4-way thermostat adaptable valves for two-pipes ... - Watts Industries

4-way thermostat adaptable valves for two-pipes ... - Watts Industries

4-way thermostat adaptable valves for two-pipes ... - Watts Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

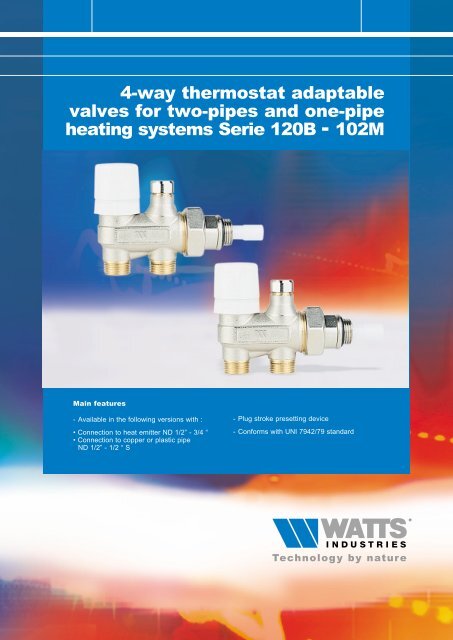

4-<strong>way</strong> <strong>thermostat</strong> <strong>adaptable</strong><br />

<strong>valves</strong> <strong>for</strong> <strong>two</strong>-<strong>pipes</strong> and one-pipe<br />

heating systems Serie 120B - 102M<br />

Main features<br />

- Available in the following versions with :<br />

• Connection to heat emitter ND 1/2” - 3/4 “<br />

• Connection to copper or plastic pipe<br />

ND 1/2” - 1/2 “ S<br />

- Plug stroke presetting device<br />

- Con<strong>for</strong>ms with UNI 7942/79 standard

4-WAY THERMOSTAT ADAPTABLE VALVES<br />

Description<br />

2<br />

The 4-<strong>way</strong> <strong>thermostat</strong> <strong>adaptable</strong> <strong>valves</strong>, Series 120B, 102M, are used as shut-off and control devices <strong>for</strong><br />

radiators in <strong>two</strong>-pipe and one-pipe heating systems respectively.<br />

The <strong>valves</strong> come in the configuration with 1/2” - 3/4” connection to the heat emitter and are provided with probe<br />

<strong>for</strong> separating the delivery flow from the return flow in the radiator.<br />

Connection of the <strong>valves</strong> to the heat emitter is through an O-ring sealed straight tailpiece and final washer with<br />

the aid of a hex. spanner.<br />

120B<br />

4-<strong>way</strong> nickel-plated <strong>thermostat</strong> <strong>adaptable</strong> valve <strong>for</strong> <strong>two</strong>-pipe systems.<br />

With presetting. Built-in lockshield valve. Connection <strong>for</strong> copper or plastic pipe.<br />

O-ring sealed straight tailpiece, complete with flow separation probe. ABS<br />

handwheel. Differential pressure (item 148): 1.5 bar.<br />

Compatible with <strong>thermostat</strong>ic actuators series 148 and electrothermic actuators 22C.<br />

Type Part Number Size body Size tube Kvs Weight (g)<br />

120B 120B12AM12 1/2" 1/2" 0,82 570<br />

120B 120B12AM34 3/4" 1/2" 0,93 570<br />

120B 120B24AM12 1/2" 1/2"S 0,82 580<br />

120B 120B24AM34 3/4" 1/2"S 0,93 580<br />

102M<br />

4-<strong>way</strong> nickel-plated <strong>thermostat</strong> <strong>adaptable</strong> valve <strong>for</strong> one-pipe systems with fixed<br />

by-pass. With presetting. Built-in lockshield valve. Connection <strong>for</strong> copper or<br />

plastic pipe. O-ring sealed straight tailpiece, complete with flow separation probe.<br />

ABS handwheel. Differential pressure (item 148) : 1.5 bar.<br />

Flow rate to radiator: 50%.<br />

Compatible with <strong>thermostat</strong>ic actuators series 148 and electrothermic actuators 22C.<br />

