Mine to Market - July 2008 - Ernest Henry Mining

Mine to Market - July 2008 - Ernest Henry Mining

Mine to Market - July 2008 - Ernest Henry Mining

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

mine<strong>to</strong>market<br />

ISSUE 87 : JULY <strong>2008</strong><br />

Nathan Fisher wins Apprentice of the Year award<br />

Record month for diamond drilling team<br />

Meet our first female ERT captain<br />

Introduction <strong>to</strong> the Copper Refinery Labora<strong>to</strong>ry

2 : mine <strong>to</strong> market<br />

Steve de Kruijff<br />

WELCOME<br />

It is pleasing <strong>to</strong> see so many of our young workforce excelling in their chosen<br />

careers. Congratulations are extended <strong>to</strong> George Fisher <strong>Mine</strong>’s Nathan Fisher for<br />

achieving Mount Isa’s Apprentice of the Year award and Bowen Coke Work’s<br />

Daniel Morris who was named Most Outstanding First Year Electrical and<br />

Refrigeration Apprentice 2007. It is important <strong>to</strong> grow and develop our future<br />

leaders as we work <strong>to</strong>gether <strong>to</strong> build sustainable platforms for future generations.<br />

On page nine, read about the success of Mount Isa <strong>Mine</strong>’s Diamond Drilling and<br />

Raiseboring teams who achieved record production figures during the month of<br />

May. Congratulations <strong>to</strong> all involved.<br />

We are also pleased <strong>to</strong> announce that Stage 2 of the Leichhardt River Remediation<br />

Project was completed on Friday 13 June. Well done <strong>to</strong> all involved in the project<br />

including Xstrata employees, contrac<strong>to</strong>rs, security staff, and Mount Isa City<br />

Council who completed the project without incident and ahead of schedule.<br />

In particular, thank you <strong>to</strong> our Environment Department for their outstanding<br />

efforts in coordinating and overseeing the project. More information on the<br />

project is available on page three.<br />

We look forward <strong>to</strong> supporting the NAIDOC week celebrations this month as well<br />

as the 50 th Isa Rodeo in August.<br />

We also look forward <strong>to</strong> continued success in all areas of our operations,<br />

remaining focused on our goal of zero harm during the second half of this year.<br />

STEVE DE KRUIJFF<br />

KEVIN HENDRY<br />

CHIEF OPERATING OFFICER<br />

EXECUTIVE GENERAL MANAGER<br />

Xstrata Copper North Queensland<br />

Xstrata Zinc Mount Isa<br />

Kevin Hendry<br />

30%<br />

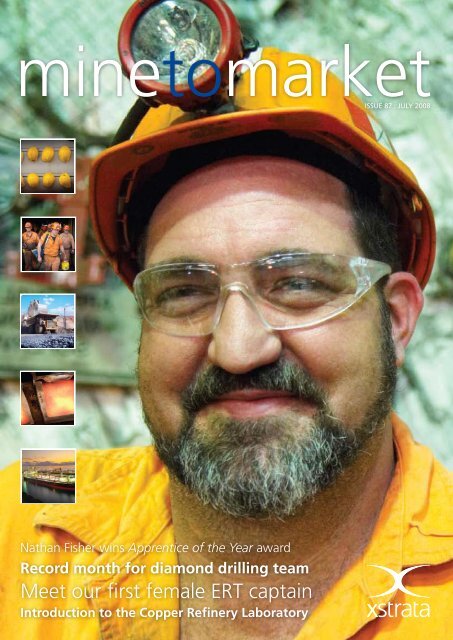

FRONT COVER<br />

Tim Silver, Boilermaker,<br />

Mount Isa Copper Operations (MICO)<br />

CONTACT THE EDITOR<br />

Input from all Xstrata North Queensland operations<br />

is invited. Any articles, innovations, achievements,<br />

ideas or suggestions are very welcome. Please contact<br />

Catherine Peters, Community Relations, Mount Isa <strong>Mine</strong>s<br />

on email: cpeters@xstratacopper.com.au<br />

or phone: 4744 3140.<br />

XSTRATA STOCK PRICE<br />

Xstrata is listed on the London and Zurich<br />

s<strong>to</strong>ck exchanges. As at 18 June <strong>2008</strong> the<br />

Xstrata share price on the London S<strong>to</strong>ck<br />

Exchange (XTA.L) was 42.32 (GBp).<br />

Price (p)<br />

Volume (m)<br />

4,250<br />

4,000<br />

3,750<br />

3,500<br />

3,250<br />

20<br />

10<br />

0<br />

Jan-<strong>2008</strong> Mar-<strong>2008</strong> May-<strong>2008</strong><br />

25%<br />

20%<br />

15%<br />

10%<br />

5%<br />

0%<br />

-5%<br />

-10%<br />

Xstrata PLC<br />

Percentage<br />

Date

ISSUE 87 : 3<br />

Leichhardt River Remediation<br />

Project complete<br />

Xstrata Mount Isa <strong>Mine</strong>s safely completed Stage 2 of the<br />

Leichhardt River Remediation Project on Friday 13 June,<br />

removing 120,000 <strong>to</strong>nnes of his<strong>to</strong>rical mine sediment material<br />

from the Leichhardt River and disposing it on the Mount Isa<br />

<strong>Mine</strong>s lease.<br />

Ed Turley, Environment Manager Xstrata Copper North<br />

Queensland, said that the final work was completed on Friday<br />

last week without incident and ahead of schedule.<br />

“Full credit is extended <strong>to</strong> all those involved in this project,<br />

including Xstrata employees, earth moving and plumbing<br />

contrac<strong>to</strong>rs, security staff, and Mount Isa City Council<br />

employees, who all helped <strong>to</strong> ensure that the Stage 2 works<br />

were completed safely and on time,” said Ed.<br />

The purpose of the Leichhardt River project was <strong>to</strong> identify and<br />

remove his<strong>to</strong>rical mine sediments from the riverbed which have<br />

been exposed over time as a result of natural erosion within the<br />

river system. The Stage 2 works involved 252 hours of operation<br />

over 24 days.<br />

“During the next six weeks, we will undertake grid sampling of<br />

the entire Stage 2 area of work within the Leichhardt River, and<br />

repeat this process following the <strong>2008</strong>/09 wet season <strong>to</strong> help<br />

ensure and verify that all exposed his<strong>to</strong>rical mine sediment has<br />

been removed,” said Ed.<br />

“Follow-up sampling will then be conducted post-wet season<br />

on an annual basis through <strong>to</strong> 2011 <strong>to</strong> ensure that river flows<br />

and natural erosion do not uncover any additional mine<br />

sediments,” he said<br />

“In addition <strong>to</strong> completing the project, we are in the process of<br />

revegetating and beautifying a vacant block of land at the end<br />

of Sunflower Street that was used by the trucks <strong>to</strong> access the<br />

river bed,” said Ed<br />

The Facts<br />

The project was completed safely and on time<br />

70,000 cubic metres (120,000 <strong>to</strong>nnes) of his<strong>to</strong>rical mine<br />

sediment was removed<br />

3,894 trips were made from the Leichhardt River bed <strong>to</strong><br />

Gardenia Gate <strong>to</strong> dispose of the material safely on the<br />

Mount Isa <strong>Mine</strong>s lease<br />

10.3 million litres of water from the mine was used for<br />

dust suppression<br />

His<strong>to</strong>rical mine sediment was replaced with<br />

approximately 15,000 cubic metres (25,000 <strong>to</strong>nnes)<br />

of clean fill from our quarry<br />

There were no exceedances on the dust or noise<br />

moni<strong>to</strong>rs registered during the project<br />

All operational areas within the Leichhardt River bed<br />

were graded on completion of the project

4 : mine <strong>to</strong> market<br />

Aurora Xstrata Commissioned<br />

Local boaties will be happy following<br />

the recent launch of the Townsville Flotilla<br />

of the Australian Volunteer Coastguards’<br />

new inshore rescue boat, one of the best<br />

and most modern in Australia.<br />

Funded through Xstrata’s Community<br />

Partnership Program North Queensland,<br />

the Aurora Xstrata <strong>to</strong>ok <strong>to</strong> the sea<br />

following a Naming and Commissioning<br />

Ceremony.<br />

Erin Jensen, the eight year old daughter of<br />

CRL employee, Steve Jensen, did the<br />

honours after winning a competition for<br />

children of Xstrata employees in Townsville<br />

<strong>to</strong> name the boat.<br />

As the Aurora Xstrata slipped quietly from<br />

its Airdock mooring, Erin <strong>to</strong>ok pride of<br />

place as the first passenger, guided by<br />

Geoff Jackson and Bob Virtue of QF8<br />

Erin Jensen drives the Aurora Xstrata under<br />

the watchful eyes of the Coast Guard<br />

volunteers Geoff Jackson and Bob Virtue.<br />

An Introduction <strong>to</strong> the Copper Refinery’s Labora<strong>to</strong>ry<br />

