure rated steel<br />

tubes.<br />

How supplied<br />

Custom manufactured to any size. We<br />

also hold a vast number of mould tools<br />

covering most standards.<br />

Tube Test Seal Type S<br />

Description<br />

This is moulded in wear-resistant<br />

elastomer-proofed fabric. The seal back<br />

is a hard grade of reinforced proofed<br />

fabric that provides considerable torsional<br />

rigidity. The back is fully moulded to lips<br />

of a more flexible proofed fabric, for high<br />

sealing integrity.<br />

A taper on the outside lip ensures efficient<br />

sealing even though an axial float of the<br />

seal is permitted.<br />

Special features<br />

• Self-energising seal that does not<br />

require axial compression.<br />

• Small seal sections compatible with<br />

long seal life.<br />

• Minimum shutdown time for seal<br />

replacement.<br />

• Ease of test head maintenance.<br />

Operating capability<br />

• Maximum operating pressure:<br />

69MPa (10,000psi).<br />

How supplied<br />

Custom manufactured to any size.<br />

Standard sizes available for tubes of<br />

nominal bore from 42.2mm (1.66 in) to<br />

431.8mm (17 in).<br />

38<br />

To order or for further details, call your local contact shown on rear cover or listed at www.jameswalker.biz