Knauf Fire Walls

Knauf Fire Walls

Knauf Fire Walls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

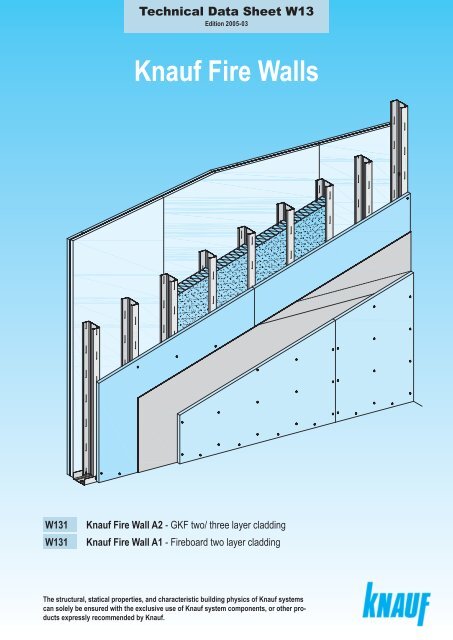

Technical Data Sheet W13<br />

Edition 2005-03<br />

<strong>Knauf</strong> <strong>Fire</strong> <strong>Walls</strong><br />

W131<br />

W131<br />

<strong>Knauf</strong> <strong>Fire</strong> Wall A2 - GKF two/ three layer cladding<br />

<strong>Knauf</strong> <strong>Fire</strong> Wall A1 - <strong>Fire</strong>board two layer cladding<br />

The structural, statical properties, and characteristic building physics of <strong>Knauf</strong> systems<br />

can solely be ensured with the exclusive use of <strong>Knauf</strong> system components, or other products<br />

expressly recommended by <strong>Knauf</strong>.

<strong>Knauf</strong> <strong>Fire</strong> <strong>Walls</strong><br />

Technical data / sound protection / thermal insulation / fire protection<br />

Technical data / sound protection / thermal insulation<br />

System<br />

Technical data<br />

dimensions<br />

wall stud cladding<br />

thickn. thickness type<br />

D h d<br />

W131 <strong>Knauf</strong> <strong>Fire</strong> Wall A2<br />

<strong>Fire</strong> protection<br />

System<br />

spacing of studs<br />

31.25 cm 31.25 cm<br />

W132 <strong>Knauf</strong> <strong>Fire</strong> Wall A1<br />

spacing of studs<br />

31.25 cm 31.25 cm<br />

d h d<br />

D<br />

<strong>Fire</strong><br />

rating<br />

W131 <strong>Knauf</strong> <strong>Fire</strong> Wall A2 with <strong>Knauf</strong> Boards GKF<br />

W132 <strong>Knauf</strong> <strong>Fire</strong> Wall A1 with <strong>Fire</strong>board<br />

126<br />

151<br />

176 100<br />

116<br />

141<br />

F90<br />

F90<br />

50<br />

75<br />

50<br />

75<br />

166 100<br />

161 100<br />

3 x 12.5<br />

+<br />

0.5<br />

Cladding<br />

GKF<br />

+<br />

metal sheet<br />

layer<br />

min.<br />

thickness<br />

mm<br />

<strong>Fire</strong>-resistant<br />

Boards<br />

3 x 12.5<br />

GKF A2<br />

+ +<br />

metal sheet 0.5<br />

Solid Board +<br />

<strong>Fire</strong>-resistant board<br />

GKF A2<br />

+<br />

metal sheet<br />

weight<br />

approx.<br />

kg/m²<br />

20 + 12.5<br />

Insulation<br />

without insulation<br />

or<br />

mineral wool<br />

building material class A<br />

W13<br />

2) 3)<br />

3)<br />

R w,R insulation<br />

sulation<br />

U value inmm<br />

dB mm W/(m²K)<br />

<strong>Knauf</strong> Sound Protection Proof L 001-03.05<br />

1) data of weight without insulation<br />

2) R w,R = calculation value of the sound reduction index of the separating partition acc. to DIN 4109 without longitudinal transmission via flanking components<br />

