Knauf Designed Ceilings

Knauf Designed Ceilings

Knauf Designed Ceilings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

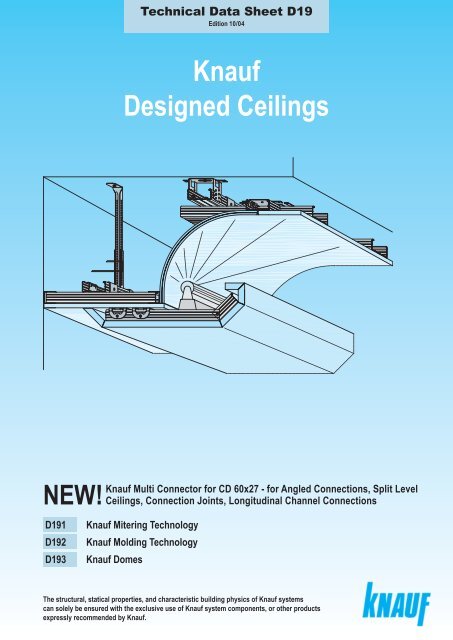

Technical Data Sheet D19<br />

Edition 10/04<br />

<strong>Knauf</strong><br />

<strong>Designed</strong> <strong>Ceilings</strong><br />

NEW!<br />

<strong>Knauf</strong> Multi Connector for CD 60x27 - for Angled Connections, Split Level<br />

<strong>Ceilings</strong>, Connection Joints, Longitudinal Channel Connections<br />

D191<br />

D192<br />

D193<br />

<strong>Knauf</strong> Mitering Technology<br />

<strong>Knauf</strong> Molding Technology<br />

<strong>Knauf</strong> Domes<br />

The structural, statical properties, and characteristic building physics of <strong>Knauf</strong> systems<br />

can solely be ensured with the exclusive use of <strong>Knauf</strong> system components, or other products<br />

expressly recommended by <strong>Knauf</strong>.

