Cultivating Palmaria palmata - Bord Iascaigh Mhara

Cultivating Palmaria palmata - Bord Iascaigh Mhara

Cultivating Palmaria palmata - Bord Iascaigh Mhara

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 9: Results of tank cultivation trials of <strong>Palmaria</strong> <strong>palmata</strong> in<br />

2010/2011 and economic analysis<br />

9.1 Case study: land-based tank cultivation of <strong>Palmaria</strong> <strong>palmata</strong>: Summary of results<br />

Trials on land-based tank cultivation were started in August 2010 at the three hatcheries (DOMMRS, MRI Carna<br />

Laboratories, QUB Marine Laboratory Portaferry) and at Cartron Point Shellfish Ltd., Co. Clare. The tank set-up<br />

varied depending on the facilities and equipment available (Table 9.1) but followed the recommendations in<br />

Chapter 8.1 and 8.2. Different tank sizes were used, and growth in both natural and nutrient-enriched seawater<br />

was compared.<br />

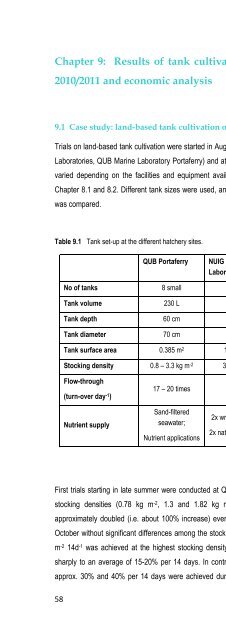

Table 9.1 Tank set-up at the different hatchery sites.<br />

58<br />

QUB Portaferry NUIG Carna<br />

Laboratories<br />

DOMMRS Cartron Point<br />

Shellfish<br />

No of tanks 8 small 4 large 2 large 2 large<br />

Tank volume 230 L 1000 L 1000 L 1000 L<br />

Tank depth 60 cm 90 cm 90 cm 90 cm<br />

Tank diameter 70 cm 119 cm 119 cm 119 cm<br />

Tank surface area 0.385 m 2 1.112 m 2 1.112 m 2 1.112 m 2<br />

Stocking density 0.8 – 3.3 kg m -2 3.6 kg m -2 3.6 kg m -2 1.8 kg m -2<br />

Flow-through<br />

(turn-over day -1 )<br />

Nutrient supply<br />

17 – 20 times 7 - 15 8 - 9 times 8 - 9 times<br />

Sand-filtered<br />

seawater;<br />

Nutrient applications<br />

2x wrasse effluent<br />

2x natural seawater<br />

Raw seawater +<br />

slow release<br />

fertiliser<br />

Sand-filtered<br />

seawater + slow<br />

release fertiliser<br />

First trials starting in late summer were conducted at QUB Portaferry, using high seawater flow rates, different<br />

stocking densities (0.78 kg m -2 , 1.3 and 1.82 kg m -2 ) and no additional nutrient supply. The biomass<br />

approximately doubled (i.e. about 100% increase) every 14 days over a 2-month period between August and<br />

October without significant differences among the stocking densities (Table 9.2). A maximum yield of 2 kg FW<br />

m -2 14d -1 was achieved at the highest stocking density in September. From October onwards, yield dropped<br />

sharply to an average of 15-20% per 14 days. In contrast, at DOMMRS and Cartron Point Shellfish, yields of<br />

approx. 30% and 40% per 14 days were achieved during November and December 2010. Additional nutrient