Knauf Free-Spanning Ceiling D131

Knauf Free-Spanning Ceiling D131

Knauf Free-Spanning Ceiling D131

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

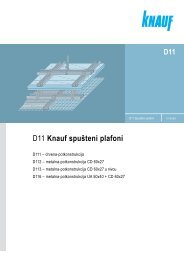

<strong>Knauf</strong> <strong>Free</strong>-<strong>Spanning</strong> <strong>Ceiling</strong><br />

Construction and application, jointing, surface treatment<br />

<strong>D131</strong><br />

Construction<br />

<strong>Knauf</strong> <strong>Free</strong>-<strong>Spanning</strong> <strong>Ceiling</strong>s are solely fastened<br />

to the walls at perimeter. <strong>Knauf</strong> Boards<br />

GKB/ GKBI impregnated, Fire-Resistant Boards<br />

GKF/ GKFI or LaVita Shielding Boards are<br />

screwed to a metal grid made of <strong>Knauf</strong> CW profi<br />

les as single or double profi les.<br />

The application of additional loads like lighting fi x-<br />

tures with max. 100 N (10 kg) per double profi le<br />

and exposed ceilings like e.g. D127 <strong>Knauf</strong> Apertura<br />

Acoustical <strong>Ceiling</strong> with load per unit area of<br />

Application<br />

Metal Grid<br />

● Perimeter connection to walls with UW runners.<br />

Fastening according to table page 3 at<br />

centers of ≤ 625 mm.<br />

● For sound protection requirements seal up<br />

carefully with acoustical sealant according to<br />

DIN 4109, supplement 1, chapter 5.2; porous<br />

sealant strips like Sealing Tape are usually not<br />

suitable in this case.<br />

● CW profi les as double profi les are screwed at<br />

web with metal screws LB 3.5 x 9.5 mm at<br />

max. 750 mm centers.<br />

● Support of CW profi les in UW runners ≥ 30<br />

mm. Crimp, screw or rivet upper fl anges of<br />

CW profi les and UW runners to each other if<br />

no covering strip is necessary.<br />

Jointing / Surface Treatment<br />

Jointing<br />

For higher optical quality requirements like occuring<br />

streak of light, <strong>Knauf</strong> boards with 4-AK<br />

edges are the ideal basis for a perfect jointing<br />

with joint tape, <strong>Knauf</strong> Fugenfüller Leicht or Readygips.<br />

With 4-AK Boards the usual displacement<br />

of cut edges of at least 400 mm can be replaced<br />

by the much more effective cross joint<br />

application and jointing.<br />

Filling Material<br />

Fill joints with <strong>Knauf</strong> Uniflott without using tape.<br />

If using tape, hand fill with <strong>Knauf</strong> Fugenfüller<br />

Leicht or with Ames Machine and <strong>Knauf</strong> Jointfiller-Super.<br />

<strong>Knauf</strong> Unifl ott impregnated is additionally water-repellent<br />

and fi ts to the color of impregnated<br />

<strong>Knauf</strong> Boards. Use <strong>Knauf</strong> Finish-Pastös for the<br />