<strong>Knauf</strong> Mitering Technology<br />

<strong>Knauf</strong> Mitered Boards<br />

D191<br />

Miter cuts<br />

30° 45°<br />

60° 75°<br />

90° 120°<br />

Examples: <strong>Knauf</strong> Mitered Boards<br />

Board thickness<br />

9.5 mm to 25 mm<br />

Pre-treatment<br />

Board length<br />

max. 3 m<br />

Prime miters with <strong>Knauf</strong> Tiefengrund<br />

and glue with <strong>Knauf</strong> Weißleim (PVA)<br />

Other board thicknesses or factory glued/<br />

partially glued boards on request<br />

Necessary order information:<br />

Version-No. (e.g. 1 )<br />

dimensions and<br />

marking of the face side S<br />

S<br />

S<br />

S<br />

S<br />

1x 90° miter<br />

1<br />

1x 90° miter 1x 90° miter 1x 90° miter<br />

2 3 4<br />

2x 90° miters<br />

2x 90° miters<br />

2x 90° miters<br />

1x 45° + 1x 90° miters<br />

5 6 7 8<br />

2x 60° miters + board strip<br />

3x 90° miters<br />

3x 90° miters<br />

9 10 11<br />

4x 90° miters<br />

2+2 90° miters<br />

12 13<br />

14<br />

2+2 90° miters<br />

2<br />

2+1 90° miters 2+1 90° miters 3+2 90° miters<br />

15 16 17

<strong>Knauf</strong> Mitering Technology<br />

Order Form / Request<br />

Please fill in and send to the <strong>Knauf</strong> Sales Support<br />

(facsimile +49 93 23 / 31 14 47)<br />

Mitering Technology - <strong>Knauf</strong> Mitered Boards<br />

D191<br />

request order Date:<br />

to<br />

from<br />

Name<br />

Company<br />

Street<br />

Postal code / city<br />

Phone / facsimile<br />

Commission/<br />

building project/<br />

object<br />

Thickness of<br />

cladding<br />

(mm)<br />

12.5<br />

2x 12.5<br />

15 18<br />

other<br />

20<br />

25<br />

Board type<br />

GKB / GKBI<br />

GKF / GKFI<br />

Piano<br />

Thermoboard<br />

other<br />

Item (cs-no., etc.)<br />

amount / length<br />

item<br />

amount<br />

board length<br />

Miter layout<br />

detail<br />

(e.g. D191-S14)<br />

dimensions of miter layout (mm)<br />

glued<br />

unglued<br />

Type<br />

straight<br />

arched R =<br />

mm<br />

convex<br />

concave<br />

Notes / drawings<br />

(incl. dimensions)<br />

3

<strong>Knauf</strong> Mitering Technology<br />

<strong>Knauf</strong> Mitered Boards<br />

Details: Examples<br />

D191<br />

Multi<br />

Connector<br />

CD 60x27<br />

Separation Strip 65 + Uniflott<br />

<strong>Knauf</strong> Mitered Board<br />

UD runner 28x27<br />

Nonius<br />

suspension<br />

<strong>Knauf</strong> Drywall Screw TN<br />

CW stud<br />

miter layout<br />

<strong>Knauf</strong> Drywall Screw TB<br />

casing UW runner<br />

Separation Strip 65 + Uniflott<br />

miter layout<br />

<strong>Knauf</strong> Apertura board<br />

with non-perforated,<br />

mitered perimeter<br />

UD runner 28x27<br />

D191-S1<br />

Cornice<br />

D191-S2<br />

Canopy<br />

Nonius<br />

suspension<br />

UD 28x27<br />

CD 60x27<br />

Multi<br />

Connector<br />

Nonius<br />

suspension<br />

miter layout<br />

glued and stapled<br />

<strong>Knauf</strong> board strip<br />

(thickness as necessary)<br />

<strong>Knauf</strong> Mitered Board<br />

<strong>Knauf</strong> Mitered<br />

Board<br />

miter layout<br />

2x <strong>Knauf</strong> Drywall<br />

Screws TN<br />

D191-S3 Crown Frieze D191-S4 Horizontal Fins<br />

60<br />

pre-fabricated<br />

drill on site and<br />

screw with CD channel<br />

150<br />

UD 28x27<br />

miter layout<br />

protruding ceiling<br />

light compatible<br />

miter layout<br />

4<br />

D191-S5<br />

Vertical<br />

Fins<br />

D191-S6 Baffle D191-S7 Protruding

<strong>Knauf</strong> Mitering Technology<br />

<strong>Knauf</strong> Mitered Boards<br />

Details: Examples<br />

D191<br />

<strong>Knauf</strong> Perforated<br />

Acoustical Channel<br />

(see page 16)<br />

<strong>Knauf</strong> Mitered<br />

Board<br />

<strong>Knauf</strong> Drywall Screw TN<br />

<strong>Knauf</strong> Apertura Board<br />

glued and<br />

stapled<br />

miter layout<br />

miter layout<br />

D191-S8<br />

Panel Ceiling<br />

D191-S9<br />

Module Ceiling<br />

Nonius<br />

suspension<br />

recessed ceiling<br />

light compatible<br />

Nonius<br />

suspension<br />

CD 60x27<br />

<strong>Knauf</strong> Board<br />

lower C channel<br />

CD 60x27<br />

<strong>Knauf</strong> Mitered<br />

Board<br />

<strong>Knauf</strong> board strip<br />

<strong>Knauf</strong> Drywall Screw TN<br />

miter layout<br />

miter layout<br />

D191-S10<br />

Recessed<br />

D191-S11<br />

Split Level Ceiling with Frieze<br />

Nonius<br />

suspension<br />

Nonius<br />

suspension<br />

<strong>Knauf</strong> All Purpose<br />

Screw FN 4.3x35<br />

e.g. CD 60x27<br />

lower C channel<br />

CD 60x27<br />

<strong>Knauf</strong> Mitered<br />

Boards<br />

glued<br />

<strong>Knauf</strong> Drywall Screw TN<br />

e.g. pre-fabricated element<br />

glued and stapled<br />

D191-S12 Split Level Ceiling with Steps D191-S13<br />

Split Level Ceiling with<br />

Indirect Illumination<br />

5

<strong>Knauf</strong> Mitering Technology<br />

<strong>Knauf</strong> Mitered Boards<br />

