Ore Bin / Oregon Geology magazine / journal - Oregon Department ...

Ore Bin / Oregon Geology magazine / journal - Oregon Department ...

Ore Bin / Oregon Geology magazine / journal - Oregon Department ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

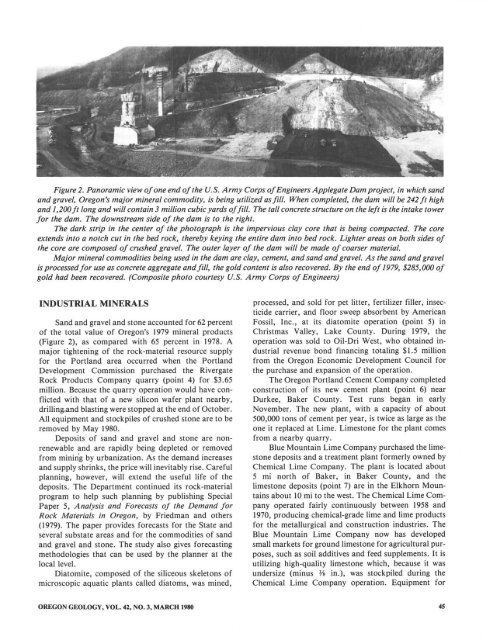

Figure 2. Panoramic view of one end of the U. S. Army Corps of Engineers Applegate Dam project, in which sand<br />

and gravel, <strong>Ore</strong>gon's major mineral commodity, is being utilized as fill. When completed, the dam will be 242 ft high<br />

and 1,200ft long and will contain 3 million cubic yards of fill. The tall concrete structure on the left is the intake tower<br />

for the dam. The downstream side of the dam is to the right.<br />

The dark strip in the center of the photograph is the impervious clay core that is being compacted. The core<br />

extends into a notch cut in the bed rock, thereby keying the entire dam into bed rock. Lighter areas on both sides of<br />

'he core are composed of crushed gravel. The outer layer of the dam will be made of coarser material.<br />

Major mineral commodities being used in the dam are clay, cement, and sand and gravel. As (he sand and gravel<br />

is processed for use as concrete aggregate and fill, the gold content is also recovered. By the end of 1979, $285,000 of<br />

gold had been recovered. (Composite photo courtesy U.S. Army Corps of Engineers)<br />

INDUSTRIAL MINERALS<br />

Sand and gravel and stone accounted for 62 percent<br />

of the total value of <strong>Ore</strong>gon's 1979 mineral products<br />

(Figure 2), as compared with 65 percent in 1978. A<br />

major tightening of the rock-material resource supply<br />

for the Portland area occurred when the Portland<br />

Development Commission purchased the Rivergate<br />

Rock Products Company quarry (point 4) for $3.65<br />

million. Because the quarry operation would have conflicted<br />

with that of a new silicon wafer plant nearby,<br />

drilling.and blasting were stopped at the end of October.<br />

All equipment and stockpiles of crushed stone are to be<br />

removed by May 1980.<br />

Deposits of sand and gravel and stone are nonrenewable<br />

and are rapidly being depleted or removed<br />

from minin'g by urbanization. As the demand increases<br />

and su pply shrinks, the price will inevitably rise. Careful<br />

planning, however, will extend the useful life of the<br />

deposits. The <strong>Department</strong> continued its rock-material<br />

program to help such planning by publishing Special<br />

Paper 5, Analysis and Forecasts of the Demand for<br />

Rock Materials in <strong>Ore</strong>gon, by Friedman and others<br />

(1979). The paper provides forecasts for the State and<br />

several substate areas and for the commodities of sand<br />

and gravel and stone. The study also gives forecasting<br />

methodologies that can be used by the planner at the<br />

local level.<br />

Diatomite, composed of the siliceous skeletons of<br />

microscopic aquatic plants called diatoms, was mined,<br />

processed, and sold for pet litter, fertilizer filler, insecticide<br />

carrier, and floor sweep absorbent by American<br />

Fossil, Inc., at its diatomite operation (point 5) in<br />

Christmas Valley, Lake County. During 1979, the<br />

operation was sold to Oil-Dri West, who obtained industrial<br />

revenue bond financing totaling $1.5 million<br />

from the <strong>Ore</strong>gon Economic Development Council for<br />

the purchase and expansion of the operation.<br />

The <strong>Ore</strong>gon Portland Cement Company completed<br />

construction of its new cement plant (point 6) near<br />

Durkee, Baker County. Test runs began in early<br />

November. The new plant, with a capacity of about<br />

500,000 tons of cement per year, is twice as large as the<br />

one it replaced at Lime. Limestone for the plant comes<br />

from a nearby quarry.<br />

Blue Mountain Lime Company purchased the limestone<br />

deposits and a treatment plant formerly owned by<br />

Chemical Lime Company. The plant is located about<br />

5 mi north of Baker, in Baker County, and the<br />

limestone deposits (point 7) are in the Elkhorn Mountains<br />

about 10 mi to the west. The Chemical Lime Company<br />

operated fairly continuously between 1958 and<br />

1970, producing chemical-grade lime and lime products<br />

for the metallurgical and construction industries. The<br />

Blue Mountain Lime Company now has developed<br />

small markets for ground limestone for agricultural purposes,<br />

such as soil additives and feed supplements. It is<br />

utilizing high-quality limestone which, because it was<br />

undersize (minus ~ in.), was stockpiled during the<br />

Chemical Lime Company operation. Equipment for<br />

OREGON GEOLOGY, VOL. 42, NO.3, MARCH 1980<br />

45