LINC FEED 45 - Lincoln Electric - documentations

LINC FEED 45 - Lincoln Electric - documentations

LINC FEED 45 - Lincoln Electric - documentations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

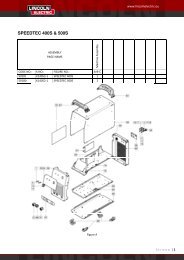

2. Left Knob: Adjusts values in left display.<br />

3. MSP4 Display Window: Shows detailed welding<br />

and diagnostic information.<br />

4. Set Knob: Changes the value on the MSP4 display.<br />

5. Left Button: Changes the MSP4 display to show the<br />

Weld Mode or Arc Control.<br />

6. 12-pin Connector: Connector for a remote control<br />

and a push-pull gun.<br />

7. Water Cooling Line: Warm water from torch.<br />

8. Water Cooling Line: Cool water to torch.<br />

9. EURO Connector.<br />

10. Right Button: Changes the MSP4 display to show<br />

Start Options or End Options.<br />

11. Set-Up: Lights when feeder is set-up.<br />

12. Thermal: Lights when the drive overheats.<br />

13. Right Knob: Adjusts values in the right display.<br />

14. Right Display Window: Shows Voltage or Trim.<br />

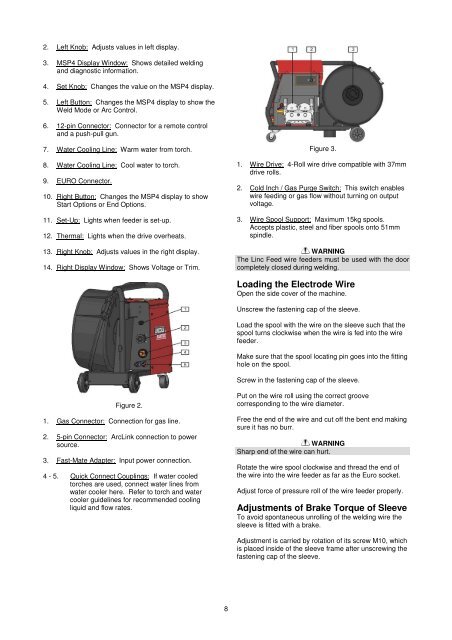

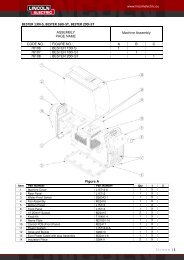

Figure 3.<br />

1. Wire Drive: 4-Roll wire drive compatible with 37mm<br />

drive rolls.<br />

2. Cold Inch / Gas Purge Switch: This switch enables<br />

wire feeding or gas flow without turning on output<br />

voltage.<br />

3. Wire Spool Support: Maximum 15kg spools.<br />

Accepts plastic, steel and fiber spools onto 51mm<br />

spindle.<br />

WARNING<br />

The Linc Feed wire feeders must be used with the door<br />

completely closed during welding.<br />

Loading the Electrode Wire<br />

Open the side cover of the machine.<br />

Unscrew the fastening cap of the sleeve.<br />

Load the spool with the wire on the sleeve such that the<br />

spool turns clockwise when the wire is fed into the wire<br />

feeder.<br />

Make sure that the spool locating pin goes into the fitting<br />

hole on the spool.<br />

Screw in the fastening cap of the sleeve.<br />

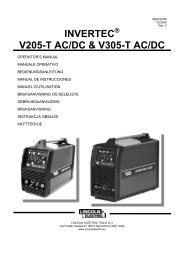

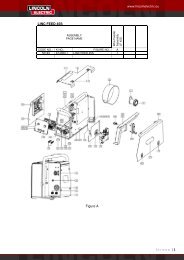

Figure 2.<br />

1. Gas Connector: Connection for gas line.<br />

2. 5-pin Connector: ArcLink connection to power<br />

source.<br />

3. Fast-Mate Adapter: Input power connection.<br />

4 - 5. Quick Connect Couplings: If water cooled<br />

torches are used, connect water lines from<br />

water cooler here. Refer to torch and water<br />

cooler guidelines for recommended cooling<br />

liquid and flow rates.<br />

Put on the wire roll using the correct groove<br />

corresponding to the wire diameter.<br />

Free the end of the wire and cut off the bent end making<br />

sure it has no burr.<br />

WARNING<br />

Sharp end of the wire can hurt.<br />

Rotate the wire spool clockwise and thread the end of<br />

the wire into the wire feeder as far as the Euro socket.<br />

Adjust force of pressure roll of the wire feeder properly.<br />

Adjustments of Brake Torque of Sleeve<br />

To avoid spontaneous unrolling of the welding wire the<br />

sleeve is fitted with a brake.<br />

Adjustment is carried by rotation of its screw M10, which<br />

is placed inside of the sleeve frame after unscrewing the<br />

fastening cap of the sleeve.<br />

8