3) Insulation layer acc. to DIN EN 13162; length related flow resistance acc. to DIN EN 29 053: r 5 kPa s/m² ; WLG: 040<br />

spacing of studs<br />

31.25 cm 31.25 cm<br />

spacing of studs<br />

31.25 cm 31.25 cm<br />

d h d d h d<br />

D<br />

D<br />

mm mm mm<br />

single metal stud frame with GKF cladding<br />

+<br />

0.5<br />

75<br />

Solid<br />

20 + 12,5 Board + GKF<br />

+ + 71<br />

0,5 metal sheet<br />

layer<br />

single metal stud frame with <strong>Knauf</strong> <strong>Fire</strong>board cladding<br />

2x 15<br />

+<br />

0.5<br />

type/<br />

building<br />

material class<br />

<strong>Fire</strong>board<br />

+<br />

metal sheet<br />

layer<br />

62<br />

1)<br />

Sound<br />

protection<br />

50<br />

55<br />

50<br />

55<br />

Proof<br />

ABP<br />

P-3073/0639<br />

<strong>Fire</strong>board A1<br />

without insulation<br />

Z-PA-III<br />

2x 15<br />

or<br />

4.290<br />

ABP<br />

+ + mineral wool<br />

P-3074/0649<br />

metal sheet 0.5 building material class A<br />

no<br />

40<br />

no<br />

40<br />

55 80<br />

Thermal<br />

insulation<br />

1.65<br />

0.57<br />

0.49<br />

0.39<br />

no<br />

40<br />

60<br />

80<br />

1.79 no<br />

0.58 40<br />

0.50 60<br />

0.40 80<br />

1.39 no<br />

0.33 80<br />

2<br />

Note<br />

<strong>Fire</strong> walls are fire-resistant walls that keep their stability and enclosing function under the influence of fire<br />

because they are especially resistant to dropping constructional components.<br />

(impact stress of 3000 Nm proofed after fire)

<strong>Knauf</strong> <strong>Fire</strong> Wall A2<br />

W131<br />

Single metal stud frame: two layer cladding with <strong>Knauf</strong> Solid Boards 20 mm + GKF 12.5 mm<br />

