nanovea.com TRIBOMETERS | Wear Friction Tribology

nanovea.com TRIBOMETERS | Wear Friction Tribology

nanovea.com TRIBOMETERS | Wear Friction Tribology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TRIBOMETERS</strong> | <strong>Wear</strong> <strong>Friction</strong> <strong>Tribology</strong><br />

<strong>nanovea</strong>.<strong>com</strong>

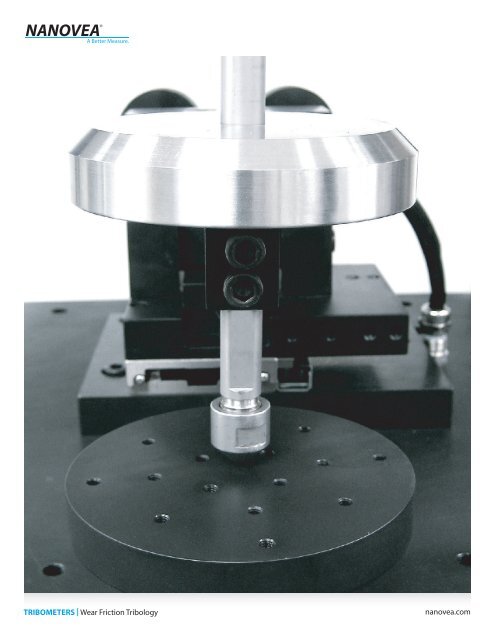

TRIBOMETER INTRO<br />

The Nanovea Tribometer (Table Top 60 x 39 x 62 cm) offers precise and repeatable wear and<br />

friction testing using pin-on-disk and linear modes. Designed, at the core, with a high quality<br />

motor and a 20bit position encoder, the Tribometer provides access to an unmatched range of<br />

rotational speeds from 0.01 to 2000rpm. High resolution means that data can be accurately<br />

recorded at specified interval of time or position (>0.006°). The motor has an integrated selftuning<br />

system which ensures that speed remains calibrated through time. Full and precise control<br />

of the motor ensures that a series of step speeds can be run continuously during the tests.<br />

For wear measurement, weight loss can be measured using a sensitive weight scale before<br />

and after the test. Furthermore, an LVDT can be attached to the measuring arm to record<br />

depth during the test. This gives the possibility to follow the change of wear rate versus time.<br />

<strong>Friction</strong> force is measured directly with a stiff load cell which offers high resolution with<br />

excellent mechanical and thermal stability;<br />

unlike other systems that rely only on LVDT for<br />

friction measurement. A ball, pin or flat holder is attached to the measuring arm which can be precisely<br />

positioned to a resolution of 2.5micron using the standard motorized table. Several testing options are<br />

available to closely match real environment conditions. The Tribometer <strong>com</strong>es standard with an acrylic<br />

enclosure and attached valves which brings inert and other gases to achieve a controlled environment. An<br />

optional humidifier and dehumidifier module allows precise control of the humidity levels. For high<br />

temperature pin on disk, up to 900°C, an oven allows control to better than 1°C. A linear heating plate is<br />

used for reciprocating test up to 300°C. Various cups are available for controlled liquid testing. Tests can<br />

either be done under full immersion or using the Lubrication system with drop by drop or control spray. A<br />

liquid heating module is also available to provide controlled liquid heating up to 150°C. To precisely measure wear track volume, a full 3D non-contact<br />

optical profiler, installed on the Tribometer platform, is available to quantify wear loss in a fast and convenient way without removing the sample. The<br />

Tribometer software uses this information and the test parameters to calculate a precise wear rate for the specific test. The profiler, which has extended<br />

capability, can also be used for surface topography measurements including roughness. A Flexible mobile imaging option allows zoom-in ability to record<br />

the sample surface for playback review.<br />

TRIBOMETER TESTING<br />

Pin-on-Disk (ASTM G99) | Pin-on-Disk operates on the following principle: a flat, pin or ball is loaded<br />

onto a test sample with a precisely known weight and at a specific position from the center to create a<br />

circular wear track as the bottom plate rotates. The friction coefficient is determined during the test by<br />

measuring the deflection of the direct load cell. <strong>Wear</strong> rates for the pin and the disk are calculated from the<br />

volume of material lost during the test.<br />

Linear Reciprocating (ASTM G133) | The Linear Module<br />

reproduces the reciprocating motion typical in many real-world<br />

mechanisms. The instrument produces a friction coefficient for both the forward and backward movements<br />

of the stroke. This reciprocating technique is very useful for studying the static coefficient of friction over<br />

time, as opposed to the kinetic coefficient measured with the Pin-on-Disk wear testing geometry. The<br />

software allows change of friction at any specific point along one lap to be plotted versus time.<br />

CONTROLLED ENVIRONMENT TESTING<br />

Humidity Control System | A standard acrylic enclosure makes it possible to use specific salt baths to create various humid atmospheres. A full<br />

humidity control system is available for applications requiring a higher level of control. This advanced option includes a dehumidification and<br />

humidification apparatus in addition to the automatic humidity controller with sensor.

