Knauf Safety Engineering

Knauf Safety Engineering

Knauf Safety Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

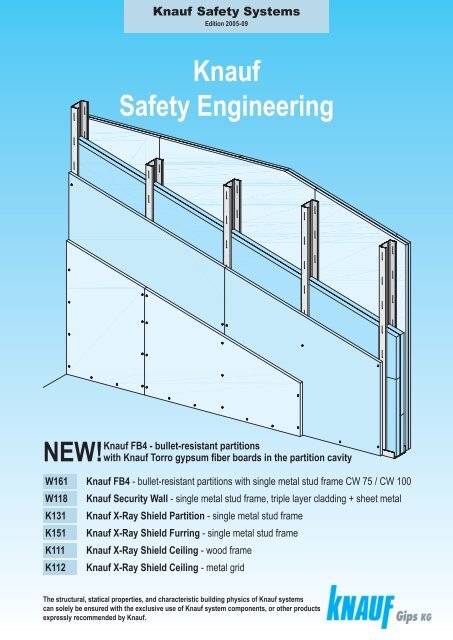

<strong>Knauf</strong> <strong>Safety</strong> Systems<br />

Edition 2005-09<br />

<strong>Knauf</strong><br />

<strong>Safety</strong> <strong>Engineering</strong><br />

NEW!<br />

<strong>Knauf</strong> FB4 - bullet-resistant partitions<br />

with <strong>Knauf</strong> Torro gypsum fiber boards in the partition cavity<br />

W161 <strong>Knauf</strong> FB4 - bullet-resistant partitions with single metal stud frame CW 75 / CW 100<br />

W118<br />

K131<br />

K151<br />

K111<br />

K112<br />

<strong>Knauf</strong> Security Wall - single metal stud frame, triple layer cladding + sheet metal<br />

<strong>Knauf</strong> X-Ray Shield Partition - single metal stud frame<br />

<strong>Knauf</strong> X-Ray Shield Furring - single metal stud frame<br />

<strong>Knauf</strong> X-Ray Shield Ceiling - wood frame<br />

<strong>Knauf</strong> X-Ray Shield Ceiling - metal grid<br />

The structural, statical properties, and characteristic building physics of <strong>Knauf</strong> systems<br />

can solely be ensured with the exclusive use of <strong>Knauf</strong> system components, or other products<br />

expressly recommended by <strong>Knauf</strong>.

<strong>Knauf</strong> <strong>Safety</strong> <strong>Engineering</strong><br />

Survey<br />

<strong>Knauf</strong> System<br />

<strong>Knauf</strong> FB4 bullet-resistant partitions W161<br />

Fire protection<br />

Sound protection<br />

2x 12.5 mm<br />

<strong>Knauf</strong> Diamant GKFI<br />

<strong>Knauf</strong> CW Stud 75<br />

spacing of studs 62.5 cm<br />

2x 28 mm<br />

<strong>Knauf</strong> Torro gypsum<br />

fiber board panel in the<br />

cavity of the partition<br />

F90<br />

R w,R<br />

47 dB<br />

2x 12.5 mm<br />

<strong>Knauf</strong> Diamant GKFI<br />

<strong>Knauf</strong> CW Stud 100<br />

spacing of studs 62.5 cm<br />

2x 28 mm<br />

<strong>Knauf</strong> Torro gypsum<br />

fiber board panel in the<br />

cavity of the partition<br />

insulation layer<br />

F90<br />

R w,R<br />

53 dB<br />

<strong>Knauf</strong> Security Wall burglary-retardant W118<br />

3x 12.5 mm<br />

<strong>Knauf</strong> Boards GKF/ GKFI,<br />

<strong>Knauf</strong> Diamant GKFI<br />

<strong>Knauf</strong> CW Stud 100<br />

spacing of studs 31.25 cm<br />

2x 0.5 mm<br />

sheet metal layers<br />

F90<br />

R w,R<br />

55 dB<br />

Fire wall<br />

quality<br />

<strong>Knauf</strong> X-Ray Shield Partitions K131<br />

12.5 mm<br />

<strong>Knauf</strong> X-Ray Shield GKF<br />

<strong>Knauf</strong> CW Stud 50/75/100<br />

spacing of studs 62.5 cm<br />

2x 12.5 mm<br />

<strong>Knauf</strong> X-Ray Shield GKF +<br />

<strong>Knauf</strong> Board GKF<br />

<strong>Knauf</strong> CW Stud 50/75/100<br />

spacing of studs 62.5 cm<br />

<strong>Knauf</strong> X-Ray Shield<br />

laminated with<br />

rolled lead sheets<br />

0.5 to 3 mm<br />

Self-adhesive<br />

lead strip on<br />

CW Studs and<br />

UW Runners<br />

F30<br />

F90<br />

R w,R<br />

41 to 44 dB<br />

R w,R<br />

50 to 53 dB<br />

<strong>Knauf</strong> X-Ray Shield Furrings K151<br />

2<br />

12.5 mm<br />

<strong>Knauf</strong> X-Ray Shield GKF<br />

<strong>Knauf</strong> CD Channel 60x27<br />

spacing of channels 62.5 cm<br />

2x 12.5 mm<br />

<strong>Knauf</strong> X-Ray Shield GKF +<br />

<strong>Knauf</strong> Board GKB<br />

<strong>Knauf</strong> CD Channel 60x27<br />

spacing of channels 62.5 cm<br />

<strong>Knauf</strong> X-Ray Shield<br />

laminated with<br />

rolled lead sheets<br />

0.5 to 3 mm<br />

Self-adhesive<br />

lead strip on<br />

CD Channels and<br />

UD Runners<br />

-<br />

-<br />

see Technical<br />

Data Sheet W62<br />

<strong>Knauf</strong> Furrings<br />

and Installation<br />

Shaft Walls

<strong>Knauf</strong> <strong>Safety</strong> <strong>Engineering</strong><br />

Survey, <strong>Knauf</strong> Boards<br />

<strong>Knauf</strong> System<br />

Fire protection<br />

Sound protection<br />

<strong>Knauf</strong> X-Ray Shield Ceiling K111<br />

12.5 mm<br />

<strong>Knauf</strong> X-Ray Shield GKF<br />

wood frame<br />

<strong>Knauf</strong> X-Ray Shield<br />

laminated with<br />

lead sheet 0.5 to 3 mm<br />

Self-adhesive<br />

lead sheet strips on<br />

lower channels and<br />

cut edge joints<br />

-<br />

-<br />

<strong>Knauf</strong> X-Ray Shield Ceiling K112<br />

12.5 mm<br />

<strong>Knauf</strong> X-Ray Shield GKF<br />

metal grid<br />

<strong>Knauf</strong> X-Ray Shield<br />

laminated with<br />

lead sheet 0.5 to 3 mm<br />

Self-adhesive<br />

lead sheet strips on<br />

lower channels and<br />

cut edge joints<br />

-<br />

-<br />

Notes<br />

Sound protection values of partitions are only valid if <strong>Knauf</strong> Profiles are used.<br />

For proofs and further information about fire / sound protection see particular system.<br />

<strong>Knauf</strong> Boards<br />

Cladding<br />

Board type<br />

Thickness<br />

Width<br />

<strong>Knauf</strong> Board<br />

GKB (GKBI) wallboard (impregnated)<br />

12.5 mm<br />

1250 mm<br />

GKF (GKFI) fire-resistant board (impregnated) 12.5 mm 1250 mm<br />

<strong>Knauf</strong> Diamant (hard gypsum board)<br />

GKFI fire-resistant board impregnated<br />

12.5 mm<br />

1250 mm<br />

<strong>Knauf</strong> X-Ray Shield (laminated with rolled lead sheets) GKF fire-resistant board<br />

12.5 mm<br />

625 mm<br />

<strong>Knauf</strong> LaVita Electro-Shielding Boards<br />

GKF fire-resistant board<br />

12.5 mm<br />

1250 mm<br />

<strong>Knauf</strong> LaVita Electro-Shielding Boards<br />

Shielding:<br />

high frequency electromagnetic waves<br />

low frequency electric alternating fields<br />

<strong>Knauf</strong> LaVita Electro-Shielding Boards are being used as cladding<br />

on metal grids or timber frames for partitions, furrings and ceilings.<br />

Wood Frame Partitions<br />

scheme drawings<br />

conductive connection for wood<br />

frames with LaVita Arrester Tape<br />

longitudinal conductive connection<br />

of LaVita Electro-Shielding Boards<br />

with LaVita Arrester Plate if<br />

horizontal joints are necessary<br />

Detail A<br />

A<br />

ceiling and roof cladding<br />

LaVita Arrester Plate<br />

LaVita Arrester Tape<br />

conductive connection for wood<br />

grids with LaVita Arrester Tape<br />

for lateral cladding:<br />

cover cut edge joints on wood frame<br />

with LaVita Arrester Plate<br />

Note<br />

For installation and further details see Technical Data Sheet K736 "<strong>Knauf</strong> LaVita Electro-Shielding Board"<br />

3

<strong>Knauf</strong> FB4, bullet-resistant partition<br />

Requirements, Technical Data / Fire Protection / Sound Protection, Specification<br />