Type Part Number Size body Size tube Kvs Weight (g)<br />

102M 102M12AM12 1/2" 1/2" 2 560<br />

102M 102M12AM34 3/4" 1/2" 2,15 560<br />

102M 102M24AM12 1/2" 1/2"S 2 570<br />

102M 102M24AM34 3/4" 1/2"S 2,15 580<br />

Technical feature<br />

Max. temp. 110°C<br />

Max. pressure<br />

10 bar<br />

Max. differential pressure<br />

1.5 bar<br />

Fluids which can be used Water also with glycol ≤ 50%<br />

120B<br />

102M<br />

Kvn coefficient with proportional band 2K DN 1/2" = 1.76 DN 3/4" = 1.84<br />

DN 1/2" = 0.58 DN 3/4" = 0.62<br />

Kvn coefficient with proportional band 1K DN 1/2" = 1.56 DN 3/4" = 1.61<br />

DN 1/2" = 0.34 DN 3/4" = 0.38<br />

Design feature<br />

Valve body<br />

Plug seal<br />

Handwheel<br />

Radiator probe<br />

Panel radiator probe<br />

O-ring<br />

Tailpiece<br />

Brass CW617N<br />

EPDM<br />

ABS<br />

Modified polyether (PPE + PA)<br />

Copper<br />

EPDM<br />

Brass CW617N

4-WAY THERMOSTAT ADAPTABLE VALVES<br />

Application<br />

These <strong>valves</strong> are designed <strong>for</strong> manual room temperature control using just one connection <strong>for</strong> water inlet/outlet<br />

to/from the heat emitter. They can also be used <strong>for</strong> automatic temperature control when coupled to <strong>thermostat</strong>ic<br />

actuators (Series 148, 148SD, 148CD) or else electrothermic actuators (Art. 22C). The use of <strong>thermostat</strong>ic<br />

<strong>valves</strong> allows installation of metering systems (see Sections on Measuring and metering systems) as required by<br />

Italian legislation (Act 10/91 Art. 26). The <strong>valves</strong> are provided with active memory presetting which, when using<br />

<strong>thermostat</strong>ic or thermoelectric actuators, enables exact balancing of the heating system.<br />

3<br />

Such balancing is obtained by turning the ring nut located under the handwheel in order to limit the plug stroke.<br />

Above all, when removing the handwheel <strong>for</strong> <strong>thermostat</strong>ting the system, the active memory presetting holds the<br />

balancing made permanently.<br />

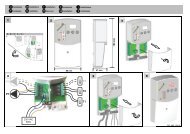

Installation<br />

Valve selection is based on the type of system (one-pipe or <strong>two</strong>-pipe) as well as size of the connection to the<br />

radiator and connecting piping. Valves, Series 120B, 102M, can be installed on heat emitters supplied by<br />

copper or plastic <strong>pipes</strong>. When it is required to <strong>thermostat</strong> the system, merely unscrew the control handwheel from<br />

the valve and substitute it with a <strong>thermostat</strong>ic or electrothermic actuator by tightening the ring nut.<br />

All this can be done without any plumbing work and with the system running. As with all the <strong>two</strong>-pipe and<br />

one-pipe <strong>valves</strong>, likewise <strong>valves</strong> 120B, 102M should be connected in the bottom part of the heat emitter.<br />

In order to ensure correct <strong>thermostat</strong>ic operation (i.e. with <strong>thermostat</strong>ic actuator Series 148), the delivery pipe<br />

must be connected to the connection under the valve control handwheel which should al<strong>way</strong>s be mounted in the<br />

horizontal direction. In the case of panel type radiators, use the copper probe (art. RV141). When excluding and<br />

removing the radiator, it is also necessary to regulate the special built-in lockshield. All this should be done<br />

without interrupting circulation of the fluid in the rest of the ring circuit.<br />

Reliability of the <strong>thermostat</strong> <strong>adaptable</strong> <strong>valves</strong>, Series 120B, 102M, is guaranteed thanks to the 100% testing of<br />

the production which checks pressure tightness of the valve body and its components towards the outside and<br />

that of the plug during its flow shut-off function.<br />

102M<br />

4<br />

3<br />

1<br />

2<br />

Details<br />

5<br />

1) O-ring sealed straight tailpiece<br />

2) Probe holder insert<br />

3) Lockshield<br />

120B<br />

4) Presetting stuffing box nut, can be<br />

replaced with the system under<br />

pressure through art. 225.<br />

4<br />

3<br />

1<br />

2<br />

5) By-pass

4-WAY THERMOSTAT ADAPTABLE VALVES<br />

Operation<br />

4<br />

Valve operation is controlled either by manual movement or by automatic movement of the plug which shuts off<br />

the heat carrier fluid.<br />

In <strong>valves</strong> of the 102M series, known as partial flow types <strong>for</strong> one-pipe systems, the water flow calculated <strong>for</strong> the<br />

entire ring circuit, is subdivided into one part <strong>for</strong> heat exchange and one part reaching the next heat emitter<br />

directly. This permanently open by-pass allows constant circulation of the heat carrier fluid even when the valve<br />

is fully closed with respect to the heat emitter. In <strong>valves</strong> of the 120B series <strong>for</strong> <strong>two</strong>-pipe systems, the flow of<br />

water reaches the heat emitter directly where the heat exchange takes place.<br />

