SIMATIC ET 200S - Bit-modular distributed I/O system - Induteq

SIMATIC ET 200S - Bit-modular distributed I/O system - Induteq

SIMATIC ET 200S - Bit-modular distributed I/O system - Induteq

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Bit</strong>-<strong>modular</strong> <strong>distributed</strong> I/O <strong>system</strong><br />

Product Brief · March 2003

<strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> the multi-functional, extremely<br />

flexible <strong>distributed</strong> I/O <strong>system</strong><br />

<strong>SIMATIC</strong>® <strong>ET</strong> 200®S is a <strong>distributed</strong> I/O<br />

<strong>system</strong> with degree of protection IP20.<br />

It combines extremely simple installation<br />

and maximum flexibility with<br />

permanent savings in life-cycle costs.<br />

Summary of features<br />

· <strong>Bit</strong>-<strong>modular</strong> design for precise adaptation<br />

to the automation task<br />

· Independent wiring<br />

· Wide range of modules:<br />

- Input/output modules<br />

- Process modules<br />

-Motor starters<br />

- Control functionality with CPU integration<br />

· Various connection possibilities for<br />

the terminal modules<br />

· Reserve modules for reservation of<br />

unused module slots<br />

· Replaceable terminal box<br />

· Use also possible for time-critical<br />

tasks<br />

· Integration of "Safety Integrated"<br />

· Replacement of electronics modules<br />

and motor starters during operation<br />

(hot swapping)<br />

· Simple diagnostics for exact channel<br />

permits high availability: High-feature<br />

or standard; <strong>system</strong> faults, for<br />

example a missing supply voltage, are<br />

automatically signalled as plain text<br />

using the bus without programming<br />

input.<br />

Applications<br />

· The comprehensive range of modules<br />

with uniform handling for configuring,<br />

installation and programming<br />

mean that the <strong>ET</strong> <strong>200S</strong> can be used as<br />

a universal I/O <strong>system</strong>.<br />

· The mechanical design of the <strong>ET</strong> <strong>200S</strong><br />

permits use with increased mechanical<br />

loading. The <strong>system</strong> properties<br />

support high plant availability<br />

requirements. The <strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> is<br />

therefore exceptionally suitable for<br />

use with extremely time-critical applications.<br />

Design<br />

The bit-<strong>modular</strong> design permits fast and<br />

optimum adaptation to the requirements<br />

of any automation <strong>system</strong>:<br />

· No stocking of spares<br />

· No superfluous channels<br />

The plant setting-up times can be significantly<br />

reduced even with frequently<br />

changing requirements by the replacement<br />

or combination of various I/O<br />

modules.<br />

The <strong>ET</strong> <strong>200S</strong> results in wiring savings of<br />

up to 80% for the following reasons:<br />

· All supply voltages are only<br />

connected once, and automatically<br />

connected to the next module when<br />

mounting side by side.<br />

· All motor starters are completely<br />

prewired apart from the motor<br />

connection (with a conventional<br />

design, up to 15 connections must be<br />

made.)<br />

IM 151Interface<br />

module<br />

PM-D power module<br />

PM-E power module<br />

Electronics modules<br />

Terminal modules<br />

Motor starters<br />

· The power supply to the individual<br />

motor starters is handled by a power<br />

bus with a rating up to 50 A.<br />

· All terminals have the characteristics<br />

of terminal blocks - signal and motor<br />

cables can therefore be directly<br />

connected to the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong><br />

without intermediate terminals.<br />

· Safety technology is also part of the<br />

<strong>system</strong> - and thus also prewired as far<br />

as possible.<br />

The compact design, flush mounting<br />

side by side, omission of various cable<br />

ducts and the elimination of terminal<br />

blocks mean that space savings are<br />

guaranteed. This is also particularly<br />

important when using motor starters.<br />

With a completely <strong>distributed</strong> design<br />

directly on the machine, only the power<br />

supplies and host control <strong>system</strong>s are<br />

usually required in the control room.<br />

When comparing the <strong>ET</strong> <strong>200S</strong> to established<br />

solutions you can achieve up to<br />

50% less space requirements in the<br />

control cabinet and 80% saving in<br />

wiring!<br />

Bus terminating module<br />

TM-D t8<br />

terminal module with<br />

integral power bus<br />

PE/N assembly<br />

The bit-<strong>modular</strong> design of the <strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong><br />