The labora<strong>to</strong>ry is an integral part of<br />

the Townsville Copper Refinery’s<br />

(CRL) operation. The first labora<strong>to</strong>ry<br />

building (southern) was constructed<br />

at the time the refinery was built and<br />

began operation in 1959. The second<br />

(northern) wing of the labora<strong>to</strong>ry<br />

followed in the mid 1960s with<br />

the decision <strong>to</strong> purchase the first<br />

mass spectrometer. At the peak of<br />

operations, 15 chemists, assayers, and<br />

labora<strong>to</strong>ry technicians were employed<br />

in the labora<strong>to</strong>ry.<br />

Today, the ISO 9001 accredited<br />

labora<strong>to</strong>ry is staffed by a team of three<br />

labora<strong>to</strong>ry analysts – Marcia Bacon,<br />

Geoff Douthett and Scott Foster – who<br />

perform all refinery sample analysis and<br />

required services including:<br />

analysis of process solutions<br />

and effluents <strong>to</strong> moni<strong>to</strong>r plant<br />

operations and ensure statu<strong>to</strong>ry<br />

compliance;<br />

preparation and analysis of anode<br />

samples (CRL and Mount Isa <strong>Mine</strong>s)<br />

<strong>to</strong> ensure compliance with elemental<br />

composition requirements;<br />

preparation and analysis of samples<br />

from all cathode produced <strong>to</strong> ensure<br />

quality compliance and <strong>to</strong> enable<br />

assay report generation;<br />

Analyst, Scott Foster, loading a sample in<br />

the Glow Discharge Mass Spectrometer.<br />

preparation and analysis of anode<br />

slimes samples <strong>to</strong> enable shipment<br />

assay report generation; and<br />

provision of technical support <strong>to</strong><br />

plant operations and project work.<br />

The team routinely processes 1,000<br />

samples per month, performing over<br />

8,000 analyses on these samples. This<br />

high throughput is achieved by using<br />

highly au<strong>to</strong>mated instruments that<br />

have replaced classical wet chemical<br />

techniques. Instruments used include:<br />

Inductively Coupled Plasma Emission<br />

Spectrometer (ICP) – used <strong>to</strong> analyse<br />

process solutions and solutions<br />

prepared from process solids;<br />

Optical Emission Spectrometer (OES)<br />

– used <strong>to</strong> all analyse cathode and<br />

anode samples;<br />

Glow Discharge Mass Spectrometer<br />

(GDMS) – used <strong>to</strong> analyse trace<br />

components in cathode samples.<br />

Last year, the labora<strong>to</strong>ry re-commenced<br />

providing contract cathode copper<br />

analytical services <strong>to</strong> domestic and<br />

overseas cus<strong>to</strong>mers. Currently there<br />

are four domestic and two overseas<br />

cus<strong>to</strong>mers – Oman and Myanmar –<br />

who are sending an average of<br />

80 cathode samples per month<br />

for analysis.<br />

The income generated from this service<br />

is ensuring labora<strong>to</strong>ry operations are<br />

more cost effective with improved<br />

utilisation of specialist equipment.<br />

Thank you Keith Lowrey for your<br />

contribution

ISSUE 87 : 5<br />

Analyst, Marcia Bacon, performing a volumetric titration.<br />

“The labora<strong>to</strong>ry team routinely<br />

processes 1,000 samples<br />

per month, performing over<br />

8,000 analyses on these samples.”

6 : mine <strong>to</strong> market<br />

Mount Isa Apprentice of the Year<br />

bound for Canberra forum<br />

Last month the Mount Isa Group<br />

Apprenticeship, Traineeship and<br />

Employment group (MIGATE) announced<br />

Nathan Fisher, a third year apprentice<br />

based at George Fisher <strong>Mine</strong>, as their<br />

Mount Isa Apprentice of the Year<br />

As the Apprentice of the Year, Nathan<br />

was then selected <strong>to</strong> be a finalist <strong>to</strong><br />

represent Queensland at the Today’s<br />

Skills Tomorrow’s Leaders Forum, <strong>to</strong> be<br />

held in Canberra next month. The forum<br />

is designed for apprentices who excel in<br />

their traineeship and apprenticeship skills<br />

and will be the next generation of<br />

industry leaders.<br />

“The selection process involved a<br />

telephone interview with an independent<br />

judging panel. Then a few days later I<br />

found out I was chosen <strong>to</strong> be the<br />

Queensland representative at the<br />

Today’s Skills Tomorrow’s Leaders<br />

Forum,” said Nathan.<br />

Xstrata Zinc Maintenance and Support<br />

Manager, Tony Ross, was involved in the<br />

nomination process. “I would like <strong>to</strong> pass<br />

on my congratulations <strong>to</strong> Nathan on<br />

winning the MIGATE Apprentice of the<br />

Year, and also on being chosen <strong>to</strong><br />

represent Queensland at the Canberra<br />

forum,” said Tony. “Nathan is an<br />

exceptional Au<strong>to</strong> Electrical Apprentice for<br />

our Mobile Maintenance Department at<br />

George Fisher <strong>Mine</strong>. He exhibits a mature<br />

disposition and has strong desires <strong>to</strong><br />

achieve the most from his chosen<br />

career,” he said.<br />

As an apprentice at George Fisher <strong>Mine</strong>,<br />

Nathan works on the remote controls for<br />

underground au<strong>to</strong>mation such as the<br />

<strong>Mine</strong>Gem and Line of Site remotes.<br />

Nathan’s role involves maintaining<br />

underground au<strong>to</strong>mation equipment,<br />

fault-finding, diagnosing issues and<br />

improving the remote control operations<br />

of underground equipment. He also<br />

works on machinery lighting systems,<br />

starting and charging systems,<br />

two-way radio systems and reverse<br />

camera systems.<br />

Nathan has thanked his colleagues at<br />

George Fisher <strong>Mine</strong>. “I couldn’t have<br />

done it without Andy Watson and<br />

Cyril Murphy’s help <strong>to</strong> give me the extra<br />

exposure <strong>to</strong> other mining equipment<br />

<strong>to</strong> help me gain more experience,”<br />

said Nathan.<br />

Today’s Skills Tomorrow’s Leaders Forum<br />

will be launched by the Governor-<br />

General at Government House in<br />

Canberra. Led by Lifestyle Strategist,<br />

Ian Hutchinson, the forum will guide<br />

participants <strong>to</strong> create an informed vision<br />

for their future and a realistic action plan<br />

<strong>to</strong> achieve their goals.<br />

“Nathan is a great asset <strong>to</strong> George Fisher<br />

<strong>Mine</strong> and will make a good ambassador<br />

for both Xstrata Zinc and MIGATE,”<br />

said Tony.<br />

In addition <strong>to</strong> his apprenticeship, Nathan<br />

also competed at the World Trade Skills<br />

in 2007 which is an assignment based<br />

competition <strong>to</strong> test apprentices’ skills.<br />

The World Trade Skills program,<br />

organised by WorldSkills Australia,<br />

promotes trade and skill excellence<br />

through competitions across Australia<br />

and around the globe for those who<br />

want <strong>to</strong> be the best in their field<br />

Andrew Watson (left), Acting Superintendent Mobile Maintenance, and Phil Sharam (right),<br />

George Fisher <strong>Mine</strong> Maintenance Manager, with Nathan Fisher Apprentice of the Year.

ISSUE 87 : 7<br />

First female captain<br />

for Xstrata Copper<br />

A proud Nicole King prepares <strong>to</strong> lead<br />

EHM’s ERT team as Xstrata North<br />

Queensland’s first female captain.<br />

Congratulations <strong>to</strong> <strong>Ernest</strong> <strong>Henry</strong> <strong>Mining</strong>’s Community<br />

Relations Officer, Nicole King, who was recently chosen<br />

<strong>to</strong> lead EHM’s Emergency Response Team at the QRC<br />

<strong>Mine</strong>s Rescue Challenge.<br />

Nicole, who has been involved with emergency response<br />

and competitions for the last three years, is the first<br />

female captain from Xstrata Copper’s North Queensland<br />

Division <strong>to</strong> compete at this event. The QRC <strong>Mine</strong>s Rescue<br />