To ensure efficiency of this, in <strong>valves</strong> Series 120B, 102M, the delivery and return flow is separated by a probe<br />

inserted in the heat emitter. The hydraulic flow rate and pressure drop cahracteristics <strong>for</strong> the <strong>valves</strong> can be<br />

deduced from the appropriate charts.<br />

102M<br />

Total Kv values (flow rate towards radiator + by-pass flow rate) Setting positions<br />

Setting positions 1 2 3 4 5 6 7 A<br />

DN 1/2" 1.50 1.60 1.75 1.80 1.85 1.90 1.95 2.00<br />

DN 3/4" 1.55 1.75 1.90 1.95 2.00 2.05 2.10 2.15<br />

102M<br />

“Supply coefficient” of the heating emitter, expressed in percentage<br />

of the flow passing through the distribution ring circuit is equal to:<br />

DN 1 2 3 4 5 6 7 A<br />

DN 1/2" - 3/4" 22% 30% 34% 36% 38% 40% 42% 50%<br />

120B - 102M<br />

Kv values in the various presetting positions<br />

Setting positions 1 2 3 4 5 6 7 A<br />

DN 1/2" 0.30 0.53 0.63 0.70 0.74 0.77 0.79 0.82<br />

DN 3/4" 0.30 0.56 0.67 0.75 0.81 0.85 0.88 0.93<br />

Overall dimension (mm)<br />

120B/102M<br />

105<br />

30 60<br />

70<br />

35

4-WAY THERMOSTAT ADAPTABLE VALVES<br />

Flow rate/pressure drop charts<br />

120B - DN 1/2" - 3/4"<br />

pos 3 Kv 0.65<br />

pos 4 Kv 0.73<br />

5<br />

pos 2 Kv 0.55<br />

pos 6 Kv 0.81<br />

[ kPa ]<br />

pos 1 Kv 0.30<br />

A Kv 0.88<br />

[ m bar ] [ mm w.g. ]<br />

20<br />

200<br />

2000<br />

10<br />

8<br />

100<br />

80<br />

1000<br />

800<br />

5<br />

4<br />

50<br />

40<br />

500<br />

400<br />

PRESSURE DROP<br />

3<br />

2<br />

1<br />

0.8<br />

0.5<br />

30<br />

20<br />

10<br />

5<br />

300<br />

200<br />

100<br />

50<br />

0.3<br />

3<br />

30<br />

0.2<br />

2<br />

20<br />

0.1<br />

1<br />

10 20 30 50 100 200 300 500 1000 2000 3000 [ l/h ]<br />

10<br />

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3<br />

3<br />

[ m /h ]<br />

FLOW RATE<br />

With actuator 148<br />

120B - DN 1/2" - 3/4"<br />

BP 3K=Kv 0.7<br />

BP 2K=Kv 0.6<br />

[ kPa ]<br />

BP 1K=Kv 0.36<br />

[ m bar ][ mm w.g. ]<br />

20<br />

200<br />

2000<br />

10<br />

8<br />

100<br />

80<br />

1000<br />

800<br />

PRESSURE DROP<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0.8<br />

0.5<br />

50<br />

40<br />

30<br />

20<br />

10<br />

5<br />

500<br />

400<br />

300<br />

200<br />

100<br />

50<br />

0.3<br />

3<br />

30<br />

0.2<br />

2<br />

20<br />

0.1<br />

1<br />

10 20 30 50 100 200 300 500 1000 2000 3000 [ l/h ]<br />

10<br />

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3<br />

3<br />

[ m /h ]<br />

FLOW RATE

4-WAY THERMOSTAT ADAPTABLE VALVES<br />

Flow rate/pressure drop charts<br />

6<br />

102M - DN 1/2"<br />

pos 3 Kv 1.75<br />

pos 1 Kv 1.50 A Kv 2.00<br />

[ kPa ]<br />

20<br />

By-Pass Kvs 1.25<br />

[ m bar ][ mm w.g. ]<br />

200<br />

2000<br />

10<br />

8<br />

100<br />

80<br />

1000<br />

800<br />

PRESSURE DROP<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0.8<br />

0.5<br />

50<br />

40<br />

30<br />

20<br />

10<br />

5<br />

500<br />

400<br />

300<br />

200<br />

100<br />

50<br />

0.3<br />

3<br />

30<br />

0.2<br />

2<br />

20<br />

0.1<br />

1<br />

10 20 30 50 100 200 300 500 1000 2000 3000 [ l/h ]<br />

10<br />

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3<br />

3<br />

[ m /h ]<br />

FLOW RATE<br />