2

<strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> <br />

simple installation and wiring<br />

Installation<br />

It’s impossible to be simpler!<br />

· Snap the interface module onto the<br />

standard rail.<br />

· The terminal modules can then be<br />

fitted side by side without tools.<br />

· The self-coding prevents destruction<br />

of the electronics as a result of an I/O<br />

module being inadvertently plugged<br />

into the wrong position.<br />

You can watch a corresponding installation<br />

film on the Internet:<br />

www.siemens.com/simatic-dp/et200s<br />

Strip-free Fast Connect <strong>system</strong><br />

The insulation displacement <strong>system</strong><br />

without the need for wire stripping<br />

presents even more advantages when<br />

installing. The TM-P and TM-E electronics<br />

and power modules have been<br />

extended by the Fast Connect insulation<br />

displacement <strong>system</strong> without wire stripping.<br />

All common conductor<br />

cross-sections from 0.25 to 1.5 mm²<br />

can be connected using the new<br />

<strong>system</strong>. Preparation for installation is<br />

unnecessary. In addition to the advantages<br />

of the proven <strong>ET</strong> <strong>200S</strong> <strong>system</strong>, the<br />

new technology also enables:<br />

· Time savings of up to 60% during<br />

installation compared to conventional<br />

connection <strong>system</strong>s<br />

· No stripping or crimping necessary<br />

· Simple and reliable installation using<br />

a screwdriver<br />

· Reduction in error rate during installation<br />

· Definition of stripping length is<br />

unnecessary<br />

· Reliability with gas-tight connection<br />

Snap on<br />

Wire up, test<br />

"Independent wiring"<br />

The so-called independent wiring is a<br />

specific characteristic of <strong>SIMATIC</strong><br />

<strong>ET</strong> <strong>200S</strong>: the mechanical components<br />

(terminal modules) are isolated from<br />

the electronic components (electronics<br />

modules, power modules, motor<br />

starters). The independent wiring not<br />

only facilitates design of the station, it<br />

also has a positive effect on the availability<br />

during operation:<br />

· Complete prewiring is possible prior<br />

to fitting the electronics modules and<br />

motor starters - either using screw or<br />

spring-mounted terminals as well as<br />

the Fast Connect <strong>system</strong> without<br />

stripping.<br />

· The subsequent wiring test is even<br />

possible under power because endangered<br />

electronics components have<br />

not yet been inserted.<br />

· Thanks to the self-assembling power<br />

buses, much of the cross-wiring<br />

belongs to the past - this reduces test<br />

requirements and possible sources of<br />

error.<br />

· The terminal modules have been<br />

designed with the form and function<br />

of a commercially available terminal<br />

block. This guarantees simple, clear<br />

wiring with acquainted handling.<br />

· The module inscriptions are not<br />

hidden by the wiring.<br />

· The removable terminal box permits<br />

simple connection of simulation<br />

computers for preliminary commissioning.<br />

Plug on finished!<br />

Hot swapping for maximum availability<br />

Hot swapping of electronics modules<br />

and motor starters is possible without<br />

tools. The <strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> can<br />

continue operation during swapping,<br />

meaning that the application remains<br />

fully functional in many cases.<br />

With motor starters, it is even possible<br />

to omit isolation of the <strong>system</strong> which is<br />

usually obligatory.<br />

Accessories<br />

The <strong>ET</strong> <strong>200S</strong> is well equipped for practice<br />