Details: Examples<br />

D191<br />

glued and<br />

stapled<br />

glued and stapled<br />

Direct Bracket<br />

screwed with<br />

LN 3.5x9 to<br />

CD channel<br />

miter layouts<br />

miter layouts<br />

D191-S14<br />

Cornice for Indirect Illumination<br />

D191-S15<br />

Protruding - Stepped<br />

Nonius<br />

suspension<br />

CD 60x27<br />

Clip for CD 60x27,<br />

screwed<br />

Multi Connector<br />

(shorten if necessary)<br />

e.g. canted channel<br />

CD 60x27<br />

45<br />

70<br />

<strong>Knauf</strong> Perforated<br />

Acoustical Channel (s. pg. 16)<br />

<strong>Knauf</strong> Mitered<br />

vertical fin<br />

Board<br />

(pre-fabricated with Daisy Chain Clip)<br />

D191-S16<br />

Fin Ceiling<br />

CD 60x27<br />

Multi Connector<br />

<strong>Knauf</strong> Mitered<br />

Boards<br />

CD 60x27<br />

e.g. <strong>Knauf</strong> Apertura<br />

Board<br />

<strong>Knauf</strong> All Purpose<br />

Screw FN 4.3x35<br />

6<br />

D191-S17<br />

UD 28x27<br />

CD 60x27<br />

Panelling of Beams - Stepped<br />

e.g. CW channel<br />

<strong>Knauf</strong> Drywall Screw TN<br />

<strong>Knauf</strong> Mitered<br />

miter layouts<br />

Boards<br />

joint

<strong>Knauf</strong> Mitering Technology<br />

<strong>Knauf</strong> Mitered Boards<br />

Details: Cornice Construction<br />

D191<br />

r 100 mm<br />

miter layout<br />

miter layout<br />

D191-S18<br />

Cornice with Stucco<br />

Indirect Illumination<br />

D191-S19<br />

Ceiling Perimeter with Stucco<br />

Detail: Column Capital<br />

miter layouts<br />

D191-S20<br />

Column Capital<br />

7

<strong>Knauf</strong> Arch Elements<br />

Factory Molded<br />

D192<br />

Length of elements l<br />

90°<br />

180°<br />

Thickness of elements d<br />

element molding boards<br />

mm<br />

mm<br />

r<br />

l<br />

r<br />

l<br />

12<br />

18<br />

24<br />

2x 6<br />

3x 6<br />

4x 6<br />

length l max. 3480 mm<br />

(r 700 mm)<br />

length l max. 1150 mm<br />

(r 700 mm)<br />

Arch Versions: Examples<br />

length l max. 3480 mm<br />

(r 350 mm)<br />

length l max. 1150 mm<br />

(r 350 mm)<br />

Other dimensions on request<br />

radius r :<br />

angle :<br />

100 mm<br />

180°<br />

Concave Inside Arches<br />

S Arch<br />

Segment Arch<br />

f<br />

ac<br />

r<br />

e<br />

si<br />

de<br />

d<br />

90°<br />

180°<br />

f<br />

ac<br />

e<br />

r<br />

si<br />

de<br />

d<br />

f<br />

a<br />

c<br />

e<br />

s<br />

i<br />

d<br />

e<br />

f<br />

a c<br />

e<br />

s<br />

r<br />

i<br />

d<br />

e<br />

Convex Outside Arches<br />

d<br />

d<br />

Arches with Extensions<br />

si<br />

de<br />

r<br />

e<br />

e<br />

d<br />

r<br />

ac<br />

f<br />

i<br />

e<br />

90°<br />

f<br />

a c<br />

180°<br />

f<br />

a c<br />

e<br />

s<br />

i<br />

e<br />

d<br />

a c<br />

e<br />

s<br />

i<br />

d<br />

e<br />

s<br />

f<br />

length of layout L<br />

max. length of layout 3480 mm, depending on<br />

radius and thickness of cladding<br />

angle 90°:<br />

r .<br />

L=<br />

2<br />

angle 180°:<br />

L = r .<br />

all angles up to 180°:<br />

. r .<br />

L =<br />

180<br />

Detail: Example<br />

Universal Bracket for CD 60x27,<br />

screwed with LN 3.5x9 mm<br />

to CD-channel<br />

place Flex Profile 100 underneath joint<br />

90° arch with extension<br />

Clip for CD 60x27, screwed<br />

CD 60x27<br />

Nonius suspension<br />

Intersection Connector<br />

or Clip for CD 60x27<br />

CD 60x27<br />

<strong>Knauf</strong> Drywall Screw TN<br />

CD 60x27<br />

Uniflott +<br />

separation strip 65<br />

8<br />

D192-S2<br />

Split level Ceiling: Convex 90° Arch

<strong>Knauf</strong> Arch Elements<br />

Factory Molded<br />

Details: Examples<br />

D192<br />

Uniflott +<br />

Joint Tape<br />

<strong>Knauf</strong> Drywall Screw TN<br />

90° Arch with<br />

extensions<br />

place Flex Profile 100<br />

underneath joint<br />

<strong>Knauf</strong> Drywall Screw TN<br />

e.g. metal strip<br />

canted, 0.6 mm<br />

Nonius<br />

suspension<br />

D192-S3<br />

90° Arch with extension<br />

place Flex Profile 100<br />

underneath joint<br />

Recessed lighting: 90° Arch<br />

Direct Bracket<br />

screwed to CD channel<br />

with LN 3.5 x 9<br />

CD channel 60x27<br />

spacing 300 mm<br />

Uniflott +<br />

Separation Strip 65<br />

Universal connector<br />

for CD 60x27<br />

CD 60x27<br />

Uniflott +<br />

Joint Tape<br />

Universal Bracket for CD 60x27<br />

metal screw LN 3.5x9 mm<br />

S Arch<br />

place Flex Profile 100<br />

underneath joint<br />

Nonius<br />

suspension<br />

D192-S4<br />

S Arch<br />

lateral cladding<br />

e.g. <strong>Knauf</strong> Ceiling Steel Dowel<br />

e.g. gypsum fiber glass ring<br />

on the floor and ceiling<br />

metal screw<br />

LN 3.5x9 mm<br />

Universal Bracket<br />

for CD 60x27<br />

120° Arch<br />

<strong>Knauf</strong> Drywall Screw TN<br />

CD 60x27<br />

place Flex Profile 100<br />

underneath joint<br />

200<br />

D192-S5<br />