fi nal fi lling coat as fi ne skimming before sanding<br />

the joints.<br />

Application<br />

For double layer cladding, fill joints of first layer,<br />

smooth joints of second layer. Cover all screw<br />

heads as well.<br />

Recommendation: Fill and tape cut edges of<br />

visible layers no matter which filling material is<br />

used.<br />

<strong>Knauf</strong> Spezialgrund as primer for skimming of<br />

entire ceiling surface to regulate the behavior of<br />

soaking and to improve the optical conformity is<br />

15 kg/m² resp. max. single load of 100 N with<br />

suitable anchors directly to the metal grid is permissible.<br />

Joints of free-spanning channels are<br />

not allowed! Settlement joints have to be taken<br />

over into the construction of the free-spanning<br />

ceilings. Use control joints in the case of ceiling<br />

areas over approx. 15 m length, or for narrow<br />

ceiling spaces caused by a break of a wall.<br />

Separate connections of boards to components<br />

made of a different building material,<br />

Cladding<br />

● Screw <strong>Knauf</strong> Board Strips GKF, 25 mm thick,<br />

as covering strips on upper fl anges of CW<br />

profi les with Drywall Screws TN 3.5 x 35 mm<br />

at max. 250 mm centers, on CW double profi<br />

les alternating.<br />

● Apply <strong>Knauf</strong> Boards lateral to CW profi les.<br />

● Displace cut edge joints at least 400 mm while<br />

placing them on profi les. If using 4AK Boards<br />

(4-side taperd egdes) cross joints are allowed<br />

in connection with fi lling with joint tape.<br />

● Start fastening of <strong>Knauf</strong> boards either in the<br />

middle or at a corner in order to prevent upsetting<br />

deformation. Press boards fi rmly on to<br />

the grid and screw with Drywall Screws TN at<br />

170 mm centers alternating to CW profi les.<br />

a system component to create of surfaces with<br />

higher quality standards according to data sheet<br />

no. 2 „Verspachtelung von Gipsplatten - Oberfl<br />

ächengüten“ of the IGG.<br />

Application temperature/ climate<br />

Filling and covering of joints should only take<br />

place after the boards have been allowed to rest<br />

in the given humidity and temperature zones,<br />

and no more longitudinal changes can be expected,<br />

i.e. expansion or contraction. Joints<br />

should be filled at a minimum temperature of<br />

10°C. In case of mastic asphalt screed, fill in<br />

joints after screed has been applied.<br />

Surface Treatment<br />

Use a primer on <strong>Knauf</strong> Boards before coating or<br />

painting them. Ensure that the primer and the<br />

coat or paint are compatible.<br />

After wallpapering of paper and fi ber glass wallpapers<br />

and the application of resin / cellulose<br />

plasters quick drying must be assured through<br />

adequate airing. The following coats can be<br />

used to cover <strong>Knauf</strong> Boards:<br />

● Wall Papers: paper-, textile and synthetic wall<br />

papers. Use only adhesives made of cellulose<br />

according to „Merkblatt Nr. 16, Technische<br />

Richtlinien für Tapezier- und Klebearbeiten“,<br />

Frankfurt/Main 2002, released by Bundesausschuss<br />

Farbe und Sachwertschutz.<br />

especially columns, or thermical highly stressed<br />

built-ins like lighting fi xtures, for instance with<br />

control joints.<br />

<strong>Knauf</strong> profi les are delivered galvanized. The corrosion<br />

protective coating is suffi cient for indoor<br />

application, including bathrooms and kitchens in<br />

private housing. For other areas, e.g. under infl<br />

uence of outdoor air, additional corrosion protection<br />

is necessary (see DIN 18168-1 table 2).<br />

● Screwing of boards, 12.5 mm thick, with Drywall<br />

Screws TN 3.5 x 25 mm; 18 or 25 mm →<br />

TN 3.5 x 35 mm; 2 x 12.5 mm → TN 3.5 x 25<br />

mm + TN 3.5 x 35 mm.<br />

● With double layer cladding centers of screws<br />

of fi rst layer can be extended to max. 500 mm<br />

if the second layer is applied subsequently<br />

(within one working day).<br />

● Use separation strip Trenn-Fix 65 and fi ller<br />

or acrylate for connections to other components.<br />

<strong>Ceiling</strong> below ceiling<br />

Application according to instructions on page 7.<br />

● Plasters: <strong>Knauf</strong> structured plasters, e.g. re sin<br />

plasters, thin plasters, entire area smoothing<br />

like e.g. <strong>Knauf</strong> Board-Finish, mineral plasters<br />

in connection with paper taped jointing.<br />

● Coats: Washable and abrasion-proof emulsion<br />

paint, multicolored (rainbow) emulsion,<br />

oil paint, matte-fi nish lacquer, alkyd resin<br />

paint, polymer resin paint, PUR lacquer, or epoxybased<br />

lacquer, according to intended use<br />

or as required.<br />

● Alkaline coats such as lime, water glass colors<br />

and silicate-based paints are unsuitable<br />

for gypsum board surfaces. Silicate-based<br />

emulsion paints may be used after referring to<br />

the manufacturer’s recommendations and following<br />

the stipulated guidelines closely.<br />

Gypsum board surfaces that have constantly<br />

been exposed to light without any protection can<br />

develop yellowing agents that show up despite<br />

a coat of paint. Therefore a trial coat is recommended<br />

that will extend across several boards<br />

including all joints. Yellowing can, however, be<br />

successfully avoided only by using a special<br />

shielding primer.<br />

<strong>Knauf</strong> Direkt Technical Information Service: Phone +49 18 05 / 31-10 00, Fax +49 18 05 / 31-40 00<br />

<strong>Knauf</strong> websites: www.knauf.de, www.knauf.com e-Mail: knauf-direkt@knauf.de<br />

<strong>Knauf</strong> Headquarters, Am Bahnhof 7, D-97346 Iphofen, Phone +49 93 23 / 31-0, Facsimile +49 93 23 / 31-277<br />

12<br />

© All technical changes reserved. Only the current printed instructions are valid. Our warranty is expressly limited to our products in flawless condition. All application quantities and delivery amounts are based on empirical data that is not easily transferable to<br />

other deviating areas. All rights reserved. All amendments, reprints and photocopies, including those of excerpts, require the express permission of <strong>Knauf</strong> Gips KG, Am Bahnhof 7, 97346 Iphofen, Germany.<br />

Edition: June 2005<br />

<strong>D131</strong> / engl. / D / 06.05 / FB / D