wilpinjong coal project wilpinjong coal project - Department of ...

wilpinjong coal project wilpinjong coal project - Department of ...

wilpinjong coal project wilpinjong coal project - Department of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

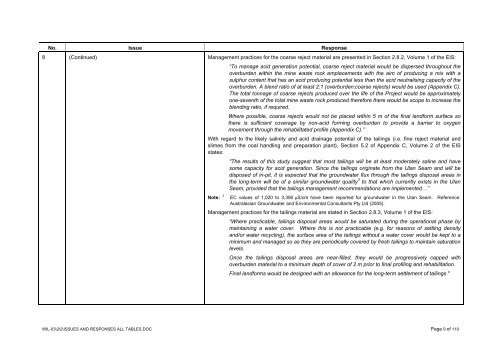

No. Issue Response<br />

8 (Continued) Management practices for the coarse reject material are presented in Section 2.8.2, Volume 1 <strong>of</strong> the EIS:<br />

“To manage acid generation potential, coarse reject material would be dispersed throughout the<br />

overburden within the mine waste rock emplacements with the aim <strong>of</strong> producing a mix with a<br />

sulphur content that has an acid producing potential less than the acid neutralising capacity <strong>of</strong> the<br />

overburden. A blend ratio <strong>of</strong> at least 2:1 (overburden:coarse rejects) would be used (Appendix C).<br />

The total tonnage <strong>of</strong> coarse rejects produced over the life <strong>of</strong> the Project would be approximately<br />

one-seventh <strong>of</strong> the total mine waste rock produced therefore there would be scope to increase the<br />

blending ratio, if required.<br />

Where possible, coarse rejects would not be placed within 5 m <strong>of</strong> the final landform surface so<br />

there is sufficient coverage by non-acid forming overburden to provide a barrier to oxygen<br />

movement through the rehabilitated pr<strong>of</strong>ile (Appendix C).”<br />

With regard to the likely salinity and acid drainage potential <strong>of</strong> the tailings (i.e. fine reject material and<br />

slimes from the <strong>coal</strong> handling and preparation plant), Section 5.2 <strong>of</strong> Appendix C, Volume 2 <strong>of</strong> the EIS<br />

states:<br />

"The results <strong>of</strong> this study suggest that most tailings will be at least moderately saline and have<br />

some capacity for acid generation. Since the tailings originate from the Ulan Seam and will be<br />

disposed <strong>of</strong> in-pit, it is expected that the groundwater flux through the tailings disposal areas in<br />

the long-term will be <strong>of</strong> a similar groundwater quality 3 to that which currently exists in the Ulan<br />

Seam, provided that the tailings management recommendations are implemented…”<br />

Note: 3<br />

EC values <strong>of</strong> 1,020 to 3,390 μS/cm have been reported for groundwater in the Ulan Seam. Reference:<br />

Australasian Groundwater and Environmental Consultants Pty Ltd (2005).<br />

Management practices for the tailings material are stated in Section 2.8.3, Volume 1 <strong>of</strong> the EIS:<br />

“Where practicable, tailings disposal areas would be saturated during the operational phase by<br />

maintaining a water cover. Where this is not practicable (e.g. for reasons <strong>of</strong> settling density<br />

and/or water recycling), the surface area <strong>of</strong> the tailings without a water cover would be kept to a<br />

minimum and managed so as they are periodically covered by fresh tailings to maintain saturation<br />

levels.<br />

Once the tailings disposal areas are near-filled, they would be progressively capped with<br />

overburden material to a minimum depth <strong>of</strong> cover <strong>of</strong> 2 m prior to final pr<strong>of</strong>iling and rehabilitation.<br />

Final landforms would be designed with an allowance for the long-term settlement <strong>of</strong> tailings."<br />

WIL-03\2\2\ISSUES AND RESPONSES ALL TABLES.DOC Page 9 <strong>of</strong> 119