Topgear - ddcsn

Topgear - ddcsn

Topgear - ddcsn

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Issue 4 2009<br />

TOPGEAR<br />

BEST PERFORMING ENGINES. BEST PERFORMING NETWORK.<br />

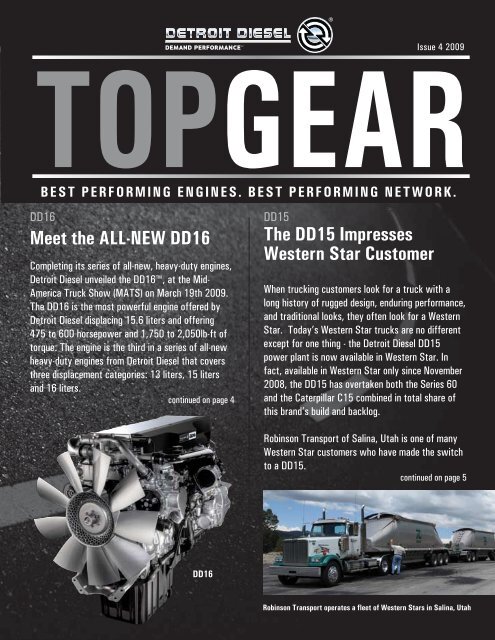

DD16<br />

Meet the ALL-NEW DD16<br />

Completing its series of all-new, heavy-duty engines,<br />

Detroit Diesel unveiled the DD16, at the Mid-<br />

America Truck Show (MATS) on March 19th 2009.<br />

The DD16 is the most powerful engine offered by<br />

Detroit Diesel displacing 15.6 liters and offering<br />

475 to 600 horsepower and 1,750 to 2,050lb-ft of<br />

torque. The engine is the third in a series of all-new<br />

heavy-duty engines from Detroit Diesel that covers<br />

three displacement categories: 13 liters, 15 liters<br />

and 16 liters.<br />

continued on page 4<br />

DD15<br />

The DD15 Impresses<br />

Western Star Customer<br />

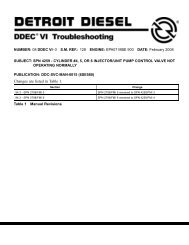

When trucking customers look for a truck with a<br />

long history of rugged design, enduring performance,<br />

and traditional looks, they often look for a Western<br />

Star. Today’s Western Star trucks are no different<br />

except for one thing - the Detroit Diesel DD15<br />

power plant is now available in Western Star. In<br />

fact, available in Western Star only since November<br />

2008, the DD15 has overtaken both the Series 60<br />

and the Caterpillar C15 combined in total share of<br />

this brand’s build and backlog.<br />

Robinson Transport of Salina, Utah is one of many<br />

Western Star customers who have made the switch<br />

to a DD15.<br />

continued on page 5<br />

DD16<br />

Robinson Transport operates a fleet of Western Stars in Salina, Utah

2<br />

BlueTec<br />

A BIG Advantage from a simple name<br />

Nearly four years ago, when Detroit<br />

Diesel first confirmed that it would<br />

employ SCR (selective catalytic<br />

reduction) technology in order to meet<br />

the EPA2010 emissions reduction<br />

regulations, the goal was simply to be<br />

able to meet the target NOx and PM<br />

levels on time. At the time it was clear<br />

that EGR and advanced combustion<br />

techniques would only solve part of<br />

the challenge. SCR would have to<br />

accomplish the rest. But what was<br />

not fully understood was how the<br />

aftertreatment hardware would be<br />

packaged on the vehicle or how the<br />

systems would perform not only for<br />

emissions reduction but also overall<br />

operating cost. The next few years of<br />

development on the Detroit Diesel 2010<br />

system would prove to be time well<br />

spent. BlueTec emissions technology<br />

would become the name of Detroit<br />

Diesel’s system of a new, optimized<br />

engine family plus aftertreatment<br />

that would deliver outstanding fuel<br />

economy with near zero emissions.<br />

The most surprising advantage for<br />

Detroit Diesel would be in an invention<br />

that would acquire an almost overly<br />

simple name. The 1-Box TM system is<br />

the name of Detroit Diesel’s proprietary<br />

design of aftertreatment for 2010<br />

that encompasses both the 2007<br />

www.detroitdiesel.com<br />

BlueTec 1-Box System<br />

particulate emissions system (diesel<br />

oxidation catalyst, or DOC, and diesel<br />

particulate filter, or DPF) plus the<br />

2010 SCR catalyst. It is an innovation<br />

that is truly a competitive advantage<br />

for Detroit Diesel. “Detroit Diesel and<br />

Daimler Trucks engineers worked<br />

together to develop a fully-integrated<br />

aftertreatment system to meet Detroit<br />

Diesel’s goals for EPA 2010 – NOx<br />

reduction, fuel economy improvements<br />

and simple truck packaging options. The<br />

result is the “1-Box” system, it includes<br />

all the aftertreatment functionality of<br />

the 2007 system and the necessary<br />

components to meet EPA 2010. The<br />

1-Box also meets the goal of best-inclass<br />

lifecycle cost.” said Rakesh Aneja,<br />

senior manager - aftertreatment and<br />

applications, Detroit Diesel.<br />

The factor that makes the 1-Box<br />

system so unique is the innovative<br />

design for arranging all of this emissions<br />

aftertreatment into two parallel flowing<br />

exhaust streams within a manageable<br />

space on the chassis. With the 1-Box<br />

system the Detroit Diesel engineers<br />

found a way to provide lower back<br />

pressure within its 2010 aftertreatment<br />

system (ATS).<br />

“The 1-Box is a paradigm shift for our<br />

customers; it is the first time in the<br />

history of North American heavy-duty<br />

trucking industry that a new technology<br />

introduction will provide a simultaneous<br />

environmental benefit and customer<br />

benefit via monetary lifecycle cost<br />

savings. Moreover, there is a highdegree<br />

of integration between the ATS<br />

and vehicle packaging (e.g. integrated<br />

mounting for ATS, steps and fairings,<br />

thermal impact protection). This was<br />

made possible by the outstanding<br />

collaboration between Daimler Trucks<br />

The 1-Box engineering team (from right to<br />

left) Matt Oaks, Jeff Girbach, Jeff Begeman,<br />

Rakesh Aneja<br />

and Detroit Diesel engineers.” said<br />

Aneja.<br />

As you have probably already heard<br />

and possibly even seen, the Detroit<br />

Diesel BlueTec 1-Box system provides<br />

dealers with a unique solution that<br />

competitors can’t match. While some<br />

competitors will describe their SCR<br />

system as “basically the same as all<br />

other SCR systems”, our dealer can<br />

point to the features and benefits of the<br />

BlueTec 1-Box system as a competitive<br />

advantage to offer their customers.<br />

Key Features and Benefits:<br />

• Low back-pressure<br />

• Robust diesel particulate filter (DPF)<br />

with high soot load capacity<br />

• Unique low temperature regeneration<br />

controls for DPF regeneration to<br />

minimize catalyst aging and to<br />

reduce cost<br />

• Optimized diesel exhaust fluid (DEF)<br />

dosing controls to maximize NOx<br />

conversion efficiency<br />

More information on the BlueTec<br />

1-Box system can be found on www.<br />

DDCSalesPro.com (Click on the<br />

BlueTec logo and look for the sales<br />

presentations).

