Untitled - Proton OnSite

Untitled - Proton OnSite

Untitled - Proton OnSite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HYDROGEN<br />

Understanding Hydrogen and it’s Impact<br />

on Power Producer’s Bottomline<br />

RAJEEV BHALLA & SIDDHARTH RASTOGI FOR MVS ENGINEERING – INDIA; THOMAS SKOCZYLAS FOR PROTON ONSITE – USA.<br />

Unknown to many, Quality of Hydrogen in a Hydrogen-cooled Turbine Generator plays an<br />

important role for the bottomline of a power generation utility. Some power generation<br />

companies are paying attention to this and deriving benefits including improved efficiency,<br />

better yields from same fossil burn. We explore the simple physics behind this and why<br />

the power generation industry needs to pay close attention to this.<br />

Purpose of Hydrogen cooling in<br />

Turbine Alternators<br />

Hydrogen is used for cooling Generator’s Rotor<br />

windings in Turbine Generator (TG), for<br />

the following reasons:<br />

<br />

Hydrogen has one of the lowest gas densities<br />

thus offering least resistance to the<br />

rotation of the Rotor within the Generator.<br />

In turn there is lower energy requirement<br />

for rotating the machine countering<br />

the offered drag / windage factor.<br />

<br />

Hydrogen offers the highest heat conductivity<br />

property compared to Air or other<br />

gases and hence, is a very efficient carrier<br />

of generated heat, from a electrical machine.<br />

From hereon, the heated Hydrogen<br />

is carried to the outside of the machine,<br />

where it is cooled and returned continuously,<br />

in closed loop circulation.<br />

These are the two reasons why Hydrogen<br />

is the preferred gas for Large Electrical<br />

rotating machine cooling. Predominantly<br />

used for high rotational speed machines,<br />

where drag losses play significant absorbed<br />

energy impact. Therefore Hydrogen cooling<br />

is popular in machines typically 100 MW or<br />

larger Steam Turbine, and / or, Gas Turbine,<br />

driven Generators.<br />

Importance of Maintaining<br />

Hydrogen Pressure, Purity and<br />

Dryness<br />

<br />

A limited, higher pressure of Hydrogen<br />

purge maintained within the Rotor rotating<br />

space, increases the gas density. This<br />

increased density increases the specific<br />

gas conductivity (v/v). Meaning, a lesser<br />

volume of Hydrogen gas moved across<br />

the rotating machine will effectively remove<br />

all the heat. Usually the Hydrogen<br />

pressure is maintained in the range 3 to<br />

4 Bar(g).<br />

<br />

Hydrogen has molecular weight of 2,<br />

while Air is 29. This means Air weighs<br />

more than 14 times compared to Hydrogen.<br />

The impurity which will afflicts Hydrogen<br />

purge is Air due to limited ingress.<br />

It is important to note, each percentage<br />

point increase of Air impurity in Hydrogen<br />

will have a 14 times exponential increase<br />

in Gas density within the Rotor space in<br />

the Generator. Thus, the increased drag<br />

caused is also exponential in value. The<br />

best performance will be derived only<br />

when the Hydrogen purity within the TG<br />

is maintained near constant at 99.5%.<br />

<br />

Most people understand this aspect well,<br />

and many Generator manufacturers even<br />

provide/recommend a Hydrogen gas drier<br />

within the Hydrogen gas closed-loop circulation.<br />

Wet gas is severly detrimental to<br />

the life of the windings due to increased<br />

risk of corrosion and insulation failure.<br />

Hence, it is very important that purge gas<br />

Dew point be maintained as low as possible.<br />

Usual industry standard is to achieve<br />

control at (-) 20°C, or lower.<br />

Industry practice for Hydrogen<br />

control in Turbine Alternators<br />

<br />

This is easily achieved using good quality<br />

down stream gas pressure regulating<br />

valves. It is recommended to use a well<br />

designed valve, and never think an ordinary<br />

air pressure regulator will, do a reliable<br />

job.<br />

<br />

Most conscientious power generation<br />

companies use online Gas analysers and<br />

are content maintaining the TG purge purity<br />

in a range of 98% to 99.5%. They utilize<br />

the Bleed-and-Feed control for maintaining<br />

purity by sending out an operator<br />

to manually adjust the fresh Hydrogen gas<br />

inlet and TG vent valve, to replace some<br />

gas within the Rotor space thus improve<br />