Challenge was held at Dairy Farmers Stadium in<br />

Townsville on 20-22 June.<br />

We look forward <strong>to</strong> reporting Nicole’s team and the<br />

Mount Isa <strong>Mine</strong>s team’s performance in next month’s<br />

issue of <strong>Mine</strong> <strong>to</strong> <strong>Market</strong><br />

Xstrata introduces Manual Task Risk Matrix<br />

Xstrata’s Occupational Therapist, Brad Pritchard, recently<br />

hosted a Manual Task Risk Matrix training day, delivered by<br />

University of Queensland Lecturer Robin Burgess-Limerick,<br />

that focused on the delivery and use of Xstrata’s new<br />

Manual Task Risk Matrix. The most recent evolution of<br />

manual task risk analysis <strong>to</strong>ols, the Matrix combines<br />

analysis of direct risk fac<strong>to</strong>rs <strong>to</strong> manual task injury with<br />

hazardous environmental fac<strong>to</strong>rs.<br />

The training day was attended by Mount Isa Physiotherapy<br />

Centre physiotherapists David Rose, Kurt Thomas, Nicholas<br />

Kluzec, Chipo Emmanuel, Louise Rose, and Sarah Lyons.<br />

“The day provided us a great opportunity <strong>to</strong> explore<br />

Xstrata’s new Manual Task Risk Matrix, which was<br />

developed in conjunction with Robin Burgess-Limerick at<br />

the University of Queensland. The Manual Task Risk Matrix<br />

will provide us with an effective <strong>to</strong>ol that will assist in the<br />

proactive identification and analysis of hazardous manual<br />

tasks,” said Brad.<br />

“We are now in the process of introducing the <strong>to</strong>ol in<strong>to</strong><br />

our Safety and Health management systems, and are<br />

preparing <strong>to</strong> begin site wide training in the use of the <strong>to</strong>ol.<br />

We are introducing the <strong>to</strong>ol through our Manual Handling<br />

Training sessions delivered by Mount Isa Physiotherapy<br />

Centre,” he said.<br />

Introduction of the <strong>to</strong>ol across our North Queensland<br />

operations will help us take another step <strong>to</strong>wards reaching<br />

our goal of Zero Harm<br />

Converterman for the Copper Smelter, Adam Chapman,<br />

reviews the risk matrix before commencing work.

8 : mine <strong>to</strong> market<br />

Buddy shows his true colours<br />

Delta Dog Buddy with his<br />

owner, Alma Corbett.<br />

Delta Dog Buddy, a regular visi<strong>to</strong>r<br />

<strong>to</strong> The Townsville Hospital, was<br />

happy <strong>to</strong> show his ‘true colours’<br />

when he visited the hospital in<br />

the lead up <strong>to</strong> the State of Origin<br />

series. Accompanied by his<br />

owner, Alma Corbett, true<br />

Queenslander Buddy proudly<br />

wore his maroon jersey!<br />

The Delta Pet Partners Program<br />

involves trained, accredited dogs<br />

and their handlers visiting hospitals,<br />

aged care facilities, acute mental<br />

health units and day respite<br />

centres, bringing much pleasure <strong>to</strong><br />

those they meet with. This program<br />

is supported by Xstrata through<br />

the XCPP NQ<br />

Who are you tipping <strong>to</strong> win the Bledisloe Cup?<br />

Orla Hansen<br />

Ciaran Moran<br />

Nathan Walsh<br />

Alan Richardson<br />

Graduate Geologist,<br />

GFM<br />

Senior <strong>Mining</strong> Engineer,<br />

MICO<br />

Apprentice Electrician,<br />

Townsville Refinery<br />

Superintendent <strong>Mine</strong><br />

Services, EHM<br />

“Coming from New<br />

Zealand, naturally I<br />

support the All Blacks.<br />

Go All Blacks!”<br />

“The Wallabies – they<br />

have a greater home<br />

advantage.”<br />

“I have <strong>to</strong> say the<br />

Wallabies. They’re due<br />

for a win.”<br />

“I’d pick the All Blacks –<br />

they have been doing<br />

pretty well of late.”

ISSUE 87 : 9<br />

Diamond drilling teams achieve record month<br />

May was a record month for diamond drillers at George Fisher<br />

<strong>Mine</strong> (GFM) with a <strong>to</strong>tal of 13,877 metres drilled during the month.<br />

Leigh Neindorf, Zinc Lead Operations <strong>Mine</strong> Projects Manager,<br />

said the figure comprises 12,044 metres of diamond drilling and<br />

1,833 metres of reverse circulation drilling.<br />

“This is a remarkable effort on behalf of all diamond drillers<br />

from the Mount Isa <strong>Mine</strong>s operation. The figure consists of<br />

4,998 metres from the three surface drilling rigs operated<br />

by Major Drilling, and 8,879 metres from the seven underground<br />

diamond drill rigs operated by Xstrata and Barminco,” said Leigh.<br />

Drilling is done <strong>to</strong> provide samples which will in turn be logged<br />

and assayed (the process whereby rock samples are analysed for<br />

the concentration of metal) <strong>to</strong> improve the geological knowledge<br />

of an area.<br />

Xstrata Copper’s Diamond Drilling Team also made a great<br />

contribution <strong>to</strong> the business during May, drilling 5,613 metres<br />

of diamond drill core with the three rigs employed at George<br />

Fisher <strong>Mine</strong>.<br />

Nick Slade, Manager MICO Coordination, said “with the<br />

remaining three drilling rigs in the Mount Isa Copper Operations,<br />

a <strong>to</strong>tal of 9,485 metres of diamond drilling was completed during<br />

the month of May across the operations by our own workforce.<br />

Core samples produced by the<br />

Diamond Drilling team.<br />

“The month of May was also an injury free month for the<br />

Diamond Drilling Department in Xstrata Copper. These safety and<br />

production achievements combined <strong>to</strong> form Xstrata Copper’s<br />

best month in 10 years for our in-house diamond drilling and<br />

raiseboring team. They should take pride in their achievement<br />

and celebrate what they are capable of achieving as we go<br />

forward,” added Nick.<br />

The Xstrata management team would like <strong>to</strong> thank and<br />

congratulate all involved in diamond drilling across the Mount<br />

Isa <strong>Mine</strong>s lease<br />

Every year, St Kieran’s Year 5 students from Mount Isa visit Cloncurry for a three day school camp. The camp<br />

involves students travelling out <strong>to</strong> EHM <strong>to</strong> experience a world class working operation. This year, students<br />

commented on how “big” everything was at the open pit mine and how much fun the <strong>to</strong>ur was.

10 : mine <strong>to</strong> market<br />

A day in the life of: a coke burner<br />

Have you ever wondered what is involved in the coke making<br />

process at Xstrata Zinc’s Bowen Coke Works (BCW)?<br />

Established in 1933, BCW uses a special type of coal called<br />

coking coal <strong>to</strong> make coke. This is sourced from Collinsville coal<br />

mine. The coking process converts this coal in<strong>to</strong> coke, most of<br />

which is used as a fuel in the Mount Isa <strong>Mine</strong>s’ lead smelter<br />

blast furnace. The remaining product is sold domestically<br />

and overseas.<br />

Cokemaking requires specialist expertise. Just ask John Williams,<br />

employee of 34 years with approximately 10 years as a burner<br />

at BCW, why this process is so challenging and he’ll tell you,<br />

“because it all comes down <strong>to</strong> using your judgement. There are<br />

no mechanical processes – you need <strong>to</strong> be able <strong>to</strong> make<br />

judgements using your own eyes.”<br />

By the time the crushed coal gets <strong>to</strong> John and the team for<br />

weighing, levelling, pushing and charging, it has already gone<br />

through a series of grinding <strong>to</strong> get it down <strong>to</strong> a fine size.<br />

There are three grades of coke: Metallurgical Coke (100 <strong>to</strong><br />

45 millimetres), Nut Coke (45 <strong>to</strong> 10 millimetres), and Coke<br />

Breeze which is less than 10 millimetres. Depending upon the<br />

coal type, coals are blended in different ratios <strong>to</strong> provide a suitable<br />

mix for the coking process. Coals are crushed down <strong>to</strong> a size of<br />

under three millimetres (more than 90%) in a hammer mill then<br />

conveyed <strong>to</strong> a s<strong>to</strong>rage bin above the oven battery.<br />

A predetermined charge of coal is loaded from the s<strong>to</strong>rage bin<br />

in<strong>to</strong> two canister cars. All charges are weighed accurately using<br />

a weight bridge. Canister cars run along rails on <strong>to</strong>p of the oven<br />

battery <strong>to</strong> the fine coal bins ready <strong>to</strong> be put in<strong>to</strong> the ovens –<br />

a process known as charging.<br />

The charge is loaded in<strong>to</strong> the oven from the bot<strong>to</strong>m of the<br />

canister car through a series of port (charge) holes. To ensure<br />

the charge is evenly distributed, a machine called a ram,<br />

which travels alongside the oven battery, is used <strong>to</strong> level out<br />

the coal bed.<br />

The coal inside the oven ignites due <strong>to</strong> the heat and drives off<br />

the volatiles. Air <strong>to</strong> the oven is carefully controlled <strong>to</strong> combust<br />

these volatiles and heat the oven charge.<br />

Coke remains in the ovens for three days where it is heated<br />

through regular adjustments <strong>to</strong> the oven damper tiles <strong>to</strong><br />

ensure the heat inside the oven is at the correct temperature.<br />

Using their judgment and experience, the coke burners control<br />

and restrict the amount of air entering the oven using a damper<br />

tile which is placed across the <strong>to</strong>p of the oven.<br />

“Everything is determined by the eye. I use my knowledge and<br />

experience <strong>to</strong> look inside the oven and make any adjustments,”<br />

said John.<br />

“However, the key <strong>to</strong> good judgement is through experience,”<br />

he said. “As for our team, we’ve got it down pat. Most of<br />

the blokes have been here for at least four <strong>to</strong> five years.<br />