Encasement of Columns<br />

9

<strong>Knauf</strong> Molded Boards<br />

Molded On Site<br />

Inside Arch - Concave Outside Arch - Convex Board Bending radius r<br />

thickness dry<br />

d d<br />

bending<br />

wet<br />

bending<br />

mm<br />

mm mm<br />

d<br />

i<br />

s<br />

e<br />

o<br />

t<br />

f<br />

be<br />

ace<br />

d<br />

Bending instruction<br />

r<br />

com<br />

s i<br />

d<br />

e<br />

p<br />

resse<br />

d<br />

s<br />

i<br />

d<br />

e<br />

f<br />

t<br />

o<br />

a<br />

c<br />

b e<br />

e<br />

r<br />

c om<br />

s<br />

i<br />

p<br />

d<br />

e<br />

d<br />

r e s s e<br />

6.5(Mold Board) 1000 300<br />

9.5<br />

2000 500<br />

12.5 2750 1000<br />

longitudinal bending only<br />

D192<br />

Length of layout L<br />

angle 90°<br />

r .<br />

L=<br />

2<br />

angle<br />

L = r .<br />

180°<br />

all angles up to 180°<br />

. r .<br />

L =<br />

180<br />

wet bending<br />

length of layout<br />

longitudinal direction<br />

Wet bending<br />

1. Put the cut-to-length <strong>Knauf</strong> Boards on a grid made of<br />

channels or similar with the side to be compressed on top and<br />

excessing the grid on the perimeters (so excess water can drip off).<br />

2. Perforate the board laterally and longitudinally with Spike Roller.<br />

3. Wet the board by spraying or with lambskin roller and let settle for<br />

a few minutes. Repeat process until excessive water drains.<br />

4. Lay board on precast molding device, fix with tape<br />

and let dry.<br />

batten<br />

to fix the<br />

board<br />

molding device<br />

angle or CD channel<br />

to support boards<br />

<strong>Knauf</strong> board strip<br />

cut board<br />

d 12.5 mm<br />

molding device<br />

Dry bending<br />

1. Bend <strong>Knauf</strong> Boards over metal grid or frame, fix with<br />

<strong>Knauf</strong> drywall screws.<br />

Detail: Example Wet Bent<br />

additional Nonius suspension<br />

e.g.<br />

Nonius Hanger bottom<br />

(screwed to upper<br />

C channel with<br />

metal sheet screw<br />

LN 3.5x9 mm)<br />

<strong>Knauf</strong> Drywall Screw<br />

TN 3.5x25<br />

place Flex Profile 100<br />

underneath joint<br />

r = 300 - 400 mm<br />

Universal Bracket for CD 60x27<br />

metal screw LN 3.5x9 mm<br />

glued and<br />

stapled<br />

bent Mold Boards<br />

2x 6.5 mm<br />

additional Nonius suspension<br />

e.g.<br />

Nonius Stirrup<br />

for CD 60x27<br />

<strong>Knauf</strong> Drywall Screws TN 3.5x25<br />

lower C channel CD 60x27<br />

Intersection Connector for CD 60x27<br />

upper C channel CD 60x27<br />

ca.50<br />

<strong>Knauf</strong> Mitered Board<br />

10<br />

D192-S1<br />

Concave Barrel Vault with <strong>Knauf</strong> Molded Boards

Parallel Slotting<br />

Molded On Site<br />

D192<br />

Concave Inside Arch<br />

ace<br />

f<br />

si<br />

r<br />

de<br />

radius r 50 mm<br />

Application<br />

single layer cladding<br />

Convex Outside Arch Board thickness<br />

9.5 mm / 12.5 mm<br />

Board length<br />

max. 2.5 m<br />

Other board thicknesses on request<br />

r<br />

f<br />

a<br />

c<br />

e<br />

i d e<br />

s<br />

paper side = face side<br />

double layer cladding<br />

molding<br />

Length of layout L<br />

angle 90°<br />

r .<br />

L=<br />

2<br />

angle<br />

L = r .<br />

180°<br />

all angles up to 180°<br />

. r .<br />

L =<br />

180<br />

Uniflott<br />

paper side<br />

smoothing<br />

fill slots with<br />

Uniflott<br />

metal sheet covering of edge joints<br />

Flex Profile 100<br />

Joint Tape<br />

<strong>Knauf</strong> Drywall Screw<br />

TN 3.5x25<br />

paper side<br />

smoothing<br />

fill slots with<br />

Uniflott<br />

Flex Profile 100<br />

<strong>Knauf</strong> Drywall Screw<br />

TN 3.5x25<br />

Uniflott<br />

1.<br />

2.<br />

face<br />

s<br />

ide<br />

molding device<br />

support of boards<br />

e.g. angle<br />

fill slots with<br />

Uniflott<br />

<strong>Knauf</strong> Board with<br />

parallel slots<br />

Place board on precast molding device, face side up,<br />

bulk fill with Uniflott and plane down.<br />

After drying skim whole face side area with Uniflott.<br />

Details: Examples<br />

fill slots with Uniflott<br />

skim entire surface with Uniflott<br />

paper side = face side<br />

<strong>Knauf</strong> Board with parallel<br />

slotting and<br />

miters<br />

place Flex Profile 100<br />

underneath joint<br />

place Flex Profile 100<br />

underneath joint<br />

fill slots with Uniflott<br />

skim entire surface with Uniflott<br />

paper side = face side<br />

e.g. steel girder<br />

e.g. Column Clip<br />

CD 60x27<br />

<strong>Knauf</strong> Drywall Screw TN<br />

<strong>Knauf</strong> Board with parallel<br />

slotting and miters<br />

Elements glued and<br />

stapled with each other<br />

miter layout<br />

miter layout<br />

D192-S7<br />

Rounded Cornice<br />

D192-S8<br />

Encasement of Girder<br />

Note<br />

Factory molded elements made of <strong>Knauf</strong> Boards with parallel slotting on request<br />