Series 60<br />

1,000,000 Series 60’s and Counting<br />

When the first Series 60 ® rolled off<br />

the production line in 1987, Barack<br />

Obama hadn’t even started law school,<br />

Cheers was one of the most popular<br />

television shows and Michael Phelps<br />

was just learning how to walk let alone<br />

swim. More than twenty years after<br />

its introduction, the Series 60 is still a<br />

leader in fuel economy, reliability and<br />

performance.<br />

So it comes as no surprise that when<br />

the 1,000,000th engine rolled off the<br />

production line Barney Young was<br />

there. Barney has worked at Detroit<br />

Diesel for over 40 years, most recently<br />

as a Product Verification Lab Auditor.<br />

While working on another Detroit Diesel<br />

product line, Barney was transferred<br />

to the Series 60 because it was an<br />

innovative new product and the company<br />

was implementing a ground-breaking<br />

Barney Young pictured with one of the 1st<br />

Series 60’s (2nd from the right in the back<br />

row).<br />

product development approach.<br />

“The new way of developing the Series<br />

60 opened the doors of communication;<br />

the engineers wouldn’t make a change<br />

without consulting the manufacturing<br />

personnel,” said Young. The result was<br />

an engine that was designed not only to<br />

last longer, but to be easier<br />

to manufacture and service.<br />

Along with a new approach<br />

to design and manufacture,<br />

Detroit Diesel used a<br />

new product validation<br />

methodology. Instead of<br />

success testing, Detroit<br />

Diesel implemented a failure<br />

testing approach. Subjecting<br />

the Series 60 to the most<br />

rigorous field conditions,<br />

product engineers were able<br />

to understand more quickly<br />

product issues and get them<br />

corrected before introduction.<br />

The 1,000,000th engine milestone was<br />

marked by a unique opportunity for all<br />

employees to sign a commemorative<br />

banner and get their photo taken next<br />

to the engine. So when Young saw it,<br />

he said “it was like seeing one of my<br />

grown-up grand children”. The engine<br />

has had numerous changes over the<br />

years to meet the demanding emissions<br />

regulations, but its core design is still in<br />

place. “We put a lot into the engine so it<br />

would be around for 1,000,000 units,”<br />

Young said.<br />

The Series 60 used cutting edge diesel<br />

engine technology back in 1987, being<br />

the first to incorporate electronics into<br />

heavy-duty engines. In fact, the Series<br />

60 took Detroit Diesel market share from<br />

2% to an industry leading 33% in 1997<br />

- a remarkable achievement in a mature<br />

market.<br />

The development of the Series 60<br />

changed the way Detroit Diesel does<br />

business. So it comes as no surprise<br />

that the same processes that made the<br />

Series 60 successful were implemented<br />

From the right: Barney Young, Bill Tritten and Dan<br />

Theriault are pictured with the 1,000,000th Series 60<br />

with the new DD15. Introduced with<br />

the latest in diesel engine technology,<br />

including turbo compounding and<br />

the Amplified Common Rail System<br />

(ACRS TM ), the DD15 gives customers<br />

a technological advantage that goes<br />

right to their bottom line. “I wouldn’t be<br />

surprised if we are all here in 20 years<br />

taking photos with the 1,000,000th<br />

DD15,” said David Siler, director Detroit<br />

Diesel marketing.<br />

For more information on the Series 60<br />

and DD15 visit www.detroitdiesel.com/<br />

engines<br />

www.detroitdiesel.com 3

DD16<br />

ALL-NEW DD16<br />

continued from page 1<br />

Part of the Detroit Diesel engine family,<br />

the DD16 shares a common platform<br />

design that is leveraged on a global<br />

scale by Daimler Trucks. “The DD16<br />

makes any mountain pass look like a<br />

rolling hill in the prairie,” said David Siler,<br />

director of marketing for Detroit Diesel.<br />

“The public response at MATS was<br />

tremendous, the heavy-duty market has<br />

been waiting for a new ‘King of the Hill’<br />

with CAT leaving the market; I think we<br />

have it with the DD16.”<br />

All the power without sacrificing<br />

fuel economy<br />

Ideal for the toughest jobs, such as oil<br />

fields, mining, construction, logging and<br />

other specialized hauling applications,<br />

the DD16 offers remarkable gradeability<br />

so climbing hills is no problem and thanks<br />

to the integrated engine brake, getting<br />