Good judgement comes only from experience.”<br />

A coke burner’s week is based around three cycles. Once the<br />

oven is charged, the coal ignites due <strong>to</strong> the heat in the oven.<br />

The coal is left in the oven for three days (during the week) or<br />

four days (over the weekend), by which time the volatile matter<br />

in the coal is released and burnt off. The two, three day week<br />

cycles; Monday <strong>to</strong> Wednesday, and Wednesday <strong>to</strong> Friday,<br />

burns 7.2 <strong>to</strong>nnes of coke per oven, while the four-day burn<br />

cycle from Friday <strong>to</strong> Monday burns 9.36 <strong>to</strong>nnes of coke per oven.<br />

The recovery rate for this <strong>to</strong>nnage is approximately 72%.<br />

Because of the cyclical nature of the job, John and the other<br />

five coke burners at BCW take it in turns <strong>to</strong> cover the Monday<br />

<strong>to</strong> Sunday shift.<br />

“My day starts at 6am when I begin by making adjustments<br />

<strong>to</strong> the ovens before attending the PASS meeting. There are<br />

54 ovens at the coke works and each oven takes<br />

10 <strong>to</strong> 12 minutes <strong>to</strong> charge, level and push,” said John.<br />

“At around 12pm and then again at around 4.30pm, I do a full<br />

check of every oven <strong>to</strong> ensure the oven is burning correctly and<br />

make any adjustments. We let the coal burn for three <strong>to</strong> four<br />

hours at a time but continual moni<strong>to</strong>ring is the key <strong>to</strong> ensuring<br />

the successful burning of the coal. On a production day, the<br />

last oven is pushed at around 5.30pm. After pushing has been<br />

completed, I make any further adjustments <strong>to</strong> the other ovens<br />

before finishing for the day,” he said.<br />

John has seen a lot of changes <strong>to</strong> the coke making process over<br />

the past 30 years. “When I started in 1974, we only used <strong>to</strong><br />

charge 27 ovens per day and now we charge 54. The team has<br />

also grown in size. Coke burning used <strong>to</strong> be a one-man job and<br />

now there are six of us <strong>to</strong> cover the weekly shifts but at the<br />

same time we are doing an increased range of duties when not<br />

on the coke burning roster.”<br />

“One of the most enjoyable aspects of working here is the<br />

mateship,” said John. “We’re a close group of blokes and<br />

always help each other out. The flexibility provided by the team<br />

mates makes for a good work-life balance. We’re always there<br />

<strong>to</strong> back each other up.”<br />

After three or four days in the oven, the coke is ready <strong>to</strong> be<br />

pushed out of the oven. The red hot coke is pushed in<strong>to</strong> a hot<br />

car using a ram and travels along the track <strong>to</strong> the quench <strong>to</strong>wer<br />

where it is cooled using re-cycled water.<br />

The cooled coke is then pushed from the hot car and conveyed<br />

<strong>to</strong> a crushing and screen plant where the coke is sized in<strong>to</strong><br />

different fractions <strong>to</strong> suit cus<strong>to</strong>mer requirements. It is then<br />

loaded for despatch and the cokemaking production cycle<br />

begins again

ISSUE 87 : 11<br />

The coal inside the oven ignites due <strong>to</strong> the heat and drives off the volatiles.<br />

After three days the coke is ready <strong>to</strong> be pushed out of the oven.<br />

John Williams adjusts a damper tile.

12 : mine <strong>to</strong> market<br />

Calendar<br />

Sustainability reports<br />

<strong>July</strong><br />

2 New Starter’s Induction (Mount Isa)<br />

5-6 Isa Campdraft<br />

6-13 NAIDOC Week – Advance Australia Fair<br />

7 Townsville Show Holiday<br />

8-10 Rockhana Festival (Cloncurry)<br />

12 Mid-winter Christmas Party – Donna Kuskopf,<br />

Isa Rodeo Queen Quest Entrant,<br />

(Overlander Hotel)<br />

10-13 Cloncurry S<strong>to</strong>ckman’s Challenge and Campdraft<br />

14 Student Free Day (Qld)<br />

15 School Resumes (Qld)<br />

18-20 Boulia Camel Races<br />

26 Quamby Rodeo<br />

Townsville Cup<br />

26-27 North West Regional Forum,<br />

Queensland Arts Council (Mount Isa)<br />

August<br />

1 Cloncurry Merry Muster<br />

Charity gold coin donation morning tea (CRL)<br />

6 New Starter’s induction (Mount Isa)<br />

16 Boarder Run, charity bike ride (Camooweal)<br />

8-10 Xstrata Mount Isa Rotary Rodeo<br />

28 Community Information Session (Mount Isa)<br />

30 Cancer Council Relay for Life Challenge<br />

(Mount Isa)<br />

September<br />

3 New Starter’s induction (Mount Isa)<br />

10 Bowen Community Information Session<br />

Townsville Service Awards Dinner<br />

11 Bowen Community Partnership Function<br />

13-16 Cloncurry Art Show<br />

19 School holidays begin (Qld)<br />

In June, all employees should have received a copy of their<br />

respective North Queensland and site sustainability reports.<br />

This year, five reports were produced: Xstrata Copper<br />

North Queensland Division, Xstrata Zinc North Queensland,<br />

Mount Isa <strong>Mine</strong>s, <strong>Ernest</strong> <strong>Henry</strong> <strong>Mining</strong>, and Townsville<br />

Operations. The 2007 reports incorporated for the first time,<br />

a GRI Index (Global Reporting Initiative) for greater<br />

transparency.<br />

If you have not received your reports, please contact your<br />

Community Relations Department member:<br />

Copper – Melissa Trim on ext. 2596 or email<br />

mtrim@xstratacopper.com.au; and<br />

Zinc – Jemma Schweikert on ext. 6552 or email<br />

jschweikert@xstratazinc.com.au<br />

Safety reminder<br />

All employees are reminded that operation of vehicles both<br />

on and off the mine lease is governed by the legislative<br />

requirements of the Queensland Transport Operations<br />

(Road Use Management) Act 1995. Operating a mo<strong>to</strong>r vehicle<br />

while using a mobile phone (that is not on a hands-free device)<br />

is not only unsafe, but is illegal and prohibited both on and<br />

off site. Not complying with this rule on site may result in<br />

disciplinary action as a result of contravening a safety rule.<br />

Breaking this rule off site is a bookable traffic offence

ISSUE 87 : 13<br />

Xstrata hosts Kalkadoon site <strong>to</strong>ur<br />

Xstrata Mount Isa <strong>Mine</strong>s’ Environment and Community<br />

Relations teams hosted a site <strong>to</strong>ur of the tailings dams<br />

and the Leichhardt River Remediation Project works for<br />

several direc<strong>to</strong>rs of the Kalkadoon Community Pty Ltd<br />

and native title applicants in early June.<br />

The site <strong>to</strong>ur was used as an orientation opportunity for<br />

the Kalkadoon representatives <strong>to</strong> become familiar with<br />

the tailings dam area before cultural heritage surveys are<br />

held in coming months.<br />

Following a site induction conducted by Senior<br />

Environmental Advisor, Anne Williams, Indigenous Affairs<br />

Advisor, Zane Hughes, and Anne escorted the group <strong>to</strong><br />

the tailings dams <strong>to</strong> discuss the production and the<br />

environmental management aspects of the tailings dams.<br />

Issues such as water management, water reuse, seepage<br />

collection and moni<strong>to</strong>ring, dust control and closure<br />

planning opportunities were also discussed. Future plans<br />

for the design of the tailings dams and the benefits of<br />

changed management in enabling increased capture of<br />

water for reuse were explained, with a focus on areas<br />

where cultural heritage clearances will be required for<br />

future projects.<br />

The group also visited the Leichhardt River <strong>to</strong> inspect<br />

the Stage 2 works of the Leichhardt River Remediation<br />

Project.<br />

During the next quarter, Xstrata will also host a two day<br />

forum for the Kalkadoon Community Pty Ltd Board of<br />

direc<strong>to</strong>rs <strong>to</strong> discuss a number of environmental,<br />