CONTROLLED ENVIRONMENT TESTING<br />

Pin-on-Disk High Temperature (Up to 900°C) | Analysis of friction & wear properties at elevated<br />

temperatures is be<strong>com</strong>ing increasingly important, as engineers face ever more challenging materials in<br />

applications such as the design of advanced fuel efficient <strong>com</strong>bustion engines and power plants. The High<br />

Temperature removable heating element enables the rotating disk to reach temperatures up to 900°C; suitable<br />

for use in the study of high temperature ceramics, lubricants, oils, additives and self-lubricating materials. Two<br />

level of oven are available, one for temperature up to 600°C and one for elevated temperatures up to 900°C. A<br />

thermocouple measures temperature directly on the ball or in the oven close to the sample surface. This is<br />

more accurate than measuring remotely from under the sample or close to the heating element.<br />

Linear High Temperature (Up to 300°C) | Available for wear & friction testing of in-situ conditions, in a<br />

range of deposition technologies. This range is also ideal to study polymers just under their melting point.<br />

Temperatures near 37°C are suitable for bio material studies of wear and friction properties under bodily<br />

fluid, such as those found in artificial joint applications.<br />

Lubrication Systems | An advanced Lubrication system makes it possible for drop-by-drop or controlled<br />

spray testing on the surface surface. Specialized cups with spill protection features are available for<br />

submerged testing.<br />

Liquid Heating Module (Up to 150°C) | A heating coil is available to control liquid temperature up to 150°C. This allows temperatures near 37°C<br />

which are suitable for bio material studies of wear and friction properties under bodily fluid, such as those found in artificial joint applications. This range of<br />

temperatures is also ideal for the study of lubrications such as oils.<br />

ENHANCED TESTING<br />

Electrical Resistance Contact Detector | To extend the capability of the Tribometer, an electrical rotative connector can be installed at the base of<br />

the motor to provide electrical contact to the rotating sample under test. There are multiple uses such as measuring the change in resistance during wear<br />

of an insulator coating to a conductive substrate or to connect a device under test to detect the exact moment when the device fails under wear testing.<br />

An additional area of use includes measuring corrosion with wear using a specific corrosion cell, electrodes and potentiostat.<br />

TRIBOMETER OPTICS<br />

3D Optical Profiler | To precisely measure the wear track with 2D and 3D, a full non-contact optical profiler<br />

can be integrated on the Tribometer platform. This advanced feature provides measurement of volume while<br />

software uses the information and the test parameters to calculate a precise wear rate for the specific test. The<br />

profiler, which has extended capability, can also be used for roughness, dimensions and many other surface<br />

topography studies. The optical profiler has zero influence from sample reflectivity, variations require no<br />

sample preparation and has advanced ability to measure high surface angles. Unlike other optical<br />

techniques, Nanovea optical profiler provides ability to measure any material, whether transparent,<br />

opaque, specular, diffusive, polished or rough. Large pen selection for varying dynamic vertical<br />

measurements. Excellent vertical and spatial resolution. The superior availability to surface topography measurement during tribological study is ideal<br />

for determining the correlation between surface characteristics and wear and friction results.<br />

Digital Mobile Imaging | The flexible mobile zoom imaging capture can be moved by hand to<br />

conveniently allow zoom-in microscope capability while recording for play back review. This feature is<br />

especially useful for later review of surface wear during actual testing. Zoom from 5x to 200x is available.

TRIBOMETER SOFTWARE<br />

Tribometer <strong>Wear</strong>/<strong>Friction</strong> Software | Includes a <strong>com</strong>plete set of features for installing the<br />

Tribometer and analyzing wear and friction data: <strong>Wear</strong> rate calculation of ball and sample and quickly<br />

exportable in CSV format for Excel. Easily filters data, graph manipulations, test parameters &<br />

information editing. Additional options include: Note saving, Real-time display of coefficient of friction,<br />

temperature, depth and pin-substrate electrical contact, Macros test running single sample at multiple<br />

speeds. Automated motorized radial positioning, High temperature furnace control and ON-OFF<br />

lubrication control. Coefficient of friction safety monitor with automatic shut off at friction threshold.<br />