down the other side is just as easy.<br />

“We have taken the best of all of our<br />

performance-enhancing technologies and<br />

included them in the DD16,” said Admir<br />

Kreso, director, HDEP engineering for<br />

Detroit Diesel . “The result is one of<br />

the hardest working and most powerful<br />

engines on the market today.”<br />

With the DD16’s wide and flat torque<br />

curve that pulls strong down to 1000<br />

RPM, the engine will be able to stay<br />

in top gear longer, a significant boost<br />

to fuel economy. The engine’s air<br />

management system features Detroit<br />

Diesel’s exclusive turbo compounding<br />

technology – which converts exhaust<br />

gas energy into usable horsepower.<br />

Turbo compounding, together with<br />

the DD16’s simplified turbocharger<br />

design and improved EGR system, also<br />

contribute to the engine’s superior<br />

power, torque response and fuel<br />

economy.<br />

The DD16 also features the<br />

electronically-controlled amplified<br />

common rail fuel system (ACRS) that<br />

optimizes the injection events within<br />

each stroke. The “amplified” means the<br />

highest fuel pressure is generated within<br />

the injectors, leading to reduced pressure<br />

throughout the rest of the system and<br />

greater component reliability.<br />

When combined with turbo compounding<br />

technology, the DD16 offers smooth<br />

and refined performance with lower<br />

fuel consumption than ever thought<br />

possible with such a powerful engine.<br />

And, the DD16’s enhanced power and<br />

multi-torque ratings help improve fuel<br />

economy, a feature that used to be<br />

compromised with big power engines,<br />

and reduce powertrain wear and tear.<br />

Built from a proven platform<br />

Since the DD16 shares a common<br />

platform with the DD15, parts<br />

availability will not be a problem. Detroit<br />

Diesel’s parts distribution and service<br />

network ensures that all of its North<br />

American parts and service outlets are<br />

stocked with genuine Detroit Diesel<br />

parts; and that trained and qualified<br />

technicians are always available.<br />

“Extreme environments such as<br />

mountains and coal mines can take<br />

a major toll on engines,” said Kreso.<br />

“The DD16 not only excels in these<br />

conditions, but in long-haul applications<br />

it boasts durability already proven by<br />

DD15 .”<br />

A quiet ride too<br />

A key attribute of the DD16 is its quiet<br />

in-cab and on-the-road performance.<br />

The combination of the multi-injection<br />

event capability of the ACRS, which<br />

enables combustion rate shaping, and<br />

the stiff engine block, which reduces<br />

noise and vibration, the DD16 makes for<br />

a comfortable ride.<br />

“Driver comfort is a priority at Detroit<br />

Diesel,” said Siler. “We understand that<br />

the in-cab environment is one of the<br />

most important aspects of a driver’s<br />

workday, and the quiet DD16 only<br />

enhances the overall driving experience.”<br />

The engine’s integrated engine brake,<br />

which is standard on the DD16, has<br />

already become a benchmark in low<br />

noise levels among other compression<br />

brakes. It provides the customer<br />

with three modes of engine retarding<br />

capability, which can barely be heard in<br />

the cab.<br />

Ready for 2010 with BlueTec<br />

BlueTec® emissions technology – Detroit<br />

Diesel’s chosen technology to meet<br />

the upcoming EPA 2010 emissions<br />

standards was part of the original design<br />

for the DD16. It will be available in the<br />

exclusive 1-Box TM configuration, which<br />

not only optimizes space and adapts to<br />

a wide variety of truck applications, but<br />

also has a unique design that reduces<br />

the exhaust back pressure resulting in<br />

improved fuel economy.<br />

Chassis Availability<br />

The DD16 will be available in Western<br />

Star® trucks in March 2010 followed<br />

by Freightliner® trucks in May 2010.<br />

The engine will be assembled at Detroit<br />

Diesel’s state-of-the-art production<br />

facility in Redford, Mich.<br />

Visit www.DetroitDiesel.com/engines/<br />

DD16 for more information.<br />

4<br />

www.detroitdiesel.com

DD15<br />

DD15 Impresses<br />

continued from page 1<br />

Owner and President Mr. Kim Robinson<br />

explains his feelings about switching<br />

away from his long-time preference for<br />

CAT motors to the Detroit Diesel brand.<br />

“We’ve tried just about every engine over<br />

the years…Cummins, CAT, the Detroit<br />

Diesel Series 60. We had settled on<br />