W161<br />

Requirements<br />

<strong>Knauf</strong> FB4 bullet-resistant partitions are classifi<br />

ed as resistance class FB4 NS according<br />

to DIN EN 1522 after testing by the Beschussamt<br />

Ulm. The resistance class FB4<br />

includes the biggest hand fi rearm caliber<br />

that can be tested according to DIN EN<br />

1522, the 44 Remington Magnum, as well<br />

as all calibers of lower resistance classes.<br />

For the classifi cation into one of the resistance<br />

classes the test specimen may not<br />

have a full penetration after being shot with the<br />

appropriate ammunition.<br />

The addition „S“ or „NS“ indicates, if spalling occurs<br />

during testing. „NS“ means not spalling.<br />

Technical Data / Fire Protection / Sound Protection<br />

W161 <strong>Knauf</strong> FB4<br />

Single metal stud frame, double layer cladding<br />

+ <strong>Knauf</strong> Torro the cavity of partition<br />

Technical Data<br />

dimensions<br />

cladding<br />

type / thickness<br />

d<br />

mm<br />

stud<br />

(cavity)<br />

h<br />

mm<br />

wall weight<br />

thickness<br />

D<br />

mm<br />

approx.<br />

kg/m² 1)<br />

Fire resistance<br />

class<br />

Sound<br />

pro-<br />

tection<br />

R w,R<br />

dB<br />

Insulation<br />

thickness<br />

2) mm 3)<br />

spacing of studs<br />

62.5 cm<br />

d h d<br />

D<br />

<strong>Knauf</strong><br />

Diamant GKFI 75 125 143 F90 47 -<br />

2x 12.5<br />

spacing of studs<br />

62.5 cm<br />

d h d<br />

D<br />

<strong>Knauf</strong><br />

Diamant GKFI 100 150<br />

2x 12.5<br />

143 F90 53 20<br />

1) weight without insulation<br />

2) R w,R = calculation value of sound reduction index of separating construction component according to DIN 4109,<br />

without longitudinal transmission via flanking components<br />

3) insulation according to DIN EN 13162, length related flow resistance according to DIN EN 29053: r 5 kPa s/m² , building material class min. B2<br />

Note<br />

see also Technical Data Sheet<br />

W15 <strong>Knauf</strong> Diamant Partitions<br />

Proofs<br />

Sound protection: <strong>Knauf</strong> Test Report L 001-07.05<br />

Fire protection: ABP P-3070/0609<br />

Bullet resistance FB4 NS S 04 0137 05 / B<br />

Specification<br />

Item Description No. of units Unit price Total price<br />

....... Non-load bearing partition DIN 4103-1 as metal stud partition,<br />

installation zone 1 / 2 *, height in m ................, thickness 125/ 150 * mm,<br />

sound reduction index DIN 4109 R w,R<br />

in dB 47/ 53 * dB,*<br />

fi re resistance class according to DIN 4102-2 F90, *<br />

perimeter fi xed.<br />

Bullet-resistant according to DIN EN 1522 resistance class FB4 NS,<br />

2 x 28 mm gypsum fi ber boards <strong>Knauf</strong> Torro in the cavity of partition ,<br />

density ≥ 1500 kg/m³,<br />

cladding with Diamant hard gypsum boards GKFI 12,5 mm, double layer.<br />

Product/ System: <strong>Knauf</strong> FB4 W161 .......... m² .......... € .......... €<br />

4<br />

* Cancel not applicable items Sub-total ................ €

<strong>Knauf</strong> FB4, bullet-resistant partition<br />

Construction, Notes, Cladding, Consumption of Material<br />

W161<br />

Construction<br />

<strong>Knauf</strong> FB4 bullet-resistant partitions consist<br />

of a single metal stud frame made of UW 75<br />

/ UW 100 Runners and CW 75 / CW 100 Studs<br />

(spacing: 625 mm) and double layer cladding<br />

screwed to the studs on both sides. The<br />

cladding made of <strong>Knauf</strong> Diamant hard gypsum<br />

boards GKFI 12.5 mm is appropriate for<br />

Notes<br />

● Install CW Studs and <strong>Knauf</strong> Torro tight.<br />

● Install door and window openings in coordination<br />

with manufacturers. Design metal frame<br />

around the opening considering the load of<br />

<strong>Knauf</strong> Torro (84 kg/m²).<br />

● <strong>Knauf</strong> Torro Boards can be cut with electrical<br />

hand-held circular saw (diamond saw blade)<br />

with exhaust unit.<br />

● For jointing and surface treatment see page<br />

23.<br />

● For further information about metal stud partitions<br />

with <strong>Knauf</strong> Diamant cladding see <strong>Knauf</strong><br />

Technical Data Sheet W15.<br />

higher mechanical requirements as it provides<br />

a hard surface and higher shock resistance,<br />

higher bracket loads are allowable.<br />

Being rated as fi re-resistant boards they are also<br />

adequate for all fi re protective constructions.<br />

Wall heights installation zone 1: ≤ 4 m (CW 75)<br />

resp. ≤ 5.5 m (CW 100)/ installation zone 2:<br />

≤ 3.5 m (CW 75) resp. ≤ 5 m (CW 100).<br />

Application<br />

The application of the metal frame and <strong>Knauf</strong><br />

Torro is described on page 8.<br />

The metal frame is fastened to the fl anking construction<br />

components at the whole perimeter.<br />

A double layer of special gypsum fi ber boards<br />

<strong>Knauf</strong> Torro, 28 mm, dimensions (b x h) 624 x<br />

600 mm, is installed in the cavity of the partition.<br />

Cladding<br />

● Cladding preferably with vertically applied<br />

fl oor-to-ceiling <strong>Knauf</strong> Diamant hard gypsum<br />

boards GKFI, double layer.<br />

● Displace joints.<br />

● For fire protection requirements fill connection<br />

to floor with filler, for sole sound protection requirements<br />

Acoustical Sealant or acrylate can<br />

be used.<br />

● Fastening of fi rst layer with Diamant Screws<br />

HGP 3.9 x 23, of second layer with HGP<br />

3.9 x 35. Spacing of screws of fi rst layer 75<br />

cm, of second layer 25 cm.<br />

Consumption of Material<br />

Consumption of material per m² partition without allowance for loss and waste.<br />

Amounts refer to partition area of: H=2.75 m; L=4.0 m; A=11.0 m².<br />

description<br />

unit<br />

italic = not provided by <strong>Knauf</strong><br />

metal stud frame<br />

UW Runner 75x40x0.6<br />

resp.<br />

UW Runner 100x40x0.6<br />

<strong>Knauf</strong> CW Stud 75x50x0.6<br />

resp.<br />

<strong>Knauf</strong> CW Stud 100x50x0.6<br />

Angle L 13x30x0.8<br />

m<br />

<strong>Knauf</strong> Torro 28 mm, 624x600 mm m²<br />

<strong>Knauf</strong> Acoustical Sealant; (pouch 550 ml)<br />

pcs<br />

0.5<br />

<strong>Knauf</strong> Nailable Plug "K" 6/35; (100 pcs. box)<br />

pcs<br />

2.0<br />

insulation (see page 4) .... mm thick m² as required<br />

cladding<br />

<strong>Knauf</strong> Diamant GKFI (hard gypsum board); 12.5 mm m² 4.0<br />

Diamant Screw HGP 3.9 x 23<br />

Diamant Screw HGP 3.9 x 35<br />

jointing<br />

<strong>Knauf</strong> Uniflott; (5 kg/25 kg bag)<br />

<strong>Knauf</strong> Joint Tape; (23 m/75 m/150 m roll)<br />

m<br />

m<br />

pcs<br />

kg<br />

m<br />

amount as average value<br />

0.7<br />

1.8<br />

0.3<br />

2.0<br />

12<br />

28<br />

0.8<br />

as required<br />

5

<strong>Knauf</strong> FB4, bullet-resistant partition<br />

Wall heights<br />

Stud<br />

Spacing<br />

of studs<br />

metal<br />

thickness 0.6 mm cm<br />

Maximum wall heights<br />

with fire protection<br />

installation zone (definition see page 23)<br />

1 2<br />

m m<br />

W161<br />

Single metal stud frame CW 75, double layer cladding with <strong>Knauf</strong> Diamant, lined with <strong>Knauf</strong> Torro<br />

<strong>Knauf</strong> Stud<br />

CW 75<br />

62.5<br />

4<br />

3.5<br />

Notes<br />

<strong>Knauf</strong> Torro (dimensions: b = 624 mm, h = 600 mm)<br />

2 strings of Acoustical Sealant between Torro layers for fixing.<br />

Sections<br />

horizontal section<br />

spacings of studs<br />

625 mm 625 mm 575 mm<br />

starting section standard section section before end section end section<br />

2x 12.5 mm <strong>Knauf</strong> Diamant<br />

<strong>Knauf</strong> CW Stud 75<br />

Details scale 1:5<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

place vertically in first section (b = 600, h = 624)<br />

Nailable Plug<br />

Acoustical Sealant<br />

<strong>Knauf</strong> CW 75<br />

A<br />

A<br />

direction of installation<br />

Diamant Screw HGP 3.9x23<br />

Diamant Screw HGP 3.9x35<br />

<strong>Knauf</strong> CW Stud 75<br />

turn last stud for<br />

installation reasons<br />

2x 12.5 mm <strong>Knauf</strong> Diamant<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

Nailable Plug<br />

scheme drawing<br />

vertical section A-A<br />

offset of boards<br />

approx. 300 mm<br />

W161-A1<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

place vertically in first section<br />

Connection to wall<br />

W161-B1<br />

Uniflott<br />

2x 12.5 mm <strong>Knauf</strong> Diamant<br />

Joint<br />

Angle L 13/30/0.8<br />

crimp with UW Runner<br />

W161-A2<br />

Connection<br />

to wall<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

<strong>Knauf</strong> CW Stud 75<br />

Uniflott<br />

2x 12.5 mm<br />

<strong>Knauf</strong> Diamant<br />

metal screw<br />

<strong>Knauf</strong> CW 75<br />

crimp with<br />

UW Runner<br />

Acoustical Sealant<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

Nailable<br />

Plug<br />

6<br />

W161-D1<br />

Corner<br />

W161-A3<br />

Connection to wal e.g. W112<br />

W161-VU1<br />

Floor connection

<strong>Knauf</strong> FB4, bullet-resistant partition<br />

Wall heights<br />

Stud<br />

Spacing<br />

of studs<br />

metal<br />

thickness 0.6 mm cm<br />

Maximum wall heights<br />

with fire protection<br />

installation zone<br />

1 2<br />

m m<br />

W161<br />

Single metal stud frame CW 100, double layer cladding with <strong>Knauf</strong> Diamant, lined with <strong>Knauf</strong> Torro<br />

