Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Silicon</strong> <strong>Detectors</strong> !<br />

Manfred Krammer!<br />

Institute of High Energy Physics, Vienna, Austria!

<strong>Silicon</strong> <strong>Detectors</strong> <br />

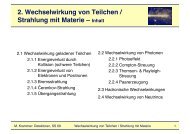

Content!<br />

2 Basics!<br />

3 Detector Structures!<br />

4 Performance!<br />

6 The CMS Inner Tracker!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 1!

2 Basics!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 2!

2.1 Materials <br />

Elemental semiconductors!<br />

! Germanium: Used in nuclear physics, due to small band gap<br />

(0.66 eV) needs cooling (usually done with liquid nitrogen at 77 K)!<br />

! <strong>Silicon</strong>: Standard material for vertex and tracking detectors in high<br />

energy physics, can be operated at room temperature, synergies with<br />

micro electronics industry.!<br />

! Diamond (CVD or single crystal): Large band gap, requires no<br />

depletion zone, very radiation hard, drawback is a low signal and high<br />

cost!!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 3!

2.1 Materials <br />

Compound semiconductors!<br />

Compound semiconductors consist of two (binary semiconductors) or<br />

more atomic element. Depending on the column in the periodic system<br />

of elements one differentiates between IV-IV- (e.g. SiGe, SiC), III-V-,<br />

und II-VI compounds!<br />

! important III-V compounds:!<br />

– GaAs: Faster and probably more radiation resistant than Si. !<br />

!Drawback is less experience in industry and cost.!<br />

– GaP, GaSb, InP, InAs, InSb, InAlP!<br />

! important II-VI compounds: !<br />

– CdTe: High atomic numbers (48+52) hence very efficient to detect<br />

photons.!<br />

– ZnS, ZnSe, ZnTe, CdS, CdSe, Cd 1-x Zn x Te, Cd 1-x Zn x Se!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 4!

2.2 Material Properties <br />

Bond model of semiconductors!<br />

Example of column IV elemental semiconductor (2dim projection) :!<br />

T = 0 K! T > 0 K!<br />

Valence electron!<br />

Conduction electron!<br />

! Each atom has 4 closest neighbors, the 4 electrons in the outer shell are<br />

shared and form covalent bonds.!<br />

! At low temperature all electrons are bound!<br />

! At higher temperature thermal vibrations break some of the bonds " free e -<br />

cause conductivity (electron conduction)!<br />

! The remaining open bonds attract other e - " The holes change position<br />

(hole conduction)!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 5!

2.2 Material Properties <br />

Energy bands: isolator–semiconductor–metal!<br />

In an isolated atom the electrons have only discrete energy levels. In solid state<br />

material the atomic levels merge to energy bands. In metals the conduction and<br />

the valence band overlap, whereas in isolators and semiconductors these levels<br />

are separated by an energy gap (band gap). In isolators this gap is large.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 6!

2.2 Material Properties <br />

Intrinsic carrier concentration!<br />

! Due to the small band gap in semiconductors electrons already occupy!<br />

the conduction band at room temperature.!<br />

!<br />

! Electrons from the conduction band may recombine with holes.!<br />

!<br />

! A thermal equilibrium is reached between excitation and recombination!<br />

Charged carrier concentartion n e = n h = n i !<br />

This is called intrinsic carrier concentration:!<br />

$<br />

n i = N C N V " exp # E g<br />

&<br />

% 2kT<br />

'<br />

) * T 3 $<br />

2<br />

" exp # E g<br />

&<br />

( % 2kT<br />

'<br />

)<br />

(<br />

In ultrapure silicon the intrinsic carrier concentration is1.45·10 10 cm -3 . !<br />

!<br />

With approximately 10 22 Atoms/cm 3 about 1 in 10 12 silicon atoms is ionised.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 7!

2.3 Constructing a Detector <br />

The ideal semiconductor detector!<br />

One of the most important parameter of a detector is the signal to noise ratio<br />

(SNR). A good detector should have a large SNR. However this leads to two<br />

contradictory requirements:!<br />

# Large signal <br />

" low ionisation energy " small band gap!<br />

# Low noise <br />

" very few intrinsic charge carriers " large band gap!<br />

An optimal material should have E g ≈ 6 eV. !<br />

In this case the conduction band is almost empty at room temperature and the<br />

band gap is small enough to create a large number of e - h + pairs through<br />

ionisation.!<br />

Such a material exist, it is Diamond. However even artificial diamonds (e.g. CVD<br />

diamonds) are too expensive for large area detectors.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 8!