Wall heigths<br />

Stud<br />

Spacing<br />

of studs<br />

Maximum<br />

wall heights<br />

metal thickness 0.6 mm<br />

<strong>Knauf</strong> stud<br />

CW 50<br />

cm<br />

31.25<br />

m<br />

5<br />

<strong>Knauf</strong> stud<br />

CW 75<br />

31.25 7.5<br />

<strong>Knauf</strong> stud<br />

CW 100<br />

31.25<br />

9<br />

Details scale 1:5<br />

Nailable Plug,<br />

a 100 cm<br />

Acoustical Sealant<br />

CW stud<br />

galvanized metal sheet,<br />

0.5 mm thick<br />

joint overlap 10 cm<br />

cladding horizontal<br />

W131-VO3<br />

Connection to ceiling<br />

separation strip Trenn-Fix 65<br />

<strong>Knauf</strong> Uniflott<br />

Acoustical Sealant<br />

Ceiling Steel Dowel, a 50 cm<br />

washer 30 mm<br />

t 2 mm<br />

UW runner<br />

<strong>Knauf</strong> CW stud<br />

connect to UW runner<br />

with blind metal rivets<br />

galvanized metal sheet<br />

0.5 mm thick<br />

joint overlap 10 cm,<br />

cladding horizontal<br />

insulation<br />

W131-A3<br />

<strong>Knauf</strong> Uniflott<br />

separation strip<br />

Trenn-Fix 65<br />

<strong>Knauf</strong> CW stud<br />

UW runner<br />

<strong>Knauf</strong> Solid Board 20 mm<br />

<strong>Knauf</strong> Board GKF 12.5 mm<br />

Connection to solid wall<br />

<strong>Knauf</strong> Uniflott<br />

<strong>Knauf</strong> Uniflott<br />

Drywall Screw TN<br />

<strong>Knauf</strong> Solid Board 20 mm<br />

W131-VM3<br />

Joint<br />

<strong>Knauf</strong> Board GKF 12.5 mm<br />

insulation<br />

W131-B3<br />

Joint<br />

Drywall Screw TN 3.5 x 35<br />

Drywall Screw TN 3.5 x 45<br />

<strong>Knauf</strong> Board GKF 12.5 mm<br />

<strong>Knauf</strong> Solid Board 20 mm<br />

connect CW stud to UW runner<br />

with blind metal rivets<br />

washer 30 mm<br />

t 2 mm<br />

Ceiling Steel Dowel, a 50 cm<br />

<strong>Knauf</strong> Uniflott<br />

UW runner<br />

<strong>Knauf</strong> CW stud<br />

Drywall Screw TN 3.5 x 45,<br />

a = approx. 25 cm<br />

galvanized<br />

metal sheet<br />

<strong>Knauf</strong> Solid<br />

Board 20 mm<br />

<strong>Knauf</strong> Board<br />

GKF 12.5 mm<br />

<strong>Knauf</strong> Uniflott<br />

W131-VU3<br />

Connection to floor<br />

W131-D3<br />

Corner<br />

3

<strong>Knauf</strong> <strong>Fire</strong> Wall A2<br />

Single metal stud frame: three layer cladding with <strong>Knauf</strong> Boards GKF 12.5 mm<br />

Wall heights<br />

Stud<br />

Spacing<br />

of studs<br />

Maximum<br />

wall heights<br />

W131<br />

metal thickness 0.6 mm<br />

<strong>Knauf</strong> stud<br />

CW 50<br />

cm<br />

31.25<br />

m<br />

5<br />

<strong>Knauf</strong> stud<br />

CW 75<br />

31.25 7.5<br />

<strong>Knauf</strong> stud<br />

CW 100<br />

31.25<br />

9<br />

Details scale 1:5<br />

W131-VO1<br />

Connection to ceiling<br />

separation strip Trenn-Fix 65<br />

<strong>Knauf</strong> Uniflott<br />

Acoustical Sealant<br />

Ceiling Steel Dowel, a 50 cm<br />

washer 30 mm<br />

t 2 mm<br />

UW runner<br />

connect CW stud to UW runner<br />

with blind metal rivets<br />

W131-A1<br />

Nailable Plug, a 100 cm<br />

Acoustical Sealant galvanized metal sheet<br />

<strong>Knauf</strong> CW stud 0.5 mm thick<br />

joint overlap 10 cm<br />

<strong>Knauf</strong> Uniflott<br />

separation strip<br />

Trenn-Fix 65<br />

<strong>Knauf</strong> Boards GKF<br />

3 x 12.5 mm<br />

Connection to solid wall<br />

<strong>Knauf</strong> CW stud<br />

UW runner<br />

<strong>Knauf</strong> Boards GKF<br />

3 x 12.5 mm<br />

insulation<br />

W131-VM1<br />

Joint<br />

Drywall Screw TN<br />

galvanized metal sheet<br />

0.5 mm thick,<br />

joint overlap 10 cm,<br />

horizontal cladding<br />

W131-B1<br />

<strong>Knauf</strong> Uniflott<br />

UW runner<br />

<strong>Knauf</strong> CW stud<br />

Drywall Screw TN 3.5x55,<br />

washer 30 mm<br />

a = approx. 25 cm<br />

t 2 mm<br />

<strong>Knauf</strong> Ceiling Steel Dowel<br />

a 50 cm<br />

connect CW stud to UW runner<br />

with blind metal rivets<br />

Joint<br />

Drywall Screw TN<br />

<strong>Knauf</strong> Uniflott<br />

4<br />

W131-VU1<br />

Connection to floor<br />

W131-D1<br />

Corner

<strong>Knauf</strong> <strong>Fire</strong> Wall A1<br />

Single metal stud frame: two layer cladding with <strong>Knauf</strong> <strong>Fire</strong>board 15 mm<br />

Wall heights<br />

Stud<br />

Spacing<br />

of studs<br />

Maximum<br />

wall heights<br />

W132<br />

metal thickness 0.6 mm<br />

cm<br />

m<br />

<strong>Knauf</strong> stud<br />

CW 100<br />

31.25 9<br />

Details scale 1:5<br />

Nailable Plug, a 100 cm<br />

Acoustical Sealant galvanized metal sheet 0.5 mm,<br />

<strong>Knauf</strong> CW stud joint overlap 10 cm<br />

W132-VO1<br />

Connection to ceiling<br />

separation strip Trenn-Fix 65<br />

<strong>Knauf</strong> <strong>Fire</strong>board Filler<br />

Acoustical Sealant<br />

UW runner 100x40x0.6<br />

<strong>Knauf</strong> Ceiling Steel Dowel,<br />

a 50 cm<br />

connect CW stud 100x50x0.6<br />

to UW runner with<br />

blind metal rivets<br />

W132-A1<br />

<strong>Knauf</strong> <strong>Fire</strong>board Filler <strong>Knauf</strong> <strong>Fire</strong>board 2x 15 mm<br />