CAT power because of the all around<br />

engine performance and the strong parts<br />

and service support.” But increasing<br />

amounts of downtime had crept into<br />

the picture the past few years when<br />

Robinson decided to take a step back to<br />

see what else was out there. “What I<br />

found most compelling about the DD15<br />

was its combination of outstanding<br />

pulling power and fuel economy. My<br />

drivers and I were accustomed to<br />

settling for either better fuel economy<br />

Robinson Transport’s fleet has evolved from 1946 to today.<br />

or stronger power but not both. What<br />

has impressed me the most about the<br />

DD15 is its ability to power up faster<br />

than other engines yet still be more fuel<br />

efficient” said Robinson.<br />

Robinson Transport is a specialized<br />

hauler of coal products with a reputation<br />

among its customers for exemplary<br />

customer service even in the face of<br />

the extreme operating conditions in the<br />

Susco Mine. Founded in 1946 by Kim’s<br />

father, Robinson Transport has grown<br />

to an operation of 70 tractors and over<br />

100 employees. Robinson specs his<br />

trucks with a goal to perform under<br />

extreme duress yet still deliver a profit<br />

to the bottom line every<br />

month. “We gross out at<br />

129,500 pounds pulling<br />

out of the mines in extreme<br />

temperatures. We encounter<br />

9% grades and over 8,000<br />

feet of altitude on occasion.<br />

Our trucks average 220,000 miles<br />

per year. If an engine can last here it<br />

can last just about anywhere”, added<br />

Robinson. From the research on the<br />

DD15, we concluded it would fit in well<br />

with our fleet. “The Detroit Diesel DD15<br />

is more than capable of meeting our<br />

challenging goals. Fuel economy is up.<br />

Power is good. Support we get from<br />

Western Star and Detroit Diesel are very<br />

good”, says Robinson.<br />

To hear what others are saying about<br />

the DD15 check out www.detroitdiesel.<br />

com/engines/DD15.<br />

BEST PERFORMING ENGINES. BEST PERFORMING NETWORK.<br />

Network<br />

2009 Freightliner<br />

Dealer Meeting<br />

Freightliner Dealer Principals from across<br />

the United States and Canada came<br />

together April 22 - 24 in Charlotte, North<br />

Carolina at the 2009 Freightliner Dealer<br />

Meeting. With the theme of “Focus”,<br />

discussions centered on the current<br />

state of the trucking industry and the<br />

new product initiatives for Freightliner<br />

trucks and Detroit Diesel that will<br />

support the dealer network in these<br />

troubled economic times.<br />

During the opening ceremonies attendees<br />

were given a first hand look at the new<br />

Freightliner heavy duty model with<br />

variations for line haul and vocational<br />

applications. This product will be<br />

revealed to the public later this year.<br />

Detroit Diesel also proudly displayed a<br />

BlueTec® emissions technology equipped<br />

Freightliner Cascadia, a cutaway<br />

BlueTec 1-Box system and the Detroit<br />

Diesel DD13 engine.<br />

The second day of the event dealers<br />

attended four breakout sessions, most<br />

notably to Top Gear readers, was the<br />

Detroit Diesel 2010 Emissions Update.<br />

In the breakout session dealers heard<br />

from David Siler, director of marketing<br />

for Detroit Diesel; Tim Tindall, director<br />

of component sales for Detroit Diesel;<br />

and Randy Debortoli, project manager<br />

for 2010 emissions for Daimler Trucks<br />

North America. The discussion included<br />

the 2010 product line up and emission<br />

solutions from Detroit Diesel, integration<br />

of these products into the various<br />

Freightliner chassis configurations, and<br />

diesel exhaust fluid (DEF) infrastructure.<br />

The retention material is available on<br />

Freightliner SalesCenter.<br />

Overall, the meeting and the Detroit<br />

Diesel breakout sessions were<br />

a success. When asked, 97% of<br />

dealers agreed that the Detroit Diesel<br />

presentation was useful and informative.<br />

They also indicated they would like more<br />

information on competitive selling of<br />

2010 emissions technologies. Detroit<br />

Diesel Marketing is pleased to announce<br />

competitive selling presentations are<br />

available on DDCSalesPro.com. We<br />

encourage you to log in and check out<br />

the latest information available.<br />

www.detroitdiesel.com 5

Marketing<br />

Detroit Diesel on the road<br />

Detroit Diesel took its products on the<br />

road this year to more than a dozen<br />