purity to the max. This process is done<br />

once in 2 – 3 hours. Good, but not good<br />

enough! As one can easily calculate, this<br />

constant fluctuation of purity results in<br />

average purity of Hydrogen of around 98<br />

to 98.5%.<br />

<br />

TGs which have within loop Hydrogen<br />

38 APRIL11 energetica india

HYDROGEN<br />

® . ® .<br />

Dryer are the lucky ones. They at least<br />

have the technical facility to keep Hydrogen<br />

Dew point in check. Many Power<br />

Utilities are using commercially available<br />

Hydrogen gas supplied in Gas cylinders<br />

or Bullets. Commercial Hydrogen is typically<br />

procured from the off-gas stream<br />

of process industries such as Chlor-Alkali<br />

plants. This Commercial grade Hydrogen<br />

of 99.8% purity (or worse), and questionable<br />

Dew point is wet (saturated). Ensuing<br />

wet gas affects the Generator winding<br />

life. One needs superior quality gas<br />

to keep the Dew point low. Just like, you<br />

need clean water, to wash dirty clothes. Either<br />

this be done by online Hydrogen dryer<br />

or use Hydrogen gas of superior Dew<br />

point (-) 60°C or better, and successfully<br />

use the ‘displacement method’ to control<br />

purge atmosphere Dew point.<br />

Financial Impact of Low purity<br />

The loss is so large that we must not ignore it!<br />

Data gleaned from Turbine Generator OEM,<br />

indicate, windage loss of 250 kW (thereby<br />

loss of 250 kW extra saleable power), for<br />

every one percent reduction in Hydrogen<br />

purity 1 . Every 1% lower Hydrogen purity, will<br />

1 As reported in article – “Seals from<br />

Aerospace”published in Power Engineering<br />

magazine dated Nov. 1, 2004. Authors: Peter<br />

translate to Rs. 4 million (Rs. 40 Lacs) potential<br />

loss per year 2 .<br />

Loss due to poor H2 Pressure<br />

Management<br />

Low Hydrogen pressure will lead to lower<br />

mass – heat conductivity. The Hydrogen circulation<br />

is usually through a fixed volume<br />

Hydrogen circulation blower. Lower heat<br />

removal will heat up the Generator and the<br />

operator will be forced to operate the TG at<br />

lower load. And, again there is loss of revenue!<br />

Higher Hydrogen pressure will lead to<br />

higher leakage from Generator’s Shaft seals<br />

and body. This will require more Hydrogen replacement<br />

volume to maintain the pressure.<br />

Loss due to Dew point<br />

Wet gas within the Generator’s Rotor space<br />

will lead to pre-mature windings insulation<br />

failure. Further revenue loss and repercussions,<br />

need not be extolled.<br />

How do <strong>Proton</strong> <strong>OnSite</strong> products help<br />

® (Automatic Purity, Pressure<br />

and Dew Point control)<br />

Rice, Siemens Westinghouse Power Corporation<br />

and Anastassios Dimitriadis, Siemens Power<br />

Generation.<br />

2 Assuming power selling agreement of Rs. 2.0 and<br />

average 8000 running hours for the TG per annum.<br />

StableFlow ® can be easily retrofitted to the<br />

Turbine Generator’s Hydrogen (sample)<br />

line without disturbing the existing Hydrogen<br />

piping and instrumentation. Unlike<br />

existing analyzers and instrumentation<br />

that simply does passive management,<br />

StableFlow ® actively and automatically<br />

controls the Hydrogen Pressure, Purity &<br />

Dew point simultaneously, by controlling<br />

the “vent rate” and new Hydrogen feed<br />

flow. It maintains all three parameters,<br />

within very close limits of the set points<br />

for Pressure, Purity and Dew point.<br />

® <br />

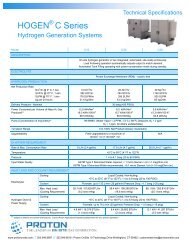

HOGEN ® (PEM Water Electrolysis Type H2<br />

Generators) delivers 24 x 7 High quality<br />

Hydrogen directly to the Turbine Generator.<br />

Hydrogen gas is available on-demand<br />

closely following consumption pattern for<br />

capacity control across 0 – 100%, at 15<br />

or 30 Bar(g), 99.9995% pure, and at (-)<br />

70°C Dew point. Having a HOGEN ® is like<br />

having a cylinder that never goes empty.<br />

HOGEN ® conforms to the world leading<br />

international codes and standards and is<br />

the only Hydrogen Generator of its type<br />

that can be installed in a safe area.<br />

Both above products, each, by themselves<br />

help earn more money for the Power<br />

generation utility, and if used together, are a<br />

formidable money making machine!<br />

energetica india<br />

APRIL11<br />

39