ceramat gas burner - Orkli

ceramat gas burner - Orkli

ceramat gas burner - Orkli

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OUTSTANDING<br />

ADVANTAGES<br />

HIGH SPECIFIC LOAD, STABLE COMBUSTION<br />

Ceramat Gas Burner has an open porosity of approximately 95%,<br />

making it highly permeable. The <strong>gas</strong> or <strong>gas</strong>/air mixture passing<br />

through it can easily permeate the entire surface and burns off in<br />

the form of a flame carpet. The flames remain on the surface and<br />

do not lift off. This offers the advantages of stable combustion,<br />

a wide range of modulation and high specific load, which allow<br />

compact <strong>burner</strong> design.<br />

WIDE MODULATION RANGE<br />

Ceramat Gas Burner is suitable for use in both blue-flame and<br />

radiant modes and offers a correspondingly wide modulation<br />

range, as well as the possibility of precise, continuous adjustment.<br />

ELECTRICAL CONDUCTIVITY<br />

SiC coating makes Ceramat <strong>burner</strong> conductive. Electricity can pass<br />

through the material, being this a great advantage for the control of<br />

the flame detection. The ionization signal is very good, similar to a<br />

metal <strong>burner</strong>.<br />

EVEN RADIATION<br />

Ceramat Gas Burner can also be used as a radiant <strong>burner</strong>. The<br />

<strong>burner</strong> surface is resistant up to 1.000 °C and only glows to a<br />

depth of 1 mm, while the temperature on the underside remains<br />

at approximately 150 °C. The material also resists thermal shock.<br />

With its high resistance to heat and changing temperatures, it<br />

can be used under unusually difficult combustion conditions.<br />

LOW HEAT EXPANSION<br />

Since the material practically does not expand when heated, the<br />

shape remains virtually unchanged during operation. This<br />

makes it possible to use simple frame and <strong>burner</strong> designs and<br />

ensures uniform, stable combustion.<br />

RIGID, SELF-SUPPORTING STRUCTURE<br />

The silicon carbide coating gives rigidity to the fibers. This coating<br />

bonds the fibers together at their interfaces to form a rigid<br />

structure. Thus Ceramat Gas Burner is self-supporting and will<br />

not significantly sag, even on larger <strong>burner</strong> surfaces and when<br />

exposed to fan pressure. No additional support is required.<br />

LOW EMISSIONS<br />

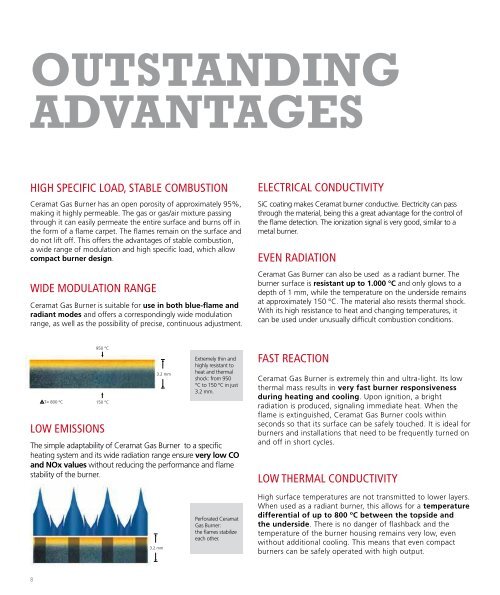

Extremely thin and<br />

highly resistant to<br />

heat and thermal<br />

shock: from 950<br />

°C to 150 °C in just<br />

3.2 mm.<br />

The simple adaptability of Ceramat Gas Burner to a specific<br />

heating system and its wide radiation range ensure very low CO<br />

and NOx values without reducing the performance and flame<br />

stability of the <strong>burner</strong>.<br />

Perforated Ceramat<br />

Gas Burner:<br />

the flames stabilize<br />

each other.<br />

FAST REACTION<br />

Ceramat Gas Burner is extremely thin and ultra-light. Its low<br />

thermal mass results in very fast <strong>burner</strong> responsiveness<br />

during heating and cooling. Upon ignition, a bright<br />

radiation is produced, signaling immediate heat. When the<br />

flame is extinguished, Ceramat Gas Burner cools within<br />

seconds so that its surface can be safely touched. It is ideal for<br />

<strong>burner</strong>s and installations that need to be frequently turned on<br />

and off in short cycles.<br />

LOW THERMAL CONDUCTIVITY<br />

High surface temperatures are not transmitted to lower layers.<br />

When used as a radiant <strong>burner</strong>, this allows for a temperature<br />

differential of up to 800 ºC between the topside and<br />

the underside. There is no danger of flashback and the<br />

temperature of the <strong>burner</strong> housing remains very low, even<br />

without additional cooling. This means that even compact<br />

<strong>burner</strong>s can be safely operated with high output.<br />

NO HEALTH HAZARDS<br />

The self-supporting<br />

structure simplifies<br />

frame design and<br />

construction.<br />

At approximately 25 to 30 μm, the diameter of the silicon<br />

carbide coated fibers is much greater than the maximum 3μm<br />

range considered critical for human health conditions. In addition,<br />

the fibers are solidly welded together. If they should break off,<br />

they are heavy enough to fall to the ground instead of being<br />

inhaled, a fact that has been confirmed by independent studies.<br />

Therefore, Ceramat Gas Burner installation and operation does<br />

not generate health hazards.<br />

8 9