ceramat gas burner - Orkli

ceramat gas burner - Orkli

ceramat gas burner - Orkli

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

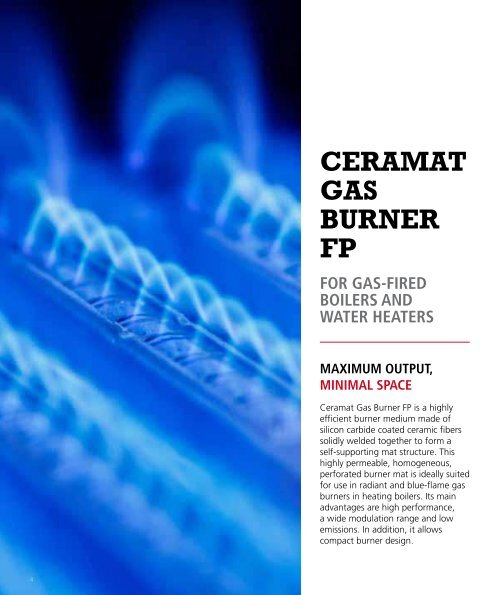

CERAMAT<br />

GAS<br />

BURNER<br />

FP<br />

FOR GAS-FIRED<br />

BOILERS AND<br />

WATER HEATERS<br />

CHARACTERISTICS<br />

• High specific load: the combination of<br />

a highly permeable <strong>burner</strong> material and<br />

perforations supports specific loads of<br />

up to 30 Kw/dm 2 with a perfectly stable<br />

flame for all the limit <strong>gas</strong>es. This makes<br />

it possible to design small, compact<br />

<strong>burner</strong>s and systems.<br />

• Wide modulation range: the<br />

material’s flame stability and<br />

temperature resistance support a<br />

modulation range of 1:30. Star-stop<br />

emissions due to frequent on-off cycles<br />

can be substantially reduced, resulting<br />

in low emissions and easily modulated<br />

water temperature for combination<br />

boilers.<br />

• Electrical conductivity: SiC coating<br />

makes Ceramat <strong>burner</strong> conductive.<br />

Electricity can pass through the material,<br />

being this a great advantage for the<br />

control of the flame detection. The<br />

ionization signal is very good, similar to a<br />

metal <strong>burner</strong>.<br />

• Wide radiation range: this ensures low<br />

NOx emissions at low flame temperatures.<br />

• Stable combustion: with all common<br />

<strong>gas</strong> types and limit <strong>gas</strong>es, <strong>burner</strong>s ignite<br />

and operate safely with Ceramat Gas<br />

Burner FP.<br />

• Load-bearing, self-supporting mat<br />

with thermal expansion: Ceramat Gas<br />

Burner FP makes it possible to design<br />

simple, cost-efficient <strong>burner</strong>s.<br />

• Variable geometry: for optimal heat<br />

transfer, the flat <strong>burner</strong> surface can be<br />

fully adapted to the heating system.<br />

• Variable perforation: the perforation<br />

pattern of the <strong>burner</strong> surface is<br />

customizable and determined as a<br />

function of system requirements.<br />

MAXIMUM OUTPUT,<br />

MINIMAL SPACE<br />

Ceramat Gas Burner FP is a highly<br />

efficient <strong>burner</strong> medium made of<br />

silicon carbide coated ceramic fibers<br />

solidly welded together to form a<br />

self-supporting mat structure. This<br />

highly permeable, homogeneous,<br />

perforated <strong>burner</strong> mat is ideally suited<br />

for use in radiant and blue-flame <strong>gas</strong><br />

<strong>burner</strong>s in heating boilers. Its main<br />

advantages are high performance,<br />

a wide modulation range and low<br />

emissions. In addition, it allows<br />

compact <strong>burner</strong> design.<br />

TECHNICAL DATA<br />

Type of combustion<br />

Application<br />

Dimensions<br />

Perforation<br />

Geometry<br />

Thickness<br />

Gas types<br />

Premix, fan assisted or atmospheric<br />

Gas boilers, water heaters, room heaters<br />

Max.: 500 x 250 mm (19.7 x 9.8 inches) or according to customer specification<br />

Variable perforation according to customer specification<br />

Variable flat geometry according to customer specification<br />

3.2 +/- 0.5 mm (0.126 +/- 0.02 inches)<br />

All <strong>gas</strong> types according to EN 437, ANSI Z21.1 ff. (natural <strong>gas</strong>, propane, town <strong>gas</strong>)<br />

Specific load Min.: 1 Kw/dm 2 (31,700 BTU/hr/ft 2 ) / Max.: 30 Kw/dm 2 (951,000 BTU/hr/ft 2 )<br />

Radiation range 1 - 7.5 Kw/dm 2 (31,700 - 237,750 BTU/hr/ft 2 )<br />

Modulation range 1:30<br />

Pressure drop < 5 Pa at 1.5 Kw/dm 2 / < 45 Pa at 35 Kw/dm 2 / (< 0.000725 PSI at 47,550 BTU/hr/ft 2 )<br />

(< 0.006525 PSI at 1,109,500 BTU/hr/ft 2 )<br />

Maximum surface temperature<br />

Maximum temperature difference on the surface<br />

and between upper and lower side<br />

Colour<br />

1.000 ºC (1,850 ºF)<br />

800 ºC<br />

Anthracite black<br />

Please follow mounting instructions. Complete <strong>burner</strong> modules also available.<br />

4<br />

5