2.3 Constructing a Detector <br />

Estimate SNR in an intrinsic silicon detector!<br />

Lets make a simple calculation for silicon: ! ! ! !<br />

!Mean ionization energy I 0 = 3.62 eV, mean energy loss per flight path<br />

!dE/dx = 3.87 MeV/cm, intrinsic charge carrier density at T = 300 K<br />

!n i = 1.45 · 10 10 cm -3 . !<br />

Assuming a detector with a thickness of d = 300 µm and an area of A = 1 cm 2 .!<br />

" Signal of a mip in such a detector:!<br />

!<br />

dE dx " d<br />

I 0<br />

= 3.87"106 eV cm" 0.03cm<br />

3.62eV<br />

"!Intrinsic charge carrier in the same volume (T = 300 K):!<br />

# 3.2"10 4 e $ h + $pairs<br />

n i<br />

d A =1.45 "10 10 cm -3 " 0.03cm"1cm 2 # 4.35 "10 8 e $ h + $pairs<br />

!<br />

!<br />

"!Number of thermal created e – h + -pairs are four orders of magnitude larger<br />

than signal!!!!<br />

Have to remove the charge carrier! !<br />

! !" Depletion zone in reverse biased pn junctions!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 9!

2.4 Doping <br />

Bond model: n-doping in Si!<br />

Doping with an element 5 atom (e.g. P, As, Sb). The 5 th valence electrons is<br />

weakly bound.!<br />

The doping atom is called donor!<br />

The released conduction electron<br />

leaves a positively charged ion!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 10!

2.4 Doping <br />

Bond model: n-doping in Si!<br />

The energy level of the donor is just below the edge of the conduction band. At<br />

room temperature most electrons are raised to the conduction band.!<br />

The fermi level E F moves up. !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 11!

2.4 Doping <br />

Bond model: p-doping in Si!<br />

Doping with an element 3 atom (e.g. B, Al, Ga, In). One valence bond<br />

remains open. This open bond attracts electrons from the neighbor atoms.!<br />

The doping atom is called acceptor. !<br />

The acceptor atom in the lattice is<br />

negatively charged.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 12!

2.4 Doping <br />

Bond model: p-doping in Si!<br />

The energy level of the acceptor is just above the edge of the valence band. At<br />

room temperature most levels are occupied by electrons leaving holes in the<br />

valence band.!<br />

The fermi level E F moves down. !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 13!

2.5 The p-n Junction <br />

Creating a p-n junction!<br />

At the interface of an n-type and p-type semiconductor the difference in the fermi<br />

levels cause diffusion of surplus carries to the other material until thermal equilibrium<br />

is reached. At this point the fermi level is equal. The remaining ions create a space<br />

charge and an electric field stopping further diffusion.!<br />

The stable space charge region is free of charge carries and is called the depletion<br />

zone.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 14!

2.5 The p-n Junction <br />

Operation with forward bias!<br />

p-n junction with forward bias!<br />

Applying an external voltage V with the anode<br />

to p and the cathode to n e- and holes are<br />

refilled to the depletion zone. The depletion<br />

zone becomes narrower.!<br />

!<br />

!<br />

The potential barrier becomes smaller by eV<br />

and diffusion across the junction becomes<br />

easier. The current across the junction<br />

increases significantly.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 15!

2.5 The p-n Junction <br />

Operation with reverse bias!<br />

p-n junction with reverse bias!<br />

Applying an external voltage V with the cathode<br />

to p and the anode to n e- and holes are pulled<br />

out of the depletion zone. The depletion zone<br />

becomes larger.!<br />

!<br />

!<br />

The potential barrier becomes higher by eV and<br />

diffusion across the junction is suppressed. The<br />

current across the junction is very small<br />

leakage current.!<br />

" Thats the way we operate our semiconductor detector!!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 16!

