Compact Nanosecond Pulse Generator

Compact Nanosecond Pulse Generator

Compact Nanosecond Pulse Generator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Pulse</strong>d Power Technology<br />

<strong>Compact</strong> <strong>Nanosecond</strong> <strong>Pulse</strong> <strong>Generator</strong><br />

N.V. Zharova, I.V. Lavrinovich, V.F. Feduschak, and A.A. Erfort<br />

Institute of High Current Electronics SB RAS, 2/3, Academichesky ave., Tomsk, 634055, Russia<br />

Abstract – A compact nanosecond pulse generator<br />

was designed and tested. The generator has a specially<br />

designed unit consisting of an HCEIcap 100-<br />

0.2 capacitor and a multigap switch. The total inductance<br />

of the unit is 20 nH. The modifications<br />

made in the design allowed an increase in energy<br />

density up to 370 J/l at an electric field strength of<br />

200 kV/mm. The volume of the capacitor active<br />

part is 2.3 l. In the short-circuit mode, the unit ensures<br />

a current up to 200 kA with a risetime of<br />

100 ns at a charge voltage of 90 kV. The dimensions<br />

of the capacitor active part are<br />

Ø80 × Ø160 × 160 mm. With an X-pinch load (four<br />

W wires of diameter 15 µm), the rate of rise of the<br />

current is 140 kA/70 ns and the X-ray pulsewidth is<br />

2 ns. The peculiarity of the load is that it absorbs a<br />

small amount of energy compared to the energy<br />

stored in the capacitor. Therefore, it is proposed to<br />

use exploded wires in the discharge circuit of the<br />

capacitor to ensure a current cutoff at the instant<br />

the energy stored in the capacitor is close to zero.<br />

Thus, it will be possible to suppress or preclude the<br />

oscillation mode of the capacitor and hence to increase<br />

its lifetime.<br />

of an HCEIcap 100-0.2 capacitor and a multigap<br />

switch made it possible to design a compact nanosecond<br />

pulse generator operating into an X-pinch load.<br />

Below we consider the generator at greater length.<br />

2. Design of the generator<br />

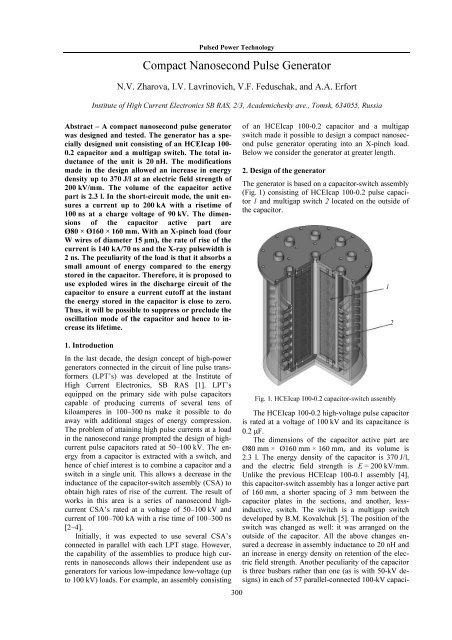

The generator is based on a capacitor-switch assembly<br />

(Fig. 1) consisting of HCEIcap 100-0.2 pulse capacitor<br />

1 and multigap switch 2 located on the outside of<br />

the capacitor.<br />

1<br />

2<br />

1. Introduction<br />

In the last decade, the design concept of high-power<br />

generators connected in the circuit of line pulse transformers<br />

(LPT’s) was developed at the Institute of<br />

High Current Electronics, SB RAS [1]. LPT’s<br />

equipped on the primary side with pulse capacitors<br />

capable of producing currents of several tens of<br />

kiloamperes in 100–300 ns make it possible to do<br />

away with additional stages of energy compression.<br />

The problem of attaining high pulse currents at a load<br />

in the nanosecond range prompted the design of highcurrent<br />

pulse capacitors rated at 50–100 kV. The energy<br />

from a capacitor is extracted with a switch, and<br />

hence of chief interest is to combine a capacitor and a<br />

switch in a single unit. This allows a decrease in the<br />

inductance of the capacitor-switch assembly (CSA) to<br />

obtain high rates of rise of the current. The result of<br />

works in this area is a series of nanosecond highcurrent<br />

CSA’s rated at a voltage of 50–100 kV and<br />

current of 100–700 kA with a rise time of 100–300 ns<br />

[2–4].<br />

Initially, it was expected to use several CSA’s<br />

connected in parallel with each LPT stage. However,<br />

the capability of the assemblies to produce high currents<br />

in nanoseconds allows their independent use as<br />

generators for various low-impedance low-voltage (up<br />

to 100 kV) loads. For example, an assembly consisting<br />

300<br />

Fig. 1. HCEIcap 100-0.2 capacitor-switch assembly<br />