industry shows and events to make<br />

sure every customer knows what great<br />

products and service we offer. The<br />

shows started in January and will<br />

continue through October of this year<br />

with the majority of them happening in<br />

the first three months of the year. The<br />

Detroit Diesel engines are a focal point<br />

of any industry event or show, and this<br />

year was no different. At every show,<br />

customers are anxious to see the new<br />

products, programs and services Detroit<br />

Diesel has to offer and they weren’t<br />

disappointed this year.<br />

Technology & Maintenance Council<br />

Exhibition, February 9-11, 2009, in<br />

Orlando, FL<br />

Daimler Trucks North America<br />

(DTNA) and Detroit Diesel held a<br />

press conference and a ride-n-drive to<br />

introduce the industry to their 2010<br />

SCR technology - Detroit Diesel BlueTec<br />

emissions technology.<br />

Mid-America Trucking Show<br />

(MATS), March 19-21 in Louisville,<br />

KY<br />

The Mid-America Trucking Show is<br />

the largest annual heavy-duty trucking<br />

industry event in North America<br />

attracting more than 70,000 attendees<br />

and over 900 exhibiting companies.<br />

Detroit Diesel DD16 at MATS<br />

Detroit Diesel took advantage of the<br />

audience and revealed the all-new<br />

DD16 to the heavy-duty trucking<br />

industry.<br />

The DD16 is a powerhouse sporting<br />

up to 600 horsepower and over<br />

2,000 lb-ft of torque. It launches<br />

into the North American market in<br />

Western Star products in March<br />

2010 and Freightliner in May 2010,<br />

the DD16, with a 15.6L displacement<br />

will be the largest on-highway engine<br />

offered by Detroit Diesel.<br />

ExpoCam<br />

April 16-18 in Montreal, QC<br />

ExpoCam is the largest industry<br />

tradeshow in Canada and Detroit<br />

Diesel was there centered between the<br />

Freightliner and Western Star booths.<br />

The Detroit Diesel booth featured<br />

the DD15, DD16, BlueTec emissions<br />

technology, and “three ways to get DEF”<br />

display.<br />

“Expocam was again a great truck show<br />

for the Canadian trucking industry with<br />

over 12,000 visitors pre-registered!”<br />

said Eric Raimondini.<br />

Detroit Diesel also teamed up with<br />

Freightliner Trucks at the World of<br />

Concrete in January, The Work Truck<br />

Show in March and again at Waste Expo<br />

in June to exhibit our engines to other<br />

segments of the market. At all three of<br />

these shows, Detroit Diesel displayed<br />

segment focused engines and materials<br />

as part of the Freightliner Trucks team.<br />

Detroit Diesel BlueTec emissions<br />

technology 1-Box system at MATS<br />

The event was a success with many of<br />

the industry press attending.<br />

Detroit Diesel’s exhibit featured the<br />

DD15, DD13, BlueTec® emissions<br />

technology and “three ways to get diesel<br />

exhaust fluid (DEF).” display.<br />

Also on display were the DD15,<br />

DD13, BlueTec emissions technology,<br />

Detroit Diesel’s exclusive 1-Box<br />

system and “three ways to get DEF.”<br />

Presentations were made throughout<br />

the day on Detroit Diesel’s BlueTec<br />

emissions technology and the all new<br />

DD16.<br />

Detroit Diesel booth at ExpoCam<br />

6<br />

www.detroitdiesel.com

Network<br />

Service works to keep OUR Customers... OUR Customers<br />

This is what<br />

Dale Allemang<br />

and his team do<br />

every day. As<br />

the director of<br />

field service for<br />

Daimler Trucks<br />

North America,<br />

Dale and his team<br />

work with our<br />

800+ outlets to<br />

make sure our<br />

customers remain<br />

satisfied.<br />

Dale started his career at Detroit Diesel<br />

in 1980 and has been involved in the<br />

engineering of Detroit Diesel products<br />

and customer care ever since. Dale and<br />

his team are the eyes and ears for our<br />

service outlets regarding all technical<br />

issues related to trucks and engines.<br />

The entire Field Service team is focused<br />

on identifying the root cause of all<br />

customer product challenges, finding<br />

the best solution and working back<br />

through engineering and the customer<br />

support center to ensure the solution<br />

is shared appropriately to contain the<br />

issue quickly. Since, the field service<br />

team is responsible for both truck and<br />

engine technical support, every member<br />

undergoes extensive training on both<br />

product lines. They also rely on a group<br />

of experts from field service, engineering<br />