community, exploration and contracting projects<br />

Skills for the future<br />

The Xstrata Skills Centre is hosting<br />

an eight week Skills for the Future<br />

program for Year 9 and 10 school<br />

students, giving them a taste of life<br />

as an apprentice.<br />

Renita Casey from Spinifex College<br />

has been attending the Skills for the<br />

Future program and is learning about<br />

safety systems, electronics, hand <strong>to</strong>ols<br />

and soldering.<br />

“Our exercise is <strong>to</strong> build a robot<br />

from screws and steel, and solder it<br />

<strong>to</strong>gether, which is a lot of fun,” said<br />

Renita, who is considering becoming a<br />

school-based apprentice.<br />

Renita’s instruc<strong>to</strong>r at the Skills Centre,<br />

Kerry Brisbane, Electrical Apprentice<br />

Team Leader, said the students take<br />

the Skills for the Future program<br />

very seriously.<br />

Dave Watson, Skills Centre Superintendent, with student Renita Casey.<br />

“It is similar <strong>to</strong> being an apprentice<br />

because the students undergo an<br />

induction, pre-employment medical<br />

and use their Personal Protective<br />

Equipment (PPE) and workwear.<br />

They are a very dedicated and keen<br />

group of students,” said Kerry<br />

“In previous years, Year 9 students<br />

have been involved, however this is the<br />

first year that Year 10 has also come<br />

onboard and it’s proving <strong>to</strong> be very<br />

successful,” said Kerry

14 : mine <strong>to</strong> market<br />

Daniel Morris – Most Outstanding Apprentice<br />

Bruce Coles –<br />

BCW Superintentent<br />

presents Daniel Morris<br />

(right) with his award.<br />

Bowen Coke Works’<br />

Daniel Morris was named<br />

Most Outstanding First Year<br />

Electrical and Refrigeration<br />

Apprentice 2007 at the<br />

recent TORGAS Awards<br />

evening held in Townsville.<br />

Congratulations Daniel<br />

Employee profiles<br />

Gavin Power<br />

Opera<strong>to</strong>r/Maintainer,<br />

Bowen Coke Works<br />

Kirsty Rolley<br />

<strong>Mine</strong> Technician,<br />

EHM<br />

George Page<br />

Day Gang – Skid Steer<br />

Opera<strong>to</strong>r, Zinc Lead<br />

Concentra<strong>to</strong>r<br />

Allan Hughes<br />

Apprentice Boilermaker,<br />

Copper Concentra<strong>to</strong>r<br />

Birthplace: Collinsville.<br />

Birthplace: Herber<strong>to</strong>n.<br />

Birthplace: Mount Isa.<br />

Birthplace: Darwin.<br />

Years with Xstrata:<br />

18 months.<br />

My role at Xstrata involves:<br />

Helping <strong>to</strong> produce coke for<br />

the Mount Isa smelters.<br />

Strengths: Slow <strong>to</strong> anger.<br />

Weaknesses: Fast food.<br />

Family: Wife Kaylene,<br />

2 teenage kids – Ecekiel and<br />

Jemmason.<br />

Favourite TV Show/Movie:<br />

None.<br />

Holiday destination of my<br />

dreams: Adelaide apparently<br />

– I am going there <strong>to</strong> watch<br />

my daughter play netball in the<br />

under 15 Queensland team.<br />

Five celebrities I would<br />

like <strong>to</strong> invite <strong>to</strong> dinner: Will<br />

Smith, Martin Lawrence, and<br />

Michael Jordan – 3 is enough.<br />

If I could change something<br />

it would be? To have a four<br />

day weekend.<br />

Wish for the future: To<br />

continue close family ties.<br />

Years with Xstrata: 2 years.<br />

My role at Xstrata involves:<br />

Operating heavy machinery.<br />

Strengths: Patience and a<br />

good sense of humour.<br />

Weaknesses: Tat<strong>to</strong>os,<br />

piercings and rodeo riders.<br />

Family: No children, not<br />

married yet!<br />

Favourite TV Show/Movie:<br />

8 Seconds.<br />

Holiday destination of my<br />

dreams: Canada – Calgary<br />

Stampede.<br />

Five celebrities I would like<br />

<strong>to</strong> invite <strong>to</strong> dinner: Katherine<br />

Heigl, Tim McGraw, Gary<br />

Allen, Ty Murrya, and Johnny<br />

Knoxville.<br />

If I could change something,<br />

it would be: Cloncurry’s<br />

temperature!<br />

Wish for the future:<br />

To become a millionaire.<br />

Years with Xstrata: 1 year.<br />

My role at Xstrata involves:<br />

operating the bobcat,<br />

housekeeping, and ensuring<br />

the hygiene of the plant.<br />

Strengths: Bronco branding,<br />

watching TV.<br />

Weaknesses: Spoiling my<br />

daughters.<br />

Family: My wife and two<br />

daughters.<br />

Favourite TV Show/Movie:<br />

Remember the Titans and<br />

Heroes.<br />

Holiday destination of my<br />

dreams: Georgina.<br />

Five celebrities I would like<br />

<strong>to</strong> invite <strong>to</strong> dinner: Ernie<br />

Dingo, Matty Bowen, and Carl<br />

Webb <strong>to</strong> join my wife and<br />

myself.<br />

If I could change something<br />

it would be? Nothing.<br />

Wish for the future: To pay<br />

off my house.<br />

Years with Xstrata:<br />

18 months.<br />

My role at Xstrata involves:<br />

supporting tradesmen <strong>to</strong><br />

maintain the concentra<strong>to</strong>r.<br />

Strengths: Team player.<br />

Weaknesses: 12 hour shifts.<br />

Family: There are <strong>to</strong>o many<br />

<strong>to</strong> name!<br />

Favourite TV Show/Movie:<br />

Ramsay’s Kitchen Nightmares.<br />

Holiday destination of your<br />

dreams: Amsterdam<br />

Five celebrities I would like<br />

<strong>to</strong> invite <strong>to</strong> dinner: Jessica<br />

Alba, Gordon Ramsay, 2 PAC,<br />

Steady Eddy, and Allan Langer.<br />

If I could change something,<br />

it would be: To work only a<br />

38 hour week.<br />

Wish for the future:<br />

To win lot<strong>to</strong>.

ISSUE 87 : 15<br />

Building community and<br />

cultural resilience<br />

The Queensland Arts Council (QAC), an XCPP NQ partner,<br />

will hold a series of workshops about resilience in<br />

communities later this month in Mount Isa.<br />

The forum will aim <strong>to</strong> ensure we better understand how<br />

our communities tick and their influence on the landscape<br />

and lifestyles of our regions.<br />

The QAC North West Regional forum, titled Bouncing<br />

Back – Playing <strong>to</strong> your Strengths, will be held in Mount Isa<br />

on 26 and 27 <strong>July</strong> at the Xstrata Entertainment Centre at<br />

Buchanan Park.<br />

Ms Ros Derrett OAM, Head of the Office of Regional<br />

Engagement at Southern Cross University, will facilitiate<br />

the forums. Ros has worked extensively in education,<br />

<strong>to</strong>urism, community cultural development and arts<br />

administration in Australia and overseas, and was the<br />

facilita<strong>to</strong>r for the inaugural QAC Forum Series in 2004<br />

funded by the XCPP NQ.<br />

“Once we understand who we are as a community and<br />

determine where we want <strong>to</strong> be, we can bring <strong>to</strong>gether<br />

the appropriate resources we need <strong>to</strong> enhance the quality<br />

of life for residents and visi<strong>to</strong>rs. This will ensure creativity,<br />

prosperity and liveability for all stakeholders and<br />

demonstrate our resilience when the challenges arise,”<br />

said Ms Derrett.<br />

The forum workshops will provide a special lens on<br />

community resilience and will help bring individuals and<br />

groups <strong>to</strong>gether. These partnerships are important and<br />

require a special approach so that each stakeholder group<br />

in the community gets the best from the relationship<br />

WHEN: Saturday 26 and Sunday 27 <strong>July</strong>, <strong>2008</strong>.<br />

WHERE: Xstrata Entertainment Centre, Buchanan Park, Mount Isa<br />

HOW TO REGISTER: Queensland Arts Council<br />

Phone 07 3004 7511 or visit www.qac.org.au<br />

Biggest Morning Tea<br />

Various departments at Mount Isa <strong>Mine</strong>s<br />

held a morning tea in support of the Cancer<br />

Council’s Biggest Morning Tea.<br />

There were cakes galore at Central Office<br />

as employees and senior management<br />

joined <strong>to</strong> raise vital funds for the worthy<br />

cause. A <strong>to</strong>tal of $231 was raised.<br />

Over at the Xstrata Copper Exploration<br />

offices, Lina Will, Compliance and Travel<br />

Coordina<strong>to</strong>r, organised a morning tea,<br />

as she does every year <strong>to</strong> coincide with her<br />

birthday. This year Lina invited the entire<br />

Strategic Planning Department and raised a<br />

combined <strong>to</strong>tal of over $310.<br />

Also present at the Biggest Morning Tea<br />

was Bill Duchatel who was a guest of the<br />

Strategic <strong>Mine</strong> Planning team. Bill worked<br />

on the 500 Orebody in the mid <strong>to</strong> late 60s<br />

as part of the Sub Level Caving team and<br />

was onsite <strong>to</strong> provide the 500 Orebody<br />

pre-feasibility study team with some<br />

his<strong>to</strong>rical background as part of an all day<br />

review. Bill explained the challenges<br />

encountered by his team when mining in<br />

the reactive ore of the 500 Orebody.<br />

The review helped define the operational<br />

solutions that were developed <strong>to</strong> address<br />

the challenges of mining in reactive ground.<br />

Thank you Sue Kenworthy for your<br />

contribution<br />

Lina Will collects donations for the Exploration/Strategic <strong>Mine</strong> Planning Biggest Morning Tea.<br />

Bill Dutcatel hosts a review of the 500 Orebody pre-feasibility study with the Strategic<br />

<strong>Mining</strong> Planning team. Fom left <strong>to</strong> right: Richard Fry, Eamonn Dare, Fiona Leddick,<br />

Jim Faulkner, Bill Duchatel, Org van Baalen, Chris Carr, Myles Johns<strong>to</strong>n and Pete Christen.