2.5 The p-n Junction <br />

Width of the depletion zone!<br />

Example of a typical p + -n junction in a silicon detector:!<br />

Effective doping concentration N a = 10 15 cm –3 in p+ region and N d = 10 12 cm –3 in<br />

n bulk.!<br />

Without external voltage:!<br />

W p = 0.02 µm !<br />

W n = 23 µm!<br />

Applying a reverse bias voltage of 100 V:!<br />

W p = 0.4 µm !<br />

W n = 363 µm!<br />

Width of depletion zone in n bulk:!<br />

W "<br />

2# 0 # r µ$V<br />

with!<br />

" =<br />

1<br />

e µN eff<br />

p + n junction!<br />

V !… !External voltage!<br />

" !… !specific resistivity!<br />

µ !… !mobility of majority charge carriers!<br />

N eff !… !effective doping concentration!<br />

!<br />

!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 17!

2.5 The p-n Junction <br />

Current-voltage characteristics!<br />

Typical current-voltage of a p-n junction (diode): exponential current increase<br />

in forward bias, small saturation in reverse bias.!<br />

!<br />

Ideal diode equation:! * #<br />

I = I 0 " exp eV & -<br />

% ( ) 1 I<br />

,<br />

/ 0 … reverse saturation current!<br />

+ $ kT ' .<br />

!<br />

S.M. Sze, Semiconductor Devices , J. Wiley & Sons, 1985!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 18!

2.6 Detector Characteristics <br />

Leakage Current!<br />

A silicon detector is operated with reverse bias, hence reverse saturation<br />

current is relevant (leakage current). This current is dominated by thermally<br />

generated e - h + pair. Due to the applied electric field they cannot recombine and<br />

are separated. The drift of the e - and h + to the electrodes causes the leakage<br />

current. !<br />

Measured detector leakage current, CMS<br />

strip detector (measurement at room<br />

temperature):!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 19!

2.6 Detector Characteristics <br />

Depletion Voltage!<br />

The depletion voltage is the minimum voltage at which the bulk of the sensor is<br />

fully depleted. The operating voltage is usually chosen to be slightly higher<br />

(overdepletion).!<br />

High resistivity material (i.e. low doping) requires low depletion voltage.!<br />

Depletion voltage as a function of the<br />

material resistivity for two different<br />

detector thicknesses (300 µm, 500 µm).!<br />

reverse bias voltage V [V]!<br />

resistivity " [kOhm cm]!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 20!

2.6 Detector Characteristics <br />

Capacitance of a detector!<br />

For a typical Si p-n junction (N a >> N d >> n i ) the detector capacitance is given<br />

as:!<br />

!<br />

C =<br />

" 0<br />

" r<br />

2µ# V $ A<br />

Measured detector capacitance as a<br />

function of the bias voltage, CMS strip<br />

detector:!<br />

" !… !specific resistivity of the bulk!<br />

µ !… !mobility of majority charge carrier!<br />

V !… !bias voltage !!<br />

A !… !detector surface!<br />

!<br />

!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 21!

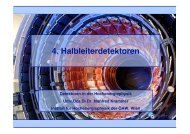

3 Detector Structures!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 22!

3.1 Microstrip Detector <br />

DC coupled strip detector!<br />

Through going charged particles create e - h + pairs in the depletion zone (about<br />

30.000 pairs in standard detector thickness). These charges drift to the electrodes.<br />

The drift (current) creates the signal which is amplified by an amplifier connected<br />

to each strip. From the signals on the individual strips the position of the through<br />

going particle is deduced. !<br />

!<br />

A typical n-type Si strip detector:!<br />

! p + n junction: <br />

N a ≈ 10 15 cm -3 , N d ≈ 1–5·10 12 cm -3 !<br />

! n-type bulk: ! > 2 k#cm <br />

" thickness 300 µm !<br />

! Operating voltage < 200 V.!<br />

! n + layer on backplane to improve<br />

ohmic contact!<br />

! Aluminum metallization !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 23!

3.1 Microstrip Detector <br />

AC coupled strip detector!<br />

AC coupling blocks leakage current from the amplifier.!<br />

! Integration of coupling capacitances in<br />

standard planar process.!<br />

! Deposition of SiO 2 with a thickness of 100–<br />

200 nm between p+ and aluminum strip!<br />

! Depending on oxide thickness and strip width<br />

the capacitances are in the range of 8–<br />

32 pF/cm.!<br />

! Problems are shorts through the dielectric<br />

(pinholes). Usually avoided by a second layer<br />

of Si 3 N 4 .!<br />

AC coupled strip detector:!<br />

Several methods to connect the bias voltage: polysilicon resistor,<br />

punch through bias, FOXFET bias.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 24!