<strong>Knauf</strong> Stud<br />

CW 100<br />

62.5<br />

5.5<br />

5<br />

Notes<br />

<strong>Knauf</strong> Torro ( dimensions: b = 624 mm, h = 600 mm )<br />

2 strings of Acoustical Sealant between the Torro layers for fixing.<br />

Sections<br />

horizontal section<br />

spacings of studs<br />

625 mm 625 mm 575 mm<br />

starting section standard section section before end section end section<br />

A<br />

Schemazeichnung<br />

vertical section A-A<br />

Details scale 1:5<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

place vertically in first section ( b = 600, h = 624 )<br />

2x 12.5 mm <strong>Knauf</strong> Diamant<br />

<strong>Knauf</strong> CW Stud 100<br />

Nailable Plug<br />

<strong>Knauf</strong> CW 100<br />

A<br />

direction of installation<br />

Diamant Screw HGP 3.9x23<br />

Diamant Screw HGP 3.9x35<br />

turn last stud for<br />

installation reasons<br />

2x 12.5 mm <strong>Knauf</strong> Diamant<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

Nailable Plug<br />

Acoustical Sealant<br />

offset of boards<br />

approx. 300 mm<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

Uniflott<br />

Angle L 13/30/0.8<br />

place vertically in first section<br />

2x 12.5 mm <strong>Knauf</strong> Diamant crimp with UW Runner<br />

W161-A11 Connection to wall W161-B11 Joint<br />

W161-A12 Connection to wall<br />

Flex Profile 100<br />

<strong>Knauf</strong> CW Stud 100<br />

Uniflott<br />

2x 12.5 mm<br />

<strong>Knauf</strong> Diamant<br />

insulation<br />

<strong>Knauf</strong> CW 100<br />

crimp with<br />

UW Runner<br />

Acoustical<br />

Sealant<br />

Nailable<br />

Plug<br />

metal screw<br />

2x 28 mm <strong>Knauf</strong> Torro<br />

W161-D11<br />

Corner<br />

W161-A13<br />

Connection to wall e.g. W112<br />

W161-VU11<br />

Floor connection<br />

7

<strong>Knauf</strong> FB4, bullet-resistant partition<br />

Application<br />

W161<br />

8<br />

Metal frame<br />

● Apply Acoustical Sealant (two strings) to backside<br />

of runners for connection to ceiling and<br />

fl oor. Fasten runners with appropriate fasteners<br />

(e.g. <strong>Knauf</strong> Nailable Plug). Spacing of fasteners<br />

max. 1 m. Aligne UW Runner exactly<br />

horizontal at floor!<br />

● Apply Acoustical Sealant (two strings) to backside<br />

of CW Stud and fasten it to the fl anking<br />

wall where installation starts. Spacing of fasteners<br />

max. 1 m, min. 3 fasteners.<br />

<strong>Knauf</strong> Torro in the cavity of partition<br />

● To fi x the fi rst <strong>Knauf</strong> Torro boards apply Acoustical<br />

Sealant into CW Stud, slide-in board<br />

(width 600 mm) vertically and press-on tightly<br />

against CW Stud (pound with rubber mallet if<br />

necessary).<br />

Subsequently shorten second layer by 300<br />

mm and glue it to the already installed board<br />

with 2 strings of Acoustical Sealant using<br />

screw clamps.<br />

● Apply following <strong>Knauf</strong> Torro displaced to each<br />

other by approx. 300 mm, glue both layers to<br />

each other with Acoustical Sealant and presson<br />

tightly to CW Studs.<br />

● For metal frame with CW 100: To aligne <strong>Knauf</strong><br />

Torro elements correctly in the cavity of the<br />

partition, glue gypsum board pieces (approx.<br />

40x40x12.5 mm) at a spacing of approx. 1 m<br />

into CW Stud fl anges with Acoustical Sealant<br />

and press <strong>Knauf</strong> Torro boards against the<br />

same fl ange. To make installation easier apply<br />

pieces of roof laths (or two gypsum board<br />

pieces) between other fl ange and <strong>Knauf</strong> Torro<br />

board (remove before applying the cladding).<br />

● Cut top <strong>Knauf</strong> Torro according to the necessary<br />

height and install it.<br />

● Starting the second section install <strong>Knauf</strong> Torro<br />

horizontally (width 624 mm) to reach the modular<br />

spacing of 625 mm while still taking care<br />

of the joint displacement (approx. 300 mm).<br />

Carry on until all sections are lined with 2 x<br />

28 mm <strong>Knauf</strong> Torro. Install CW Studs (apply<br />

one string of Acoustical Sealant in the middle<br />

of the web of the stud) with web turned to the<br />

boards and crimp with Stamp Pliers.<br />

Caution: turn last stud, that means install with<br />

opening towards the boards!<br />

● Fixation of the last section is carried out using<br />

metal sheet angles with <strong>Knauf</strong> L Angle Profi<br />

le 13/30/08. Put fi rst angle profi le against<br />

UW Runners (apply Acoustical Sealant before)<br />

and crimp. Subsequently fasten to fl anking<br />

wall at the shorter, perforated angle arm<br />

with a spacing of approx. 500 mm. Glue gypsum<br />

board piece (approx. 40x40x12,5 mm)<br />

between angle profi le and <strong>Knauf</strong> Torro with<br />

a spacing of approx. 1 m using Acoustical<br />

Sealant. Install <strong>Knauf</strong> Torro boards, press-on<br />

against the respective angle arm and fasten<br />

second angle profi le on the opposite side of<br />

the partition again aligned with the fl ange of<br />

the UW Runners.<br />

1st section<br />

last section<br />

2 3 4<br />

2nd section (up to section before end section)<br />

Torro Torro<br />

ro<br />

ro<br />

Torro<br />

Torro<br />

625<br />

2 4<br />

offset approx. 300<br />

spacings of studs<br />

575 625<br />

600<br />

offset approx. 300<br />

Torro<br />

Torro<br />

624<br />

624<br />

600<br />

turn last CW Stud<br />

624<br />

600<br />

Torro<br />

600<br />

ro ro<br />

Torro Torro<br />

Angle L 13/30/0,8<br />

624<br />

624<br />

600<br />

scheme drawings, all dimensions in mm<br />

600<br />

1<br />

Torro<br />

624<br />

Torro<br />

624<br />

600<br />

Torro Torro<br />

600<br />

624<br />

624<br />

Torro<br />

Torro<br />

600<br />

600<br />

624<br />

624<br />

Torro ro<br />

600<br />

ro<br />

600<br />

600<br />

600<br />

1<br />

1<br />

624<br />

Torro<br />

624<br />

624<br />

Torro<br />

624<br />

600<br />

turn last CW Stud

<strong>Knauf</strong> Security Wall, burglary-retardant<br />

Requirements, Technical Data / Fire Protection / Sound Protection, Specification<br />

W118<br />

Requirements<br />

The <strong>Knauf</strong> Security Wall as burglary-retardant<br />

metal stud partition accomplishes burglar resistance<br />

A according to VdS (association of indemnity<br />

insurers) resp. WK 3 according DIN EN V<br />

1627 to 1630.<br />

For <strong>Knauf</strong> Security Walls a protection of utility<br />

patents (Nr. 29622165.1) does exist.<br />

With triple layer cladding made of <strong>Knauf</strong> Boards<br />

GKF on both sides and two horizontally applied<br />

layers of sheet metal on each side between the<br />

board layers the <strong>Knauf</strong> Security Wall with a<br />

metal stud spacing of 31.25 cm with or without<br />

mineral wool has a fi re protection rate F90 resp.<br />

is classifi ed as fi re wall according to DIN 4102-3<br />

with a permissible partition height of 9 m.<br />

Technical Data / Fire Protection / Sound Protection<br />

W118 <strong>Knauf</strong> Security Wall<br />

Single metal stud frame, triple layer cladding<br />

+ sheet metal layers<br />

Technical Data<br />

dimensions<br />

cladding stud<br />

type / thickness (cavity)<br />

d<br />

mm<br />

h<br />

mm<br />

wall<br />

thickness<br />

D<br />

mm<br />

Sound Insupro-<br />

lation<br />

weight<br />

tection<br />

R w,R<br />

thickness<br />

approx.<br />

kg/m² 1) dB 2) mm 3)<br />

Fire resistance<br />

class<br />

spacing of studs<br />

31.25 cm 31.25 cm<br />

d h d<br />

D<br />

<strong>Knauf</strong> Boards<br />

GKF<br />

3x 12.5<br />

+<br />

sheet metal<br />

layers<br />

2x 0.5 mm<br />

100<br />

177<br />

82 F90 4) 55 80<br />

1) weight without insulation<br />

2) R w,R = calculation value of sound reduction index of the separating construction component according to DIN 4109,<br />

without longitudinal transmission via flanking components<br />

3) insulation according to DIN EN 13162, length related flow resistance according to DIN EN 29053: r 5 kPa s/m² , building material class min. B2<br />

4) insulation: without or mineral wool insulation according to DIN EN 13162 (building material class A)<br />

see also Technical Data Sheet<br />

Sound protection: <strong>Knauf</strong> Test Report Partitions 009<br />

Note W11 <strong>Knauf</strong> Metal Stud Partitions<br />

Proofs<br />

Fire protection: ABP P-3073/0639<br />

Specification<br />

Item Description No. of units Unit price Total price<br />

....... Non-load bearing partition DIN 4103-1/ Fire Wall DIN 4102-3, non-load bearing *,<br />

as metal stud partition, installation zone 1 / 2 *,<br />

height in m ................, thickness 177 mm,<br />

sound reduction index DIN 4109 R w,R<br />

in dB 55, *<br />

thermal transmission coeffi cient according to DIN 4108-2, U value in W/(m²•K) 0.36, *<br />

fi re resistance class according to DIN 4102-2 F90,*<br />

special requirement: burglary-retardant grading A<br />

according to VdS (association of indemnity insurers)/<br />

WK3 according to DIN V EN 1627 to 1630 *.<br />

Perimeter fi xed, triple layer cladding with<br />

<strong>Knauf</strong> Boards GKF/ GKFI/ Diamant GKFI * and 2 layers of sheet metal ≥ 0.5 mm thick on<br />

each side of the partition between the gypsum board layers.<br />

Product/ System: <strong>Knauf</strong> Security Wall W118 .......... m² .......... € .......... €<br />