11

Bent CD Channels<br />

Factory-Bent<br />

D192<br />

Concave<br />

min. bending radius 500 mm<br />

Convex<br />

min. bending radius 1000 mm<br />

standard lengths of bent CD channels: 2600 / 3100 / 4000 mm<br />

start and end sections are not bent on either side for 150 mm<br />

Bent CD channel<br />

r1<br />

r<br />

d<br />

radius r1<br />

r1 = r + d + 27<br />

length of layout L1<br />

1 r1 .<br />

L1 =<br />

.<br />

180<br />

= radius of bent CD channel<br />

= radius of <strong>Knauf</strong> Board face side<br />

= thickness <strong>Knauf</strong> Board<br />

Face side <strong>Knauf</strong> Board<br />

radius r<br />

h<br />

r = +<br />

2<br />

B²<br />

8h<br />

16<br />

L = B² + . h²<br />

3<br />

r<br />

B<br />

h<br />

length of layout L<br />

. r .<br />

L =<br />

180<br />

alternative approximate formula<br />

arc length<br />

B<br />

h<br />

radius r<br />

<strong>Knauf</strong> Board<br />

mm<br />

1000 - 2500<br />

2500 - 5000<br />

5000<br />

axial spacing<br />

lower C channels<br />

mm<br />

300<br />

400<br />

500<br />

b<br />

b<br />

Detail: Example<br />

Detail A<br />

Detail B<br />

d 27<br />

Nonius-Hanger top<br />

Universal Bracket<br />

for CD 60x27<br />

metal screw<br />

LN 3.5x9 mm<br />

27<br />

d<br />

Clip for CD 60x27,<br />

screwed to CD channel<br />

bent concave<br />

CD channel 60x27<br />

lower C channel CD 60x27<br />

<strong>Knauf</strong> Drywall Screw TN<br />

<strong>Knauf</strong> Board, molded on site<br />

Universal Bracket screwed<br />

to Nonius Hanger top<br />

Universal Bracket for<br />

CD 60x27<br />

metal screw<br />

LN 3.5x9 mm<br />

direct fixing:<br />

Universal Bracket<br />

suspension:<br />

Universal Bracket<br />

suspension:<br />

Nonius Hanger top, Nonius Suspension Stud<br />

Universal Bracket<br />

Detail C<br />

bent concave<br />

CD channel 60x27<br />

12<br />

D192-S9<br />

r1<br />

r<br />

Concave Barrel Vault<br />

r1<br />

r<br />

1<br />

<strong>Knauf</strong> Board<br />

bent on site<br />

r<br />

r1<br />

<strong>Knauf</strong> Board with<br />

90° miter<br />

skim transition<br />

widely<br />

Uniflott +<br />

Joint Tape<br />

LB 3.5x9.5<br />

UD runner<br />

connect before<br />

application<br />

UD 28x27 not<br />

fixed to the wall<br />

Uniflott +<br />

Separation Strip 65

<strong>Knauf</strong> Domes<br />

Berlin, München (Munich)<br />

D193<br />

Flat Dome Munich (München)<br />

rise of cladding -h-<br />

358.5 mm<br />

diameter of cladding<br />

radius of cladding<br />

number of drawing<br />

-d-<br />

-r-<br />

2600 mm<br />

2536 mm<br />

34501-TV/D19<br />

Flat Dome Berlin<br />

rise of cladding<br />

diameter of cladding<br />

radius of cladding<br />

number of drawing<br />

calculation of r´<br />

r´<br />

= r² -<br />

d<br />

2<br />

-h-<br />

-d-<br />

-r-<br />

235 mm<br />

2132 mm<br />

2536 mm<br />

34502-TV/D19<br />

dome surface area F rise h<br />

F = 2 . . r . h h = r - r´<br />

2<br />

r<br />

d<br />

r´ h<br />

Included in delivery: kit for flat domes Berlin or Munich (München)<br />

metal grid<br />

Complete (except Nonius suspension / thread rod with necessary screwing),<br />

drawing (e.g. no. 34502-TV/D19) and instruction<br />

cladding:<br />

Complete cladding (<strong>Knauf</strong> board strips 12.5 mm and board segments 9.5 mm)<br />