and other areas of the organization to<br />

help resolve issues.<br />

Another main focus for the team is to<br />

monitor the efficiency of our outlets<br />

customer service. Efficient service<br />

requires every outlet to be properly<br />

trained and have the necessary tools and<br />

parts to complete a repair. To ensure an<br />

“excellent customer service experience”<br />

the field service team uses the Service<br />

Satisfaction Index (SSI). SSI defines an<br />

“excellent customer service experience”<br />

as: Informing the customer of the<br />

specific repairs, whether parts required<br />

are in stock, all estimated costs, and<br />

the exact timing to complete the repair<br />

-- all within two hours of arriving at the<br />

outlet.<br />

The Field Service team is also busy<br />

developing a program to elevate our<br />

customer service to the next level via<br />

a new proprietary technology. The<br />

team is fine tuning a proactive tool that<br />

incorporates telematics, GPS, cellular<br />

technology and vehicle/engine electronics<br />

to provide diagnostic details in real time<br />

to our service outlets. This allows Detroit<br />

Diesel to immediately evaluate and direct<br />

the customer to the nearest appropriate<br />

service facility. Imagine no more waiting<br />

for a diagnosis or the right part! Imagine<br />

the confidence in knowing your repair is<br />

completed correctly the first time! The<br />

Field Service Team has targeted a 2010<br />

launch for this tool that will continue to<br />

deliver Detroit Diesel’s “best performing<br />

network”.<br />

Technical solutions, a great customer<br />

experience, and exploring the latest<br />

technology to improve customer service<br />

- you can expect all this and more from<br />

Dale Allemang and his field service team.<br />

DD15<br />

15,000th DD15 TM<br />

Detroit Diesel announced today that<br />

it has delivered its 15,000th DD15 TM<br />

engine to Old Dominion Freight Line.<br />

Based in Thomasville, N.C., Old Dominion<br />

Freight Line has been a Detroit Diesel<br />

customer for over 30 years. It currently<br />

has more then 500 DD15 equipped<br />

tractors in its fleet.<br />

“What I like most about the DD15 is its<br />

reliability, fuel economy and simplicity,”<br />

said Ed Richardson, vice president of<br />

equipment and maintenance for Old<br />

Dominion Freight Line. “The engine has<br />

surpassed our expectations.”<br />

The DD15’s success is due in part to<br />

its Amplified Common Rail Fuel System<br />

(ACRS TM ) - the first high-pressure,<br />

electroncially-controlled amplified<br />

common rail fuel system for heavy<br />

duty engines in North America. ACRS -<br />

when combined with the engine’s turbo<br />

compounding technology - helps the<br />

DD15 deliver up to five percent better<br />

fuel economy than the Detroit Diesel<br />

Series 60 ®.<br />

BEST PERFORMING ENGINES. BEST PERFORMING NETWORK.<br />

Added Andrew Reed, owner, Rick<br />

Reed & Sons Trucking, the DD15’s<br />

performance has been impressive, The<br />

Versailles, Kentucky based company<br />

runs six DD15 equipped trucks for its<br />

livestock hauling business.<br />

“We haul a lot of heavy loads, and even<br />

with the extra weight, we’re passing<br />

people as we go up hills,” said Reed.<br />

“Our trucks run great. The DD15 not<br />

only provides superior power, but the<br />

fuel mileage has been outstanding, too.”<br />

www.detroitdiesel.com 7

BlueTec<br />

Detroit Diesel Delivers First BlueTec Customer Demo Units<br />

Detroit Diesel has delivered its first<br />

two BlueTec® emissions technology<br />

customer demo units (CDU) to Schneider<br />

National, Inc., the nation’s largest<br />

truckload carrier. The CDUs will be<br />

integrated into Schneider’s fleet to gain<br />

valuable real-world experience with the<br />

technology in advance of EPA 2010<br />

regulations.<br />

Delivered in late January 2009, the<br />

Schneider CDUs are Freightliner<br />

Cascadia’s equipped with Detroit<br />

Diesel DD15 engines, and have already<br />

logged more than 100,000 miles.<br />

Steve Duley, vice president of<br />

purchasing for Schneider National, noted<br />

that they keep close tabs on the units<br />

and provide Detroit Diesel feedback<br />

every day, including responses from<br />

drivers and technicians.<br />

“By actually field testing the technology,<br />

we are putting the units into real-life<br />

situations, which ultimately helps<br />

Detroit Diesel engineers to identify every<br />

possible issue in advance,” said Duley.<br />