with a versatile range of accessories:<br />

· System-integrated shield connection<br />

<strong>system</strong> with the following advantages:<br />

- Low-impedance connection via<br />

3 x 10 mm busbar<br />

- Individual lengths<br />

- Simple, fast installation with plug on<br />

technology<br />

- Space-saving<br />

- Cost-effective as result of standard<br />

components<br />

· Individual colored labels for the<br />

terminals on the terminal modules<br />

and for identification of slot numbers;<br />

available in various colors and also<br />

individually packed.<br />

· Identification labels for numbering<br />

the terminal modules: pre-labelled or<br />

blank.<br />

· DIN A4 labelling sheets in various<br />

colors, pre-perforated, suitable for<br />

printing with laser printer<br />

More information available at:<br />

www.s7-smartlabel.de<br />

Terminal module with new strip-free Fast<br />

Connect <strong>system</strong><br />

3

<strong>SIMATIC</strong>T <strong>ET</strong> <strong>200S</strong> <br />

increased safety with fail-safe signal modules<br />

The <strong>ET</strong> <strong>200S</strong> provides you with the<br />

capability to design economical solutions<br />

for safety-oriented applications for<br />

the production industry. It comprises a<br />

fail-safe CPU S7-315F, corresponding<br />

fail-safe I/O modules for the <strong>ET</strong> <strong>200S</strong><br />

<strong>distributed</strong> I/O <strong>system</strong>, and special<br />

drivers for interfacing field devices from<br />

other vendors.<br />

Fail-safe components<br />

The following fail-safe CPUs are available:<br />

CPU 315F of the S7-300®,<br />

CPU 416F of the S7-400® and<br />

IM 151-7F-CPU of the <strong>ET</strong> <strong>200S</strong>.<br />

Applications with the maximum safety<br />

category 4 to EN954-1 can be implemented<br />

in a simple manner using the<br />

new fail-safe modules of the <strong>ET</strong> <strong>200S</strong><br />

<strong>system</strong> and a <strong>SIMATIC</strong> F-CPU.<br />

Safety signals, for example from light<br />

barriers, EMERGENCY STOP buttons,<br />

protective door switches etc., are<br />

recorded on site by the <strong>distributed</strong><br />

fail-safe input module "4/8F-DI" of the<br />

<strong>ET</strong> <strong>200S</strong> <strong>system</strong>. The safety-oriented<br />

data are then transmitted together with<br />

the standard data to the host PLC via a<br />

common PROFIBUS DP cable using the<br />

PROFIsafe profile. A special bus cable,<br />

or even an extra safety bus <strong>system</strong>, is no<br />

longer necessary. "Safe" and "normal"<br />

modules can be mixed together.<br />

Advantages compared to conventional<br />

safety <strong>system</strong>s<br />

· Significant saving of components<br />

(less hardware)<br />

· Less assembly and installation work<br />

· High flexibility<br />

· When changes are necessary,<br />

programming replaces wiring<br />

· Implementable fail-safe and<br />

fault-tolerant motor starters<br />

<strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> with fail-safe<br />

motor starter and S7-300F CPU<br />

S7-400 F with F-CPU and standard<br />

I/Os<br />

<strong>ET</strong> 200M with standard I/Os<br />

Operator panel<br />

<strong>ET</strong> 200M with<br />

fail-safe I/Os<br />

<strong>ET</strong> <strong>200S</strong> with standard I/Os, fail-safe<br />

I/Os and fail-safe motor starters<br />

Laser scanner<br />

Light curtain<br />

Example of a configuration (fail-safe I/Os shown in yellow, standard I/Os in blue)<br />