Suspension<br />

suspender for square tube 20/20<br />

(delivery unbent)<br />

with<br />

Nonius Suspension Stud<br />

+ Nonius Hanger top<br />

or thread rod M6<br />

Channel connection<br />

square tube CD channel connector<br />

(delivery attached to square tube)<br />

Flush Connector<br />

connection of CD channels at vertex<br />

Dome: Example<br />

scheme drawings - no scale<br />

suspensions<br />

detail: vertex construction<br />

detail: channel connection<br />

D193-S1<br />

Vertical section of dome<br />

rise of<br />

cladding<br />

h<br />

diameter of cladding<br />

d<br />

radius of callding<br />

r<br />

D193-D1<br />

Top view<br />

half dome<br />

= suspension points<br />

13

<strong>Knauf</strong> <strong>Designed</strong> <strong>Ceilings</strong><br />

Examples<br />

Mitered Ceiling with Suspended Canopy-Type Ceiling Unit<br />

D191/D192<br />

"B"<br />

"A"<br />

D191-S26<br />

"C"<br />

Detail "B"<br />

Detail "A"<br />

canopy customized design<br />

e.g. high grade steel<br />

miter layout<br />

Detail "C"<br />

Wave Ceiling<br />

"D"<br />

"E"<br />

D192-S10<br />

spline<br />

spline<br />

e.g. made of gypsum fiber board<br />

by <strong>Knauf</strong> Integral<br />

Detail "D"<br />

Detail "E"<br />

14

Accessories<br />

Multi Connector for CD 60x27<br />

D19<br />

Multi Connector<br />

Multi Connector Adaptor<br />

Adaptor 90° Adaptor 135° Adaptor Z 12.5 Adaptor 30° - 280°<br />

Adaptor for other<br />

fixed angles<br />

on request<br />

(e.g. 120°)<br />

fix with LN 3.5x9<br />

Assembly<br />

Examples of Use<br />

(scheme drawings)<br />

angled connection<br />

connection joint<br />

connect Multi Connector to Adaptors,<br />

Adaptors should lock in place,<br />

push angled connection into<br />

CD channel and fix with screw<br />

angle 90°<br />

2x Multi Connector<br />

2x Adaptor 90°<br />

angle 90° with cantilever<br />

2x Multi Connector<br />

2x Adaptor 90°<br />

Multi Connector can be shortened with<br />

metal shears<br />

fix Multi Connector to each<br />

CD channel with 2 <strong>Knauf</strong> Drywall<br />

Screws TN 3.5x25<br />

angle 45° or 135°<br />

2x Multi Connector<br />

2x Adaptor 135°<br />

angle adjustable 30° to 280°<br />

2x Multi Connector<br />

2x Adaptor 30° to 280°<br />

Fire protection from above<br />

the whole angled connection<br />

(Adaptor, CD channel, Multi Connector)<br />

shall be fixed with 2 <strong>Knauf</strong> Drywall<br />

Screws TN 3.5x25 to each CD channel<br />

split level ceiling 90°<br />

3x Multi Connector<br />

4x Adaptor 90°<br />

connection joint, 12.5 mm cladding<br />

2x Multi Connector<br />

2x Adaptor Z 12.5<br />

longitudinal connection<br />

- 2 CD channels<br />

Push Multi Connector into<br />

CD channel up to stopper<br />

(shortening is not allowed)<br />

screw<br />

cladding to<br />

Multi Connector<br />

for higher differences<br />

see above<br />

ca. 137 mm<br />

longitudinal connection: 2 CD channels<br />

1x Multi Connector<br />

joint of channels (at stopper)<br />

Details: Examples<br />

Nonius<br />

suspension<br />

Multi Connector with<br />

Adaptors 135°<br />

CD 60x27<br />

<strong>Knauf</strong> Drywall Screws<br />

TN 3.5x25<br />

<strong>Knauf</strong> Drywall<br />

screw TN<br />

<strong>Knauf</strong> Board with<br />

45° miter<br />

CD 60x27<br />

Multi Connector with<br />

Adaptors Z 12.5<br />

<strong>Knauf</strong> Board 12.5 mm<br />

e.g. UD runner<br />

<strong>Knauf</strong> Board<br />

Multi Connector with Adaptors 135°<br />

(shorten connector if necessary)<br />

D191-S21 Split Level Ceiling 45°<br />

D191-S27<br />

Connection Joint<br />

15

Accessories<br />

Daisy Chain Clip for CD 60x27<br />

D19<br />

Assembly<br />

(channel connection)<br />

Fields of application<br />

delivery untwisted<br />

channel connection<br />

connection of CD channels 60x27<br />

(lower to upper channel)<br />

vertical fin<br />

completely factory pre-fabricated with<br />

Daisy Chain Clip and primed white<br />

adjust angle roughly before<br />

assembly<br />

adjust to lower and upper<br />

C channel during assembly<br />

Details: Examples<br />

bend around upper<br />

C channel during assembly<br />

screwing to lower C channel<br />

with LN 3.5x9 mm is optional<br />

Vertical Fins<br />

Bend over Daisy Chain Clip and screw to CD channel if necessary<br />

Note<br />

Daisy Chain Clip is not allowed as channel connection for ceilings<br />

with fire protection requirements<br />

Nonius Suspension<br />

e.g. Nonius Stirrup<br />

for CD 60x27<br />

Multi<br />

Connector<br />

<strong>Knauf</strong> Board<br />

cavity dowel<br />

alternating fixing of<br />

vertical fins to CD channel<br />

first fin<br />

fix Daisy Chain Clip to<br />

CD channel with LN 3.5x9 mm screws<br />

cross section<br />

lower / upper C channel:<br />

cut Daisy Chain Clip, fix to lower<br />

C channel with LN 3.5x9 mm screws<br />

<strong>Knauf</strong> Perforated Acoustical<br />

Channel<br />

Universal Bracket<br />

Mat.-no. 00012641<br />

for CD 60x27 color: black<br />

Clip for CD 60x27<br />

fleece: black<br />

perforation: Ø 20 / 25<br />

45 70<br />

9 25 9<br />

1 m<br />

<strong>Knauf</strong> Mitered Board 2d+1.5 25<br />

miter layout vertical fin miter layout <strong>Knauf</strong> Mitered Board<br />

Daisy Chain Clip<br />

(alternating fixing)<br />

<strong>Knauf</strong> Perforated Acoustical Channel<br />

vertical fin<br />

D191-S23<br />

Canopy with Vertical Fins<br />

Daisy Chain Clip<br />

(alternating fixing)<br />

16<br />

D191-S24<br />

2d+1.5<br />

25<br />

Stepped Fin Ceiling<br />

45 70<br />

<strong>Knauf</strong> Perforated Acoustical Channel<br />

vertical fin<br />

miter layout vertical fins

Accessories<br />

Universal Connector for CD 60x27<br />

D19<br />

Assembly<br />

delivery unbent<br />

Fields of application<br />

(scheme drawings)<br />

straight longitudinal connection<br />

optional suspension point<br />

joint of channels<br />

longitudinal connections up to 30° *)<br />

optional suspension point<br />

joint of channels<br />

folding point at<br />

half angle<br />

optional<br />

folding point<br />

predetermined<br />

folding point<br />

a<br />

a<br />

a<br />

1/3<br />

a<br />

1)<br />

adjust roughly depending on use<br />

adjust correctly during assembly<br />

a<br />

= spacing of suspenders depending<br />

on ceiling system<br />

1) if used as suspender<br />

joint of channels<br />

half angle<br />

joint of channels<br />

max. 30°<br />

T or double T connection T connection up to 45° *)<br />

with T connection<br />

ceiling opening optional<br />

ceiling opening<br />

optional<br />

max. 45°<br />

half-angle<br />

Options for Suspensions *)<br />

(scheme drawings)<br />

load bearing capacity class according to DIN 18168-2<br />

0.4 kN (40 kg)<br />

Nonius Hanger top<br />

0.4 kN (40 kg)<br />

slotted strip steel<br />

0.4 kN (40 kg)<br />

direct wire<br />

0.15 kN (15 kg)<br />

wire and cleat<br />

0.1 kN (10 kg)<br />

directly on timber<br />

17 mm<br />

Note<br />

*) <strong>Ceilings</strong> with fire protection requirements: Fix Universal Connector to CD channel 60x27<br />

with metal screws LB 3.5x9.5 mm according to technical approval ABP P-3043/0339<br />

17

Cantilevers<br />

Scheme Drawings<br />

D19<br />

Only gypsum boards<br />

thickness 12.5 mm<br />

A<br />

100 mm<br />

A<br />

A<br />

With metal angle<br />

thickness 2 mm<br />

B<br />

B<br />

150 mm<br />

B<br />

With CD channel<br />

CD 60x27x0.6<br />

C<br />

ca.150 mm<br />

C<br />

C<br />

With metal cantilever<br />

thickness 2 mm<br />

D<br />

200 mm<br />

D<br />

a<br />

a<br />

With UA channel<br />

UA 50x40x2.0<br />

E<br />

300 mm<br />

300 mm<br />

structural analysis<br />

necessary<br />

side view<br />

E<br />

18<br />

Note<br />

For other cantilevers consult specialist<br />

Metal angle and metal cantilever are not available at <strong>Knauf</strong>.