The HCEIcap 100-0.2 high-voltage pulse capacitor<br />

is rated at a voltage of 100 kV and its capacitance is<br />

0.2 F.<br />

The dimensions of the capacitor active part are<br />

Ø80 mm × Ø160 mm × 160 mm, and its volume is<br />

2.3 l. The energy density of the capacitor is 370 J/l,<br />

and the electric field strength is E = 200 kV/mm.<br />

Unlike the previous HCEIcap 100-0.1 assembly [4],<br />

this capacitor-switch assembly has a longer active part<br />

of 160 mm, a shorter spacing of 3 mm between the<br />

capacitor plates in the sections, and another, lessinductive,<br />

switch. The switch is a multigap switch<br />

developed by B.M. Kovalchuk [5]. The position of the<br />

switch was changed as well: it was arranged on the<br />

outside of the capacitor. All the above changes ensured<br />

a decrease in assembly inductance to 20 nH and<br />

an increase in energy density on retention of the electric<br />

field strength. Another peculiarity of the capacitor<br />

is three busbars rather than one (as is with 50-kV designs)<br />

in each of 57 parallel-connected 100-kV capaci-

Oral Session<br />

tors. This was done to compensate for the stray inductance<br />

arising in non-multichannel switching. Finally,<br />

one more peculiarity of the HCEIcap 100-0.2 capacitor<br />

with external switching [6] is the dynamics of the<br />

action of currents on the plates that is responsible for<br />

their denser packing. The effect shows up with time as<br />

a slight increase in capacitance (within the space factor)<br />

and a decrease in gas release due to better contacts<br />

between the Al plates and the busbars.<br />

The HCEIcap 100-0.2 assembly was tested in the<br />

short-circuit mode at a charge voltage of 90 kV. Figure<br />

2 shows a waveform of the current obtained in this<br />

mode. It is seen from the waveform that the assembly<br />

ensures a current of 200 kA in 100 ns at a charge voltage<br />

of 90 kV.<br />

diameter 13 m. The amplitude of the load current<br />

was 160 kA with a rise time of 120 ns. A typical<br />

waveform of the load current is shown in Fig. 4. The<br />

voltage across the capacitor was found by the formula:<br />

1<br />

Ut () U0<br />

IC<br />

() tdt.<br />

C ∫<br />

I, kA U, kV<br />

T, ns<br />

Fig. 4. Waveforms of the load current and capacitor voltage<br />

at a charge voltage U 0 = 87 kV<br />

80 ms/d<br />

200 kA<br />

Fig. 2. Waveform of the current in the short-circuit mode at<br />

a charge voltage of 90 kV<br />

The generator based on the HCEIcap 100-0.2 assembly<br />

also contains a load unit (Fig. 3) located<br />

through the center of the assembly. The arrangement<br />

of the load in the immediate vicinity of the assembly<br />

provides low inductance of the busbars and hence a<br />

slight decrease in the amplitude of the load current.<br />

The peculiarity of the load is that it absorbs a small<br />

amount of energy compared to the energy stored in the<br />

capacitor. Thus, a voltage reversal greater than 50%<br />

arises across the capacitor. This greatly decreases the<br />

lifetime of the pulse capacitor that may cause its failure<br />

with time.<br />

One of the possible ways to suppress this undesirable<br />

effect is to use electrically exploded conductors<br />

(EEC’s) in the discharge circuit of the capacitor<br />

(Fig. 5).<br />

EEC<br />

Load<br />

Fig. 3. X-pinch generator<br />

3. Results<br />

The generator was tested for the operation into an<br />

X-pinch load. The load was four tungsten wires of<br />

301<br />

Fig. 5. Expected design of the capacitor-switch assembly<br />

with EEC’s

<strong>Pulse</strong>d Power Technology<br />

Required parameters were chosen by the EEC algorithm<br />

[7]. With these parameters, the EEC’s slightly<br />

limit the current during its rise time (Fig. 6, а), but<br />