* Cancel not applicable items Sub-total ................ €<br />

9

<strong>Knauf</strong> Security Wall, burglary-retardant<br />

Construction + Application, Consumption of Material<br />

W118<br />

Construction + Application<br />

<strong>Knauf</strong> Security Walls consist of a single metal<br />

stud frame, and a both side triple layer cladding<br />

of <strong>Knauf</strong> Boards GKF or GKFI impregnated<br />

with sheet metal layers between the gypsum<br />

board layers.<br />

The metal framework is fastened at the entire<br />

perimeter. Insulation material for sound and<br />

thermal insulation can be installed into the metal<br />

frame construction.<br />

Movement joints have to be taken over into the<br />

construction of the partitions. For continuous<br />

partitions use control joints at approx. 15 m.<br />

Apply Acoustical Sealant (two strings) or Sealing<br />

Tape to backside of UW 100 Runners<br />

and CW 100 Studs at perimeter for the connection<br />

of fl anking constructional components and<br />

fasten runners with appropriate dowels:<br />

Ceiling Steel Dowel for reinforced concrete ceilings<br />

and Nailable Plug for masonry.<br />

Spacing of dowels 0.5 m at ceilings, 1 m at walls<br />

(at leats 3 dowels). Install cut to length CW 100<br />

studs into UW runners at a spacing of 31.25 cm,<br />

aligne and fi x with two metal rivets (3 x 8 mm)<br />

each to bottom and top. Install door openings<br />

using UA profi les.<br />

Apply two layers of sheet metal, ≥ 0.5 mm thick,<br />

as plates or coil material on each side horizontally<br />

between board layers. Overlap joints at least<br />

10 cm. Apply vertical joints on studs. Screwing<br />

with Drywall screws only to fasten for installation,<br />

remove while applying the boards.<br />

Cladding<br />

● Cladding preferably with vertically applied<br />

fl oor-to-ceiling <strong>Knauf</strong> boards GKF, triple layer.<br />

● Displace joints.<br />

● No joints at door opening profi les.<br />

● For fire protection requirements fill connection<br />

to floor with filler, for sole sound protection requirements<br />

Acoustical Sealant or acrylate can<br />

be used.<br />

Consumption of Material<br />

Consumption of material per m² partition without allowance for loss and waste.<br />

Amounts refer to partition area of: H= 6 m; L= 10 m; A= 60 m².<br />

description unit amount as average value<br />

italic = not provided by <strong>Knauf</strong><br />

W118<br />

metal stud frame<br />

UW Runner 100x40x0.6; (4 m long)<br />

m<br />

0.3<br />

<strong>Knauf</strong> CW Stud 100x50x0.6<br />

m<br />

3.8<br />

blind metal rivets 3x8 mm (connection CW Stud to UW Runner)<br />

pcs<br />

2.1<br />

<strong>Knauf</strong> Acoustical Sealant; (pouch 550 ml)<br />

pcs<br />

0.1<br />

resp.<br />

<strong>Knauf</strong> Sealing Tape; (30 m roll) 95/3,2 mm<br />

m<br />

0.5<br />

<strong>Knauf</strong> Nailable Plug "K" 6/35; (100 pcs. box)<br />

resp. <strong>Knauf</strong> Nailable Plug "K" 6/50; (100 pcs. box)<br />

(for connections to plastered surfaces)<br />

<strong>Knauf</strong> Ceiling Steel Dowel, (100 pcs. box)<br />

washer Ø 30 mm, t 2 mm pcs 0.8<br />

insulation (see page 9)<br />

.... mm thick<br />

cladding<br />

<strong>Knauf</strong> Fire-Resistant Board GKF / GKFI (impregn.); 12.5 mm<br />

resp. <strong>Knauf</strong> Diamant GKFI (impregn.), 12.5 mm<br />

pcs<br />

pcs<br />

m²<br />

m²<br />

0.3<br />

0.8<br />

as req.<br />

6.0<br />

galvanized sheet metal 0.5 mm thick; (joint overlap 10 cm)<br />

<strong>Knauf</strong> Drywall Screws; (fixing of metal sheets)<br />

TN 3.5 x 35 mm<br />

TN 3.5 x 45 mm<br />

<strong>Knauf</strong> Drywall Screws TN / Diamant Screws HGP; (fastening of cladding)<br />

3.5 x 25 mm / 3.9 x 23 mm<br />

3.5 x 35 mm / 3.9 x 35 mm<br />

3.5 x 55 mm / 3.9 x 55 mm<br />

jointing<br />

resp.<br />

or<br />

or<br />

<strong>Knauf</strong> Uniflott; (5 kg/25 kg bag)<br />

<strong>Knauf</strong> Uniflott impregnated; (5 kg bag)<br />

<strong>Knauf</strong> Jointfiller Super; (20 kg bag)<br />

(for machine filling with Ames machine)<br />

<strong>Knauf</strong> Fugenfüller Leicht; (5 kg/10 kg/25 kg bag)<br />

<strong>Knauf</strong> Joint Tape; (23 m/75 m/150 m roll)<br />

Trenn-Fix 65, self-adhesive; (50 m roll)<br />

Alux Corner Trim width 52 mm; (30 m roll)<br />

m²<br />

pcs<br />

pcs<br />

kg<br />

m<br />

m<br />

m<br />

4.4<br />

4<br />

4<br />

17<br />

23<br />

38<br />

1.1<br />

1.4<br />

1.1<br />

as req.<br />

0.8<br />

as req.<br />

as req. = as required<br />

10

<strong>Knauf</strong> Security Wall, burglary-retardant<br />

Single metal stud frame, triple layer cladding + sheet metal layers<br />

Wall heights<br />

Stud<br />

metal<br />

thickness 0.6 mm<br />

Spacing<br />

of studs<br />

cm<br />

Maximum wall heights<br />

with fire protection<br />

installation zone<br />

1 2<br />

m m<br />

W118<br />

<strong>Knauf</strong> Stud<br />

CW 100<br />

31.25 9<br />

9<br />

Note<br />

The <strong>Knauf</strong> Security Wall meets the<br />

requirements of fire walls as well<br />

Details scale 1:5<br />

Acoustical Sealant<br />

<strong>Knauf</strong> CW Stud<br />

galvanized sheet metal<br />

t 0.5 mm, cladding horizontal<br />

UW Runner<br />

W118-VO1<br />

Connection to ceiling<br />

Trenn-Fix 65<br />

<strong>Knauf</strong> Uniflott<br />

Acoustical Sealant<br />

<strong>Knauf</strong> Ceiling Steel Dowel<br />

a 50 cm<br />

washer Ø 30 mm<br />

t 2 mm<br />

UW Runner 100x40x0.6<br />

connect <strong>Knauf</strong> CW Stud<br />

to UW Runner with<br />

blind metal rivets<br />

galvanized sheet metal<br />

0.5 mm thick<br />

joint overlap 10 cm<br />

cladding horizontal<br />

Drywall Screw TN<br />

Uniflott<br />

W118-A1<br />

Nailable Plug<br />

<strong>Knauf</strong> Uniflott<br />

Trenn-Fix 65<br />

<strong>Knauf</strong> Boards GKF<br />

galvanized sheet metal 0.5 mm thick<br />

cladding horizontal<br />

Connection to solid wall<br />

Drywall Screws TN<br />

<strong>Knauf</strong> CW Stud<br />

<strong>Knauf</strong> Boards GKF<br />

insulation<br />

<strong>Knauf</strong> CW Stud<br />

Uniflott<br />

<strong>Knauf</strong> Boards GKF<br />

W118-VM1<br />

Joint<br />

W118-B1<br />

<strong>Knauf</strong> CW Stud<br />

connect <strong>Knauf</strong> CW Stud<br />

100x50x0.6<br />

to UW Runner with Drywall Screws TN 3.5x55,<br />

blind metal rivets<br />

a = approx. 25 cm<br />

washer Ø 30 mm<br />

t 2 mm<br />

<strong>Knauf</strong> Ceiling Steel Dowel<br />

a 50 cm<br />

Drywall Screw TN<br />

Uniflott<br />

Joint<br />

galvanized<br />

sheet metal<br />

cladding<br />

horizontal<br />

<strong>Knauf</strong> Boards<br />

GKF<br />

<strong>Knauf</strong><br />

CW Stud<br />

Drywall<br />

Screw TN<br />

W118-VU1<br />

Connection to floor<br />

W118-D1<br />

Corner<br />

11

X-Ray Shield Partitions / Furrings<br />

Requirements, Technical Data<br />

K131 / K151<br />

Requirements<br />

Formerly for radiation protective purposes used<br />

heavy concrete constructions in hospitals and<br />

medical practices can nowadays simply, effi -<br />

cient and fl exible be replaced by <strong>Knauf</strong> X-Ray<br />

Shielding Systems with lead sheet laminated<br />

<strong>Knauf</strong> Boards. <strong>Knauf</strong> X-Ray Shielding Systems<br />