<strong>Knauf</strong> <strong>Designed</strong> <strong>Ceilings</strong><br />

Specifications<br />

D19<br />

Item Description No. of units Unit price Total price<br />

....... Ceiling lining/ suspended ceiling * DIN 18168-1,<br />

Installation height in m .............., suspension height in cm ....................,<br />

anchored on reinforced concrete/ wooden beams *, spacing in cm ............./<br />

steel girder, type ................, spacing in cm ....................., *<br />

cladding with <strong>Knauf</strong> Boards GKB/ GKF *,<br />

Board thickness 12.5 mm/ 2 x 12.5 mm/ 25 mm *.<br />

Product/ System: <strong>Knauf</strong> Gypsum Board Ceiling D112/ D113 * .......... m² .......... € .......... €<br />

........<br />

<strong>Knauf</strong> Mitering Technology D191<br />

Frieze as upgrade to ceiling lining/ suspended ceiling *,<br />

continous, consisting of <strong>Knauf</strong> board strips with miters, thickness in mm ................ ,<br />

width in mm: .........................., Installation according to drawing no. ................... . ........... m .......... € .......... €<br />

........ Vertical Fins/ Baffle/ Protruding *<br />

consisting of <strong>Knauf</strong> Mitered Boards,<br />

board thickness: 12.5 mm/ 15 mm/ 18 mm *,<br />

including additional subconstruction,<br />

Installation according to drawing no. ................ . ........... m .......... € .......... €<br />

........ Cornice as upgrade to ceiling lining/ suspended ceiling *,<br />

consisting of <strong>Knauf</strong> Mitered Boards, Board thickness in mm .................,<br />

including additional subconstruction,<br />

installation according to drawing no. ........... . ........... m .......... € .......... €<br />

........ Wall Junction as upgrade to ceiling lining/ suspended ceiling *,<br />

sliding/ with connection joint *. ........... m .......... € .......... €<br />

........ Split Level Ceiling as upgrade to ceiling lining/ suspended ceiling *,<br />

height difference in mm ................, angle 45°/ 90°/ ..........°, *<br />

including additional subconstruction,<br />

installation according to drawing no. ........... . ........... m .......... € .......... €<br />

........<br />

<strong>Knauf</strong> Molding Technology D192<br />

Arch Elements made of Molding Boards,<br />

thickness: 12 mm/ 18 mm/ 24 mm *.<br />

angle 90°/ 180°/ ............° *, radius in mm ....................., concave/ convex *,<br />

with one side/ two side extension *, including additional subconstruction,<br />

installation according to drawing no. ................ . ........... m .......... € .......... €<br />

........ Arch made of <strong>Knauf</strong> Boards, with parallel slotting/ molded on site *,<br />

thickness: 12.5 mm/ 2 x 12.5 mm *,<br />

angle .....................° *, radius: ...................., concave/ convex *,<br />

including additional subconstruction,<br />

installation according to drawing no. ................ . ........... m .......... € .......... €<br />

........ Barrel Vault made of <strong>Knauf</strong> Boards, molded on site,<br />

thickness in mm ....................,<br />

angle .....................° *, radius: ...................., concave *,<br />

including subconstruction consisting of bent upper CD channels,<br />

lower CD channels and rigid suspension,<br />

Installation according to drawing no. ................ . ........... m .......... € .......... €<br />

........ Dome Ceiling made of <strong>Knauf</strong> Boards, molded on site,<br />

thickness: 12.5 mm gypsum board strips and 9.5 mm cladding,<br />

radius dome 2536 mm *,<br />

diameter 2132 mm (Berlin) / 2600 mm (München) *,<br />

rise 235 mm (Berlin) / 358.5 mm (München) *,<br />

including subconstruction,<br />

installation according to drawing no. 34502-TV/D19(Berlin) / no. 34501-TV/D19(München) *.<br />

Product/ System: <strong>Knauf</strong> Dome Berlin/ München * D193 ......... pcs .......... € .......... €<br />

* Cancel not applicable items Sub-total ................ €<br />

19

<strong>Knauf</strong> <strong>Designed</strong> <strong>Ceilings</strong><br />

Construction and Application, Jointing, Surface Treatment<br />

Construction<br />

<strong>Knauf</strong> <strong>Ceilings</strong> as ceiling lining or suspended<br />