3.1 Microstrip Detector <br />

Polysilicon bias – 1!<br />

! Deposition of polycristalline silicon between p + implants and a common bias<br />

line. !<br />

! Sheet resistance of up to R s ≈ 250 k#/$. Depending on width and length a<br />

resistor of up to R ≈ 20 M# is achieved (R = R s·length/width).!<br />

! To achieve high resistor values winding poly structures are deposited.!<br />

! Drawback: Additional production<br />

steps and photo lithograpic masks<br />

required.!<br />

Cut through an AC coupled strip<br />

detector with integrated poly resistors:!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 25!

3.1 Microstrip Detector <br />

Polysilicon bias – 2!<br />

Top view of a strip detector with<br />

polysilicon resistors:!<br />

CMS-Microstrip-Detektor: Close view of<br />

area with polysilicon resistors, probe<br />

pads, stip ends.!<br />

CMS Collaboration, <strong>HEPHY</strong> Vienna!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 26!

3.3 Hybrid Pixel <strong>Detectors</strong> <br />

Principle!<br />

Flip-Chip pixel detector:!<br />

On top the Si detector, below the readout chip,<br />

bump bonds make the electrical connection for<br />

each pixel. !<br />

Detail of bump bond connection.<br />

Bottom is the detector, on top the<br />

readout chip:!<br />

S.L. Shapiro et al., Si PIN Diode Array Hybrids for Charged !<br />

Particle Detection, Nucl. Instr. Meth. A 275, 580 (1989)!<br />

L. Rossi, Pixel <strong>Detectors</strong> Hybridisation, !<br />

Nucl. Instr. Meth. A 501, 239 (2003)!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 27!

3.3 Hybrid Pixel <strong>Detectors</strong> <br />

Bump bonding process – 2!<br />

Electron microscope pictures before and after the reflow production step. !<br />

PbSn bump, diameter 25 µm, pitch: 50 µm, reflow by heating to app. 300 °C.!<br />

L. Rossi, Pixel <strong>Detectors</strong> Hybridisation, Nucl. Instr. Meth. A 501, 239 (2003)!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 28!

4 Performance!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 29!

4.1 Signal to Noise Ratio <br />

Introduction!<br />

! The signal generated in a silicon detector depends essentially only!<br />

on the thickness of the depletion zone and on the dE/dx of the !<br />

particle.!<br />

!<br />

!<br />

! The noise in a silicon detector system depends on various !<br />

parameters: geometry of the detector, the biasing scheme, the !<br />

readout electronics, etc. !<br />

!<br />

! Noise is typically given as equivalent noise charge ENC. This is !<br />

the noise at the input of the amplifier in elementary charges. !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 30!

4.1 Signal to Noise Ratio <br />

Noise contributions!<br />

The most important noise contributions are:!<br />

1. Leakage current (ENC I )!<br />

2. Detector capacity (ENC C )!<br />

3. Det. parallel resistor (ENC Rp )!<br />

4. Det. series resistor (ENC Rs )!<br />

Alternate circuit diagram of a<br />

silicon detector. !<br />

The overall noise is the quadratic sum of all contributions:!<br />

ENC = ENC 2 C + ENC 2 2<br />

I + ENC Rp<br />

2<br />

+ ENC Rs<br />

!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 31!

4.1 Noise Contributions <br />

Detector capacity!<br />

The detector capacity at the input of a charge sensitive amplifier is<br />

usually the dominant noise source in the detector system. !<br />

This noise term can be written as:!<br />

ENC C<br />

= a + b " C<br />

The parameter a and b are given by the design of the (pre)-amplifier.<br />

C is the detector capacitance at ! the input of the amplifier channel.!<br />

Integration time t p is crucial, short integration time leads usually to<br />

larger a and b values. Integration time is depending on the accelerator<br />

time structure.!<br />

Typical values are (amplifier with ~ 1 µs integration time): !<br />

a ≈ 160 e und b ≈ 12 e/pF!<br />

To reduce this noise component segmented detectors with short<br />

strip or pixel structures are preferred. !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 32!

4.1 Signal to Noise Ratio <br />

Summary!<br />

To achieve a high signal to noise ratio in a silicon detector system the<br />

following conditions are important:!<br />

! Low detector capacity (i.e. small element size)!<br />

! Low leakage current!<br />

! Large bias resistor!<br />

! Short and low resistance connection to the amplifier!<br />

! Usually long integration time!<br />

Obviously some of the conditions are contradictory. Detector and<br />

front end electronics have to be designed as one system. The<br />

optimal design depends on the application.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 33!