4

<strong>ET</strong> <strong>200S</strong> <br />

Motor starters for every application<br />

The <strong>ET</strong> <strong>200S</strong> motor starters are used for<br />

protecting and switching all kinds of AC<br />

loads. The completely prewired devices<br />

are available in a variety of performance<br />

classes as direct, reversing or soft starters<br />

up to a max. power of 7.5 kW. The<br />

terminal modules contain the self-assembling<br />

power bus (one-time infeed<br />

for up to 20 motor starters) and the terminals<br />

for direct connection of the motor<br />

cable. A motor starter can be<br />

plugged/unplugged without isolating<br />

the plant.<br />

Motor starter of the <strong>ET</strong> <strong>200S</strong><br />

Standard motor starter<br />

· Circuit-breaker/contactor combination<br />

up to 5.5 kW<br />

· Direct or reversing starter<br />

· Self-assembling power bus up to 40 A<br />

· SIGUARD safety technology optional<br />

High-feature motor starter<br />

· Combination of starter circuit-breaker,<br />

electronic overload relay and<br />

contactor or soft starter up to 7.5 kW<br />

· Extensive diagnostics messages, e.g.<br />

momentary current value<br />

· Statistics, e.g. current of the last overload,<br />

can be read-out using the ES<br />

motor starter service and startup software<br />

switch<br />

· Parameterization via bus<br />

· Only two current setting ranges up to<br />

7.5 kW<br />

Graded safety concept<br />

The motor starters of the <strong>ET</strong> <strong>200S</strong> offer<br />

a graded safety concept. Depending on<br />

application it is possible to select the<br />

optimum solution on a function/cost basis<br />

to suit each case in hand.<br />

<strong>ET</strong> <strong>200S</strong> SIGUARD<br />

<strong>ET</strong> <strong>200S</strong> SIGUARD saves a lot on wiring<br />

on the basis of conventional safety relays<br />

in less complex local safety applications.<br />

Power modules for Emergency-Stop<br />

or safety door applications are<br />

available just like modules for time delay<br />

and contact multiplication.<br />

The safety sensors are connected directly<br />

on these local modules.<br />

Function monitoring, e.g. for cross connection,<br />

is implemented just like the<br />

monitoring of the switching function of<br />

the motor starters in the <strong>ET</strong> <strong>200S</strong><br />

SIGUARD modules. <strong>ET</strong> <strong>200S</strong> SIGUARD<br />

modules automatically signal operating<br />

and error states via PROFIBUS diagnostics<br />

to the higher-level controller.<br />

Cascading of safety segments within an<br />

<strong>ET</strong> <strong>200S</strong> station is possible by corresponding<br />