separation strip Trenn-Fix 65<br />

Drywall Screws TN<br />

Connection to solid wall<br />

<strong>Knauf</strong> CW stud 100x50x0.6<br />

<strong>Knauf</strong> <strong>Fire</strong>board 2x 15 mm<br />

<strong>Knauf</strong> CW stud 100x50x0.6<br />

Fiber Glass Joint Tape<br />

<strong>Knauf</strong> <strong>Fire</strong>board Filler<br />

insulation<br />

W132-VM1<br />

Joint<br />

galvanized metal sheet<br />

0.5 mm thick,<br />

joint overlap 10 cm,<br />

horizontal cladding<br />

W132-B1<br />

Fiber Glass<br />

Joint Tape<br />

UW runner<br />

Joint<br />

UW runner 100x40x0.6<br />

<strong>Knauf</strong> <strong>Fire</strong>board Filler<br />

<strong>Knauf</strong> <strong>Fire</strong>board 2x 15 mm<br />

<strong>Knauf</strong> Ceiling Steel Dowel,<br />

a 50 cm<br />

to UW runner with<br />

connect CW stud 100x50x0.6<br />

blind metal rivets<br />

<strong>Knauf</strong> CW stud<br />

Drywall Screw TN 3.5x45,<br />

a = approx. 25 cm<br />

<strong>Knauf</strong> <strong>Fire</strong>board Filler<br />

W132-VU1<br />

Connection to floor<br />

W132-D1<br />

Corner<br />

5

<strong>Knauf</strong> <strong>Fire</strong> <strong>Walls</strong><br />

Power sockets / settlement joints / deflection head<br />

Installation of power sockets<br />

W131<br />

W132<br />

W13<br />

12.5<br />

15<br />

approx.<br />

100 x 100<br />

approx.<br />

100 x 100<br />

12.5<br />

15<br />

mineral wool<br />

entire area<br />

power<br />

socket<br />

box made of<br />

<strong>Fire</strong>-Resistant<br />

Boards GKF<br />

mineral wool strip<br />

bxh 312x625 mm or<br />

mineral wool on entire area<br />

<strong>Fire</strong>board<br />

Filler<br />

box made<br />

of <strong>Fire</strong>board<br />

<strong>Fire</strong>board<br />

Filler<br />

Note<br />

Power sockets, switch sockets, splitter sockets etc. are allowed to be installed at any position, but not opposite to each other.<br />

Entry of single electric cables is allowed. The remaining opening has to be closed with gypsum mortar.<br />