ensure a current cutoff at the instant the energy in the<br />

capacitor is close to zero (Fig. 6, b). An example of<br />

calculated waveforms of the current and voltage is<br />

shown in Fig. 6. The calculation was performed for<br />

30 Cu wires of length 10 cm and diameter 70 µm.<br />

I C , kA<br />

370 J/l at an electric field strength of 200 kV/mm. The<br />

volume of the active part was 2.3 l. The capacitorswitch<br />

assembly in the short-circuit mode produced a<br />

current up to 200 kA in 100 ns at a charge voltage of<br />

90 kV. The dimensions of the capacitor active part are<br />

Ø80 × Ø160 × 160 mm. The rate of rise of the current<br />

at an X-pinch load (four Ø15-m tungsten wires) is<br />

140 kA/70 ns and the X-ray pulsewidth is 2 ns. The<br />

peculiarity of this load is that it absorbs a small<br />

amount of energy compared to the energy stored in the<br />

capacitor. Therefore it was proposed to use exploded<br />

wires in the discharge circuit of the capacitor to ensure<br />

a current cutoff at the instant the energy in the capacitor<br />

is close to zero. Thus, it will be possible to suppress<br />

or preclude the oscillation mode of the capacitor<br />

and hence to increase its lifetime.<br />

References<br />

U, kV<br />

T, ns<br />

а<br />

T, ns<br />

b<br />

Fig. 6. Calculated waveforms of the load current (а) and<br />

voltage across different circuit elements (b)<br />

Conclusion<br />

The compact nanosecond pulse generator was designed<br />

and tested. The generator has a specially designed<br />

assembly consisting of an HCEIcap 100-0.2<br />

capacitor and a multigap switch. The total inductance<br />

of the assembly is 20 nH. The modifications made in<br />

the design allowed an increase in energy density up to<br />

[1] A.A. Kim, B.M. Kovalchuk, A.N. Bastrikov et al.,<br />

in Proc. of the 13th IEEE Int. <strong>Pulse</strong>d Power Conf.,<br />

2001, V. 2, pp. 1491–1494.<br />

[2] N.A. Ratakhin, V.F. Feduschak, A.A. Erfort,<br />

A.V. Saushkin, N.V. Zharova, S.A. Chaikovsky,<br />

and V.I. Oreshkin, “Table-top <strong>Pulse</strong> Power <strong>Generator</strong><br />

for Soft X-Ray Radiography”, in Proc. of<br />

the 14th Int. Symp. on High Current Electronics,<br />

Tomsk, 2006, pp. 511–513.<br />

[3] V.F. Feduschak, N.V. Zharova, I.V. Lavrinovich et<br />

al., “<strong>Compact</strong> <strong>Pulse</strong>d Power <strong>Generator</strong>”, in Proc.<br />

of the 15th Int. Symp. on High Current Electronics,<br />

Tomsk, 2008, pp. 303–304.<br />

[4] N.A. Ratakhin, V.F. Fedushchak, A.A. Erfort et<br />

al., “Development of high-current pulse capacitors<br />

rated at 100 kV”, in Proc. of Int. Conf. on Physics<br />

of <strong>Pulse</strong>d Discharges in Condensed Media, Nikolaev,<br />

2009, pp. 140–142.<br />

[5] A.A. Zherlitsyn, B.M. Kovalchuk, A.V. Kharlov,<br />

and E.V. Kumpyak, “<strong>Pulse</strong>d Current <strong>Generator</strong><br />

with Variable <strong>Pulse</strong> Shape”, in Proc. of the 14th<br />

Int. Symp. on High Current Electronics, Tomsk,<br />

2006, pp. 287–289.<br />

[6] High-voltage capacitor with a built-in controllable<br />

switch by V.S. Verkhovsky, N.V. Zharova,<br />

I.V. Lavrinovich, and V.F. Feduschak, RF Patent<br />

75783: IPC H 01 G 4/00, H 01 T 2/02, applied<br />

08.04.08, published 20.08.08, Bulletin No. 23<br />

[7] E.I. Azarkevich, A.V. Kobluchko, Yu.A. Kotov,<br />

and T.A. Lisetskaya, “Computational model of an<br />

electrical-explosion opening switch, High-voltage<br />

spark gap and electrical-explosion opening<br />

switches”, in Proc. of a Joint Meeting of Scientific<br />

Councils of the USSR AS on Scientific Foundations<br />

of Electrophysics and Electrical Power Engineering<br />

and Problems of <strong>Pulse</strong>d Power Technology,<br />

Tomsk, Nov 27–28, 1986, pp. 109–111.<br />

302