With actuator 148<br />

102M - DN 1/2"<br />

BP 2K=Kv 1.76<br />

[ kPa ]<br />

20<br />

BP 1K=Kv 1.56<br />

[ m bar ][ mm w.g. ]<br />

200 2000<br />

10<br />

8<br />

100<br />

80<br />

1000<br />

800<br />

PRESSURE DROP<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0.8<br />

0.5<br />

50<br />

40<br />

30<br />

20<br />

10<br />

5<br />

500<br />

400<br />

300<br />

200<br />

100<br />

50<br />

0.3<br />

3<br />

30<br />

0.2<br />

2<br />

20<br />

0.1<br />

1<br />

10 20 30 50 100 200 300 500 1000 2000 3000<br />

[ l/h ]<br />

10<br />

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3<br />

3<br />

[ m /h ]<br />

FLOW RATE

4-WAY THERMOSTAT ADAPTABLE VALVES<br />

102M - DN 3/4"<br />

pos 3 Kv 1.90<br />

[ kPa ]<br />

pos 1 Kv 1.55 A Kv 2.15<br />

[ m bar ][ mm w.g. ]<br />

7<br />

20<br />

200<br />

2000<br />

10<br />

8<br />

100<br />

80<br />

1000<br />

800<br />

PRESSURE DROP<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0.8<br />

0.5<br />

50<br />

40<br />

30<br />

20<br />

10<br />

5<br />

500<br />

400<br />

300<br />

200<br />

100<br />

50<br />

0.3<br />

3<br />

30<br />

0.2<br />

2<br />

20<br />

0.1<br />

1<br />

10 20 30 50 100 200 300 500 1000 2000 3000 [ l/h ]<br />

10<br />

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3<br />

3<br />

[ m /h ]<br />

FLOW RATE<br />

With actuator 148<br />

102M - DN 3/4"<br />

BP 2K=Kv 1.84<br />

[ kPa ]<br />

20<br />

BP 1K=Kv 1.61<br />

[ m bar ][ mm w.g. ]<br />

200 2000<br />

10<br />

8<br />

100<br />

80<br />

1000<br />

800<br />

PRESSURE DROP<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0.8<br />

0.5<br />

0.3<br />

50<br />

40<br />

30<br />

20<br />

10<br />

5<br />

3<br />

500<br />

400<br />

300<br />

200<br />

100<br />

50<br />

30<br />

0.2<br />

2<br />

20<br />

0.1<br />

1<br />

10 20 30 50 100 200 300 500 1000 2000 3000<br />

[ l/h ]<br />

10<br />

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3<br />

3<br />

[ m /h ]<br />

FLOW RATE<br />

The descriptions and photographs contained in this product specification sheet are supplied by <strong>way</strong> of in<strong>for</strong>mation only and are not binding.<br />

<strong>Watts</strong> <strong>Industries</strong> reserves the right to carry out any technical and design improvements to its products without prior notice.

Product range <strong>Watts</strong> <strong>Industries</strong><br />

- System disconnectors<br />

- Backflow protection devices<br />

- Check <strong>valves</strong><br />

- Safety units<br />

- Safety relief <strong>valves</strong><br />

- Pressure reducing <strong>valves</strong><br />

- Automatic control <strong>valves</strong><br />

- Butterfly <strong>valves</strong><br />

- Shut off <strong>valves</strong><br />

- Measuring gauges<br />

- Temperature control<br />

- Expansion vessels<br />

- Process switches<br />

- Fuel products<br />

- Gas products<br />

- Electronic controls<br />

- Installation protection products<br />

- Radiator <strong>valves</strong><br />

- System products<br />

- Manifolds and fittings<br />

Re-order no. 67-0030-UK-IT/1-06-01-Rev.0<br />

<strong>Watts</strong> <strong>Industries</strong> Italia S.r.l.<br />

Via Brenno, 21 - 20046 Biassono (MI), Italy<br />

Ph. : +39 039 49.86.1 - Fax : +39 039 49.86.222<br />

e-mail : info@wattsindustries.it - www.wattsindustries.com