“We are confident the experience we<br />

gain from CDUs will give us additional<br />

time to prepare for the transition.”<br />

Schneider’s participation in the<br />

BlueTec field test is part of its ongoing<br />

commitment to running the most energyefficient<br />

fleet in the industry.<br />

“Wise use of our natural<br />

resources is important<br />

to our customers and to<br />

Schneider National,” said Duley. “New<br />

technologies and spec’ing our equipment<br />

with energy-efficiency in mind is critical<br />

to delivering on that promise.”<br />

Duley added that a small group of<br />

drivers were briefed and trained<br />

in advance on the CDUs to further<br />

contribute to the testing and feedback.<br />

“Our CDUs help customers like<br />

Schneider gain experience with BlueTec<br />

emissions technology well ahead of<br />

2010, helping to provide an easy<br />

transition,” said David Siler, director<br />

of marketing for Detroit Diesel. “Plus,<br />

by working closely with Schneider, we<br />

will continue to refine our technology,<br />

ensuring exemplary performance and fuel<br />

economy.”<br />

Schneider National has been a Detroit<br />

Diesel customer since 1991, and more<br />

than 90 percent of its fleet is equipped<br />

with Detroit Diesel engines.<br />

“Detroit Diesel’s responsiveness, people,<br />

and above all, quality, keeps us coming<br />

back. They listen to what we think is<br />

important, and they deliver every time,”<br />

said Duley. “We believe the BlueTec<br />

emissions technology is a very good<br />

alternative for meeting new regulations<br />

in an environmentally friendly way.”<br />

BEST PERFORMING ENGINES. BEST PERFORMING NETWORK.<br />

Network<br />

Detroit Diesel is now on Facebook and Twitter<br />

Join us on Facebook and Twitter today<br />

for the latest on everything Detroit<br />

Diesel! On Facebook, search for us in<br />

the Friends search bar under “Detroit<br />

Diesel.” Join us on Twitter too, you can<br />

find Detroit Diesel @DemandItAll.<br />

www.detroitdiesel.com 8

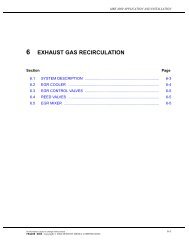

2010<br />

FactsAboutSCR.com Fast Facts<br />

Date The News Why It Matters<br />

1/27/2009 In a national independent study of 828 fleet<br />

managers, owner operators and maintenance<br />

managers, 53% said they are likely to consider<br />

purchasing an SCR-equipped truck to meet EPA<br />

2010 standards. Only 29% said they are likely to<br />

consider the purchase of an increased EGR truck.<br />

2/4/2009 The EPA has gone on record as saying that the<br />

2010 standards won’t be changing, nor will they be<br />

delayed. (Diesel Exhaust Fluid Forum, November<br />

2008)<br />

Purchase consideration for SCR is much higher than EGR when<br />

prospective buyers know that SCR results in a fuel savings and requires<br />

fewer active regenerations.<br />

The Tier 2 standards for heavy-duty highway engines and vehicles were<br />

established by the EPA in January 2001. Truck and engine OEMs have<br />

had 9 years to prepare for the 0.2 NOx standard that will go into effect on<br />

January 1, 2010. Any delay would impact billions of dollars of Federal<br />

grants for infrastructure and health care to communities that are counting<br />

on the funding. The EPA is committed to the 2010 standards.<br />

2/11/2009 An SCR engine will have a 3-5% fuel economy<br />

advantage over a non-SCR engine - which means<br />

it will burn less fuel which results in less CO2<br />

produced.<br />

Although not regulated in EPA 2010 standards, many trucking companies<br />

are interested in reducing their carbon footprint. By producing less CO2,<br />

SCR-equipped engines will help them in their efforts to reduce the country’s<br />

dependence on foreign oil and become greener.<br />

2/19/2009 For trucks using SCR, the interval between active<br />

regenerations will be significantly extended. SCR<br />

allows for more efficient combustion, is much<br />

cleaner and generates extremely low levels of<br />

engine-out PM.<br />

2/26/2009 A DEF (diesel exhaust fluid) tank can hold up to 23<br />

gallons - enough for an average over-the-highway<br />

truck to travel nearly 6,900 miles.<br />

3/4/2009 On January 1, 2010, SCR will be the only emissions<br />

technology that will meet the new standards at the<br />

tailpipe and provide a fuel savings to truckers.<br />

On average each active regeneration consumes more than a gallon<br />

of fuel. Looking at active regenerations alone, industry experts<br />

estimate an SCR truck will save several hundred gallons of diesel fuel in a<br />