Details scale 1:5<br />

a 20 mm<br />

15-20 15-20<br />

ca. 50<br />

a<br />

20<br />

a<br />

20 <br />

<br />

a<br />

<strong>Knauf</strong> Fugenfüller Leicht<br />

glued <strong>Knauf</strong> Board strips<br />

Acoustical Sealant<br />

washer 30 mm<br />

UW runner<br />

2 rows of heavy-duty dowels<br />

10 mm, a 500 mm;<br />

installed alternating, installation<br />

according to approval<br />

<strong>Knauf</strong> CW stud<br />

For deflection heads do not rivet studs and runners,<br />

do not fix boards to UW runner.<br />

20<br />

20 20<br />

20 20<br />

<br />

20<br />

Solid Board 20 mm<br />

<strong>Knauf</strong> Board GKF 12.5 mm<br />

200<br />

Solid<br />

Board 25 mm<br />

<strong>Knauf</strong><br />

CW stud<br />

50x50x0.6<br />

galvanized metal sheet<br />

0.5 mm thick,<br />

b 200 mm<br />

W131-VO4<br />

Deflection head<br />

W131-BFU3<br />

Settlement joint<br />

20<br />

20<br />

<br />

20 20<br />

<br />

20 20 20<br />

additional metal sheet<br />

b = gypsum board strip<br />

additional metal sheet<br />

<strong>Knauf</strong> CW stud<br />

50x50x0.6<br />

20<br />

20<br />

<br />

20<br />

20<br />

20<br />

<br />

UW runner 50x40x0.6<br />

fixed to ceiling and<br />

floor (once each)<br />

<strong>Knauf</strong> CW stud<br />

100 resp. 75<br />

W131-BFU1<br />

<strong>Knauf</strong> CW stud<br />

75 resp. 50<br />

Settlement joint<br />

UW runner 75 resp. 50<br />

fixed to ceiling and<br />

floor (once each)<br />

<strong>Fire</strong>board 25 mm<br />

Drywall Screw TN 3.5x35<br />

W132-BFU2 Settlement joint<br />

6<br />

Note<br />

Door installation possible, according to appoval of door manufacturer: e.g. Schörghuber, Hörmann

<strong>Knauf</strong> <strong>Fire</strong> <strong>Walls</strong><br />

Specifications<br />

W13<br />

Item Description No. of units Unit price Total price<br />

........ <strong>Fire</strong> Wall according to DIN 4102-3, non-load bearing, as drywall partition,<br />

height in m ..................., thickness 126 mm/ 151 mm/ 176 mm *,<br />

fi re resistance class according to DIN 4102-2, F 90,<br />

sound insulation according to DIN 4109 R w,R<br />

in dB 50/ 55 *, *<br />

thermal transmission coeffi cient according to DIN 4108-2, U value in W/ (m² K) ............ *,<br />

perimeter fi xed,<br />

cladding with three layers of <strong>Knauf</strong> boards GKF, 12.5 mm,<br />

with metal sheet layer 0.5 mm,<br />

with insulation building material class A, thickness in mm ............. *.<br />

Product/ System: <strong>Knauf</strong> <strong>Fire</strong> Wall W131 .......... m² .......... € .......... €<br />

........ <strong>Fire</strong> Wall according to DIN 4102-3, non-load bearing, as drywall partition,<br />

height in m ..................., thickness 116 mm/ 141 mm/ 166 mm *,<br />

fi re resistance class according to DIN 4102-2, F 90,<br />

sound insulation according to DIN 4109 R w,R<br />

in dB 50/ 55 *, *<br />

thermal transmission coeffi cient according to DIN 4108-2, U value in W/ (m² K) ............ *,<br />

perimeter fi xed,<br />

cladding with two layers of <strong>Knauf</strong> boards GKF, 20 mm + 12.5 mm,<br />

with metal sheet layer 0.5 mm,<br />

with insulation building material class A, thickness in mm ............. *.<br />

Product/ System: <strong>Knauf</strong> <strong>Fire</strong> Wall W131 .......... m² .......... € .......... €<br />

........ <strong>Fire</strong> Wall according to DIN 4102-3, non-load bearing, as drywall partition,<br />

height in m ..................., thickness 161 mm,<br />

fi re resistance class according to DIN 4102-2, F 90,<br />

sound insulation according to DIN 4109 R w,R<br />

in dB 55, *<br />

thermal transmission coeffi cient according to DIN 4108-2, U value in W/ (m² K) ............ *,<br />

perimeter fi xed,<br />

cladding with two layers of <strong>Knauf</strong> <strong>Fire</strong>board, 15 mm,<br />

with metal sheet layer 0.5 mm,<br />

with insulation building material class A, thickness in mm ............. *.<br />

Product/ System: <strong>Knauf</strong> <strong>Fire</strong> Wall A1 W132 .......... m² .......... € .......... €<br />

........ Connection to ceiling, sliding up to 20 mm, as upgrade to <strong>Knauf</strong> <strong>Fire</strong> Wall W131,<br />

installation according to drawing no. ............... ........... m .......... € .......... €<br />

........ Corner, with corner trim *, as upgrade to <strong>Knauf</strong> <strong>Fire</strong> Wall,<br />

installation according to drawing no. ............... ........... m .......... € .......... €<br />

........ Settlement joint as upgrade to <strong>Knauf</strong> <strong>Fire</strong> Wall W131,<br />

two/ three * layer cladding,<br />

width in mm .............., installation according to drawing no. ............... ........... m .......... € .......... €<br />

........ Settlement joint as upgrade to <strong>Knauf</strong> <strong>Fire</strong> Wall W132,<br />

width in mm .............., installation according to drawing no. ............... ........... m .......... € .......... €<br />