16 : mine <strong>to</strong> market<br />

Lead Smelter introduces porta count machine<br />

The lead smelter has introduced a new<br />

porta count machine <strong>to</strong> effectively carry<br />

out ‘respira<strong>to</strong>r-fit testing’ for its employees.<br />

As part of the new starter procedure,<br />

respira<strong>to</strong>r-fit tests are conducted so that<br />

the employee is fitted with the most<br />

suitable type of respira<strong>to</strong>r before they start<br />

work in the lead smelter. The respira<strong>to</strong>r-fit<br />

test is important as there are several<br />

different types and sizes of respira<strong>to</strong>rs in<br />

use. In addition, one type and size may be<br />

more effective than another, depending on<br />

the employee’s face shape.<br />

Respira<strong>to</strong>rs are used as prevention against<br />

lead absorption through inhalation, so it is<br />

very important that the respira<strong>to</strong>r used is<br />

the correct type and fit for the user.<br />

Respira<strong>to</strong>r pre-start checks are also carried<br />

out by employees at the beginning of each<br />

shift as part of the ongoing maintenance of<br />

this piece of Personal Protective Equipment.<br />

By using the porta count machine, the<br />

same faults can be identified as would be in<br />

the pre-start test, however the added<br />

feature of the machine is that it assigns a<br />

‘fit fac<strong>to</strong>r’ <strong>to</strong> the respira<strong>to</strong>r. This ‘fit fac<strong>to</strong>r’<br />

is determined through a series of tests<br />

while the employee is wearing the<br />

respira<strong>to</strong>r. These include side <strong>to</strong> side head<br />

movements, checking that breathing is<br />

normal, and determining their ability <strong>to</strong><br />

speak while wearing the respira<strong>to</strong>r.<br />

If results returned are lower than expected,<br />

the respira<strong>to</strong>r can be adjusted. For example,<br />

the elastic strap can be replaced while there<br />

is still some elasticity rather than wait until<br />

there is none. This <strong>to</strong>ol allows us <strong>to</strong> be<br />

more pro-active than reactive.<br />

My colleagues don’t know this, but...<br />

Importantly, the porta count machine does<br />

not replace the need for employees <strong>to</strong><br />

conduct pre-start checks. It is an added<br />

<strong>to</strong>ol that is used <strong>to</strong> ensure that the<br />

respira<strong>to</strong>rs are the appropriate size for the<br />

individual employee and are at optimum<br />

effectiveness.<br />

Thank you <strong>to</strong> James Roccheccioli<br />

for your contribution<br />

Allan Hancock conducts a pre-test on<br />

his respira<strong>to</strong>r prior <strong>to</strong> starting work.<br />

DJ Lyons<br />

Lab Technician,<br />

EHM<br />

Dale Moncrieff<br />

Field Technician, Handlebar Hill<br />

Open Cut mine<br />

Allan Welch<br />

Electrician Leading Hand,<br />

CRL<br />

Fiona Leddick<br />

Administration Assistant,<br />

Strategic <strong>Mine</strong> Planning<br />

Xstrata Copper<br />

My colleagues don’t know this,<br />

but I’m a boxer and I have<br />

competed in the Golden Glove.<br />

My favourite food is pizza<br />

(meat lovers).<br />

I drive a Falcon or Barina.<br />

The person I most admire is my<br />

mother Denise.<br />

In my spare time I enjoy catching<br />

up with friends.<br />

My pet hate is queues.<br />

I can’t live without my mo<strong>to</strong>rbike.<br />

My colleagues don’t know this,<br />

but I have had a hole in one.<br />

My favourite food is a good piece<br />

of steak.<br />

I drive a Commodore station<br />

wagon.<br />

The person I most admire is my<br />

colleague Steve – he is always there<br />

for advice and he never says a bad<br />

word about anyone.<br />

In my spare time I sleep in, relax,<br />

and spend time with the old man.<br />

My pet hate is when simple things<br />

are made complicated.<br />

I can’t live without my family,<br />

friends, and music.<br />

My colleagues don’t know this,<br />

but the first band I went <strong>to</strong> see was<br />

Cold Chisel at the Mount Isa Civic<br />

Centre in 1981.<br />

My favourite foods are BBQ<br />

Sweet pota<strong>to</strong> and Rib Fillet Steak<br />

with pasta.<br />

I drive an Immaculate 2004 SS<br />

Holden Crewman.<br />

The person I most admire is<br />

Jimi Hendrix – the greatest musician<br />

of all time.<br />

If I had the spare time I would<br />

learn <strong>to</strong> play the guitar.<br />

My pet hate is drivers that don’t<br />

signal when turning corners.<br />

I can’t live without State of Origin<br />

– go Queensland!<br />

My colleagues don’t know this,<br />

but I am petrified of heights.<br />

My favourite food is anything<br />

Italian.<br />

I drive a Ford Falcon (is there<br />

anything else?).<br />

The people I most admire are<br />

people that have the courage <strong>to</strong><br />

follow their dreams.<br />

In my spare time I spend time<br />

with family and friends.<br />

My pet hate is pretentious people.<br />

I can’t live without my husband<br />

and my dog.

ISSUE 87 : 17<br />

BSOC Environmental Pad Trial<br />

In order <strong>to</strong> yield world best practice rehabilitation outcomes,<br />

Black Star Open Cut mine (BSOC) has commissioned and<br />

sponsored significant research on waste rock dump cover system<br />

designs and the role of vegetation in cover systems.<br />

In 2006, specialist consultants from Canada were employed <strong>to</strong><br />

mathematically model potential moisture s<strong>to</strong>re and release cover<br />

system options. During May this year, a field trial commenced <strong>to</strong><br />

identify the most economically and environmentally beneficial<br />

moisture s<strong>to</strong>re and release cover system option for the BSOC<br />

waste rock dumps.<br />

Xstrata Zinc’s BSOC<br />

operation has sponsored<br />

an ACMER (Australian<br />

Centre for <strong>Mine</strong>rals<br />

Extension and Research)<br />

research program that<br />

will provide vital<br />

knowledge with respect<br />

<strong>to</strong> the role that<br />

vegetation plays in cover<br />

systems as they operate<br />

<strong>to</strong> minimise moisture<br />

percolation in<strong>to</strong> waste<br />

rock dumps. Currently<br />

very little is known about<br />

the role of vegetation in<br />

cover systems, so BSOC’s<br />

research will help ensure<br />

environmentally safe<br />

waste rock dumps and<br />

excellent rehabilitation<br />

outcomes, not only in<br />

Mount Isa but also at<br />

various other Xstrata<br />

operations world-wide.<br />

From left <strong>to</strong> right: Daniel Taylor, Dave Brennan, Jonythan Maps<strong>to</strong>ne,<br />

and Anu Datta pictured at the BSOC waste rock cover trial site.<br />

Over the period of one month, three scientifically instrumented<br />

test plots were constructed from approximately 13,000 cubic<br />

metres of non-acid forming waste rock. The test plots were<br />

constructed in lifts with one standing at four metres and the<br />

others being two metres tall. One of the two metre tall pads<br />

included a 0.5 metre compacted layer of non acid waste.<br />

The project also involved complex excavations for the installation<br />

of a range of scientific instrumentation which detects moisture<br />

content and soil suction. Within each of the test plots, up <strong>to</strong><br />

three sets of 16 moisture and 16 soil suction sensors were<br />

installed vertically from the surface of the cover at various depths<br />

of up <strong>to</strong> seven metres <strong>to</strong> measure the movement of moisture in<strong>to</strong><br />

the cover which would come from the infiltration of rain and then<br />

movement of moisture out of the cover because of evaporation<br />

and plants drawing on s<strong>to</strong>red moisture. It is known that in hot<br />

areas like Mount Isa, evaporation can draw moisture from<br />

more than two metres under the ground surface. An important<br />

part of the construction of the test plots included burying<br />

three four-metre-diameter rainwater tanks. These will enable us<br />

<strong>to</strong> measure water ingress rates through the various cover system<br />

configurations and compare this <strong>to</strong> the sensor readings.<br />

The data collected from instrumentation in these test plots will<br />

enable us <strong>to</strong> verify that the mathematical model developed for<br />