combination of SIGUARD modules<br />

or their terminal modules.<br />

For Category 3 or 4, external redundancy<br />

contactors are looped into the power<br />

infeed of the power bus. These contactors<br />

are also controlled and monitored<br />

by the SIGUARD modules.<br />

Fail-safe motor starter<br />

As soon as more complex or physically<br />

remote safety applications are involved,<br />

the fail-safe motor starter is the optimum<br />

solution in combination with the<br />

power module PM-D F PROFIsafe. Signals<br />

from safe sensors are read in via<br />

safe inputs at a random location in the<br />

plant, transmitted via PROFIBUS and the<br />

PROFIsafe message frame to the failsafe<br />

controller and linked there in the user<br />

program to the fail-safe motor starter or<br />

the associated power module.<br />

These motor starters based on the<br />

high-feature motor starter offer a completely<br />

new and patented technology<br />

for safety disconnection: whereas in<br />

normal operation the contactor<br />

performs disconnection, the integrated<br />

double processor monitor also switches<br />

off the circuit breaker in the event of a<br />

fault, e.g. welded contactor contacts.<br />

Each individual motor starter thus<br />

achieves Category 4 or SIL 3 without an<br />

additional redundancy contactor.<br />

Since the fail-safe motor starters monitor<br />

the contactor function regardless of<br />

whether the application is safety-relevant<br />

or not, these devices are also suitable<br />

for use in fault-tolerant processes.<br />

Additional features for high availability<br />

are:<br />

· Type of coordination 2 over the entire<br />

power range up to 7.5 kW<br />

· Emergency Stop function permits important<br />

processes to be finished despite<br />

reason to switch off, e.g.<br />

overload.<br />

Advantages in comparision to conventional<br />

safety technology:<br />

· Considerably fewer components,<br />

clearer design and much less hardware<br />

configuring and wiring<br />

· Easy installation thanks to simple connection<br />

· Motor starters have a high availability<br />

and are fail-safe<br />

· High flexibility through software-oriented<br />

assignment of the safety<br />

groups<br />

· Minimum overhead when modifying<br />

the safety application, since the<br />

wiring remains the same<br />

5

<strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> <br />

increased functionality with CPUs, IQ Sense<br />

and power supply<br />

Distributed intelligence -<br />

intelligent CPU of the <strong>ET</strong> <strong>200S</strong><br />

The IM 151-7 CPU can be used for<br />

<strong>distributed</strong> automation solutions with a<br />

medium program size. It permits <strong>distributed</strong><br />

preprocessing of production data<br />

on site.<br />

The CPU communicates with the host<br />

controller via the coexistent<br />

MPI/PROFIBUS DP slave interface. This<br />

results in the following advantages:<br />

· Reduced loading on central controller<br />

· Reduced response times to critical<br />

local signals<br />

· Programs become clearer and shorter<br />

· Troubleshooting is facilitated<br />

· Reduces loading on bus <strong>system</strong><br />

· Permits <strong>modular</strong> plant design and<br />

preliminary commissioning - even at<br />

different locations<br />

Using the new DP master module it is<br />

possible to add an integrated DP master<br />

interface to the IM 151-7 CPU and thus<br />

implement an underlying PROFIBUS<br />

line with additional <strong>distributed</strong> I/Os.<br />

All this does not require additional software<br />

handling, since <strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong><br />

can be configured, programmed and<br />

diagnosed on the PROFIBUS from any<br />

position using STEP 7. The STEP 7 Lite<br />

programming tool is available for<br />

non-networked applications.<br />

Status/control functions are also<br />

possible via the PROFIBUS. Thanks to<br />

the plug-in <strong>SIMATIC</strong> Micro Memory<br />

Card, the application program is immediately<br />

available again following<br />

module replacement. Thus <strong>SIMATIC</strong><br />

<strong>ET</strong> <strong>200S</strong> with IM 151-7 CPU can be used<br />

as a bit-<strong>modular</strong> small control <strong>system</strong>.<br />

IM 151-7 CPU interface module with integral<br />

CPU (also available as an F-version) and<br />

master module<br />

Intelligent sensor module -<br />

IQ Sense®<br />

The four-channel IQ Sense® sensor<br />

module together with the new<br />

IQ Sense sensors provides a new<br />

concept for intelligent linking of sensor<br />

technology into automation technology.<br />

The <strong>ET</strong> <strong>200S</strong> provides all functions<br />

for any PROFIBUS DP master<br />

modules.<br />

Standard function blocks are offered for<br />

simple handling on a <strong>SIMATIC</strong> S7.<br />

Up to four sensors can be connected<br />

with just two lines each, and parameterized<br />

using the Intelliteach® function.<br />

Main applications are plants and<br />

machines<br />

· with high availability demands,<br />

· with high probability of mutual influencing<br />

of sensors<br />

· with high flexibility or dynamic modifications<br />

for the sensor parameters<br />

N<br />

Power supply<br />

A highly compact power supply measuring<br />

a mere 90 mm wide is available for<br />

the <strong>ET</strong> <strong>200S</strong>. The <strong>ET</strong> <strong>200S</strong> power supply<br />