4.2 Position Resolution <br />

Introduction!<br />

The position resolution – the main parameter of a position detector –<br />

depends on various factors, some due to physics constraints and some<br />

due to the design of the system (external parameters). !<br />

! Physics processes:!<br />

! External parameter:!<br />

– Statistical fluctuations of the energy loss!<br />

– Diffusion of charge carriers!<br />

– Binary readout (thresh hold counter) or read out of<br />

analogue signal value!<br />

– Distance between strips (strip pitch)!<br />

– Signal to noise ratio!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 34!

4.2 Position Resolution <br />

Statistical fluctuation of the energy loss – 1!<br />

! <strong>Silicon</strong> position detectors are thin (300–500 µm) and absorb only a small<br />

fraction of the total energy of through going particles. !<br />

! The energy loss dE/dx follows a Landau distribution, an asymmetric<br />

probability function with a long tail to large energy deposits.!<br />

! Example of a mip measured in a 300 µm thick silicon detector:!<br />

o<br />

o<br />

Most probable energy loss<br />

(Maximum of the distribution):<br />

78 keV in 300 µm " ≈ 72 e – h +<br />

pairs per µm!<br />

Mean of the energy loss:<br />

116 keV in 300 µm " ≈ 108 e – h +<br />

pairs per µm!<br />

Pions and Protons:!<br />

W. Adam et al., CMS note 1998/092 (1998)!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 35!

4.2 Position Resolution <br />

Diffusion – 2!<br />

! h + created close to the anode (i.e. the n + backplane) and e - created<br />

close to he cathode (i.e. the p + strips or pixels) have the longest drift<br />

path. As a consequence the diffusion acts much longer on them<br />

compared to e - h + with short track paths. !<br />

" The signal measured comes from many overlapping Gaussian<br />

distributions. !<br />

Drift and diffusion acts on charge carriers:!<br />

Charge density distribution for 5<br />

equidistant time intervalls: !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 36!

4.2 Position Resolution <br />

Threshold readout versus analogue readout!<br />

! Threshold readout (one strip signal):!<br />

" position:! x = strip position<br />

" resolution: !<br />

" x # p 12<br />

p<br />

x<br />

!… !distance between strips<br />

(readout pitch)!<br />

!… !position of particle track!<br />

! charge center of gravity (signal on two strips):!<br />

!<br />

" position: !<br />

!<br />

!<br />

!<br />

!<br />

x = x 1 +<br />

" resolution: !<br />

h 1<br />

( x 2 " x 1 ) = h 1 x 1 + h 2 x 2<br />

h 1 + h 2 h 1 + h 2<br />

" x "#<br />

p<br />

SNR<br />

x 1 ,x 2 … position of 1 st and<br />

2 nd strip!<br />

h 1 ,h 2 … signal on 1 st and<br />

2 nd strip!<br />

SNR … signal to noise ratio!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 37!<br />

!<br />

!

4.2 Position Resolution <br />

Example – influence of readout pitch and SNR!<br />

Example of a detector with strip pith of 25 µm and analogue readout.!<br />

The position resolution is plotted as a function of the SNR.!<br />

Bottom curve: every strip is connected to the readout electronics!<br />

Top curve: every 2 nd strip is connected, one intermediate strip!<br />

!<br />

To benefit from intermediate strips<br />

large SNR is required!!<br />

A. Peisert, <strong>Silicon</strong> Microstrip <strong>Detectors</strong>, !<br />

DELPHI 92-143 MVX 2, CERN, 1992!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 38!

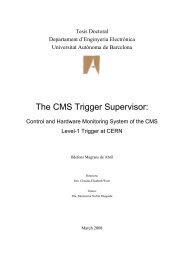

6.3 The CMS Inner Tracker!<br />

! ! !!<br />

! ! !The CMS Inner Tracker!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 39!