the cover designs<br />

effectively mimics what<br />

happens in reality and<br />

proves that the cover<br />

system will be effective<br />

in the long term. It will<br />

also allow the design <strong>to</strong><br />

be refined over time.<br />

Xstrata Zinc’s General<br />

Manager <strong>Mining</strong><br />

Anthony Kocken, said<br />

“This project involved<br />

numerous individuals<br />

undertaking a wide<br />

variety of duties and one<br />

of the greatest<br />

accomplishments of this<br />

initiative is the extent <strong>to</strong><br />

which BSOC’s personnel<br />

pulled <strong>to</strong>gether <strong>to</strong> not<br />

only get the job done,<br />

but get it done well.<br />

“All construction and<br />

excavation for this<br />

complex initiative was<br />

undertaken by BSOC’s Civil Crew. It is a real accomplishment that<br />

the project was completed safely without incident and within the<br />

expected timeframes,” said Anthony.<br />

“The individuals on the Civil Crew should be proud of themselves<br />

and their excellent achievements on this project. These individuals<br />

have significantly contributed <strong>to</strong> an important project which will<br />

yield significant environmental outcomes and could save us<br />

millions of dollars by reducing the thickness of the non acid cover<br />

on our waste rock dump,” he added.<br />

The initiative <strong>to</strong>ok a month <strong>to</strong> complete and involved over<br />

1,000 man and equipment hours. The next phase of the initiative<br />

involves building an extra two plots which specifically examine<br />

the role of vegetation in cover systems. This phase is expected <strong>to</strong><br />

commence in the coming months

18 : mine <strong>to</strong> market<br />

The Open Pit Opera<strong>to</strong>r’s Experience<br />

Following on from last month’s Myuma<br />

s<strong>to</strong>ry we bring you: The Open Pit<br />

Opera<strong>to</strong>r’s Experience.<br />

The Open Pit Opera<strong>to</strong>r’s Experience is<br />

prepared by Black Star Open Cut (BSOC)<br />

mine employees and is a series of<br />

vocational talks given <strong>to</strong> Indigenous<br />

participants seeking exposure <strong>to</strong> the<br />

mining industry. One of the presenters<br />

is Drill and Blast Leading Hand and local<br />

Indigenous woman, Wanita Gosbee.<br />

Wanita had her first taste of mining<br />

when she attended a mining access<br />

program at the Hard Times <strong>Mine</strong>.<br />

From there Wanita worked for a number<br />

of contrac<strong>to</strong>rs on the lease before<br />

starting with BSOC. It has been an<br />

onwards and upwards career progression<br />

for Wanita who has recently been acting<br />

in the position of BSOC’s Drill and<br />

Blast Supervisor.<br />

“In the role of Drill and Blast Leading<br />

Hand, I look after a crew of seven people<br />

<strong>to</strong> ensure our daily tasks are undertaken.<br />

I’m the blast controller, which means I’m<br />

responsible for charging and stemming<br />

holes, then connecting all the holes<br />

<strong>to</strong>gether. The health and safety of the<br />

employees is my highest priority.<br />

Therefore it is critical that I ensure the<br />

area is clear prior <strong>to</strong> firing,” said Wanita.<br />

An explanation of Wanita’s job<br />

description and role expectations<br />

accompanied by video footage of BSOC<br />

is a major part of The Open Pit<br />

Opera<strong>to</strong>r’s Experience presentation<br />

which she delivered <strong>to</strong> students from the<br />

Spinifex Junior campus, as well as the<br />

Myuma visi<strong>to</strong>rs <strong>to</strong> BSOC.<br />

“I’m more than happy <strong>to</strong> provide advice<br />

<strong>to</strong> others wishing <strong>to</strong> enter the mining<br />

industry. I have a diverse range of work<br />

experience, from living and working on<br />

my family’s cattle property <strong>to</strong> now<br />

holding a shot firer’s licence. I enjoy<br />

sharing my experiences with people <strong>to</strong><br />

help them <strong>to</strong> achieve their goals or<br />

obtain future job opportunities within<br />

the mining industry,” Wanita said.<br />

“But there’s one piece of advice that has<br />

always helped me, and that’s <strong>to</strong> turn up<br />

<strong>to</strong> work with the right attitude,” she said.<br />

As a result of Wanita’s presentation <strong>to</strong><br />

Myuma visi<strong>to</strong>rs at Black Star Open Cut<br />

mine, a number of students graduated<br />

from a structured vocational training<br />

program with Xstrata Zinc. Two students<br />

were located at BSOC, one in administration<br />

at George Fisher <strong>Mine</strong> (GFM) and one at<br />

the workshop at GFM<br />

Wanita Gosbee, Lyle James, and Anthony Kocken at Black Star Open Cut mine.

ISSUE 87 : 19<br />

Xstrata named mining<br />

sec<strong>to</strong>r leader<br />

Xstrata has recently been named as a<br />

‘platinum’ level company and the mining<br />

sec<strong>to</strong>r leader by Business in the Community’s<br />

(BITC) Corporate Responsibility Index 2007.<br />

This follows Xstrata’s recent inclusion in the<br />

Dow Jones Sustainability Index for 2007/8<br />

as the mining sec<strong>to</strong>r leader. Xstrata’s BITC<br />

rating of 96% has also resulted in Xstrata<br />

leading the sec<strong>to</strong>r in the 2007 Australian<br />

Corporate Responsibility Index of businesses<br />

with operations or interests in that country<br />

Title of Artwork: Advance Australia Fair?<br />

Artists Description<br />

The government has said SORRY – so let’s Advance Australia and be Fair.<br />

The kangaroo and emu are the two unique Indigenous animals that are on the<br />

Australian coat of arms and, some say, were chosen because they move forward<br />

and find it difficult <strong>to</strong> go backwards. Their positions have been switched, left and<br />

right, <strong>to</strong> represent the switch in the Governments attitude.<br />

They are surrounded by the stars of the Southern Cross which, like Aboriginal people,<br />

have been here since the beginning of time. There must be a change in attitudes<br />

Celebrating Naidoc<br />

of black and white and all the colours<br />

Week<br />

in between. Black people must<br />

<strong>2008</strong><br />

s<strong>to</strong>p waiting<br />

for governments and white people <strong>to</strong> fix their problems – they must start fixing the<br />

www.naidoc.org.au<br />

CELEBRATING NAIDOC WEEK <strong>2008</strong><br />

problems that they can. Governments must not look at Indigenous problems and<br />

say “This is going <strong>to</strong> cost <strong>to</strong>o much <strong>to</strong> fix” or “The problem is <strong>to</strong>o big”.<br />

Now is the best time because we are in a time of great prosperity which is ripped<br />

from the land that rightly belongs <strong>to</strong> Aboriginal people.<br />

For the background we have used the colours of the land, the sorry is in blue<br />

representing water and a healing point. The Southern Cross is in the colours of the<br />

sunset, the time when it first comes out. The lines connecting the Southern Cross<br />

represent the spirits of our ances<strong>to</strong>rs that are looking down on us and keeping an eye<br />

on us. The lines are black for our ances<strong>to</strong>rs and the orange is power and knowledge<br />

that they have and have given.<br />

Aboriginals and Torres Strait Islanders’ future, like this poster, can be built on the<br />

Rudd Government’s SORRY. Advance Australia, both Fair and Dark.<br />

Artists Duwun Lee and Laniyuk Lee

20 : mine <strong>to</strong> market<br />

Handlebar Hill Open Cut – a preferred training ground<br />

Third Year University of Ballarat geology<br />

students visit Handlebar Hill Open Cut mine.<br />

Xstrata Zinc’s Handlebar Hill Open Cut (HHOC) mine last month<br />

cemented its place as a preferred training ground as a group of<br />

geology students from the University of Ballart visited the mine<br />

<strong>to</strong> complete mapping exercises as part of their geology<br />

curriculum.<br />

The third year undergraduate students participated in a training<br />

program organised between the university and Xstrata Zinc<br />

which involved mapping of the Mount Isa Valley mineral<br />

outcrops and areas of the HHOC lease.<br />

“Mount Isa provides a varied and complex geology which is<br />

perfect for our third year students <strong>to</strong> map and study,” said<br />

Stafford McKnight, Lecturer in <strong>Mine</strong>ralogy and Petrology for the<br />

School of Science and Engineering at the University of Ballarat.<br />

“The aim of this exercise was geographical mapping and taking<br />

advantage of the particularly good geology in and around<br />

Mount Isa and Cloncurry,” said Stafford.<br />

“The students mapped in pairs; completed a detailed study of<br />

rock structures, and then produced two maps and two reports<br />

<strong>to</strong> accompany a 15 minute presentation <strong>to</strong> senior Xstrata<br />

employees,” he said.<br />

He said new training initiatives like this will help <strong>to</strong> combat a<br />

huge shortage of trained professionals within the industry<br />

On the move<br />

Megan Moar<br />

has moved from a<br />

Receptionist role <strong>to</strong> an<br />

Environmental Technician’s<br />

role at EHM.<br />

Ben McLean<br />

has been promoted from<br />

an underground Diesel<br />

Fitter at GFM <strong>to</strong> a<br />

Maintenance Planner for<br />

Zinc Lead Maintenance.<br />

Jessica Bosca<strong>to</strong><br />

is the new Management<br />

Accountant for Townsville<br />

Operations.<br />

Rob Hanson<br />

has been promoted <strong>to</strong><br />

Electrical and<br />

Communications<br />

Superintendent, MICO.

