ceramat gas burner - Orkli

ceramat gas burner - Orkli

ceramat gas burner - Orkli

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

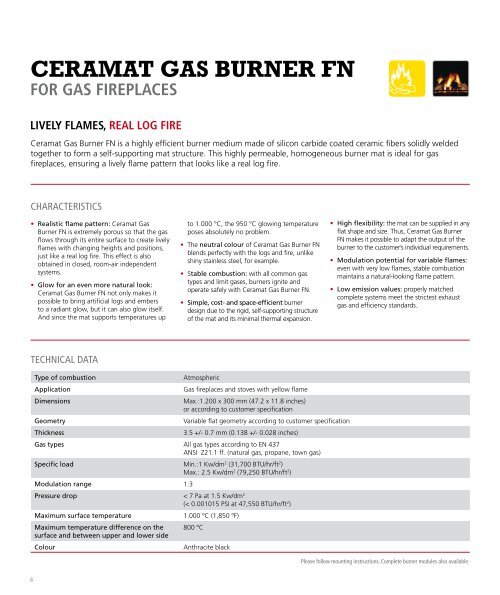

CERAMAT GAS BURNER FN<br />

FOR GAS FIREPLACES<br />

LIVELY FLAMES, REAL LOG FIRE<br />

Ceramat Gas Burner FN is a highly efficient <strong>burner</strong> medium made of silicon carbide coated ceramic fibers solidly welded<br />

together to form a self-supporting mat structure. This highly permeable, homogeneous <strong>burner</strong> mat is ideal for <strong>gas</strong><br />

fireplaces, ensuring a lively flame pattern that looks like a real log fire.<br />

CERAMAT GAS BURNER FP<br />

FOR INDUSTRIAL FURNACES AND DRYERS<br />

INSTANT REACTIVITY, OPTIMIZED PRODUCTION<br />

Ceramat Gas Burner FN is a highly efficient <strong>burner</strong> medium made of silicon carbide coated ceramic fibers solidly welded<br />

together to form a self-supporting mat structure. This highly permeable, homogeneous <strong>burner</strong> mat is ideal for radiant <strong>gas</strong><br />

<strong>burner</strong>s in industrial furnaces and drying installations.<br />

CHARACTERISTICS<br />

CHARACTERISTICS<br />

• Realistic flame pattern: Ceramat Gas<br />

Burner FN is extremely porous so that the <strong>gas</strong><br />

flows through its entire surface to create lively<br />

flames with changing heights and positions,<br />

just like a real log fire. This effect is also<br />

obtained in closed, room-air independent<br />

systems.<br />

• Glow for an even more natural look:<br />

Ceramat Gas Burner FN not only makes it<br />

possible to bring artificial logs and embers<br />

to a radiant glow, but it can also glow itself.<br />

And since the mat supports temperatures up<br />

to 1.000 °C, the 950 °C glowing temperature<br />

poses absolutely no problem.<br />

• The neutral colour of Ceramat Gas Burner FN<br />

blends perfectly with the logs and fire, unlike<br />

shiny stainless steel, for example.<br />

• Stable combustion: with all common <strong>gas</strong><br />

types and limit <strong>gas</strong>es, <strong>burner</strong>s ignite and<br />