........ Wall opening for power sockets, as upgrade to <strong>Knauf</strong> <strong>Fire</strong> Wall,<br />

dimensions in mm .............................., installation according to drawing no. ............... ......... pcs .......... € .......... €<br />

........ Door opening with lintel, enforced fl oor to ceiling,<br />

with metal studs UA 50/ 75/ 100 *, incl. connections to fl oors and ceilings,<br />

fi x with angels, dowels and screws.<br />

basic dimensions B/H in mm ..............................,<br />

wall thickness in mm ..........., installation according to drawing no. ............... . ......... pcs .......... € .......... €<br />

* Cancel not applicable items Sub-total ................ €<br />

7

<strong>Knauf</strong> <strong>Fire</strong> <strong>Walls</strong><br />

Construction and application, surface treatment<br />

W13<br />

Construction<br />

<strong>Knauf</strong> <strong>Fire</strong> <strong>Walls</strong> consist of a single metal stud<br />

frame. Two or three layers of <strong>Knauf</strong> boards are<br />

screwed to both sides of the metal framework.<br />

A metal sheet is installed below the top layer of<br />

the cladding. Insulation material according to<br />

the requirements of building physics can be installed<br />

in the partitions cavity.<br />

Settlement joints have to be taken over into the<br />

construction of the <strong>Fire</strong> <strong>Walls</strong>. For continuous<br />