typical year compared to the increased EGR equipped truck.<br />

A driver could travel across the U.S. approximately 3 times on one tank of<br />

DEF. Truck stops and service centers have committed to carrying DEF, so<br />

there will be plenty of opportunity for a driver to find a place to refill or top<br />

off the DEF tank, making availability a non-issue.<br />

Reducing the amount of diesel fuel consumed is extremely important to<br />

today’s trucking companies. SCR engines will consume less diesel fuel<br />

compared to EPA 2007 engines, while increased EGR engines for 2010 will<br />

likely result in a fuel penalty when compared to 2007 engines.<br />

3/11/2009 Nearly 200 public and private organizations are part<br />

of the North American SCR Stakeholders Group.<br />

Every part of the supply and regulatory chain (government agencies,<br />

automotive, light, medium and heavy duty and vocational engine and<br />

truck manufacturers and trade associations, fuel retailers, truck stop trade<br />

associations, chemical and oil companies, DEF producers, distributors and<br />

dispensing equipment manufacturers) is represented and working together<br />

to make SCR the emissions technology of choice for 2010.<br />

3/25/2009 An online Diesel Exhaust Fluid locator is being<br />

developed by The National Renewable Energy<br />

Laboratory Center for Transportation Technologies<br />

and Systems, a division of the U.S. Department of<br />

Energy (DOE),<br />

Finding DEF will be simple and easy.<br />

It is designed to help drivers find a convenient place to refill their DEF<br />

tanks. Advanced search functions planned for the DEF locator will help<br />

drivers search by engine and vehicle type, location type, access type, DEF<br />

dispenser type, vehicles services and payment methods.<br />

www.detroitdiesel.com 9

Marketing<br />

Sales Pro: Where You Can Find It All!<br />

Have you been to Sales Pro lately? If<br />

not, here is what you are missing:<br />

With 2010 quickly approaching, Sales<br />

Pro has a wealth of information on<br />

SCR and Detroit Diesel’s BlueTec<br />

emissions technology. On the new<br />

BlueTec Emissions Information Zone<br />

page, you will find Presentations,<br />

Product Literature, and Videos<br />

relating to EPA 2010 emissions. One<br />

notable presentation is “SCR Fact vs.<br />

Fiction”. This presentation dispels<br />

a lot of the fallacy that is currently<br />

going around concerning this ground<br />

breaking technology.<br />

In addition to Sales Pro, you<br />

will also be able to access the<br />

BlueTec webpage from Freightliner<br />

SalesCenter and Western Star DRC<br />

(Dealer Resource Center).<br />

Also on Sales Pro, check out the<br />

Promotions section for an opportunity<br />

to get your very own Detroit Diesel<br />

desktop cell phone holder! All you<br />

have to do is take a brief quiz<br />

covering Sales Pro content. This neat<br />

gift is just our way of saying, “Thank<br />

you for visiting Sales Pro!”<br />

How do I get on Sales Pro?<br />

You can access Sales Pro by going to<br />

www.ddcsalespro.com. If you have<br />

not registered, select the following<br />

option: “Don’t have a User Name<br />

and Password yet? Click here.”<br />

After you complete the registration<br />

information, your request will be<br />

forwarded to your manager. Once<br />

access is approved, you will receive<br />

an email indicating that your Sales<br />

Pro account has been activated.<br />

Sales Pro Tip<br />

Did you know that you can change<br />

your email address under Profile,<br />

which is located on the upper right<br />

hand corner of Sales Pro? Many<br />

users have been issued new email<br />

addresses while still logging into<br />

Sales Pro using their old one. If you<br />

have a new email address, please<br />

update your profile. It is important<br />

that your profile is up-to-date in<br />

order for Sales Pro to keep you<br />

updated with the latest content and<br />

announcements. After your email<br />

address has been updated, your<br />

User Name will match your new<br />

information. Keep in mind that if you<br />

make a profile change in Sales Pro, it<br />

will also affect all of the Centers that<br />

you are a member of (i.e. Freightliner<br />

SalesCenter, Western Star DRC, F&I<br />

Source, etc.).<br />

Question about Sales Pro? Email<br />

SalesPro@Daimler.com.<br />

DDC-EMC-NWS-0002-0709. Specifications are subject to change without notice. Detroit Diesel Corporation is registered to ISO 9001:2001.<br />

Copyright © Detroit Diesel Corporation. All rights reserved. Detroit Diesel Corporation is a Daimler company.