operate safely with Ceramat Gas Burner FN.<br />

• Simple, cost- and space-efficient <strong>burner</strong><br />

design due to the rigid, self-supporting structure<br />

of the mat and its minimal thermal expansion.<br />

• High flexibility: the mat can be supplied in any<br />

flat shape and size. Thus, Ceramat Gas Burner<br />

FN makes it possible to adapt the output of the<br />

<strong>burner</strong> to the customer’s individual requirements.<br />

• Modulation potential for variable flames:<br />

even with very low flames, stable combustion<br />

maintains a natural-looking flame pattern.<br />

• Low emission values: properly matched<br />

complete systems meet the strictest exhaust<br />

<strong>gas</strong> and efficiency standards.<br />

• Instant reaction: full radiation is obtained<br />

within three seconds after ignition. And the<br />

radiation stops when the <strong>burner</strong> is shut off.<br />

The temperature of Ceramat Gas Burner<br />

FN surface immediately drops to a point<br />

where it can be safely touched. By effectively<br />

preventing residual heat and avoiding long<br />

pre-heating periods, this fast reaction provides<br />

optimal system control.<br />

• Homogeneous mat structure: Ceramat Gas<br />

Burner FN ensures uniform radiation.<br />

• Clean surface combustion: very low NOx<br />

and CO emissions reduce the environmental<br />

impact.<br />

• High efficiency: a properly matched system<br />

with Ceramat Gas Burner FN saves energy<br />

costs, especially when compared to electric<br />

heating systems.<br />

• Wide modulation range: the desired<br />

temperature can be precisely set and is easily<br />

adjustable when required.<br />

• Variable geometry: the <strong>burner</strong> medium<br />

makes it possible to precisely adapt the<br />

<strong>burner</strong> surface to the requirements of the<br />

installation.<br />

• Rigid, self-supporting structure: very low<br />

thermal expansion and low pressure drop<br />

simplify <strong>burner</strong> design.<br />

• High temperature resistance: despite high<br />

specific loads the <strong>burner</strong> surface has a long<br />

life expectancy.<br />

TECHNICAL DATA<br />

TECHNICAL DATA<br />

Type of combustion<br />

Application<br />

Atmospheric<br />

Gas fireplaces and stoves with yellow flame<br />

Dimensions<br />

Max.:1.200 x 300 mm (47.2 x 11.8 inches)<br />

or according to customer specification<br />

Geometry<br />

Variable flat geometry according to customer specification<br />

Thickness<br />

3.5 +/- 0.7 mm (0.138 +/- 0.028 inches)<br />

Gas types All <strong>gas</strong> types according to EN 437<br />

ANSI Z21.1 ff. (natural <strong>gas</strong>, propane, town <strong>gas</strong>)<br />

Specific load Min.:1 Kw/dm 2 (31,700 BTU/hr/ft 2 )<br />

Max.: 2.5 Kw/dm 2 (79,250 BTU/hr/ft 2 )<br />

Modulation range 1:3<br />

Pressure drop < 7 Pa at 1.5 Kw/dm 2<br />

(< 0.001015 PSI at 47,550 BTU/hr/ft 2 )<br />

Maximum surface temperature<br />

1.000 ºC (1,850 ºF)<br />

Maximum temperature difference on the 800 ºC<br />

surface and between upper and lower side<br />

Colour<br />

Anthracite black<br />

Please follow mounting instructions. Complete <strong>burner</strong> modules also available.<br />

Type of combustion<br />

Premix, fan assisted<br />

Application<br />

Industrial furnaces and dryers with radiant <strong>gas</strong> heaters<br />

Dimensions<br />

Max.: 1.200 x 300 mm (47.2 x 11.8 inches) or according to customer specification.<br />

Individual Ceramat Gas Burner can be combined to form larger <strong>burner</strong> surfaces<br />

Geometry<br />

Variable flat geometry according to customer specifications<br />

Thickness<br />

3.5 +/- 0.7 mm (0.138 +/- 0.028 inches)<br />

Gas types All <strong>gas</strong> types according to EN 437, ANSI Z21.1 ff. (natural <strong>gas</strong>, propane, town <strong>gas</strong>)<br />

Radiation range 1 - 6 Kw/dm 2 (31,700 - 190,200 BTU/hr/ft 2 )<br />

Modulation range 1:6<br />

Pressure drop < 7 Pa at 1.5 Kw/dm 2<br />

< 15 Pa at 6 Kw/dm 2<br />

(< 0.001015 PSI at 47,550 BTU/hr/ft 2<br />

< 0.002175 PSI at 190,200 BTU/hr/ft 2 )<br />

Maximum surface temperature<br />

1.000 °C (1,850 °F)<br />

Maximum temperature difference on the 800 ºC<br />

surface and between upper and lower side<br />

Colour<br />

Anthracite black<br />

Please follow mounting instructions. Complete <strong>burner</strong> modules also available.<br />

6 7