can be used in the sector of X-Ray diagnostics<br />

and X-Ray therapy of lower power.<br />

X-Ray radiation protection is provided with<br />

shielding, room enclosing constructions with a<br />

specifi c lead equivalent value of the used materials.<br />

The lead equivalent value as reference parameter<br />

shows the relation between the shielding<br />

effect of the material compared to the equivalent<br />

lead thickness. Therefore the required lead<br />

equivalent value corresponds to the thickness of<br />

the lead sheet, e.g. lead equivalent value 2 = 2<br />

mm lead sheet.<br />

The base of all building related X-Ray radiation<br />

protective actions is the Radiation Protection<br />

Programme, that has to be created by the<br />

manufacturer of the X-Ray devices. Information<br />

about the lead equivalent values of different<br />

building materials is provided in DIN 6812,<br />

table 16. While installing X-Ray shielding constructions<br />

care has to be taken that the shielding<br />

is completely tight.<br />

Technical Data<br />

System<br />

K131 X-Ray Shield Partition<br />

Dimensions<br />

Weight<br />

cladding<br />

stud wall<br />

lead sheet<br />

type thickness CW Stud thickness laminated strips<br />

d CD Channel D<br />

on the board<br />

approx.<br />

mm mm mm<br />

mm mm kg/m² 1)<br />

single metal stud frame - single layer cladding<br />

spacing of studs<br />

62.5 cm<br />

d d<br />

D<br />

<strong>Knauf</strong> Board 50 75 1 0.5<br />

0.5<br />

GKB / GKF<br />

2 1 1<br />

<strong>Knauf</strong><br />

3.5 1.5<br />

12.5 75 100 +<br />

2<br />

X-Ray<br />

4 2<br />

Shield<br />

5.5 2.5<br />

3<br />

GKF<br />

100 125 6 3<br />

31<br />

37<br />

44<br />

50<br />

57<br />

63<br />

K131 X-Ray Shield Partition<br />

single metal stud frame - double layer cladding<br />

spacing of studs<br />

62.5 cm<br />

d<br />

d<br />

D<br />

<strong>Knauf</strong> Board<br />

GKB / GKF<br />

<strong>Knauf</strong><br />

X-Ray<br />

Shield<br />

GKF<br />

50 100 1 0.5<br />

2 1<br />

3.5 1.5<br />

2x 12.5 75 125 +<br />

4 2<br />

5.5 2.5<br />

100 150 6 3<br />

0.5<br />

1<br />

2<br />

3<br />

51<br />

58<br />

65<br />

71<br />

78<br />

83<br />

K151 X-Ray Shield Furring<br />

metal stud frame: fixed directly, single layer cladding<br />

spacing of channels<br />

62.5 cm<br />

d<br />

D<br />

<strong>Knauf</strong><br />

X-Ray<br />

Shield<br />

GKF<br />

12.5<br />

27 > 40 +<br />

1<br />

2<br />

3.5<br />

4<br />

5.5<br />

6<br />

0.5 0.5<br />

1 1<br />

1.5<br />

2<br />

2<br />

2.5<br />

3<br />

3<br />

20<br />

26<br />

33<br />

39<br />

46<br />

52<br />

K151 X-Ray Shield Furring<br />

metal stud frame: fixed directly, double layer cladding<br />

spacing of channels<br />

62.5 cm<br />

d<br />

D<br />

<strong>Knauf</strong> Boards<br />

GKB / GKF<br />

<strong>Knauf</strong><br />

X-Ray<br />

Shield<br />

GKF<br />

2x 12.5<br />

27 > 53<br />

+<br />

1 0.5<br />

2 1<br />

3.5 1.5<br />

4 2<br />

5.5 2.5<br />

6 3<br />

0.5<br />

1<br />

2<br />

3<br />

30<br />

36<br />

43<br />

49<br />

56<br />

62<br />

1) weight without insulation<br />

Calculation example wall thickness D<br />

K131 single layer cladding: <strong>Knauf</strong> Board (12.5 mm) + <strong>Knauf</strong> X-Ray Shield (12.5 mm with laminated<br />

lead sheet 2.5 mm) + lead sheet strip (3 mm) + <strong>Knauf</strong> CW Stud (75 mm): wall thickness D = 105.5 mm<br />

Note<br />

For building physical data (fire protection / sound protection) see Technical Data Sheets W11 "<strong>Knauf</strong> Metal Stud Partitions",<br />

W62 <strong>Knauf</strong> "Furrings and Installation Shaft Walls" resp. Brochure BS1 "Fire Protection with <strong>Knauf</strong>"<br />

12

X-Ray Shield Partitions / Furrings<br />

Construction, Application, Specifications<br />

K131 / K151<br />

Construction<br />

<strong>Knauf</strong> X-Ray Shield Partitions/ Furrings with<br />

metal stud frame are panelled with a single/<br />

double layer cladding made of <strong>Knauf</strong> X-<br />

Ray Shields (fi re-resistant boards wit laminated<br />

lead sheet), <strong>Knauf</strong> Boards GKB resp. GKF.<br />

Application<br />

General<br />

● Apply Acoustical Sealant (two strings) or Sealing<br />

Tape to backside of runners for the connection<br />

of fl anking constructional components.<br />

For sound protection requirements<br />

seal up carefully with acoustical sealant according<br />

to DIN 4109, supplement 1, chapter<br />

5.2; porous sealant strips like Sealing<br />

Tape are usually not suitable in this case.<br />

● Fix perimeter runners and studs with suitable<br />

dowels to fl anking components. Spacing of<br />

dowels 1 m with at least 3 fi xing points at walls.<br />

Anchors for solid fl anking components: Nailable<br />

Plug/ non-solid fl anking components:<br />

Specifications<br />

The metal stud framework is fi xed at the perimeter.<br />

Insulation material as well as electric builtins<br />

can be installed into the metal frame construction.<br />

The laminated lead sheet does not affect<br />

the effectiveness of the fire resistance of<br />

anchors have to be permitted and standardized<br />

for the building material being used.<br />

Partition: Fasten UW Runners to floor and ceiling.<br />

Connection to wall with CW Stud. Install CW<br />

studs into UW runners and align.<br />

Furring: Fasten perimeter runners UD 28x27 to<br />

floor, walls and ceiling. Install CD 60x27 Channels<br />

into UD Runners and align.<br />

● Fasten Universal Bracket to existing wall with<br />

a vertical spacing of ≤ 1 m.<br />

● To avoid sound bridges install Sealing Tape<br />

below Universal Bracket or use <strong>Knauf</strong> Damping<br />

Universal Bracket. Fastening to CD Channels<br />

with LN 3.5 x 9 mm.<br />

the partitions.<br />

Movement joints have to be taken over into the<br />

construction of the X-Ray Shield Partitions and<br />

Furrings. For continuous partitions use control<br />

joints at approx. 15 m.<br />

Cladding<br />

● Affix lead sheet strips to studs and perimeter<br />

runners.<br />

● Cladding preferably with vertically applied<br />

fl oor-to-ceiling <strong>Knauf</strong> Boards.<br />

● If not using fl oor-to-ceiling <strong>Knauf</strong> Boards displace<br />

horizontal joints by min. 400 mm and<br />

back with lead sheet strips.<br />

● No joints at door opening profi les.<br />

Item Description No. of units Unit price Total price<br />

........ Non-load bearing partition DIN 4103-1 as metal stud partition, installation zone 1 / 2 *,<br />

height in m ................, thickness in mm .................,<br />

sound reduction index DIN 4109 R w,R<br />

in dB ..............., *<br />

fi re resistance class according to DIN 4102-2 F30/ F60/ F90 *, *<br />

X-Ray radiation protective, lead equivalent value in mm Pb .................,<br />

perimeter fi xed, single/ double * layer cladding<br />

with <strong>Knauf</strong> Boards GKB 12.5 mm/ GKBI 12.5 mm/ GKF 12.5 mm/ GKFI 12.5 mm/<br />

X-Ray Shields GKF 12. 5 mm *.<br />

Product/ System: <strong>Knauf</strong> X-Ray Shield Partition K131 .......... m² .......... € .......... €<br />

........ Furring DIN 4103 - 1, installation zone 1 / 2 *,<br />

height in m ................, thickness in mm .................,<br />

sound reduction index DIN 4109 R w,R<br />

in dB ..............., *<br />

in connection with existing wall, weight per unit area in kg/ m² ...................., *<br />

X-Ray radiation protective, lead equivalent value in mm Pb .................,<br />

perimeter fi xed, single/ double * layer cladding<br />

with <strong>Knauf</strong> Boards GKB 12.5 mm/ GKBI 12.5 mm/ GKF 12.5 mm/ GKFI 12.5 mm/<br />

X-Ray Shields GKF 12. 5 mm *.<br />

Product/ System: <strong>Knauf</strong> X-Ray Shield Furring K151 .......... m² .......... € .......... €<br />

........ Connection, sliding up to 20 mm, to ceiling/ to wall *,<br />

as upgrade to partition, installation according to drawing no. ............... . .......... m .......... € .......... €<br />

........ X-Ray Shielding cap for 1/ 2/ 3 * hollowboxes.<br />

Product/ System: <strong>Knauf</strong> X-Ray Shielding Caps .......... pcs .......... € .......... €<br />

........ Door opening with lintel, sidewise enforced from fl oor to ceiling,<br />

with metal studs UA/ CW * 50/ 75/ 100 *, incl. connections to fl oor and ceiling,<br />

with door frame bracket, fastened with dowels and screws.<br />

X-Ray radiation protective, lead equivalent value in mm Pb .................,<br />

basic dimensions B/H in mm .............................., wall thickness in mm ........... . .......... pcs .......... € .......... €<br />

........ Glazing opening with lintel and parapet profi le,<br />

sidewise enforced from fl oor to ceiling with metal studs UA/ CW * 50/ 75/ 100 *,<br />

incl. connections to fl oor and ceiling,<br />

with door frame bracket, fastened with dowels and screws.<br />

X-Ray radiation protective, lead equivalent value in mm Pb .................,<br />

basic dimensions B/H in mm .............................., wall thickness in mm ........... . .......... pcs .......... € .......... €<br />