ISSUE 87 : 21<br />

David Freney completes his adult apprenticeship<br />

David Freney has recently<br />

completed his boilermaking<br />

adult apprenticeship.<br />

Xstrata would like <strong>to</strong> congratulate David Freney who has recently<br />

completed his adult apprenticeship.<br />

David has worked for Mount Isa <strong>Mine</strong>s for 23 years in various<br />

positions from s<strong>to</strong>reperson <strong>to</strong> project officer, <strong>to</strong> a supervisory role<br />

for <strong>Mine</strong> Rescue.<br />

In 2005, David started his boilermaking apprenticeship as part of<br />

Xstrata’s Adult Apprenticeship Program and currently works at<br />

George Fisher <strong>Mine</strong> in Fixed Plant Maintenance.<br />

George Fisher <strong>Mine</strong>’s Supervisor for underground mechanical<br />

services, Tom Kelly, said David is an asset <strong>to</strong> his crew and<br />

department. “He has a positive attitude and a willingness <strong>to</strong> be a<br />

team player, with a strong safety focus. We are pleased <strong>to</strong> have<br />

him working for us,” he said.<br />

Congratulations David.<br />

Applications for six positions at Mount Isa <strong>Mine</strong>s in the 2009<br />

adult apprenticeship intake are currently being assessed<br />

Winners of five Apple iPods<br />

from the ICT satisfaction survey<br />

A cus<strong>to</strong>mer satisfaction survey of our current Information<br />

Communication & Technology (ICT) services was recently<br />

conducted <strong>to</strong> measure the level of satisfaction among Xstrata<br />

Copper, Xstrata Zinc and Xstrata Technology employees in<br />

Queensland and Northern Terri<strong>to</strong>ry.<br />

Five lucky employees were presented with an Apple iPod 8GB<br />

Touch as a prize for participating in the survey.<br />

“Xstrata values employee input and this survey gave an<br />

opportunity for employees <strong>to</strong> provide anonymous feedback on<br />

the services they have received over the past year, and <strong>to</strong> make<br />

suggestions for improvement,” said Greg Jamieson, Manager IT<br />

Project, Xstrata Copper North Queensland.<br />

The results of the survey will be used <strong>to</strong> help ensure the<br />

continual improvement of our ICT services going forward and<br />

provide a reference point <strong>to</strong> compare future cus<strong>to</strong>mer<br />

satisfaction levels,” said Greg<br />

David de Lange, General Manager Finance and Administration, and<br />

Peter Bates, Manager IT and Business Systems, with the winners of<br />

the ICT satisfaction survey in Mount Isa; Andrew Glover, Graduate<br />

Metallurgist Xstrata Copper, Brad Bessen, Metallurgist Xstrata Zinc,<br />

and Joh Lumsden, Pitram Opera<strong>to</strong>r Xstrata Copper.<br />

Greg Jamieson, Manager IT Project (left), and Karen Read,<br />

General Manager Business Planning and Reporting (right) with the<br />

winners of the ICT satisfaction survey in Brisbane; Lisa Marshall,<br />

Cus<strong>to</strong>mer Service Officer, Xstrata Technology and Mervyn See<strong>to</strong>,<br />

Senior Internal Audi<strong>to</strong>r, Xstrata Copper.

22 : mine <strong>to</strong> market<br />

Potential graduates visit Mount Isa<br />

A group of potential graduates prepare <strong>to</strong> <strong>to</strong>ur George<br />

Fisher <strong>Mine</strong> with Reliability Engineer, Tiffany Sproles (right).<br />

Fifty-eight potential graduates from a variety of disciplines<br />

from Australian universities visited Mount Isa <strong>Mine</strong>s for site<br />

visits as part of the Xstrata Mount Isa <strong>Mine</strong>s Graduate<br />

Program for 2009. The site visit included a <strong>to</strong>ur of Black Star<br />

Open Cut mine, Handlebar Hill Open Cut mine, George<br />

Fisher <strong>Mine</strong>, or Enterprise <strong>Mine</strong> as well as a <strong>to</strong>ur of one of<br />

the metallurgical plants.<br />

Students met with superintendents and managers during<br />

a special dinner held on the first night, and had the<br />

opportunity <strong>to</strong> socialise with existing graduates at a<br />

barbecue dinner on the second night. On the third day,<br />

each potential graduate was interviewed <strong>to</strong> determine<br />

whether they would be suitable for a graduate role in<br />

2009 with Xstrata<br />

Workplace trainer<br />

and assessor development<br />

Twenty-nine workplace trainers<br />

and assessors from the Copper<br />

Concentra<strong>to</strong>r, Copper <strong>Mine</strong><br />

Maintenance and Zinc Lead<br />

Concentra<strong>to</strong>r attended development<br />

programs during April and May.<br />

Topics covered included the training<br />

management system, auditing,<br />

training and assessing material,<br />

document control processes and<br />

assessment validation.<br />

Presenters for the programs included<br />

Vicki Anderson, Louise Wilcox, Don<br />

Healy and Sean Cavanagh, with key<br />

note addresses from Monica Thomas<br />

and Maryann Wipaki.<br />

“This initiative has been very<br />

successful and will continue <strong>to</strong> be<br />

delivered, it is important <strong>to</strong> recognise<br />

the pivotal role our workplace<br />

trainers and assessors play in the<br />

business and the value of structured<br />

selection and development programs,”<br />

said Maryann.<br />

“I would like <strong>to</strong> thank the team for<br />

their organisation and commitment<br />

<strong>to</strong>ward this program,” she said

ISSUE 87 : 23<br />

Diabetes and the Glycaemic Index<br />

MEDICAL<br />

Approximately one in four Australians<br />

suffer from either Diabetes or impaired<br />

glucose <strong>to</strong>lerance. These statistics are on<br />

the incline. According <strong>to</strong> the Australian<br />

Institute of Health and Welfare (<strong>2008</strong>),<br />

a large number of diabetes cases still<br />

remain undiagnosed, as there are often<br />

no symp<strong>to</strong>ms.<br />

Fortunately, the increased awareness<br />

of the Glycaemic Index (GI) can have<br />

beneficial outcomes for both Diabetic and<br />

non-diabetic people. The GI refers <strong>to</strong> how<br />

rapidly carbohydrate-containing foods<br />

are broken down in the digestive system<br />

and absorbed in<strong>to</strong> the blood stream.<br />

Carbohydrates that enter the blood<br />

stream quickly have high GI values, and<br />

lower GI carbohydrates are more gradually<br />

absorbed in<strong>to</strong> the blood stream.<br />

High carbohydrate foods include breads,<br />

cereals, pasta, some starchy vegetables,<br />

fruits, legumes and milk. It is the<br />

characteristics of carbohydrates and<br />

other elements (fats, acidity) in foods that<br />

influence GI. For example carbohydrates<br />

that are heavily processed and low in fibre<br />

such as white bread or finely milled flour,<br />

cause a quick rise in blood sugar levels<br />

(BSLs). On the other hand, carbohydrates<br />

that contain high levels of soluble fibre<br />

and preserve the shell of the cells, such<br />

as multigrain bread and soy products, are<br />

more difficult <strong>to</strong> digest and are therefore<br />

broken down slowly.<br />

What foods are high,<br />

intermediate or low GI?<br />

High (GI 70 or more) – white rice, high<br />

sugar cereals, white pota<strong>to</strong><br />

Intermediate (GI 56-69) – bran muffin,<br />

rockmelon and most dried fruits<br />

Low (GI 55 or less) – pears, sourdough<br />

bread and sweet pota<strong>to</strong><br />

How does GI help with diabetes?<br />

People with diabetes have difficulty<br />

regulating their BSLs and research<br />

indicates that incorporating low GI<br />

foods in<strong>to</strong> all meals can have many<br />

benefits including:<br />

Lowering the average BSL and reducing<br />

marked spikes and troughs,<br />

Improve the body’s ability <strong>to</strong> use<br />

glucose for energy,<br />

Lower ‘bad’ blood fats and improve<br />

good cholesterol, and<br />

Assists in weight management as it<br />

improves satiety after a meal.<br />

A balanced diet that is high in<br />

fruit, vegetables and wholegrain<br />

carbohydrates, and is low in<br />

saturated fat, salt, alcohol and<br />

refined sugars, will assist all people<br />