permits 2-phase connection of 240 or<br />

400 V AC.<br />

The stabilized output voltage of 24 V DC<br />

can supply a maximum of 5A continuous<br />

current and is stable at no load<br />

and is short-circuit resistant. With a high<br />

efficiency of over 92% the <strong>ET</strong> <strong>200S</strong><br />

power supply ensures efficient power<br />

conversion and a cool switchbox. The<br />

power supply can be set to standby<br />

mode and the output side thus switched<br />

to voltage-free. Three LEDs<br />

provide users at all times with clear<br />

information on the present operating<br />

status.<br />

6<br />

A plug-in terminal is used for the wiring,<br />

which means that if the worst comes to<br />

the worst the power supply can be<br />

changed quickly and reliably without<br />

rewiring. Due to its compact size the<br />

power supply can also be used in <strong>distributed</strong><br />

applications independently of the<br />

<strong>ET</strong> <strong>200S</strong>.<br />

IQ Sense sensor module<br />

Power supply for the <strong>ET</strong> <strong>200S</strong>

<strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> <br />

range of modules<br />

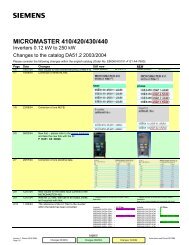

Module type Information Order No. group<br />

Interface module<br />

· IM 151-1 BASIC: max. 12 modules<br />

· IM 151-1 STANDARD: max. 63 modules<br />

· IM 151-1 FO STANDARD: similar to Standard, but with fiber-optic interface<br />

(plastic, PCF) RS 485<br />

· IM 151-1 HIGH FEATURE: max. 63 modules, DP V1 slave, isochrone mode<br />

· IM 151-7 CPU: with integrated CPU 314 of the S7-300<br />

· IM 151-7 F-CPU: with integrated CPU<br />

IM 151-1: 6ES7151-1...<br />

IM 151-7 CPU:6ES7151-7...<br />

DP master module · PROFIBUS DP master interface module for a low-level PROFIBUS line 6ES7138-4HA00-...<br />

Power modules for electronics<br />

modules and<br />

motor starters<br />

Terminal modules<br />

For power supply and monitoring of load and sensor voltage; voltage and/or<br />

fuse failure; additional LEDs provide information on status of voltage and<br />

fuse; different functions AC, DC, PROFIsafe<br />

· PM-E 24 V DC or PM-E 24 V DC; with diagnostics<br />

· PM-E 24 V DC to 230 V AC with diagnostics and fuse<br />

· PM-E F 24 V DC PROFIsafe for electronics modules<br />

· PM-D F 24 V DC PROFIsafe for F-motor starters<br />

For the electrical and mechanical connections of the I/O modules and<br />

process wiring. Available with screw and spring-mounted terminals and with<br />

the Fast Connect <strong>system</strong> without stripping<br />

TM-P for power; TM-E for electronics; TM-D for motor starters<br />

Electronic modules<br />

Provide the <strong>ET</strong> <strong>200S</strong> with digital inputs and outputs; high-feature versions increase the plant availability and<br />

offer supplementary functions and diagnostics<br />

Digital input modules<br />

Digital output modules<br />

Analog input modules<br />

Analog output modules<br />

· 2-channel and 4-channel<br />

· Available from 24 V DC to 230 V AC<br />

· Different functionalities: standard, high-feature<br />

· Fail-safe input module 4/8F-DI 24 V DC PROFIsafe<br />

· 2-channel and 4-channel<br />

· Available from 24 V DC to 230 V AC; 0.5 to 5 A<br />

· Different functionalities: standard, high-feature<br />

· Electronics and relays<br />

· Fail-safe output module 4F-DO 24 V DC/2A PROFIsafe<br />

· 2-channel<br />

· Current and voltage inputs, thermocouple and resistance measurements<br />

· Functionalities: standard, high-feature, high-speed<br />

· 2-channel<br />

· Current and voltage outputs<br />

· Functionalities: standard, high-feature<br />

6ES7138-4CA..<br />

6ES7138-4CB..<br />

6ES7138-4CF..<br />

3RK1903-0A..<br />

6ES7193-4.../3RK1903-0A..<br />

6ES7131-4...<br />

6ES7 138-4FA..<br />

6ES7132-4...<br />

6ES7 138-4FB..<br />

6ES7134-4...<br />

6ES7135-4...<br />

Reserve modules · As reserve module for unused slots within an <strong>ET</strong> <strong>200S</strong> station 6ES7138-4...<br />