* Cancel not applicable items Sub-total ................ €<br />

13

<strong>Knauf</strong> X-Ray Shield Partitions<br />

Single metal stud frame, single / double layer cladding<br />

Wall heights<br />

Stud<br />

metal<br />

thickness 0.6 mm<br />

alowable heights of metal stud partitions according to DIN 18183<br />

Spacing<br />

of studs<br />

cm<br />

Maximum wall heights<br />

single layer cl. double layer cl.<br />

installation zone (definition see page 23)<br />

1 2 1 2<br />

m m m m<br />

K131<br />

<strong>Knauf</strong> Stud<br />

CW 50<br />

62.5<br />

3<br />

2.75<br />

4<br />

3.5<br />

<strong>Knauf</strong> Stud<br />

CW 75<br />

62.5<br />

4.5 3.75<br />

5.5<br />

5<br />

<strong>Knauf</strong> Stud<br />

CW 100<br />

62.5 5 4.25<br />

6.5<br />

5.75<br />

double layer cladding<br />

Details scale 1:5<br />

Trenn-Fix 65<br />

<strong>Knauf</strong> Uniflott<br />

Acoustical Sealant<br />

Nailable Plug<br />

lead sheet strip<br />

UW Runner<br />

<strong>Knauf</strong> CW Stud<br />

Nailable Plug<br />

Acoustical Sealant<br />

<strong>Knauf</strong> CW Stud<br />

<strong>Knauf</strong> X-Ray Shield<br />

lead sheet strip<br />

<strong>Knauf</strong> Uniflott + Trenn-Fix 65<br />

Drywall Screw<br />

TN 3.5x25<br />

<strong>Knauf</strong> Board<br />

<strong>Knauf</strong> X-Ray Shield<br />

<strong>Knauf</strong> Uniflott<br />

<strong>Knauf</strong> CW Stud<br />

UW Runner<br />

lead sheet strip<br />

Drywall Screw<br />

TN 3.5x35<br />

K131-VO1<br />

Connection to ceiling<br />

K131-A1<br />

Connection to<br />

solid wall<br />

K131-B1<br />

Joint<br />

K131-VM3<br />

Uniflott +<br />

Trenn-Fix 65<br />

back joint with<br />

runner + lead sheet strip<br />

<strong>Knauf</strong> X-Ray Shield<br />

lead sheet strip<br />

<strong>Knauf</strong> CW Stud<br />

cavity dowel<br />

<strong>Knauf</strong> X-Ray Shield<br />

UW Runner<br />

<strong>Knauf</strong> Board<br />

e.g. insulation<br />

Drywall Screw TN<br />

<strong>Knauf</strong> X-Ray Shield<br />

Joint K131-D1 T-connection K131-E1<br />

Corner<br />

<strong>Knauf</strong> CW Stud<br />

<strong>Knauf</strong> X-Ray Shield<br />

lead sheet strip<br />

UW Runner<br />

Drywall Screw<br />

TN 3.5x35<br />

Uniflott<br />

hollowbox<br />

X-Ray Shielding Cap<br />

<strong>Knauf</strong> X-Ray Shield<br />

<br />

a 10 20<br />

a<br />

a<br />

K131-VU1<br />

Connection to floor<br />

K131-C1<br />

Hollowbox<br />

14<br />

Notes<br />

Affix lead sheet strips to all <strong>Knauf</strong> CW Studs and UW Runners<br />

self-adhesive lead sheet strip, 50 mm wide<br />

thickness similar to laminated lead sheet of <strong>Knauf</strong> X-Ray Shields (see page 12)<br />

with fire protection a = 10-20 mm<br />

without fire protection a = 10-30 mm<br />

K131-VO3<br />

Deflection<br />

head

<strong>Knauf</strong> X-Ray Shield Furrings<br />

Metal stud frame: fixed directly, single / double layer cladding<br />

Wall heights<br />

maximum allowable wall height 10 m<br />

K151<br />

Universal Bracket<br />

for CD 60x27<br />

CD Channel 60x27<br />

120 / 200<br />

60<br />

Cut or bend Universal Bracket regarding to required cavity<br />

Note<br />

Details scale 1:5<br />

Affix lead sheet strips to all <strong>Knauf</strong> CW Studs & UW Runners<br />

self-adhesive lead sheet strip, 50 mm wide, thickness similar to<br />

laminated lead sheet of <strong>Knauf</strong> X-Ray Shields (see page 12)<br />

double layer cladding<br />

spacing of Universal Brackets 1000 mm<br />

K151-VO1<br />

Trenn-Fix 65<br />

<strong>Knauf</strong> Uniflott<br />

Nailable Plug<br />

lead sheet strip<br />

UD Runner 28x27<br />

Acoustical Sealant<br />

CD Channel 60x27<br />

X-Ray Shield<br />

<strong>Knauf</strong> Board<br />

Connection to<br />

ceiling<br />

insulation<br />

<strong>Knauf</strong> Board<br />

CD Channel 60x27<br />

Universal Bracket<br />

fastened to<br />

CD Channel with Metal<br />

Screws LN 3.5x9 mm<br />

Drywall Screw<br />

TN 3.5x45<br />

<strong>Knauf</strong> X-Ray Shield<br />

Uniflott<br />

CD Channel 60x27<br />

Metal Screw<br />

LN 3.5x9 mm<br />

UD Runner 28x27<br />

CD Channel 60x27<br />

piece of Sealing Tape<br />

Nailable Plug<br />

Univ. Bracket<br />

K151-A1 Inside corner<br />

K151-B1 Outside corner<br />

CD Channel 60x27<br />

Drywall Screw<br />

TN 3.5x35<br />

UD Runner 28x27<br />

lead sheet strip<br />

<strong>Knauf</strong> X-Ray Shield<br />

Uniflott + Trenn-Fix 65<br />

K151-VM1<br />

Wall attachment<br />

K151-C1<br />

Connection to X-Ray<br />

Shield Partition K131<br />

K151-E1<br />

Connection to<br />

solid wall<br />

<strong>Knauf</strong> X-Ray Shield<br />

CD Channel 60x27<br />

<strong>Knauf</strong> X-Ray Shield<br />

CD Channel 60x27<br />

UD Runner 28x27<br />

lead sheet strip<br />

Acoustical Sealant<br />

Nailable Plug<br />

Uniflott<br />

X-Ray Shielding Cap<br />

insulation<br />

Drywall Screw<br />

TN 3.5x35<br />

hollowbox<br />

48<br />

100<br />

234<br />

308<br />

380<br />

Fastening with Drywall Screws TN 3.5x35<br />

K151-VU1<br />

Connection to floor<br />

K151-VM2<br />

Hollowbox<br />

X-Ray Shielding Caps for hollowboxes<br />

15

X-Ray Shield Partitions / Furrings<br />

Door and Window Openings<br />

Horizontal sections<br />

K131 / K151<br />

italic = not provided by <strong>Knauf</strong><br />

e.g. W111<br />

X-Ray Shielding door frame<br />

X-Ray Shielding door panel<br />

Door Frame Bracket<br />

UA Profile 2 mm<br />

wall opening width Drywall Screw TB 3.5x45<br />

Drywall Screw TB 3.5x35<br />

K131-SO-H1<br />

Door opening and T-Connection<br />

lead sheet strip<br />

<strong>Knauf</strong> X-Ray Shield<br />

<strong>Knauf</strong> Board<br />

X-Ray Shielding window frame<br />

Door Frame Bracket<br />

<strong>Knauf</strong> CW Stud, floor to ceiling<br />

Drywall Screw TN 3.5x35<br />

Drywall Screw TN 3.5x45<br />

K131-SO-H2<br />

Vertical sections<br />

max. 1000 mm<br />

width of window pane<br />

Window opening with CW Stud<br />

pane size up to 0.6 m²<br />

K131-SO-H3<br />

Door Frame Bracket<br />

UA Profile 2 mm, from floor to ceiling<br />

Drywall Screw TB 3.5x35<br />

Drywall Screw TB 3.5x45<br />

Window opening with UA Profile<br />

pane size over 0.6 m²<br />

<strong>Knauf</strong> X-Ray Shield<br />

UW Runner (change)<br />

lead sheet strip<br />

<strong>Knauf</strong> Board<br />

<strong>Knauf</strong> X-Ray Shield<br />

30<br />

X-Ray Shielding door frame<br />

X-Ray Shielding door panel<br />

lead sheet strip<br />

UW Runner (change)<br />

X-Ray Shielding window frame<br />

lead glass pane<br />

e.g. light opening<br />

e.g. F145<br />

K131-SO-V1<br />

Door opening<br />

K131-SO-V2<br />

Window opening<br />

16<br />

Notes<br />

Affix lead sheet strips to all <strong>Knauf</strong> CW Studs and UW Runners<br />

Depending on opening frame type and installation conditions UW Runners are necessary.