ceiling are fi xed to the basic ceiling with a rigid<br />

suspension. <strong>Knauf</strong> boards and factory or bent<br />

on site boards with parallel slotting or mitering<br />

are fi xed to a metal grid of lower and upper C<br />

channels (D112) or a fl ush grid of C channels<br />

(D113).<br />

Settlement joints have to be taken over into the<br />

construction of the suspended ceiling systems.<br />

Use control joints in the case of ceiling areas<br />

over approx. 15 m length, or for narrow ceiling<br />

spaces caused by a break of a wall. For strongly<br />

structured suspended ceilings additional movement<br />

joints may become necessary.<br />

D19<br />

<strong>Knauf</strong> C channels are delivered galvanized. This<br />

corrosion protective coating is suffi cient for indoor<br />

rooms, including bathrooms and kitchens<br />

in private housing. For other areas, e.g. under<br />

infl uence of outdoor air, additional corrosion protection<br />

is necessary (see DIN 18168-1 table 2).<br />

Application<br />

Grid<br />

● Rigid suspension with Universal Brackets/ Nonius<br />

Hanger/ Combo Hangers/ Nonius Stirrups<br />

with Nonius Hanger Top or Anchor Hanger.<br />

● Anchored on basic ceiling made of<br />

Wood: Use <strong>Knauf</strong> Drywall Screws (fl athead)<br />

FN 5.1 x 35 mm (used in accordance with<br />

Construction Supervisory Permit no. Z-9.1-<br />

251)<br />

Reinforced concrete: <strong>Knauf</strong> ceiling steel dowel<br />

(mounted in accordance with Construction<br />

Supervisory Permit no. Z-21.1-1519)<br />

Other building materials: anchors have to be<br />

permitted and standardized for the building<br />

material being used.<br />

● For the spacing of fi xings of the suspenders on<br />

the basic ceiling and the spacing of channels<br />

see tables D112/ D113 (TDS D11 <strong>Knauf</strong> Plattendecken).<br />

For Apertura Board <strong>Ceilings</strong> see<br />

TDS D12 (<strong>Knauf</strong> Acoustical Ceiling Systems).<br />

● Connect upper C channels with hangers and<br />

align them at the required suspension height.<br />

Connect lower C channels CD 60/27 to upper<br />

C channels with: Intersection Connectors,<br />

Clip for CD 60x27 or Daisy Chain Clip. Other<br />

channel connectors: Multi Connector or Universal<br />

Connector 60/27.<br />

Cladding<br />

Cross mounting of <strong>Knauf</strong> boards to lower C<br />

channels, displacement of jointings at least 400<br />

mm ensuring that end joints bear on C channels.<br />

Start fastening of <strong>Knauf</strong> boards either in<br />

the middle or at a corner in order to prevent upsetting<br />

deformation.<br />

Press boards fi rmly on to the grid during screw<br />

attachment.<br />

Additional loads<br />

● Single loads applied directly to the cladding<br />

must not exceed 0,06 kN per spacing of lower<br />

channels and meter.<br />

● Apart from that, additional loads have to be<br />

considered for the calculation of the dead load<br />

of the suspended ceiling if they are borne by<br />

the ceilings subconstruction. The loads are to<br />

be included when determining the load class<br />

from the table on page 2 of TDS D11.<br />

● Other additional loads have to be applied directly<br />

to the basic ceiling.<br />

<strong>Knauf</strong> Drywall Screws for the fixing of <strong>Knauf</strong> boards onto metal channels with a thickness of d = 0.6 mm<br />

Thickness of boards <strong>Knauf</strong> Drywall Screws (DIN 18182-2) Spacing of screws (DIN 18181)<br />

up to 15 mm TN 3.5 x 25 mm 170 mm<br />

18 to 25 mm TN 3.5 x 35 mm 170 mm<br />

2 x 12.5 mm TN 3.5 x 25 mm + TN 3.5 x 35 mm 170 mm<br />

Jointing<br />

Fill in joints with <strong>Knauf</strong> Unifl ott without using<br />

tape. If using tape, fi ll in with <strong>Knauf</strong> Fugenfüller<br />

Leicht or with Ames machine and <strong>Knauf</strong> Jointfi<br />

ller-Super.<br />

Cover all screw heads as well. For double layer<br />

cladding, fi ll in joints of fi rst layer, smooth joints<br />

of second layer.<br />

Recommendation: Fill in and tape cut edges of<br />

visible layers no matter which fi lling material is<br />

used.<br />

Filling and covering of joints should only take<br />

place after the boards have been allowed to<br />

rest in the given humidity and temperature zones,<br />

and no more longitudinal changes can be<br />

expected, i.e. expansion or contraction. Joints<br />

should be fi lled at a minimum temperature of<br />

10°C. In case of mastic asphalt screed, fi ll in<br />

joints after screed has been applied.<br />

Surface Treatment<br />

Use a primer on <strong>Knauf</strong> Boards before coating or<br />

painting them. Ensure that the primer and the<br />

coat or paint are compatible. The following coats<br />

can be used to cover <strong>Knauf</strong> Boards:<br />

● Coats: Washable and abrasion-proof emulsion<br />

paint, multicolored (rainbow) emulsion, oil<br />

paint, matte-fi nish lacquer, alkyd resin paint,<br />

polymer resin paint, PUR lacquer, or epoxybased<br />

lacquer, according to intended use or<br />

as required.<br />

● Wall Papers: paper-, textile and synthetic wall<br />

papers. Use only adhesives made of cellulose<br />

according to „Merkblatt Nr. 16, Technische<br />

Richtlinien für Tapezier- und Klebearbeiten“,<br />

Frankfurt/Main 2002, released by Bundesausschuss<br />

Farbe und Sachwertschutz.<br />

After wallpapering of paper and fi ber glass<br />

wallpapers quick drying must be assured<br />

through adequate airing.<br />

● Alkaline coats such as lime, water glass colors<br />

and silicate-based paints are unsuitable<br />

for gypsum board surfaces.<br />

● Silicate-based emulsion paints may be used<br />

after referring to the manufacturer’s recommendations<br />

and following the stipulated guidelines<br />

closely.<br />

Gypsum board surfaces that have constantly<br />

been exposed to light without any protection can<br />

develop yellowing agents that show up despite a<br />

coat of paint. Therefore a trial coat is recommended<br />

that will extend across several boards including<br />

all joints. Yellowing can, however, be successfully<br />

avoided only by using a special shielding<br />

primer.<br />

<strong>Knauf</strong> Know-how: The shown solutions are proposals for independent and extraordinary conceptions. Factory-molded elements increasingly show up as the<br />

most cost-effective solution in implementation. Make use of our technical know-how and professional CAD Service for detailed design. We accompany you<br />

from the beginning of your conception up to the implementation. Our Call Center for Technical Information will gladly name a contact person on location.<br />

<strong>Knauf</strong> Direkt Call Center for Technical Information, Phone 0 18 05 / 31-10 00, Facsimile 0 18 05 / 31-40 00<br />

<strong>Knauf</strong> websites: www.knauf.de, www.knauf.com, e-mail: knauf-direkt@knauf.de<br />

<strong>Knauf</strong> Headquarters, Am Bahnhof 7, D-97346 Iphofen, Phone +49 93 23 / 31-0, Facsimile +49 93 23 / 31-277<br />

20<br />

All technical changes reserved. Only the current printed instructions are valid. Our warranty is expressly limited to our products in flawless condition. All application quantities and delivery amounts are based on empirical data that<br />

are not easily transferable to other deviating areas. All rights reserved. All amendments, reprints and photocopies, including those of excerpts, require the express permission of <strong>Knauf</strong> Gips KG, Am Bahnhof 7, 97346 Iphofen, Germany.<br />

Edition: October 2004<br />

D19 / engl. / D / 10.04 / FB / D