6.3 The CMS Inner Tracker <br />

The CMS Experiment!<br />

CMS<br />

A Compact Solenoidal Detetor for LHC<br />

MUON CHAMBERS<br />

INNER TRACKER<br />

E.M. CRYSTAL CAL.<br />

HADRON CAL.<br />

VERY FORWARD<br />

CALORIMETER<br />

Total Weight : 12,000 t.<br />

Overall diameter : 14.00 m<br />

Overall length : 20.00 m<br />

Magnetic field : 4 Tesla<br />

SUPERCONDUCTING COIL<br />

RETURN YOKE<br />

CMS 1000<br />

jlb<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 40!

6.3 The CMS Inner Tracker <br />

Layout of the detector!<br />

Inner Barrel –TIB<br />

Inner Disks –TID<br />

Outer Barrel –TOB<br />

Pixel<br />

End cap –TEC<br />

2,4 m<br />

Volume 24.4 m 3<br />

temperature -10 0 C<br />

dry atmosphere<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 41!

6.3 The CMS Inner Tracker <br />

Some numbers!<br />

Strip detector: <br />

!~200 m 2 of silicon sensors <br />

!24,244 single silicon sensors <br />

!15,148 modules <br />

!9,600,000 strips $ electronics channels <br />

!75,000 read out chips (APV25) <br />

!25,000,000 Wire bonds!<br />

!<br />

Pixel detector:!<br />

!1 m 2 detector area!<br />

!1440 pixel modules!<br />

!66 million pixels!<br />

!<br />

Industrial type of production in many laboratories worldwide.!<br />

!Largest <strong>Silicon</strong> detector built so far !!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 42!

6.3 The CMS Inner Tracker <br />

A worldwide collaboration!<br />

55 institutes from 9 countries (Austria, Belgium, Finland, <br />

!France, Germany, Italy, Switzerland, UK, USA) <br />

About 500 scientists and engineers involved in the design and construction!<br />

of the CMS inner tracker.!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 43!

6.3 The CMS Inner Tracker <br />

Example of strip module geometries!<br />

27 mechanical different modules + 2 types of alignment modules !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 44!

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 45!

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 46!

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 47!

Tracker Insertion!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 48!

6.3 The CMS Inner Tracker <br />

The pixel detector!<br />

~50 cm!<br />

~1 m!<br />

~40 cm!<br />

Pixel size: 100 µm x 150 µm!<br />

Barrel Pixel: <br />

3 barrel layers at r of 4.3, 7.3, 10.4 cm <br />

11520 chips (48 million pixels)!<br />

Forward Pixel: <br />

4 disks at z of ±35.5 and ±46.5 cm <br />

4320 chips (18 million pixels) <br />

Modules dilted by 20 o for better <br />

charge sharing!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 49!

6.3 The CMS Inner Tracker <br />

The pixel detector - construction!<br />

Hybrid Pixel Technology: <br />

Readout chips (ROCs) bump bonded to high resistivity silicon sensor!<br />

Barrel Pixel sensor wafer:! Bump bonds:!<br />

Thickness 270 µm <br />

n + -pixels in n-bulk with <br />

p-spray (CIS) or p-stop (SINTEF) <br />

<br />

!<br />

Bump bonding process <br />

Barrel: Indium, In-house at PSI <br />

Forward: PbSn at two vendors (RTI, IZM) <br />

!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 50!

6.3 The CMS Inner Tracker <br />

Barrel pixel: module design!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 51!

6.3 The CMS Inner Tracker <br />

A barrel pixel module !<br />

The barrel pixel consists of about 800 modules!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 52!

6.3 The CMS Inner Tracker <br />

A half disc of the forward pixel detector!<br />

Forward Pixel: consists of 672 plaquettes !<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 53!

6.3 The CMS Inner Tracker <br />

PIxel insertion!<br />

Barrel Pixel!<br />

Forward Pixel!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 54!

6.3 The CMS Inner Tracker <br />

Possible discoveries at the LHC: Higgs!<br />

A promising discovery channel for a light Standard Model Higgs Boson is!<br />

ttH"jjb l%b bb:!<br />

Final state 6 jets (4 b-jets), 1 lepton, !<br />

1 neutrino (missing Energy):!<br />

…a superb task for the <strong>Silicon</strong> detector…!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 55!

6.3 The CMS Inner Tracker <br />

Simulation from CMS: Higgs!<br />

Simulation of a 120 GeV Higgs decaying inside the CMS <strong>Silicon</strong> tracker:!<br />

M. Krammer, Praktikum 2010/11! <strong>Silicon</strong> <strong>Detectors</strong>! 56!