3D Mechanical Software | The 3D Mechanical Software is a <strong>com</strong>plete software package for<br />

scanning using the integrated non-contact profiling sensor. After a test, the wear testing arm is lifted<br />

automatically with and removed from the measuring area. User friendly ability to scan specified areas<br />

of interest or a single profile. Creates 3D representation of the scan. Quick analysis of roughness, critical<br />

dimensions, topography and full pre and post test area profile. Zoom Functions. Data export in ASCII<br />

format & Mountain analysis software. Analyze surface distance and height. Allows user to <strong>com</strong>pare scan<br />

with optical microscope observation.<br />

TRIBOMETER APPLICATIONS<br />

Nanovea Tribometers provide superior wear and friction testing, at Micro through Macro range, for <strong>Tribology</strong> study in industries including:<br />

Automotive, Tooling, Coatings, Metallurgy, Biomedical, Aerospace, Petroleum, Cosmetics and many others.

TRIBOMETER SPECS<br />

PIN-ON-DISK MODULE<br />

Maximum Load<br />

Normal Force (Weights)<br />

Load Resolution<br />

Rotational Speed<br />

Maximum Torque<br />

<strong>Friction</strong> Force Maximum<br />

<strong>Friction</strong> Resolution (noise floor)<br />

X Motorized table for radius <strong>com</strong>puter controlled<br />

Maximum speed of X radius Motorized Table<br />

Resolution of X radius position<br />

Instrument Dimension (Table Top)<br />

Weight Approx.<br />

Disk Size<br />

LINEAR RECIPROCATING MODULE<br />

Linear Speed<br />

Stroke Length (Amplitude)<br />

Frequency at full stroke<br />

Frequency maximum<br />

LVDT DEPTH MODULE<br />

Maximum Displacement<br />

Resolution (Noise Floor)<br />

PIN-ON-DISK HIGH TEMPERATURE<br />

Maximum Temperature<br />

Oven Size<br />

LINEAR HIGH TEMPERATURE<br />

Maximum Temperature<br />

LUBRICATION CUPS<br />

Linear Cup Inner Size<br />

Pin-on-Disk Cup Inner Size<br />

LUBRICATION SYSTEM<br />

Pulverization Module - Liquid Consumption<br />

Drop Count Reservoir<br />

LIQUID HEATING MODULE<br />

Maximum Temperature<br />

ELECTRICAL RESISTANCE CONTACT DETECTOR<br />

Maximum resistance<br />

3D OPTICAL PROFILER MODULE<br />

X-Y range<br />

Height Range<br />

Height Resolution<br />

Lateral Resolution<br />

DIGITAL MOBILE IMAGING<br />

Resolution<br />

Magnification<br />

40N<br />

(1) 1N, (2) 2N,(1) 5N, (1) 10N, (1) 20N<br />

30mN<br />

0.01 to 2000 rpm<br />

1270mN.m<br />

20N<br />

0.4mN<br />

50mm<br />

0 to 5mm/s<br />

2.5μm<br />

60 x 39 x 62 cm<br />

67kg<br />

100mm<br />

Up to 140mm/s<br />

0 to 35mm Adjustable<br />

2Hz<br />

40Hz<br />

1 mm<br />

0.1μm<br />

600°C or 900°C +/-1°C<br />

Diam. 250mm x 70mm<br />

300°C +/-1°C<br />

54x90x30<br />

100x30mm<br />

60 - 90 cm3/hour<br />

120ml<br />

150°C +/-1°C<br />

0 to 1000Ohms<br />

50mmx50mm<br />

100 μm<br />

14nm<br />

3micron<br />

1.3 Megapixel (1280x1024 res)<br />

10~70x,~230x<br />

*Specifications may change, please contact Nanovea for clarification.

Today's Standard For Tomorrow's Materials<br />

Nanovea is the result of over 20 years experience providing professional solutions<br />

and experienced service throughout the fields of nano/micro/macro profilometry,<br />

mechanical, tribology, imaging and other related fields of materials research & development<br />

industries. After years of client feedback and the dedication to providing superior instrumental<br />

solutions, Nanovea was launched in 2004 as a privately held California corporation.<br />

From the Irvine, CA office Nanovea designs and manufactures Profilometers, Mechanical Testers &<br />

Tribometers to <strong>com</strong>bine the most advanced testing capabilities in the industry: Scratch Adhesion,<br />

Indentation Hardness, <strong>Wear</strong> <strong>Friction</strong> & 3D Non-Contact Metrology at Nano, Micro & Macro range.<br />

Unlike other manufactures Nanovea also provides Laboratory Services, offering clients availability to<br />

the latest technology and optimal results through improvements in material testing standards.<br />

<strong>nanovea</strong>.<strong>com</strong>