walls use control joints at approx. 15 m.<br />

Application<br />

Metal stud frame<br />

● Apply Acoustical Sealant (two strings) or<br />

Sealing Tape to backside of runners for the<br />

connection of fl anking constructional components.<br />

For sound protection requirements seal<br />

up carefully with acoustical sealant according<br />

to DIN 4109, supplement 1, chapter 5.2; porous<br />

sealant strips like Sealing Tape are usually<br />

not suitable in this case.<br />

● Fix perimeter runners (UW runners at fl oor<br />

and ceiling, CW studs at walls) with suitable<br />

dowels to fl anking components, e.g. Ceiling<br />

Steel Dowel with reinforced concrete ceilings<br />

(use and application according to Construction<br />

Supervisory Permit Z-21.1-1519) and nailable<br />

plug with masonry. Spacing of dowels<br />

0.5 m at ceilings, 1 m at walls (at least 3 fi xing<br />

points).<br />

● For W131 use dowel with washer Ø 30 mm, t<br />

≥ 2 mm for connections to ceiling and fl oor.<br />

● Install CW studs at a spacing of 31.25 cm in<br />

UW runners, aligne, fi x with two metal rivets<br />

(≥ 3 x 8 mm) each to bottom and top.<br />

Cladding<br />

● Two layer cladding of W131 with horizontally<br />

applied <strong>Knauf</strong> Solid Board 20 mm + vertically<br />

applied <strong>Knauf</strong> board GKF 12.5 mm or with<br />

three layer cladding with vertically applied<br />

<strong>Knauf</strong> boards GKF 12.5 mm.<br />

● Two layer cladding of W132 with horizontally<br />

applied <strong>Knauf</strong> <strong>Fire</strong>board 15 mm.<br />

● Spacing of screws of fi rst layer 75 cm, of<br />

middle layer 50 cm and of top layer 25 cm.<br />

● Displacement of joints according to DIN<br />

18181.<br />

● Metal sheets as plates or coil material, 0.5<br />

mm thick, install horizontally under top layer,<br />

overlap all joints at least 10 cm. Screwing with<br />

Drywall screws (W131 three layers: TN 3.5 x<br />

45/ W131 two layers and W132: TN 3.5 x 35)<br />

only to fi x for installation, remove while applying<br />

the boards.<br />

Vertical joints of metal sheets only on studs.<br />

Jointing<br />

● Filling and covering of joints should only take<br />

place after the boards have been allowed to<br />

rest in the given humidity and temperature zones,<br />

and no more longitudinal changes can be<br />

expected, i.e. expansion or contraction.<br />

● Joints should be filled at a minimum temperature<br />

of 10°C.<br />

● In case of mastic asphalt screed, fill in joints<br />

after screed has been applied.<br />

● Cover all screw heads as well.<br />

● For double layer cladding, fill in joints of first<br />

layer, smooth joints of second layer.<br />

W131: Fill in joints with <strong>Knauf</strong> Uniflott without<br />

using tape. If using tape, fill in with <strong>Knauf</strong> Fugenfüller<br />

Leicht or with Ames machine and <strong>Knauf</strong><br />

Jointfiller-Super.<br />

Recommendation: Fill in and tape cut edges of<br />

visible layers no matter which filling material is<br />

used.<br />

W132: Hand filling with Fiber Glas Joint Tape<br />

and <strong>Knauf</strong> <strong>Fire</strong>board Filler.<br />

Fixing of <strong>Knauf</strong> boards with Drywall Screws TN and TB<br />

cladding<br />

fixing of <strong>Knauf</strong> boards to metal studs (minimum penetration ≥ 10 mm)<br />

thickness in mm metal thickness ≤ 0.7 mm 0.7 mm < s ≤ 2.25 mm<br />

2 x 15 <strong>Fire</strong>board TN 3.5 x 25 + TN 3.5 x 45 TB 3.5 x 35 + TB 3.5 x 45<br />

20 + 12.5 GKF TN 3.5 x 35 + TN 3.5 x 45 TB 3.5 x 35 + TB 3.5 x 45<br />

3 x 12.5 GKF TN 3.5 x 25 + TN 3.5 x 35 + TN 3.5 x 55 TB 3.5 x 25 + TB 3.5 x 45 + TB 3.5 x 55<br />

Surface treatment<br />

Use a primer on <strong>Knauf</strong> Boards before coating or<br />

painting them. Ensure that the primer and the<br />

coat or paint are compatible.<br />

After wallpapering of paper and fi ber glass wallpapers<br />

and the application of resin / cellulose<br />

plasters quick drying must be assured through<br />

adequate airing. The following coats can be<br />

used to cover <strong>Knauf</strong> Boards:<br />

● Plasters: <strong>Knauf</strong> structured plasters, e.g. resin<br />

plasters, thin plasters, entire area smoothing<br />

like e.g. <strong>Knauf</strong> Board-Finish, mineral plasters<br />

in connection with paper taped jointing.<br />

● ceramic tiles<br />

● Wall Papers: paper-, textile and synthetic wall<br />

papers. Use only adhesives made of cellulose<br />

according to „Merkblatt Nr. 16, Technische<br />

Richtlinien für Tapezier- und Klebearbeiten“,<br />

Frankfurt/Main 2002, released by Bundesausschuss<br />

Farbe und Sachwertschutz.<br />

● Coats: Washable and abrasion-proof emulsion<br />

paint, multicolored (rainbow) emulsion, oil<br />

paint, matte-fi nish lacquer, alkyd resin paint,<br />

polymer resin paint, PUR lacquer, or epoxybased<br />

lacquer, according to intended use or<br />

as required.<br />

● Alkaline coats such as lime, water glass colors<br />

and silicate-based paints are unsuitable<br />

for gypsum board surfaces. Silicate-based<br />

emulsion paints may be used after referring to<br />

the manufacturer’s recommendations and following<br />

the stipulated guidelines closely.<br />

Gypsum board surfaces that have constantly<br />

been exposed to light without any protection can<br />

develop yellowing agents that show up despite a<br />

coat of paint. Therefore a trial coat is recommended<br />

that will extend across several boards including<br />

all joints. Yellowing can, however, be successfully<br />

avoided only by using a special shielding<br />

primer.<br />

<strong>Knauf</strong> Direkt Technical Information Service: Phone +49 18 05 / 31-10 00, Fax +49 18 05 / 31-40 00<br />

<strong>Knauf</strong> websites: www.knauf.de, www.knauf.com e-mail: knauf-direkt@knauf.de<br />

<strong>Knauf</strong> Headquarters, Am Bahnhof 7, D-97346 Iphofen, Phone +49 93 23 / 31-0, Facsimile +49 93 23 / 31-277<br />

8<br />

© All technical changes reserved. Only the current printed instructions are valid. Our warranty is expressly limited to our products in flawless condition. All application quantities and delivery amounts are based on empirical data that<br />

is not easily transferable to other deviating areas. All rights reserved. All amendments, reprints and photocopies, including those of excerpts, require the express permission of <strong>Knauf</strong> Gips KG, Am Bahnhof 7, 97346 Iphofen, Germany.<br />

Edition: March 2005<br />

W13 / engl. / D / 03.05 / FB / D