IQ Sense sensor module<br />

Process modules<br />

Motor starters (also with<br />

integrated safety technology)<br />

· 4-channel<br />

· For connection of up to four IQ Sense sensors<br />

· Expanded diagnostics and IntelliTeach® functionality<br />

Intelligent modules operating independent of the CPU; use directly on site;<br />

parameterization using STEP 7 or GSD files; serial interface<br />

· Counter module: 24 V DC / 100 kHz or 5 V DC / 500 kHz 1 COUNT<br />

· SSI module 1 SSI<br />

· Positioning module for controlled positioning 1 POS<br />

· Stepper motor module 1 STEP<br />

· Pulse module (timer, pulse width modulation, stepper motor) 2 PULSE<br />

· Serial interface module 1 SI<br />

· Direct, reversing and soft starters<br />

· Functionalities: standard, high-feature, fail-safe<br />

· Up to 7.5 kW<br />

6ES7138-4...<br />

6ES7138-4...<br />

6ES7138-4...<br />

6ES7138-4...<br />

6ES7138-4...<br />

6ES7138-4...<br />

6ES7138-4...<br />

3RK1301-....<br />

3RK1301-....<br />

3RK1903-....<br />

7

Technical specifications<br />

Technical specifications of the <strong>ET</strong> <strong>200S</strong> - general<br />

Standards, approvals<br />

Degree of protection IP 20 · PROFIBUS EN 50 170, Volume 2<br />

Ambient temperature 0 to 60 °C · IEC 1131 IEC 1131, Part 2<br />

Vibration resistance up to max 5 g,<br />

(max. 2 g for motor starters)<br />

· Number of I/O modules per<br />

station, max<br />

· Station width, max<br />

· User data length, max<br />

Master <strong>system</strong> requirements<br />

· PROFIBUS DP master<br />

· Parameter length<br />

· User data length<br />

· Diagnostics length, adjustable<br />

63<br />

2 m<br />

244 byte each for inputs and<br />

outputs<br />

Corresponding to EN 50170<br />

> 32 byte, according to number<br />

and type of inserted modules<br />

According to number and type<br />

of inserted modules<br />

Up to 64 byte<br />

· UL According to standard UL508,<br />

File No. E 116536/E 75310<br />

(AC modules)<br />

· CSA According to standard C22.2<br />

No. 142. File No. LR 48323/<br />

LR 44226 (AC modules)<br />

· cULus<br />

for hazardous locations<br />

According to standard UL 508<br />

File no. E 116536<br />

According to hazardous locations<br />

UL 1604<br />

File No. E 222109<br />

According to standard CSA C22.2<br />

No. 142<br />

· FM Standard Class No. 3611,<br />

Class I Div. 2, Group A, B, C, D<br />

Class I, Zone 2, Group IIC<br />

(without motor starters)<br />

· Marine engineering American Bureau of Shipping<br />

Bureau Veritas<br />

Det Norske Veritas<br />

Germanischer Lloyd<br />

Lloyds Register of Shipping<br />

Nippon Kaiji Kyokai<br />

· Ex approval Cat. 3<br />

(for zone 2 according to<br />

ATEX-100a)<br />

EN 50 021<br />

Accessories<br />

Wide range of accessories, e.g.<br />

· Colored labelling strips, colored coding<br />

labels<br />

· System-integrated shield connection<br />

<strong>system</strong><br />

· Manuals<br />

6ES7193-4..<br />

Additional information on the<br />

<strong>SIMATIC</strong> <strong>ET</strong> <strong>200S</strong> can be found in the<br />

Internet:<br />

www.siemens.com/simatic-dp<br />

For personal consultation you can find<br />

your local <strong>SIMATIC</strong> partner at:<br />

www.siemens.com/automation/partner<br />

Using the A&D Mall you can immediately<br />

and directly order electronically<br />

in the Internet:<br />

www.siemens.com/automation/mall<br />

All designations marked in this<br />

Product Brief with ® are registered<br />

trademarks of the Siemens AG.<br />

Siemens AG<br />

Automation and Drives<br />

Postfach 4848, D-90327 Nürnberg<br />

Federal Republic of Germany<br />

www.siemens.com/simatic-dp<br />

Order No.: 6ZB5310-0KG02-0BA1<br />

Printed in the Federal Republic of Germany<br />

26100/301388 SMT 03036.<br />

© Siemens AG 2003<br />

Subject to change without prior notice.