X-Ray Shield Partitions / Furrings<br />

Material Requirements<br />

K131 / K151<br />

Consumption of material per m² partition / furring without allowance for loss and waste.<br />

Amounts refer to an area of: H=2.6 m; L=4 m; A=10.4 m².<br />

description unit amount as average value<br />

K131<br />

thickness of cladding in mm<br />

italic = not provided by <strong>Knauf</strong><br />

12.5 2x 12.5<br />

metal stud frame<br />

UW Runner 50x40x0.6; (4 m long)<br />

resp. UW Runner 75x40x0.6; (4 m long)<br />

resp.<br />

UW Runner 100x40x0.6; (4 m long)<br />

<strong>Knauf</strong> CW Stud 50x50x0.6<br />

resp.<br />

<strong>Knauf</strong> CW Stud 75x50x0.6<br />

resp.<br />

<strong>Knauf</strong> CW Stud 100x50x0.6<br />

UD Runner 28x27x0.6; (3 m long)<br />

CD Channel 60x27x0.6<br />

Universal Bracket for CD 60x27<br />

Metal Screw LN 3.5x9 mm<br />

pieces of Sealing Tape 70/3.2 mm, 75 mm long; (30 m roll)<br />

or<br />

<strong>Knauf</strong> Acoustical Sealant; (550 ml pouch)<br />

<strong>Knauf</strong> Sealing Tape; (30 m roll)<br />

30/3.2 mm<br />

resp.<br />

50/3.2 mm<br />

resp.<br />

70/3.2 mm<br />

resp.<br />

95/3.2 mm<br />

<strong>Knauf</strong> Nailable Plug "K" 6/35; (100 pcs. box)<br />

resp.<br />

<strong>Knauf</strong> Nailable Plug "K" 6/50; (100 pcs. box)<br />

(for connections to plastered surfaces)<br />

insulation .... mm thick m²<br />

cladding<br />

lead sheet strip, self-adhesive, 50 mm wide; (20 m roll)<br />

0.5 mm thick<br />

resp.<br />

1 mm thick<br />

resp.<br />

2 mm thick<br />

resp.<br />

3 mm thick<br />

<strong>Knauf</strong> X-Ray Shield; 12.5 mm<br />

625 mm wide; 2000/2600 mm long<br />

laminated lead sheet weight approx. kg/m²<br />

0.5 mm thick 16<br />

resp.<br />

1 mm thick 21.6<br />

resp.<br />

1,5 mm thick 27.3<br />

resp.<br />

2 mm thick 33<br />

resp. 2,5 mm thick 38.6<br />

resp. 3 mm thick 44.3<br />

<strong>Knauf</strong> Board GKB; 12.5 mm<br />

resp.<br />

<strong>Knauf</strong> Fire Resistant Board GKF; 12.5 mm<br />

<strong>Knauf</strong> Drywall Screw; (fastening of cladding)<br />

TN 3.5 x 25 mm<br />

TN 3.5 x 35 mm<br />

TN 3.5 x 45 mm<br />

jointing<br />

<strong>Knauf</strong> Uniflott; (5 kg/25 kg bag)<br />

<strong>Knauf</strong> Joint Tape; (23 m/75 m/150 m roll)<br />

Trenn-Fix 65, self-adhesive; (50 m roll)<br />

Edge Trim 23/15; (2.75 m long)<br />

Corner Trim 31/31; (2.6 m/3 m long)<br />

Alux Corner Trim width 52 mm; (30 m roll)<br />

m<br />

m<br />

m<br />

m<br />

pcs<br />

pcs<br />

m<br />

pcs<br />

m<br />

pcs<br />

m<br />

m²<br />

m²<br />

pcs<br />

kg<br />

m<br />

m<br />

m<br />

m<br />

m<br />

0.8<br />

2<br />

- -<br />

- -<br />

- -<br />

- -<br />

- -<br />

0.3<br />

0.8<br />

2<br />

- -<br />

1.3<br />

1.7<br />

as req.<br />

1<br />

1 3<br />

14<br />

17<br />

-<br />

0.6<br />

0.3<br />

1.3<br />

1.7<br />

as req.<br />

7<br />

22<br />

14<br />

0.9<br />

as req. as req.<br />

1.8 1.8<br />

as req.<br />

1<br />

as req.<br />

K151<br />

thickness of cladding in mm<br />

12.5 2x 12.5<br />

- -<br />

- -<br />

- -<br />

- -<br />

- -<br />

- -<br />

0.8<br />

2<br />

1.5<br />

0.8<br />

2<br />

1.5<br />

3 3<br />

0.1 0.1<br />

0.2 0.2<br />

0.8 0.8<br />

- -<br />

- -<br />

- -<br />

2.5<br />

as req.<br />

2.5<br />

as req.<br />

2.7 2.7<br />

2.7 2.7<br />

1<br />

1<br />

- 1<br />

- -<br />

-<br />

17<br />

-<br />

0.3<br />

as req.<br />

as req.<br />

as req.<br />

-<br />

8<br />

14<br />

0.5<br />

as req.<br />

as req.<br />

as req.<br />

as req.= as required<br />

Note<br />

Given values are without certain sound protection or fire protection requirements.<br />

17

<strong>Knauf</strong> X-Ray Shield Ceilings<br />

Height of Construction, Dimensioning of Substructure<br />

K111 / K112<br />

K111<br />

<strong>Knauf</strong> X-Ray Shield Ceiling<br />

with wood frame<br />

K112<br />

<strong>Knauf</strong> X-Ray Shield Ceiling<br />

with metal grid<br />

Height of construction = sum of suspension height and / or height of grid and cladding thickness<br />

System<br />

K111<br />

wood<br />

frame<br />

K112<br />

metal<br />

grid<br />

Calculation example<br />

Suspension<br />

with Nonius Hanger Top<br />

mind. mm<br />

mind. mm<br />

mind. mm<br />

Nonius Nonius Hanger Combo Universal<br />

Stirrup Bottom Hanger Bracket<br />

- - -<br />

- - -<br />

- 130 130<br />

130 130 130<br />

up to 180<br />

up to 180<br />

mm<br />

Substructure<br />

mm<br />

mm<br />

lath / channel<br />

b x h<br />

total<br />

height<br />

mm<br />

50x30 30<br />

50x30 + 50x30 60<br />

60x27<br />

60x27 + 60x27<br />

K112 with Nonius Hanger Bottom (130 mm), lower and upper channel (54 mm) and cladding (12.5 mm <strong>Knauf</strong> Board + 1 mm<br />

laminated lead sheet) and 1 mm lead sheet strip = 198.5 mm, approx. 200 mm required height of construction<br />

27<br />

54<br />

Cladding<br />

gypsum board<br />

+<br />

lead sheet<br />

mm<br />

12,5 +<br />

mm<br />

1 0.5<br />

2 1<br />

3.5 1.5<br />

4 2<br />

5.5 2.5<br />

6 3<br />

lamination<br />

on the board<br />

strip<br />

mm<br />

0.5<br />

1<br />

2<br />

3<br />

Dimensioning of substructure<br />

1. Termination of the weight of the<br />

ceiling lining / suspended ceiling<br />

depending on lead sheet lamination<br />

Depending on the lead sheet lamination +<br />

<strong>Knauf</strong> Board 12.5 mm, the weight per unit area<br />

of the ceiling lining / suspended ceiling including<br />

substructure can be taken from the y axis.<br />

Load class [ kN/m² ]<br />

(load per unit area)<br />

0.50 < p 0.65 *)<br />

[ kg/m² ] Weight of ceiling<br />

y<br />

65<br />

60<br />

<strong>Knauf</strong> Board 12.5 mm<br />

55<br />

with 3 mm lead sheet<br />

18<br />

2. Consideration of extra loads<br />

Extra loads from insulation (max. 0,05 kN/m²<br />

= 5 kg/m²) increase the total weight of the<br />

ceiling lining / suspended ceiling and should be<br />

taken into account for the load class determination.<br />

The determined weigth from thew 1st step has to be<br />

increased by the value of the extra load in the<br />

direction of the y axis (upwards).<br />

3. Determination of the load class<br />

With the resulting total weight per unit area of<br />

the ceiling lining / suspended ceiling from steps 1<br />

and 2 the load class can be determined.<br />

4. Dimensioning the substructure<br />

The following spacings of the substructure result from<br />

the load class / load per unit area:<br />

a c<br />

0.30 < p 0.50<br />

0.15 < p 0.30<br />

0.15<br />

*) design of ceilings<br />

0,50 kN/m² as well<br />

acc. to DIN 18168<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

11,5<br />

<strong>Knauf</strong> Board 12.5 mm<br />

with 2.5 mm lead sheet<br />

<strong>Knauf</strong> Board 12.5 mm<br />

with 2 mm lead sheet<br />

<strong>Knauf</strong> Board 12.5 mm<br />

with 1.5 mm lead sheet<br />

<strong>Knauf</strong> Board 12.5 mm<br />

with 1 mm lead sheet<br />

<strong>Knauf</strong> Board 12.5 mm<br />

with 0.5 mm lead sheet<br />

x

<strong>Knauf</strong> X-Ray Shield Ceilings<br />

Construction, Application, Specifications<br />

K111 / K112<br />

Construction<br />

<strong>Knauf</strong> X-Ray Shield Ceilings are fastened to the<br />

basic cielings as ceiling lining or suspended ceiling<br />

with Universal Bracket or Nonius Suspension.<br />

<strong>Knauf</strong> X-Ray Shields (<strong>Knauf</strong> Boards GKF lead<br />

sheet laminated backsides, 625 mm wide and<br />

2000 mm/ 2600 mm long) are fastened to a<br />

wooden frame made of upper and lower laths<br />

(K111) or to a metal grid made of upper and lower<br />

channels (K112). Fire protection requirements<br />

can not be fulfi lled with <strong>Knauf</strong> X-Ray Shield ceiling<br />

linings or suspended ceilings.<br />

Movement joints have to be taken over into the<br />

construction of the suspended ceilings. Use control<br />

joints in the case of ceiling areas over approx.<br />

15 m length, or for narrow ceiling spaces caused<br />

by a break of a wall.<br />

Application<br />

Substructure<br />

● Suspension on basic ceilings with Universal<br />

Bracket, Combo Hanger, Nonius Stirrup or<br />

Nonius Hanger. Fastening to wooden ceilings:<br />

<strong>Knauf</strong> fl at headed screw FN 5.1 x 35 mm; to reinforced<br />

concrete ceilings: <strong>Knauf</strong> Ceiling Steel<br />

Dowel (mounted in accordance with Construction<br />

Supervisory Permit no. Z-21.1-1519); other<br />

building materials: anchors have to be permitted<br />

and standardized for the building material<br />

being used.<br />

● For spacings of screws, laths and channels see<br />

tables K111/ K112.<br />

Specifications<br />

● Connect upper laths/ channels to suspenders<br />

and aligne.<br />

● Connection of upper to lower lath (K111): <strong>Knauf</strong><br />

Drywall Screw with coarse thread TN 4.3 x 55<br />

mm, upper to lower channel (K112): CD Intersection<br />

Connector or Ankerwinkel Clip.<br />

● Affi x lead sheet strip to lower laths/ channels.<br />

Cladding<br />

● Apply X-Ray Shields parrallel to lower laths<br />

(K111) resp. lower channels (K112).<br />

● Displace cut edge joints at least 400 mm and<br />

back with lead sheet strips.<br />

● Start fastening <strong>Knauf</strong> X-Ray Shields either in<br />

the middle or at a corner in order to prevent<br />

upsetting deformation. Press boards fi rmly on<br />

to lath / channel during screw attachment.<br />

● Fastening of X-Ray Shields to wood frame<br />

(K111) with Drywall Screws TN 3.5 x 45 mm, to<br />

metal grid (K112) with Drywall Screws TN 3.5 x<br />

35 mm, with a spacing of 150 mm.<br />

Item Description No. of units Unit price Total price<br />

........ Ceiling lining DIN 18168-1, installation height in m ..............,<br />

