Bearing, Shafts, Clamps,Collars,Hubs & Keys - Electronic Fasteners ...

Bearing, Shafts, Clamps,Collars,Hubs & Keys - Electronic Fasteners ...

Bearing, Shafts, Clamps,Collars,Hubs & Keys - Electronic Fasteners ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

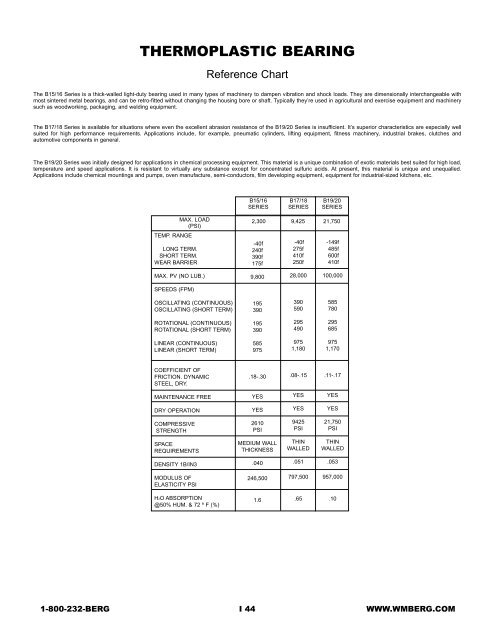

THERMOPLASTIC BEARING<br />

Reference Chart<br />

The B15/16 Series is a thick-walled light-duty bearing used in many types of machinery to dampen vibration and shock loads. They are dimensionally interchangeable with<br />

most sintered metal bearings, and can be retro-fitted without changing the housing bore or shaft. Typically they’re used in agricultural and exercise equipment and machinery<br />

such as woodworking, packaging, and welding equipment.<br />

The B17/18 Series is available for situations where even the excellent abrasion resistance of the B19/20 Series is insufficient. It’s superior characteristics are especially well<br />

suited for high performance requirements. Applications include, for example, pneumatic cylinders, lifting equipment, fitness machinery, industrial brakes, clutches and<br />

automotive components in general.<br />

The B19/20 Series was initially designed for applications in chemical processing equipment. This material is a unique combination of exotic materials best suited for high load,<br />

temperature and speed applications. It is resistant to virtually any substance except for concentrated sulfuric acids. At present, this material is unique and unequalled.<br />

Applications include chemical mountings and pumps, oven manufacture, semi-conductors, film developing equipment, equipment for industrial-sized kitchens, etc.<br />

B15/16<br />

SERIES<br />

B17/18<br />

SERIES<br />

B19/20<br />

SERIES<br />

MAX. LOAD<br />

(PSI)<br />

TEMP. RANGE<br />

LONG TERM.<br />

SHORT TERM.<br />

WEAR BARRIER<br />

2,300<br />

-40f<br />

240f<br />

390f<br />

175f<br />

9,425 21,750<br />

-40f<br />

275f<br />

410f<br />

250f<br />

-149f<br />

485f<br />

600f<br />

410f<br />

MAX. PV (NO LUB.)<br />

9,800<br />

28,000<br />

100,000<br />

SPEEDS (FPM)<br />

OSCILLATING (CONTINUOUS)<br />

OSCILLATING (SHORT TERM)<br />

195<br />

390<br />

390<br />

590<br />

585<br />

780<br />

ROTATIONAL (CONTINUOUS)<br />

ROTATIONAL (SHORT TERM)<br />

195<br />

390<br />

295<br />

490<br />

295<br />

685<br />

LINEAR (CONTINUOUS)<br />

LINEAR (SHORT TERM)<br />

585<br />

975<br />

975<br />

1,180<br />

975<br />

1,170<br />

COEFFICIENT OF<br />

FRICTION. DYNAMIC<br />

STEEL, DRY.<br />

.18-.30<br />

.08-.15<br />

.11-.17<br />

MAINTENANCE FREE<br />

YES<br />

YES<br />

YES<br />

DRY OPERATION<br />

YES<br />

YES<br />

YES<br />

COMPRESSIVE<br />

STRENGTH<br />

2610<br />

PSI<br />

9425<br />

PSI<br />

21,750<br />

PSI<br />

SPACE<br />

REQUIREMENTS<br />

MEDIUM WALL<br />

THICKNESS<br />

THIN<br />

WALLED<br />

THIN<br />

WALLED<br />

DENSITY 1B/IN3<br />

.040<br />

.051<br />

.053<br />

MODULUS OF<br />

ELASTICITY PSI<br />

246,500<br />

797,500<br />

957,000<br />

H2O ABSORPTION<br />

@50% HUM. & 72 º F (%)<br />

1.6<br />

.65<br />

.10<br />

1-800-232-BERG I 44 WWW.WMBERG.COM