X-Ray radiation protective, lead equivalent value in mm Pb .................,<br />

anchored on reinforced concrete/ wooden beams *, spacing in cm ............./<br />

steel girder, type ................, spacing in cm ....................., *<br />

substructure as wood frame with laths 50 x 30 mm<br />

single/ double * layer cladding, with <strong>Knauf</strong> X-Ray Shields GKF 12.5 mm/<br />

<strong>Knauf</strong> Boards GKB 12.5 mm/ GKBI 12.5 mm *.<br />

Product/ System: <strong>Knauf</strong> X-Ray Shield Ceiling K111 .......... m² .......... € .......... €<br />

........ Ceiling lining/ Suspended ceiling * DIN 18168-1,<br />

installation height in m .............., suspension height in cm ....................,*<br />

X-Ray radiation protective, lead equivalent value in mm Pb .................,<br />

anchored on reinforced concrete/ wooden beams *, spacing in cm ............./<br />

steel girder, type ................, spacing in cm ....................., *<br />

substructure as metal grid CD 60x27,<br />

single/ double * layer cladding, with <strong>Knauf</strong> X-Ray Shields GKF 12.5 mm/<br />

<strong>Knauf</strong> Boards GKB 12.5 mm/ GKBI 12.5 mm *.<br />

Product/ System: <strong>Knauf</strong> X-Ray Shield Ceiling K112 .......... m² .......... € .......... €<br />

........ Connection to wall as joint/ with UD Runner *, sliding/ fi xed *,<br />

for ceiling lining/ suspended ceiling *,<br />

circumferential, installation according to drawing no. ............... . .......... m .......... € .......... €<br />

* Cancel not applicable items Sub-total ................ €<br />

Note<br />

see also Technical Data Sheet D11 <strong>Knauf</strong> Suspended Ceilings<br />

19

<strong>Knauf</strong> X-Ray Shield Ceiling<br />

Wood frame<br />

max. spacings<br />

Lower and upper lath<br />

50x30 mm (bxh)<br />

centers of sus-<br />

penders (fasteners)<br />

a<br />

area load kN/m²<br />

0.30 0.56<br />

750<br />

600<br />

*)<br />

approx.<br />

250<br />

a<br />

K111<br />

ca.<br />

150<br />

spacing of<br />

upper lath<br />

c<br />

spacing of<br />

lower lath<br />

b<br />

*) see page 18 as well<br />

Details scale 1:5<br />

750 600<br />

312.5<br />

all dimensions in mm<br />

ca.<br />

100<br />

b<br />

b<br />

c<br />

Uniflott +<br />

Trenn-Fix 65<br />

ca. 150 mm<br />

Universal Bracket for<br />

wood lath, bend or<br />

cut as required and<br />

fasten to upper lath using<br />

<strong>Knauf</strong> Drywall Screws<br />

TN 3.5x25<br />

<strong>Knauf</strong> Ceiling Steel Dowel<br />

(for concrete ceilings)<br />

lower lath 50x30<br />

<strong>Knauf</strong> Drywall<br />

Screw TN 4.3x55<br />

lath as<br />

installation<br />

aid optional<br />

ca. 100 mm<br />

Universal Bracket<br />

upper lath 50x30<br />

lower lath 50x30<br />

lead sheet strip<br />

<strong>Knauf</strong> X-Ray Shield<br />

K111-A2<br />

Connection to wall<br />

with dry lining<br />

K111-D1<br />

Connection to wall<br />

fastening with fastener<br />

approved for respective<br />

building material<br />

lead sheet strip<br />

Uniflott + Joint Tape<br />

Drywall Screw<br />

TN 3.5x45<br />

upper lath 50x30<br />

lower lath 50x30<br />

<strong>Knauf</strong> Drywall<br />

Screw TN 4.3x55<br />

<strong>Knauf</strong> X-Ray Shield<br />

<strong>Knauf</strong> X-Ray Shield<br />

lead sheet strip<br />

Drywall Screw<br />

TN 3.5x45<br />

Uniflott<br />

upper lath 50x30<br />

lower lath 50x30<br />

<strong>Knauf</strong> Drywall<br />

Screw TN 4.3x55<br />

K111-B1<br />

Cut edge joint<br />

K111-C1<br />

Longitudinal edge joint<br />

Notes<br />

Affix lead sheet strips on all lower laths<br />

Back cut edge joints<br />

Self adhesive lead sheet strip, 50 mm wide<br />

thickness similar to laminated lead sheet of <strong>Knauf</strong> X-Ray Shields (see page 18)<br />

Apply <strong>Knauf</strong> X-Ray Shields lengthwise<br />

Allowed suspenders / fasteners<br />

Universal Bracket for wood laths 50x30 mm; 0.40 kN<br />

approved fasteners<br />

lath connections lower lath to 50x30 upper lath 50x30<br />

<strong>Knauf</strong> Drywall Screws TN 4.3x55 according to<br />

"General Building Supervisory Permit" no. Z-9.1-251<br />

20

<strong>Knauf</strong> X-Ray Shield Ceiling<br />

Metal grid<br />

max. spacings<br />

lower and upper<br />

channel CD 60x27<br />

area load kN/m²<br />

0.30 0.56<br />

*)<br />

ca. 250<br />

a<br />

K112<br />

centers of suspenders<br />

(fasteners)<br />

a<br />

750<br />

600<br />

ca.<br />

150<br />

spacing of<br />

upper channel<br />

c<br />

spacing of<br />

lower channel<br />

b<br />

*) see page 18 as well<br />

Details scale 1:5<br />

1000 750<br />

312.5<br />

all dimensions in mm<br />

ca.<br />

100<br />

b<br />

b<br />

c<br />

UD Runner<br />

as installation<br />

aid optional<br />

Uniflott +<br />

Trenn-Fix 65<br />

ca. 150 mm<br />

<strong>Knauf</strong> Ceiling Steel Dowel<br />

(for concrete ceilings)<br />

CD Intersection Connector or<br />

Ankerwinkel Clip for CD 60x27<br />

lower channel CD 60x27<br />

Universal Bracket for<br />

CD 60x27, bend or<br />

cut as required and<br />

fasten to upper channel<br />

using Metal Screws<br />

LN 3.5x9 mm<br />

K112-A1 Connection to wall K112-D1<br />

ca. 100 mm<br />

<strong>Knauf</strong> X-Ray Shield<br />

Uniflott + Trenn-Fix 65<br />

Connection to<br />

X-Ray Shield Furring<br />

Nonius Pin<br />

(secure against<br />

sliding out)<br />

Nonius Hanger Top<br />

(for total load of<br />

ceiling 40 kN/m²<br />

screw to upper channels<br />

with Metal Screws<br />

LN 3.5x9 mm)<br />

lead sheet strip<br />

Uniflott + Joint Tape<br />

Drywall Screw<br />

TN 3.5x35<br />

upper channel CD 60x27<br />

lower channel CD 60x27<br />

CD Intersection Connector or<br />

Ankerwinkel Clip for CD 60x27<br />

<strong>Knauf</strong> X-Ray Shield<br />

<strong>Knauf</strong> X-Ray Shield<br />

lead sheet strip<br />

Drywall Screw<br />

TN 3.5x35<br />

<strong>Knauf</strong> Uniflott<br />

upper channel CD 60x27<br />

lower channel CD 60x27<br />

CD Intersection Connector or<br />

Ankerwinkel Clip for CD 60x27<br />

K112-B1<br />

Cut edge joint<br />

K112-C1<br />

Longitudinal edge joint<br />

Notes<br />

Affix lead sheet strips on all lower channels<br />

Back cut edge joints<br />

Self adhesive lead sheet strip, 50 mm wide<br />

thickness similar to laminated lead sheet of <strong>Knauf</strong> X-Ray Shields (see page 18)<br />

Apply <strong>Knauf</strong> X-Ray Shields lengthwise<br />

Allowed suspenders<br />

Universal Bracket for CD 60x27; 0.40 kN<br />

Nonius Stirrup for CD 60x27 + Nonius Hanger Top 0.40 kN<br />

Nonius Hanger Bottom + Top 0.40 KN<br />

Combo Hanger + Nonius Hanger Top 0.40 KN<br />

Channel connections lower channel to upper channel CD 60x27<br />

CD Intersection Connector for CD 60x27<br />

Ankerwinkel Clip for CD 60x27<br />

21

<strong>Knauf</strong> X-Ray Shield Ceilings<br />

Consumption of Material<br />

K111 / K112<br />

Consumption of material per m² ceiling without allowance for loss and waste. Amounts refer to ceiling area of: 10 m x 10 m = 100 m²<br />

description<br />

unit amount as average value<br />

K111<br />

K112<br />

italic = not provided by <strong>Knauf</strong><br />

1 2<br />

3 4<br />

connection to wall<br />

(as installation aid)<br />

e.g. wood lath or UD Runner 28x27x0.6<br />

fastener appopriate for substrate<br />